SUPPLEMENT TO CHAPTER 12

FLOWSHEET CONTROLLABILITY ANALYSIS

12S.0 OBJECTIVES

This chapter supplement introduces quantitative measures for controllability assessment to

be used when developing the base-case design and in the detailed design stage (Stages 2 and 3,

Table 12.1) and highlights how their integration into the design process can help to generate

improved flowsheets that satisfy control performance criteria. At this point, the process creation

stage has been completed and several promising process flowsheets exist. As they are evaluated,

the control objectives are considered as constraints, the latter including:

•

Adequate disturbance resiliency, that is, the ability to reject disturbances quickly enough to

meet specifications

•

Insensitivity to model uncertainty, that is, the ability to control easily, and to provide

adequate closed-loop performance, with relatively insensitivity to model inaccuracies.

An approach is introduced to screen the potential designs as early as possible, to identify

the most promising designs for rigorous testing in stage 4, in which plantwide controllability

assessment is completed. As demonstrated in this chapter supplement, it is important to verify the

approximate analysis using rigorous dynamic simulation. Detailed multimedia instruction on the

use of ASPEN HYSYS for dynamic simulation is available as part of the multimedia support that

may be downloaded from the Wiley web site associated with this book. UNISIM and CHEMCAD

could be used also for dynamic simulation.

It is assumed that the reader is familiar with the basic concepts of linear systems theory.

This material is covered typically in an introductory course on process dynamics and control at the

undergraduate level. The subjects in that course that are prerequisite to understanding the concepts

in this chapter supplement are:

1. Basic linear matrix theory, linearization, complex numbers, and Laplace and Fourier

transforms. Note that Section 12S.1 provides some of this background material.

– 12S-1–

2. Pole and zero positions in the complex plane, and their impact on the time-domain

response of linear systems.

3. Linear stability theory and the impact of feedback.

4. Tuning of single-input, single-output controllers (P, PI, and PID controllers). Note that

Section 12S.4 provides instruction on model-based PI-controller tuning.

Key concepts relating to linear process models are reviewed in the first section of the

chapter. For deeper coverage, the reader is referred to the following undergraduate-level texts:

Bequette, B.W., Process Dynamics: Modeling, Analysis, and Simulation, Prentice Hall, Englewood

Cliffs, NJ, (2003).

Luyben, W.L., Process Modeling, Simulation and Control for Chemical Engineers, 2nd ed.,

McGraw-Hill, New York (1990).

Ogunnaike, B.A., and W.H. Ray, Process Dynamics, Modeling and Control, Oxford Univ. Press,

New York (1994).

Seborg, D.E., T.F. Edgar, and D.A. Mellichamp, Process Dynamics and Control, Wiley, New York

(1989).

Stephanopoulos, G., Chemical Process Control, Prentice-Hall, Englewood Cliffs, NJ (1984).

This supplement to Chapter 12,

1.

Explains how to generate linear process models in their standard forms.

2.

Defines quantitative measures that are used to analyze the controllability and resiliency

(C&R) of process flowsheets, and shows how to implement them using MATLAB.

3.

Describes a method to carry out C&R analysis using the results of steady-state process

simulations.

4.

Shows how to use quantitative analysis with steady-state and dynamic relative gain

arrays (RGA and DRGA) to reliably select control loop pairings and to use the IMC

model-based approach to provide preliminary tuning of single-loop PI controllers.

5.

Analyzes, in Section 12S.5, selected case studies in Chapter 12 to demonstrate the

utility of the quantitative methods. For completeness, these analyses are verified with

dynamic simulations using single-loop PI controllers.

– 12S-2–

After reading this chapter, the student should

1.

Be able to compute the frequency-dependent process transfer functions { P , P d } using

MATLAB, given a linear model in one of its standard forms.

2.

Generate the C&R measures: relative-gain array (RGA), and disturbance cost (DC),

given the matrices P {s} and P d {s}, describing the effects of the manipulated

variables and disturbances on the process outputs, using MATLAB.

3.

Select the appropriate pairings for a decentralized control system for a process using the

static and dynamic RGAs and appropriate resiliency measures, and provide preliminary

tuning using IMC-PI tuning rules.

4.

Perform C&R analysis to select between alternative process configurations, given the

results of process simulations using linearized models.

12S.1 GENERATION OF LINEAR MODELS IN STANDARD FORMS

In this chapter supplement, several methods are described to assist the designer in rejecting

designs that do not provide acceptable closed-loop performance, using models linearized about a

steady state. These are generated by expressing the open-loop response of the process outputs, y{s},

in terms of the variations of the inputs, u{s}, and disturbances, d{s}:

y{s} = P{s}u{s}+ P d {s}d {s}

(12S.1)

The procedure for deriving the linear state-space model and the input-output transfer

function model in Eq. (12S.1) involves the following steps:

Step 1. The nonlinear state and output equations are derived from the material and energy balances

that model the process. These are expressed in the form:

dx

= f {x, u, d }

dt

y = g {x, u, d }

– 12S-3–

(12S. 2)

where x is a vector of nx state variables, y is a vector of ny output (measured) variables,

u is a vector of nu manipulated variables, d is a vector of nd disturbances, and f and g

are vectors of nx and ny nonlinear functions, respectively.

Step 2. The state and output equations are solved at a stationary (steady) state that is defined either

in terms of the desired state variable values or those of the input variables:

f {x* ,u* , d * } = 0

y = g {x* ,u* , d * }

(12S.3)

where the stationary point is at x = x* , u = u* and d = d * . The solution of Eq. (12S.3)

requires that the degrees of freedom of the process be resolved through the specification of

nu+ nd values.

Step 3. The equations are linearized in the vicinity of the desired stationary point, by a Taylor

series expansion of Eq. (12S. 2):

dx

≅ f { x* , u* , d *} + A ( x − x* ) + BU ( u − u* ) + B D ( d − d * ) + h.o.t.

dt

y ≅ g { x* , u* , d *} + C ( x − x* ) + DU ( u − u* ) + D D ( d − d * ) + h.o.t.

(12S.4)

Note that the linear approximation is obtained by ignoring the higher order terms (h.o.t.)

of the Taylor series expansion. The matrices A, BU , B D ,C , DU and D D are the Jacobian

matrices of appropriate dimension evaluated at the stationary point, defined as follows:

{ }

A = ai , j ≡

{

∂f i

∂x j

}

BU = bU ,i , j ≡

{

}

B D = bD ,i , j ≡

{ }

C = ci , j ≡

x* ,u* ,d *

∂f i

∂u j

∂f i

∂d j

{

x* ,u* ,d *

}

DU = dU ,i , j ≡

{

x* ,u* ,d *

∂g i

∂x j

}

D D = d D ,i , j ≡

x* ,u* ,d *

∂g i

∂u j

∂g i

∂d j

x* ,u* ,d *

x* ,u* ,d *

Step 4. The linearized equations are formulated in terms of perturbation variables that express the

deviation from the stationary point (or steady state): x̂ = x − x* , ŷ = y − y* , û = u − u* and

– 12S-4–

d̂ = d − d * . Substituting the perturbation variables into Eqs. (12S.4) and ignoring higherorder terms:

d x̂

≅ A x̂ + BU û + B D d̂

dt

ŷ ≅ C x̂ + DU û + D D d̂

(12S.5)

Eqs. (12S.5) constitute the linear state-space representation of the system.

Step 5. The linearized equations are transformed into the Laplace domain:

ŷ{s} = P{s}û{s}+ P d {s}d̂ {s},

(12S.1)

where P{s} = C (s ⋅ I − A)−1 BU + DU and P d {s} = C (s ⋅ I − A)−1 B D + D D are matrices of the

appropriate dimension. Eq. (12S.1) constitutes the input-output transfer function

representation of the linear system.

As an example, the procedure for generating linear models in standard form is demonstrated

for an exothermic reactor, whose complete analysis is presented in Case Study 12S.1 of Section

12S.5.

Example 12S.1 Standard Linear Models for an Exothermic Reactor.

A continuous-stirred-tank reactor for the production of propylene glycol is analyzed in Case Study

12S.1, in Section 12S.5 below. Approximate linear models for the reactor are generated using the

five-step procedure as follows:

Step 1. Define the State and Output Equations. The hydrolysis of propylene oxide (PO) to

propylene glycol is an exothermic reaction catalyzed by H2SO4:

CH2-O-CH-CH3 + H2O → CH2OH-CH-OH-CH3

When water is supplied in excess, the reaction is second order with respect to the propylene oxide

concentration and zero order with respect to the water concentration. Its rate constant exhibits an

Arrhenius dependence on temperature, with k0 = 3.294×1026 m3/(kmol-h) and E = 1.556×105

kJ/kmol. Furthermore, it is customary to dilute the PO feed with methanol (MeOH), while the

H2SO4 catalyst enters the reactor with the feed. Operating conditions are sought for carrying out

– 12S-5–

this liquid-phase reaction in a 47-ft3 continuous-stirred-tank reactor (CSTR), with the liquid holdup

at 85% of its total volume (1.135 m3). The liquid feeds are fed at 23.9 oC, with one consisting of

18.712 kmol/h of PO and 32.73 kmol/h of MeOH. The water feed rate is from 160 – 500 kmol/h

(2.84 – 8.88 m3/h), selected to moderate the reactor temperature. To reduce the risk of vaporization,

the reactor is operated at a pressure of 3 bar. Under these conditions, the transients for the PO

concentration, CPO [kmol/m3], and temperature, T [oC], are determined by solving the following

species and enthalpy balances:

dC PO ℑ PO ,in C PO (q0 + q w )

2

=

−

− k {T }C PO

dt

V

V

(12S.6)

1

dT

2

(− ∆H ) − (q0 + q w )(T − T0 )

=

k {T }C PO

V

dt C P

(12S.7)

where, k {T } = k o e − E / R (T + 273.2 ) m3/(kmol-h), R = 8.314 kJ/kmol-K, the molar flow rate of PO in

the feed, ℑPO,in = 18.712 kmol/h, V = 1.135 m3, ∆H = –9×104 kJ/kmol, the organic volumetric feed

rate, q0= 2.556 m3/h, the water volumetric feed rate is qw, T0 = 23.9 oC, and cP = 3,558 kJ/ m3 oC.

Implicit in the assumption of perfect level control is the pairing between the effluent volumetric

flow rate, F, and the liquid level, L. This leaves the temperature, T, as the output, to be controlled

by the water feed rate, qw, as the manipulated variable. The disturbances to the process are the

volumetric organic feed rate, q0, and the feed temperature, T0. Thus, x = [C PO ,T ]T , y = [T ] ,

u = [qw ] and d = [ℑ PO ,in ,To ]T .

Step 2. Solve at the Steady State. The state equations are solved at the steady state. The degrees of

freedom are resolved by fixing all of the input variable values and solving the two equations for the

two unknown state variables.

C PO (q0 + q w )

2

− k {T }C PO

=0

V

(12S.8)

1

2

(− ∆H ) − (q0 + qw )(T − T0 ) = 0

k {T }C PO

V

CP

(12S.9)

ℑ PO ,in

V

−

Taking u* = qw* = 5.325 m3/h and d * = [ℑ PO ,in* ,To ]T = [18.712 , 23.9]T and solving Eqs. (12S.8)

and (12S.9) gives x* = [0.06 , 82.4]T . Note that the fractional conversion of PO is X = 1 –

– 12S-6–

CPO/CPO,in = 1 – 0.06/2.374 = 0.975, where CPO,in = ℑPO,in/(q0 + qw). This solution is obtained

analytically, graphically (see Case Study 12S.1), or using a numerical method (e.g., the NewtonRaphson method).

Steps 3 and 4. Linearize in the Vicinity of the Steady State. The Jacobian matrices for the linearized

approximation are:

(q0 + qw* )

−

− 2k {T* }C PO*

1

V

A=

60 (− ∆H ) 2k {T }C

*

PO*

CP

∂k {T* } 2

C PO*

∂T

2

(q + qw* ) + ∂k {T* }(− ∆H )C PO*

− 0

∂T

V

CP

−

C PO*

1

0

−

1

1

V

V

BU =

(T − T ) , B D =

60 − * 0*

60 0 (q0 + q w* )

V

V

C = [0 1], DU = [0] , D D = [0 0]

(12S.10)

(12S.11)

(12S.12)

The division by 60 in each matrix is to express time in minutes instead of hours. Note also that all

of the variables are expressed in physical units. Substituting numerical values into Eqs. (12S.10)

and (12S.11):

− 9.203 − 0.0396

,

A=

0.8870

229.8

0

− 0.0009

0.0147

,

BU =

BD =

0.1157

− 0.8596

0

These matrices are scaled by assuming that all outputs and manipulated variables are nominally at

50% of their ranges, and the disturbance variable values are constrained to vary in the range ∆d =

[±50% ±5 oC]T. Thus:

0

C

− 9.203 − 55.43

A s = S −x 1 AS x =

, S x = PO*

T*

0.1644 0.8870

0

− 0.0782

BU ,s = S −x 1 BU S u =

, S u = q w*

− 0.0555

0

2.330

0.5ℑ PO ,in* 0

B D ,s = S −x 1 B D S d =

,S d =

0.0070

0

5

0

– 12S-7–

(12S.13)

These matrices relate the input (manipulated and disturbance) variables to the output (controlled)

variables, with all of the variables scaled and in perturbation variable form.

Step 5. Generate Transfer Functions. These are computed using the scaled matrices in Eq.

(12S.13), for example

(

P{s} = C s ⋅ I − A s

)

−1

−1

BU , s + DU , s

55.43 − 0.0782

s + 9.203

= [0 1]

− 0.1644 s − 0.8870 − 0.0555

Hence,

P{s} =

− 0.0555s − 0.524

2

s + 8.32 s + 0.949

=

− 0.552(0.106 s + 1)

(0.122s + 1)(8.64s + 1)

(12S.14)

Note that P{s} is a scalar transfer function, since it relates perturbations in the single manipulated

variable, q̂w , to those in the single process output variable, Tˆ . Note that the process zero almost

cancels the fast process pole, meaning that the response to the manipulated variable is effectively

that of a first-order lag, with a time constant of approximately 9 min.

A similar computation yields the transfer function matrix, P d {s} :

−1

55.43 2.330

0

s + 9.203

P d {s} = [0 1]

0.0070

− 0.1644 s − 0.8870 0

0.410

=

(0.122s + 1)(8.64s + 1)

0.068(0.109s + 1)

(0.122s + 1)(8.64s + 1)

(12S.15)

The columns of P d {s} define the responses of Tˆ to ℑ̂ PO ,in and T̂o , respectively. Note that the

temperature response to step changes in ℑ PO ,in is of second order, while its response to changes in

the feed temperature is effectively of first order.

The reader is referred to the Wiley website that accompanies this text for useful MATLAB

functions and scripts for the generation of linear models in their standard forms.

– 12S-8–

21.2 QUANTITATIVE MEASURES FOR CONTROLLABILITY AND RESILIENCY

The quantitative assessment of the controllability and resiliency of chemical processes has

generated considerable interest. The term resiliency was introduced by Morari (1983), who also

pioneered qualitative measures for its assessment. Furthermore, Perkins (1989) presented an

approach for the simultaneous design of processes and their control systems that addresses

plantwide controllability directly.

All of the C&R measures use the linear approximations, P{s} and P d {s} , which describe

the effects of the control variables and disturbances, respectively, on the process outputs. A

commonly used controllability measure is the relative-gain array (RGA – Bristol, 1966), which

relies only on P{s} . The disturbance condition number (DCN; Skogestad and Morari, 1987) and

the disturbance cost (DC; Lewin, 1996) are resiliency measures that require a disturbance model,

P d {s} , in addition to P{s} . These C&R measures are especially useful in Stages 2 and 3 of the

design process (see Table 12.1) because they do not assume a controller structure or a specific

controller design and tuning.

It is assumed that each input variable is nominally at the midpoint of its range and is

expressed in perturbation variable form, and scaled by dividing by its nominal value. For example,

if Fi is an inlet flow rate, nominally at 500 lbmol/hr, its operating range is 0 ≤ Fi ≤ 1000 lbmol/h, in

perturbation variable form, −500 ≤ Fi ≤ 500, and in scaled form, −1 ≤ Fi ≤ 1. Thus, P{s} and

P d {s} are scaled by multiplying the gains in each column by the nominal value of the appropriate

input variable. As a result, all of the scaled inputs vary over the same range [−1, 1]. Note, however,

that the RGA is scale independent, whereas the DC is input scale dependent.

– 12S-9–

Relative-gain Array (RGA)

Steady-State RGA (Bristol, 1966)

Figure 12S.1 shows the block diagram for a multiple-input, multiple-output (MIMO)

process to be controlled by two single-loop controllers. Having closed one of the loops (y1 − u1), the

controller in the second loop, which manipulates u2 based on the feedback of y2, must be tuned. A

desirable feature of this controller is to have the effective process gain remain invariant, regardless

of the action of the other control loop.

-

c1

u1

p11

y1

p21

p12

u2

p22

y2

Figure 12S.1 MIMO process with one control loop.

When the controller c1 is put into manual operation, i.e., when it is turned off, the process

gain as seen by controller c2 is

y2

= p22

(12S.16)

u2 c ,OL

1

where u2 and y2 are the deviations of the input and output from their nominal values in the steady

state. On the other hand, when c1 is put into automatic operation, the process gain as seen by

controller c2 is

y2

c1

p21

= p22 − p12

1 + p11c1

u2 c ,CL

1

In general, for MIMO systems, a useful measure is the ratio

process gain as seen by a given controller with all other loops open

process gain as seen by a given controller with all other loops closed

– 12S-10–

(12S.17)

When this ratio is close to unity, the given controller is relatively insensitive to interaction.

Computing this ratio for the MIMO process in Figure 12S.1:

y2

u2

y2

u2

c1 ,OL

=

c1 ,CL

p22

(12S.18)

c1

p22 − p12

p21

1 + p11c1

When the top loop is closed-loop stable, and when c1 has integral action,

lim

c1

1

=

s → 0 1 + p11c1 p11

Therefore, the ratio at steady state is

y2

u2

lim

s→0 y

2

u2

Similarly,

c1 ,OL

c1 ,CL

= s lim

→0

p22

c1

p22 − p12

p21

1 + p11c1

=

p11 p22

p11 p22 − p12 p21

y2

lim u1 c1 ,OL

− p12 p21

=

s → 0 y2

p11 p22 − p12 p21

u1 c ,CL

(12S.19)

(12S.20)

1

Thus, for a two-input, two-output process, the RGA is defined as

y1

y1

u1 c2 ,OL u2 c2 ,OL

y1

y1

u

u

1 c2 ,CL

2 c2 ,CL p11 p22

− p12 p21

λ11 λ12

−1

=

Λ =

=

⋅ det ( P )

− p12 p21 p11 p22

y2

λ 21 λ 22 y2

u1 c1 ,OL u2 c1 ,OL

y2

y2

u1 c ,CL u2 c ,CL

1

1

In general, the RGA can be computed using

( )

Λ = P ⊗ P −1

T

where ⊗ denotes the element-by-element (Schur) product.

– 12S-11–

(12S.21)

(12S.22)

Theorem (2 × 2 Systems Only).

If λ11 (= λ22) is positive, there exists a pair of single-input, single-output (SISO) controllers, c1 and

c2, with integral action for the loops u1 − y1 and u2 − y2 such that the loops are stable by themselves

and together. If λ11 is negative, there are no controllers that can guarantee stability by themselves

and together. In other words, to guarantee closed-loop stability with either of the two SISO

controllers in automatic or manual, the controllers should be paired such that the RGA elements

corresponding to the pairings are positive. Negative RGA elements are an indication of the

presence of destabilizing positive feedback due to unfavorable process interactions. Similarly,

excessively large RGA elements are related to poorly conditioned processes; those in which the

effective process gain may be orders of magnitude different, depending on the input direction.

For systems of higher rank, a necessary condition for the stabilizability of a decentralized

control system is the selection of pairings such that λij > 0, and hence the RGA provides a useful

screening tool. The decentralized integral controllability (DIC) conditions (see Morari and

Zafiriou, 1989, pp. 359-367) provide additional necessary conditions for the stability of higherorder systems, which depend only on the steady-state gain matrix, P{0}.

Properties of the Steady-state RGA

The following properties are especially noteworthy when working with the RGA:

1.

∑ λij = ∑ λij =

i

1 (rows and columns sum to unity)

j

2. If P is triangular (lower or upper), Λ = I

1 0 0

− 3 2 3

e.g. P = 0 3 5 ⇒ Λ = 0 1 0

0 0 1

0 0 1

In such systems, the process interaction is in one direction only, and therefore, precludes the

possibility of the occurrence of destabilizing feedback.

3. For 2×2 systems only:

If P has an odd number of positive elements, 0 ≤ λij ≤ 1

If P has an even number of positive elements, either λij < 0 or λij > 1

– 12S-12–

Dynamic RGA (McAvoy, 1983)

Considering the same MIMO process in Figure 12S.1, y2 is expressed in terms of u1and u2:

y2 = p21u1 + p22u2

(12S.23)

When c1 is in manual operation, u1 = 0 and

y2

= p22

u2 c ,OL

1

as for the steady-state analysis. When c1 is in automatic operation and it is assumed that the first

loop can be designed to give perfect control (i.e., the first loop's output is assumed to be held at its

set point),

p

y1 = p11u1 + p12 u2 = 0 ⇒ u1 = − 12 u2

p11

Substituting for u1 in Eq. (12S.23),

(12S.24)

y2

p p

= p22 − 12 21

(12S.25)

u2 c ,CL

p11

1

Hence, the dynamic RGA (DRGA) has precisely the same form as the steady-state array. Note that

the dynamic RGA assumes perfect control, which may not be an appropriate assumption, especially

at high frequencies. The computation of the DRGA requires care since it involves complex algebra.

Because columns and rows sum to unity only at the steady state, the DRGA should be computed

using:

(

)

DRGAij {ω} = sign λ ij {0} ⋅ λ ij { jω} ,

(12S.26)

with λij{jω} computed conveniently for 2 × 2 systems using Eqs. (12S.19) and (12S.20), or using

Eq.(12S.22) in general.

An accepted rule of thumb is to avoid pairings between variables with negative RGA

elements and to select those with values close to unity, as illustrated in the following example.

– 12S-13–

Example 12S.2 LV Control of a Binary Distillation Column

Figure 12S.2 shows the LV configuration for the two-point composition control of a binary

distillation column discussed in Example 12.9. After assigning manipulated variables to regulate

the vapor and liquid inventories, the boilup rate, V, and the reflux flow rate, L, remain available to

control the distillate and bottoms product compositions, xD and xB, respectively. To assess the

controllability and resiliency of this configuration, the disturbances are taken to be the feed

composition, xF, and the flow rate, F. The column dynamics are approximated by a linear model in

transfer function form (Sandelin et al., 1990):

−0.045 − 0.5 s

0.048 − 0.5 s

−0.001 e − s 0.004 e − s F

e

L

xD 8.1s +1 e

11s +1

10 s +1

8.5 s +1

(12S.27)

x = − 0.23 −1.5 s 0.55 − 0.5 s V + − 0.16 − s − 0.65 − s x

e

e F

e

e

B 8.1s +1

10 s +1

9.2 s +1

5.5 s +1

To complete the process model definition, it is noted that the process input ranges are as follows: L

= 60 ± 60 kmol/h, V = 72 ± 72 kmol /h, F = Fnom ± 20 kmol /h, xF = xF, nom ± 6 %. In Eq. (12S.27),

the gain coefficients are in the appropriate units, and time is in minutes.

Figure 12S.2 Control of a binary distillation column using the LV configuration.

The qualitative guidelines presented in Chapter 12 are not sufficient to decide how to pair the two

manipulated variables with the two outputs. Without analysis, it is not clear whether this pairing

should be diagonal (i.e., {xD−L, xB−V } as shown in Figure 12S.2) or off-diagonal (i.e., {xD−V,

xB−L }). However, using Eq. (12S.19), λ11 in the RGA is

– 12S-14–

=

λ11

p11 p22

1.8

=

p11 p22 − p12 p21

(12S.28)

Using the property that the RGA rows and columns add to unity,

1.8 − 0.8

Λ=

,

− 0.8 1.8

and consequently, diagonal pairing is recommended, with the off-diagonal pairing resulting in

stability problems, either when both of the controllers are on automatic or when one of the

controllers is switched to manual operation. Although stable, significant interactions are anticipated

when both loops are closed, because of the large RGA element.

Figure 12S.3 Closed-loop response of the LV

configuration for binary distillation to the worstcase disturbance, d = [20, 6]T, with decentralized

PI control - Outputs: xD (solid line), xB (dashed

line); Inputs: L (solid line), V (dashed line).

To verify this, Figure 12S.3 shows the closed-loop response for the process, diagonally paired with

IMC-tuned PI controllers (xD − L loop: Kc = -50, τI = 8 min; xB − V loop: Kc = 5, τI = 10 min). For

the IMC-PI tuning rules, the reader is referred to Section 12S.4. The simulation is computed for the

worst-case disturbance, d = [20, 6]T, identified using the disturbance cost analysis, to be discussed

shortly. As expected, the response is stable but shows significant interactions, with the bottoms

composition affected more significantly. The reader can try out this example under MATLAB,

using the interactive C&R Tutorial CRGUI available on the Wiley website that accompanies this

text. In the main menu, opt for the “Binary Column.”

In some cases, the RGA elements vary significantly with the frequency, which may indicate

bandwidth limitations on the diagonal dominance of the process. For this example, Figure 12S.4

– 12S-15–

shows λ11 and λ12 as a function of the frequency. Although there is considerable variation at high

frequencies, the diagonal dominance holds for the entire frequency range of interest. In this case,

the RGA and DRGA give the same pairing recommendations. For some processes, however, the

information furnished by the dynamic RGA can be crucial for the correct pairing selection. The

following example provides one such case.

Figure 12S.4 Dynamic RGA for the diagonal

(solid line) and off-diagonal (dotted line) pairings

for Example 12S.2.

Example 12S.3 Importance of the Dynamic RGA

Consider the process:

2.5

− 5s

y1 (15 s +1)(2 s +1) e

y =

1

2

3 s +1

5

u

− 4 e − 2s

4 s +1

1 + 10 s +1

−1 − 2 s

−4

e − 5 s u 2 5 s +1 e

20 s +1

3

e − 5 s d1

10 s +1

−2

e − 5 s d 2

10 s +1

(12S.29)

Here the process inputs are limited to the ranges: u1 = 60 ± 60, u2 = 50 ± 50, d1 = d 1,nom ± 20, and

d 2 = d 2,nom ± 5, and time is in minutes.

For this system, λ11 = 2/3 in the steady-state RGA, suggesting that the variables be paired

diagonally. In the dynamic RGA, however, the diagonal dominance deteriorates at moderate

frequencies, as shown in Figure 12S.5. In fact, the process is off-diagonally dominant in the

frequency range of interest. The open-loop time constants are on the order of 10 min, and hence,

frequencies in the range 0.1 < ω < 1 rad/min are of particular interest. For this system, the offdiagonal pairing (i.e., y1 − u2 and y2 − u1) is preferred, contrary to the pairing suggested by the

steady-state RGA. To verify the analysis in Figure 12S.5, the two pairings are simulated using

– 12S-16–

IMC-PI tuning rules (see Section 21.4). For the diagonal pairing, the controllers are tuned: y1 − u1

loop, Kc = 0.6, τI = 15 min; y2 − u2 loop, Kc = −0.37, τI = 20 min. In contrast, for the off-diagonal

pairing, the controller tuning parameters are: y2 − u1 loop, Kc = 10, τI = 3 min; y1 − u2 loop: Kc = 2,

τI = 4 min. Note that the controller gains for the diagonal pairing are an order of magnitude lower

than for the off-diagonal pairing, a reflection of the bandwidth limitations imposed by the delays on

the diagonal elements of the process transfer-function matrix. For a unit-step increase in the y1

setpoint, Figure 12S.6 shows that although the diagonal controller is bandwidth limited, the tuning

for the off-diagonal configuration can be arbitrarily aggressive, only restricted by the actuator

constraints. The reader can try out this example under MATLAB, using the interactive C&R

Tutorial CRGUI available on the Wiley website that accompanies this text. In the main menu, opt

for the “Mystery Process.”

Figure 12S.5 Dynamic RGA for the diagonal

(solid line) and off-diagonal (dotted line) pairings

for Example 12S.3.

Figure 12S.6 Closed-loop response for Example

12S.3 with PI control for a setpoint change in y1

using: (a,b) diagonal pairing; (c,d) off-diagonal

pairing. Shown on the top row are outputs: y1

(solid line), y2 (dashed line), and on the bottom

row, inputs: u1 (solid line), u2 (dashed line).

– 12S-17–

Example 12S.4 Control Configuration for a Utilities Subsystem (Example 12.7 Revisited).

The analysis of the utilities subsystem in Figure 12S.8 is based on the steady-state material and

energy balances:

Fc = Fc1 + Fc 2

Tco =

(12S.30)

Fc1Tc1 + Fc 2 Tc 2

Fc1 + Fc 2

,

(12S.31)

where the controlled variables are Fc and Tco. Selecting Fc1 and Fc2 as the manipulated variables,

the steady-state gain matrix is computed by partial differentiation of Eqs. (12S.30) and (12S.31):

1

∆Fc

∆T = Fc 2 (Tc1 − Tc 2 )

co (F + F )2

c2

c1

1

∆F

− Fc1 (Tc1 − Tc 2 ) c1

∆F

(Fc1 + Fc 2 )2 c 2

(12S.32)

The λ11 element of the RGA is computed using Eq. (12S.19):

λ 11 =

p11 p22

p11 p22 − p12 p21

=

Fc1

Fc1 + Fc 2

=x

(12S.33)

where 0 ≤ x ≤ 1. Since the RGA rows and columns add to unity, the RGA matrix is

[

Λ = 1 −x x 1 −x x

]

(12S.34)

The recommended pairings depend on the operating conditions of the coolant subsystem, with

significant interactions normally occurring between the control loops. To avoid this, the

manipulated variables are defined as ϕ = Fc1+Fc2 and µ = Fc1/(Fc1+Fc2), transforming Eqs. (12S.30)

and (12S.31) to

Fc = ϕ

(12S.35)

Tco = µ ⋅ Tc1 + (1 − µ ) Tc 2

(12S.36)

After partial differentiation,

0 ∆ϕ

∆Fc 1

∆T = 0 T − T ∆µ

c1

c2

co

– 12S-18–

(12S.37)

This is a decoupled system that requires diagonal pairings, because Λ = I .

Figure 12S.7 An attractive control configuration for the utilities subsystem.

These pairings, shown in Figure 12S.7, are intuitively correct in that the total flow rate is controlled

by the sum of the two utility streams, and the coolant temperature is controlled by the fraction of

the coolant flowing through the heating system. Note that the temperature and flow controllers

manipulate the variables µ and ϕ, respectively, which are processed by a decoupler, D, to generate

corrections to the two flow rates, Fc1 and Fc2, according to:

Fc1 = ϕ ⋅ µ

Fc 2 = ϕ (1 − µ )

(12S.38)

Example 12S.5 Control Configuration for a Debottlenecked Distillation Column

Often, process design modifications can lead to potential control problems, as demonstrated by

McAvoy (1983) for a distillation column in which the reboiler capacity is doubled by the addition

of an identical reboiler in parallel with the original one (i.e., the column is debottlenecked), as

shown in Figure 12S.8.

Figure 12S.8 Debottlenecked distillation column.

– 12S-19–

A MIMO control system must be configured for the retrofitted column. To compute the RGA, a

linearized model, in the steady state, relates the changes in the designated outputs, T, L1, and L2, to

those of the manipulated variables, Q1, Q2, and B:

∆T a11 a12

∆L = a

1 21 a22

∆L2 a31 a32

a13 ∆Q1

a23 ∆Q2

a33 ∆B

(12S.39)

Since B does not affect T directly, ∆T ∆B = 0 . Furthermore, by symmetry,

a11 = a12 =

∆T

∆T

=

∆Q1 ∆Q2

a 23 = a33 =

∆L1 ∆L2

=

∆B

∆B

a 21 = a32 =

∆L1 ∆L2

=

∆Q1 ∆Q2

a 22 = a31 =

∆L1 ∆L2

=

∆Q2 ∆Q1

Hence, Eq. (12S.39)) becomes

∆T

1

∆L=

∆L2

a11

0 ∆Q1

a11

a

21 βa21 a23 ∆Q2

βa21 a21 a23 ∆B

(12S.40)

where

=

β

a22 effect of Q1 on L2

=

<1

a21 effect of Q1 on L1

Using Eq. (12S.22),

0.5

T

= 0.5

1−β

−0.5β

1−β

( )

Λ= P ⊗ P −1

0

0.5

0.5

0.5

−0.5β

1−β

0.5

1−β

(12S.41)

Note that β < 1 and is close to unity. Assuming β = 0.95, the RGA becomes

0.5

0.5

Λ = 10 − 9.5

− 9.5 10

0

0.5

0.5

(12S.42)

To ensure no loss of stability, pairings on negative RGA coefficients are avoided. Thus, only two

possible pairings remain to be considered: [Q2−T, Q1−L1, B−L2] and [Q1−T, B−L1, Q2−L2] . Neither

– 12S-20–

alternative gives good performance since, in each case, one loop has a relative gain of 10, implying

the need for severely detuned controllers. Clearly, the pairing selection for both of these controller

configurations is limited by the available outputs and manipulated variables, and does not exploit

the symmetry in the process design. This drawback can be avoided by selecting other manipulated

and controlled variables. Here, it is desired to control the total hold up (ψ = ∆L1 + ∆L2), and the

best manipulated variable to do this is intuitively the bottoms flow rate, B. Thus, the vector of

manipulated variables is redefined as u = [φ Γ ∆B]T, where φ = ∆Q1 − ∆Q2 and Γ = ∆Q1 + ∆Q2,

and the vector of controlled variables is redefined as y = [∆T Ω ψ]T , where Ω = ∆L1 − ∆L2. The

linear model, expressed in terms of these new variables, becomes

Ω (1 − β )a21

∆T =

0

ψ

0

0

a11

(1 + β )a21

0 φ

0 Γ

2a23 ∆B

(12S.43)

Note that this is a lower-triangular matrix, with the corresponding RGA:

1 0 0

Λ = 0 1 0

0 0 1

This result suggests the following pairings: (1) Ω − φ (the imbalance in the holdups controlled by

the imbalance in the heat duties of the two reboilers), (2) ∆T − Γ (the reboiler temperature

controlled by the total heat duty), and (3) ψ − ∆B (the total holdup controlled by the bottoms flow

rate). These control loops largely respond independently of each other (there is small one-way

interaction between the second and third loops), and are referred to as decoupled.

The RGA as a Measure of Process Sensitivity to Uncertainty

Thus far, the RGA has been used to measure the process interactions and to aid in selecting

the pairings for decentralized controller configurations. It is noteworthy that the magnitudes of the

RGA elements are an indication of the degree of the process sensitivity to uncertainty. This is

illustrated using a hypothetical process model,

K (1 − ε ) 1

,

P=

K

1

– 12S-21–

(12S.44)

in which the p11 coefficient is subject to a fractional uncertainty, ε. This uncertainty can

significantly affect the RGA, depending on the value of K, as shown in Figure 12S.9, where

=

λ11 K 2 (1 − ε ) [ K 2 (1 − ε ) − 1] , is displayed as a function of ε for two values of K. For K = 10, the

process is strongly diagonally dominant and hardly affected by the uncertainty ( λ11 is close to

unity). On the other hand, for K = 2, λ11 = 1.33 when ε = 0, indicating that the process has

significant interactions. Furthermore, P becomes singular at ε = 0.75 and the recommended

pairings are switched, implying that a multivariable control system is unreliable at this level of

uncertainty.

Figure 12S.9 Effect of uncertainty on the RGA for K = 2 and K = 10.

In summary, processes with RGA coefficients close to unity are relatively insensitive to

uncertainties in the process model. Conversely, processes with large RGA coefficients tend to

exhibit a high degree of sensitivity to model uncertainties.

Using the Disturbance Cost to Assess Resiliency to Disturbances

The design of process controllers for open-loop stable systems is motivated principally by

the need to impart disturbance resiliency properties to processing operations. In other words, it is

– 12S-22–

intended to maintain the outputs of multivariable processes at their set points despite external

disturbances and uncertainties in the process model. The degree to which this requirement is

satisfied is referred to as resiliency.

Given the process model of Eq. (12S.1) and assuming perfect control, the action required to

completely reject the disturbance, d, is

u{s} = − P −1{s}d ′{s}, where d ′{s} = P d {s}d {s}

(12S.45)

By computing the norm of the actuator response, u , as a function of the disturbance direction, the

relative cost of rejecting a particular disturbance, d, is computed as a function of its direction. One

quantitative measure of the control effort to reject a given disturbance vector is the Euclidean norm:

u{s} 2 = P −1{s}P d {s}d {s} ,

2

(12S.46)

it being noted that the infinity norm provides an alternative resiliency measure. Parseval's theorem

provides the direct translation of the 2-norm, in the frequency domain, to the total control action in

the time domain. This norm, u 2 , is the disturbance cost (DC; Lewin, 1996). Often, it is more

helpful to compute DC values for each manipulated variable separately. Since u 2 is a frequency

dependent measure, it can be displayed as a function of frequency and the direction of d{s}, to

show the effect of two disturbances d1 and d2, where the disturbance direction is the angle of the

disturbance vector with respect to the abscissa, that is, arg{d}. Contour maps of DC are displayed

as a function of the disturbance direction and frequency. Since the DC is based on the assumption

of perfect control, the results are independent of controller tuning or sophistication. For this reason,

the DC is helpful for screening alternative flowsheets in Stages 2 and 3 of the design process,

before it is practical to consider the details of the individual controllers. Even though perfect

control is assumed, the values of the steady-state DC indicate:

1. The settling time for disturbance rejection. Note that disturbance directions for which the

steady-state DC is high are those for which disturbance recovery is sluggish, regardless of

the sophistication of the controller.

2. The limitations due to actuator constraints. Disturbance directions for which the steadystate DC exceeds the actuator constraints are those in which offset is incurred because of

actuator saturation. Assuming that the process model has been scaled such that inputs are

constrained to lie within u ≤ 1 , steady-state DC values above unity indicate that the

– 12S-23–

actuator constraints are exceeded, and hence, such flowsheets should be avoided or

modified to ensure adequate regulation.

Furthermore, by observing the DC variation at higher frequencies (e.g., at the closed-loop

bandwidth specified), the disturbance directions are identified for which the high-frequency modes

are attenuated with difficulty or not at all.

The next example shows the utility of the disturbance cost for predicting the ease of

rejecting disturbances, as applied to the operation of a distillation tower.

Example 12S.6 Resiliency Analysis of the “Shell Process.”

To test alternative control strategies, Prett and Morari (1986) provide a linearized model, referred to

as the “Shell Process,” of a distillation tower to separate crude oil into fractions in a refinery. Part

of the model describes the dynamics of the two top compositions as a function of the manipulated

variables (the two top draw rates) and two key disturbances (the heat removal loads in pumparound streams used to remove heat and create intermediate reflux). For this example, it is

sufficient to examine the matrices specific to the nominal model:

4.05 e − 27 s

P{s} = 505.s39+1 −18 s

e

50 s +1

1.77 − 28 s

e

60 s +1

5.72 −14 s

e

60 s +1

1.2 e − 27 s

P d {s} = 451.s52+1 −15 s

e

25 s +1

1.44 − 27 s

e

40 s +1

1.83 −15 s

e

20 s +1

(12S.47)

The time units in this model are minutes, and both manipulated variables and disturbances are in

the range ±0.5. After scaling, the inputs (both disturbances and manipulated variables) are in the

range ±1.

First, the disturbance cost at steady state is computed for various disturbance vectors.

For d = [1,−1]T ,

arg(d ) = −45° : u{0} 2

−1

4.05 1.77 1.2 1.44 1

=

5.39 5.72 1.52 1.83 − 1

and for three other disturbance directions,

– 12S-24–

= 0.0606

2

(12S.48)

arg(d ) = 0° : u{0} 2

−1

4.05 1.77 1.2 1.44 1

=

5.39 5.72 1.52 1.83 0

= 0.3072

2

−1

4.05 1.77 1.2 1.44 1

arg(d ) = 45° : u{0} 2 =

5.39 5.72 1.52 1.83 1

= 0.6748

(12S.49)

2

−1

4.05 1.77 1.2 1.44 0

arg(d ) = 90° : u{0} 2 =

5.39 5.72 1.52 1.83 1

= 0.3676

2

Clearly, the worst disturbance to reject is d = [1, 1]T (45° or −135°), whereas d = [1, −1]T (−45° or

135°) is the easiest to overcome.

Figure 12S.10 Closed-loop response of the

Shell process to different disturbance

directions: Solid line = y1, dotted line = y2,

dashed line == u1, dashed-dotted line = u2.

These observations are verified by closed-loop simulations. The RGA for the matrix P{0}, with λ11

= 1.7, indicates that the control loops can operate in a stable fashion only by pairing the inputs and

outputs diagonally. Thus, diagonally paired PI controllers are tuned according to the improved

IMC-based tuning rules (see Section 21.4), with KC1 = 0.29, τI 1 = 64 min, KC2 = 0.42 and τI 2 = 67

min. As shown in Figure 12S.10, simulations confirm that disturbances acting in opposite

directions, d = [1, −1]T , are the easiest to reject, whereas those in the same direction, d = [1, 1]T,

are the most difficult.

– 12S-25–

To identify potential bandwidth limitations, the DC values are computed as a function of the

frequency.

For two disturbances, contours of DC values, computed separately for each

manipulated variable, are displayed as a function of the disturbance direction (in degrees) and

frequency, as shown in Figure 12S.11. This confirms that the worst disturbance direction is d = [1,

1]T (i.e., 45°), where the two manipulated variables are highest, with u1 having relatively high

steady-state values, but lower than unity, while u2 has low values at steady state, but values that

exceed unity at frequencies greater than 10-1.5 = 0.03 rad/min. Consequently, the fast modes in

disturbance vectors entering in this direction (45°) are not attenuated, even if perfect control were

possible. Thus, the fastest settling time possible for this disturbance is approximately five times the

inverse of the bandwidth limit, where DC =1, that is, 150 min. This analysis is corroborated by the

responses in Figure 12S.10, which indicate that the most severe bandwidth limitations are exhibited

for disturbances aligned at 45°, but with perfect steady-state disturbance rejection, with most of the

static effects eliminated using u1. Clearly, the response obtained with the decentralized PI control

system for d = [1, 1]T is considerably more sluggish, since delay times impose additional stability

limitations, as discussed in Section 12S.4. In contrast, disturbances in the direction, d = [1, −1]T,

(i.e., −45° or 135°), are more easily rejected, as the DC for each manipulated variable remains low

over the entire frequency range. Again, this is corroborated by the responses in Figure 12S.10. The

reader can try out this example under MATLAB, using the interactive C&R Tutorial CRGUI

available on the Wiley website that accompanies this text. In the main menu, opt for the “Shell

Process.”

Figure 12S.11 DC contour map for the Shell Process: (a) u1; (b) u2.

– 12S-26–

Example 12S.7 Using DC to Improve Process Resiliency (Example 12S.3 Revisited).

Returning to the process in Example 12S1.3, and noting that DRGA analysis leads to the

recommendation that the variables be paired off-diagonally (i.e., y2 – u1 and y1– u2), the resiliency

of the controlled system to disturbances is examined. DC contour maps for each of the manipulated

variables are presented in Figure 12S.12, where it is noted that the worst disturbance is d = [20, 0]T

(i.e., a disturbance direction of 0o). Furthermore, in this direction, u1 is bandwidth-limited, with

saturation occurring at a frequency of approximately 10-1 = 0.1 rad/min; that is, with a

characteristic time of 10 min. Consequently, the settling time in response to such a disturbance is

expected to be greater than 50 min. In contrast, the second input, u2, has no bandwidth limitations.

Figure 12S.12 DC contour map for Example 12S.7: (a) u1; (b) u2.

The predictions afforded by the DC contour maps in Figure 12S.12 are confirmed by

simulation for d = [20, 0]T. As seen in Figures 21.13(a) and (b), u1 saturates at its upper bound

(with manipulated variable bounds set at | u1| ≤ 60 and | u2| ≤ 50). This bandwidth limitation is the

reason for the sluggish process recovery, confirming the DC analysis that anticipates saturation in

u1, a design problem that arises because the u1 range is too small to provide adequate dynamic

resiliency. Through redesign, the range is increased to | u1| ≤ 70, and the performance is improved

significantly, as shown in Figures 21.13(c) and (d). The reader can try out this example under

MATLAB, using the interactive C&R Tutorial CRGUI available on the Wiley website that

accompanies this text. In the main menu, opt for the “Mystery Process.”

– 12S-27–

Figure 12S.13 Closed-loop response with

off-diagonal PI control to the disturbance d

= [20, 0]T for Example 12S.7, with: (a,b)

Original bounds on u1; (c,d) Enlarged

bounds on u1 (to ±70). Shown on the top

row are outputs: y1 (solid line), y2 (dashed

line), and on the bottom row, inputs: u1

(solid line), u2 (dashed line).

12S.3 TOWARD AUTOMATED FLOWSHEET C&R DIAGNOSIS

This section describes a procedure for assessing the controllability and resiliency of a

process flowsheet that relies on heuristics to create a linearized dynamic model of the process using

the results of steady-state simulations. The derived model is used to test the flowsheet C&R, using

the measures introduced in Section 12S.2. As a tutorial exercise, the procedure is applied to screen

the designs for the heat-integrated distillation columns in Example 12.2. Subsequently, in Section

12S.5, case studies are presented for three additional processes. For each case, the results of the

approximate linear analysis are compared with the results of closed-loop simulations using

nonlinear dynamic models. As will be shown, the overall approach is very promising as a short-cut

diagnostic and screening tool, which can be expected to be integrated into commercial simulation

software.

Short-Cut C&R Diagnosis

As discussed above, both steady-state and dynamic C&R analyses provide useful

information for flowsheet assessment. Clearly, the second alternative provides more information

– 12S-28–

and is more reliable. On the other hand, steady-state analysis requires much less work, and is often

adequate for screening purposes. Consequently, both approaches are considered in this section.

The following steps are involved in steady-state analysis:

1. After the flowsheet is synthesized, the control structure is considered, first by selecting the

process outputs to be controlled, y{t}, the manipulated variables, u{t}, and the disturbance

variables, d{t}. These are related by Eq. (12S.1).

2. Steady-state simulation of the flowsheet is carried out using a process simulator.

3. Steady-state gains for the overall transfer functions, P{0} and P d {0}, are computed by

perturbing each input, one at a time.

4. Steady-state C&R measures are computed using P{0} and P d {0}.

For the dynamic C&R analysis (Weitz and Lewin, 1996), the steps in the algorithm are as

follows:

1. Step 1 of the steady-state algorithm.

2. Step 2 of the steady-state algorithm.

3. The flowsheet is decomposed into component parts. These are MIMO subsections of the

flowsheet that are approximated by matrices of low-order transfer functions (usually first

order with dead time). This decomposition permits process units to be modeled in sufficient

detail, allowing inverse response and overshoot phenomena to be represented.

4. Steady-state gains for the component parts are computed by perturbation of each input, one

at a time.

5. Time constants and delay times are estimated assuming perfect mixing or plug flow, as

appropriate, with the flow rates at steady state. At this point, transfer function matrices are

defined for each component part.

6. The transfer function matrices, P{s} and P d {s} , are generated for the complete flowsheet.

This involves computing the frequency response of each component part, and recombining

the component parts, as dictated by the plant topology.

7. The frequency-dependent C&R measures are computed using the approximate linear model,

P{ jω } and P d { jω }.

– 12S-29–

Many packages are available for steady-state simulation, as discussed in Chapter 5. To

manipulate the linearized models in the Laplace, frequency, and time domains, MATLAB and

SIMULINK are used commonly, and example scripts are introduced in Section 12S.6. The most

recent commercial packages permit steady-state and dynamic simulations. These include ASPEN

HYSYS, UNISIM and Aspen Dynamics, with the former used in Sections 12S.3 and 12S.5.

All of the steps in the two algorithms are implemented using an array of computer packages

that are becoming more integrated. Note that steps 4 and 5 deserve special attention, as they are the

basis for the approximate models generated for the dynamic C&R analysis.

Generating Low-Order Dynamic Models

The linearized model for each component part, to be completed in steps 4 and 5 of the

dynamic C&R analysis, has the form

y {s} = K ⊗ Ψ {s}⋅ u {s}

c

c

c

c

(12S.50)

where uc{s} and yc{s} are m-dimensional input and n-dimensional output vectors, in complex

space, K c is a matrix of steady-state gains in n× m real space, and Ψ {s} is a matrix describing the

c

dynamics in n×m complex space (each element of which is typically a delayed, low-order transfer

function with dead time). The term ⊗ denotes the Schur (or element-by-element) product. Each

distillation column is characterized by a single time constant. For heat exchangers, separate time

constants are associated with the tube- and shell-side fluids. In the subsections that follow, it is

shown that the gains, time constants, and dead times can be estimated almost entirely using the

results of steady-state simulations.

Steady-State Gain Matrix, K c

The steady-state gains between the inputs and outputs for each component part are

generated using the following procedure:

1. The material and energy balances, in the steady state, are solved for the complete flowsheet

at the nominal operating point.

2. Small positive and negative perturbations are introduced for each input of each component

part, one at a time, and the changes in the outputs are computed.

– 12S-30–

3. The steady-state gains for each component part are computed using finite differences: Kcij =

∆yci/∆ucj, where the perturbation, ∆ucj, is sufficiently small to avoid precision losses.

Dynamics Matrix, Ψ c {s}

In this section, an approach is suggested for estimating the time constants and delay times

for distillation columns and heat exchangers.

Distillation Columns.

Time constants. Following Skogestad (1987), the dominant time constant is estimated as

τ = τ I + τC + τ R

(12S.51)

where τC and τR are the time constants (in minutes) associated with the condenser and reboiler,

respectively, and τI is the time constant (in minutes) for the column, estimated according to

N

Mi

i =1 Li

τ I =∑

(12S.52)

where Mi is the volumetric holdup (m3) on tray i, Li is the liquid flow rate (m3/min) from tray i, and

N is the number of trays. The liquid holdup is expressed as

M i = Ac (hw + how ) =

πDc2

4

(hw + how )

(12S.53)

where Dc is the column diameter (m), and hw and how are the weir height and fluid height above the

weir (m), respectively. The latter can be expressed in terms of the weir length, lw (m), using the

Francis weir equation:

how

Li

=

111 ⋅ l w

23

(12S.54)

Delay times. When the internal liquid flow rate in the column changes, a delay time is associated

with the change in the fluid holdup above the weir. For a single tray, this is estimated by

considering the time taken for how to stabilize after a change in the liquid flow rate (Shinskey,

1984):

=

θ

dM ow dt

dhow

πDc2

= A=

c

0.5

dLi dt

dLi

666 ⋅ lw ⋅ how

(12S.55)

Thus, the overall delay experienced by the bottoms product after changes in the flow rates,

temperatures, or compositions of the feed or reflux depends on the number of trays involved. In

– 12S-31–

contrast, it is noted that the distillate composition responds immediately to a change in the reflux

flow rate, but experiences a considerable delay after changes in the feed concentration or

temperature. For the latter, the delay time is estimated as the sum of the residence times on all trays

between the feed and the top tray, since such a change is assumed to propagate by affecting the

entire tray holdup rather than just the over-weir fluid.

Typical design parameters. The following heuristics are in common use: τC = τR = 0.5τI , lw =

0.65Dc and hw = 2 in.

Heat Exchangers.

It is assumed that time delays associated with heat exchangers in the major processing units,

such as the condensers and reboilers in distillation columns, are negligible. When heat exchangers

are not included in the major processing units, they are modeled as first-order lags associated with

single shell and single tube passes.

Time constants. These are estimated for the tube- and shell-side fluids using τT = VT /qT and τS =

VS /qS. The volumes of the fluid holdups in the tubes and shell, VT and VS, are estimated using the

heat transfer area, the average fluid velocity in the tubes, v, and the tube and shell diameters. The

volumetric flow rates, qT and qS, are estimated by the process simulator.

Example 12S.8: C&R Analysis for Heat-Integrated Distillation Columns (Example 12.2

Revisited)

Dynamic C&R analysis is applied to screen the heat-integrated distillation configurations for the

dehydration of methanol in Figure 12.2 of Example 12.2. Of the three heat-integrated designs, the

FS and LSR configurations provide the maximum energy savings. Clearly, the most controllable

and resilient of the two should be selected based on C&R screening. Note that Chiang and Luyben

(1988) prepared nonlinear dynamic models of the three heat-integrated configurations. They carried

out C&R analysis, using the RGA and minimum singular values, based on linear approximations to

their dynamic models. Although their findings using linear analysis were inconclusive, they

showed the FS configuration to be far less desirable using closed-loop simulations with their

nonlinear models.

– 12S-32–

In the following, each step of dynamic C&R analysis is described as it is applied to the LSF

configuration.

Step 1: Selection of the outputs, manipulated variables, and disturbances. As shown in Figure

12S.14, for the LSF configuration, the process outputs are the mole fractions of methanol in the

three product streams (xDH, xDL and xBL). The process inputs are the control variables (LH , LL and

QRH), and the disturbances are F and xF.

Figure 12S.14 Component parts for the LSF configuration.

Table 12S.1 Results from the Steady-state Simulation using PRO/II of Simulation Sciences for the Heatintegrated Configurations for the Dehydration of Methanol, Compared with a Single Column.

Variable

F, feed flow (kmol/min)

xF, feed mole frac. (CH3OH)

D, distillate flow (kmol/min)

xD, distillate mole frac (CH3OH)

B, bottoms flow (kmol/min)

xB, bottoms mole frac. (CH3OH)

N, number of trays

NF, feed tray (1≡top)

R, reflux ratio

P, working pressure (mmHg)

QR, reboiler duty (106kcal/min)

QC, condenser duty (106kcal/min)

TR, reboiler temperature (°C)

TC, condenser temperature (°C)

DC , column diameter (m)

SC

COL1

45.00

0.50

22.50

0.96

22.50

0.04

13

9

0.82

760

0.353

0.348

93.7

65.1

3.2

FS

COL1

22.04

0.50

11.02

0.96

11.02

0.04

16

12

1.12

3,900

0.205

0.180

146.3

113.4

1.3

COL2

22.96

0.50

11.48

0.96

11.48

0 04

13

9

0.82

760

0.180

0.178

93.7

65.1

2.3

– 12S-33–

LSF

COL1 COL2

45.00 33.95

0.50

0.35

11.05 11.45

0.96

0.96

33.95 22.50

0.35

0.04

16

13

13

11

1.06

1.10

3900

760

0.222 0.175

0.175 0.205

126.5

93.7

113.4

65.1

2.0

2.4

LSR

COL1 COL2

45.00 32.96

0.50

0.33

12.04 10.46

0.96

0.96

32.96 22.50

0.33

0.04

13

16

11

12

0.75

1.15

760 3,900

0.180 0.205

0.179 0.180

77.2 127.2

65.1

95.9

2.3

2.0

Figure 12S.15 Information flows between the component parts

of the heat-integrated distillation configurations: (a) FS; (b) LSF; (c) LSR.

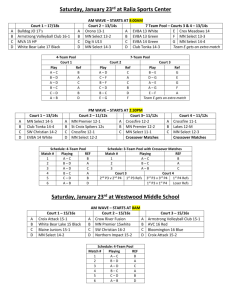

Step 2: Steady-state simulation. The simulation was carried out using the PRO/II simulator and

assuming that there is no pressure drop in the columns, no heat losses to the surroundings, and tray

– 12S-34–

efficiencies of 75%. The thermodynamic properties were computed using the UNIFAC option.

These conditions were used by Chiang and Luyben (1988), with the exception that they accounted

for heat losses. The results for the four flowsheets are in Table 12S.1. Note that the energy

requirements for the LSR and FS configurations are the lowest (0.205×106 kcal/min), followed by

the LSF configuration (0.222×106 kcal/min).

Step 3: Decomposition into component parts. It has been demonstrated that a first-order lag is a

reasonable approximation for the dynamics of a distillation column (Skogestad, 1987). Thus, the

LSF configuration is decomposed into two component parts, one for each column. Four

intermediate variables are identified to model the information transfer between the component

parts: xBH, BH, TBH and QCH (= −QRL). Note that both TBH and QCH are needed for the energy

balance in the reboiler because partial vaporization occurs.

The control variables, in perturbation variable form, are scaled between zero and their

nominal values, and the disturbances are scaled using bounds 20% above and below their nominal

values. The outputs are scaled to provide a reasonable match with the steady-state gains computed

by Chiang and Luyben (1988), it being noted that the output scaling does not affect the RGA or the

DC values.

Steps 4 and 5: Computing Kc and ψc(s). These are computed following the procedure in the section

on “Generating Low-order Dynamic Models,” which gives linearized models for the high-pressure

column in the LSF configuration:

x DH

0.017

x

0.011e−1.3s

BH

1

TBH =

− 0.33e−1.3 s

13s +1 0.916e−1.3s

BH

4e − 5e−1.3s

QCH

and for the low-pressure column:

x BL

1 0.792e− 0.1s

x = 17 s +1 0.790e− 8.5 s

DL

−1.109

0.001

−1.859 0.006 e− 0.1s

− 0.2 e− 0.1s

59.0

−123.7 1.127 e− 0.1s

− 0.994 0.001e− 0.1s

− 0.029e− 0.1s

− 0.051

0.007 e− 0.1s

0.003

– 12S-35–

0.090 e− 6.4 s LH

1.296 e− 0.1s Q

RH

− 41.05e− 0.1s

F

− 0.02e− 0.1s

0.003e− 0.1s

xF

− 2.161

− 3.291

x BH

T

BH

−

.

s

1

4

0.012e

B

H

0.038

QRL

LL

(12S.56)

(12S.57)

Step 6: Generation of transfer function matrices. The linear approximation for the flowsheet

dynamics is obtained by recombining the models for the component parts. Note that Figure 12S.15

shows schematically how the linearized models for the component parts are linked in each of the

configurations. The inputs and outputs associated with each of the configurations are represented

by the terminal junctions to the left and right. Thus, for example, the FS configuration has four

manipulated and two disturbance variables (six inputs in all), and four output variables. The blocks

marked HPC and LPC represent the component parts for the high- and low-pressure distillation

columns, respectively. The arcs represent the flow of information (intermediate variables) to and

from the component parts.

The recombination to form overall transfer functions is accomplished by algebraic

manipulation. For the LSF configuration, Eqs. (12S.56) and (12S.57) are rewritten in block-matrix

form:

x DH

x

BH PH (1,1)

TBH =

PH ( 2 ,1)

B

H

QCH

LH

PH (1,2 ) Q

RH

PH ( 2 ,2 ) F

xF

(12S.58)

x BH

T

BH

x BL

x = PL (1,1) PL (1,2 ) B H

(12S.59)

DL

QRL

LL

where the matrix blocks contain elements from the transfer function matrices in Eqs. (12S.56) and

[

]

(12S.57); for example,

PH (1,1)

=

1

13s +1

[0.017

− 1.109]

Next, by algebraic manipulation, the vector of internal variables, namely [xBH TBH BH QCH]T, is

eliminated, leading to

LH

Q + P (1,2 ) F

1

,

1

0

x

=

P

(

)

[ DH ] H

xF

LRH H

L

– 12S-36–

(12S.60)

L

x BL = P 1,1 ⋅ P 2,1 P 1,2 Q H + P 1,1 ⋅ P 2,2 F

( ) H ( ) x

(

)

(

)

(

)

H

L

x DL L

F

LRH L

L

(12S.61)

Note that Eqs. (12S.60) and (12S.61) are in the standard transfer function form of Eq. (12S.1).

Similar manipulations are used for the other two configurations. The LSR configuration involves

the most complicated manipulations, since it involves the feedback of information.

These models are compared with those derived by Chiang and Luyben (1988), who fitted

linear transfer functions to the transient open-loop responses that were computed using their

nonlinear model. In Figure 12S.16, the diagonal RGA matrix coefficients for all four configurations

are plotted against the frequency; the values reported by Chiang and Luyben appear on the right,

while those computed using the linear models derived using the C&R analysis appear on the left.

As shown, the results are in close agreement. The resonant peaks computed by Chiang and Luyben

are the result of differences in the time constants and delay times in the transfer function elements.

Furthermore, the relative gains, computed using the procedure in this section, do not vary

significantly with frequency. Hence, diagonal pairings are preferred for the decentralized control

system.

Step 7: Computation of C&R measures. Figure 12S.17 shows the DC contour maps computed for

each of the manipulated variables associated with the configurations SC, LSR, and FS, where the

ordinate is the direction of the disturbance [F, xF]T, and the abscissa is the log 10 of the frequency.

Since DC values in excess of unity correspond to saturated manipulated variables, it is apparent that

the disturbances are rejected adequately by all of the designs at the steady state (i.e., when ω = 0).

However, for a wide range of disturbance directions, the FS configuration has disturbance costs in

excess of unity at frequencies beyond 0.1 rad/min in three of the manipulated variables (LH, QRH

and FH/FL). Thus, disturbance rejection is expected to be very sluggish for this configuration. The

other two configurations have low disturbance costs, and are expected to reject these disturbances

nearly as well as a single column. Thus, the FS configuration should be rejected and the LSR

configuration selected, because its energy requirements are lower than for the LSF and SC

configurations.

– 12S-37–

Figure 12S.16 Diagonal RGA elements as a function of frequency for the four configurations to dehydrate

methanol: (a) Procedure in Section 12S.3; (b) Chiang and Luyben (1988).

To confirm these results, nonlinear dynamic simulations are carried out using HYSYS.

Three configurations are simulated: (1) the single column (SC) in the LV configuration; (2) the FS

configuration with the pairing: xDH –LH, xBH – QRH, xDL –LL and xBL –FH/FL ; (3) the LSR

– 12S-38–

configuration with the pairing: xDH –LH, xBH – QRH and xDL –LL. These pairings are selected on the

basis of the RGA. The control loops tuned using the IMC-PI tuning rules (see Section 12S.4), with

tuning parameters summarized in Table 12S.2. Note that the nominal values of the manipulated

variables are at the mid-point of their ranges.

Figure 12S.17 DC contour maps for the SC, FS and LSR configurations to dehydrate methanol. The bounds

on the disturbances are ±20% from their nominal values. The DC contour maps for each

manipulated variable are computed separately, with bold solid lines indicating DC = 1. See

Figure 12S.39 for the DC contour maps for the LSF configuration.

– 12S-39–

Table 12S.2: Tuning parameters for the SC, LSR and FS Configurations.

SC†

Loop

LSR

xDL –LL

Kc = 29; τI = 10 min

xBL – QRL

Kc = 6; τI = 10 min

Kc = 1; τI = 10 min

xBL – FH/FL‡

FS

Kc = 1; τI = 5 min

Kc = 0.5; τI = 30 min

xDH –LH

Kc = 0.15; τI = 5 min

Kc = 1; τI = 5 min

xBH – QRH

Kc = 1; τI = 10 min

Kc = 0.1; τI = 10 min

Notes: †

For the SC configuration, the temperatures on trays 2 and 10 are regulated instead of the

compositions.

‡ The xBL composition controller is the master of a lower-level flow controller to regulate

FH/FL.

Figures 21.18, 21.19 and 21.20 show the responses for the three configurations, subjected to

the worst-case disturbance in which the feed flow rate and composition simultaneously undergo

positive step changes to their design limits. As shown in Figure 12S.18, the SC configuration is

returned to its set points in approximately 100 min, with T10 most affected. Note that this response

is qualitatively similar to that of the linear approximation shown in Figure 12S.3. The simulation

can be reproduced using the METH_SC.HSC file available on the Wiley web site that accompanies

this book.

As shown in Figure 12S.19, the response of the FS configuration to the same disturbance is

very sluggish, settling in about 100 minutes, and exhibiting severe undershoots in two of the four

mole fractions: xBH (by 20 mol %) and xBL (by 10 mol %). This verifies the predictions of the DC

contour maps in Figure 12S.17, which anticipate significant bandwidth limitations. These

simulation results can be reproduced using the METH_FS.HSC file, also available on the Wiley

web site.

– 12S-40–

Figure

12S.18

Response

of

the

SC

configuration to simultaneous disturbances

in F (from 2,700 to 3,000 kmol/h) and xF

(from 0.5 to 0.6 methanol mol fraction): T2

(dashed line), T10 (solid line), set points

(dotted lines).

Figure 12S.19 Response of the FS

configuration to simultaneous disturbances

in F (from 2,700 to 3,000 kmol/h) and xF

(from 0.5 to 0.6 methanol mol fraction):

xBH (solid line), xBL (dashed line), xDL

(dash-dotted line), set points (dotted line).

Figure 12S.20 Response of the LSR

configuration to simultaneous disturbances

in F (from 2,700 to 3,000 kmol/h) and xF

(from 0.5 to 0.6 methanol mol fraction):

xDH (dashed line), xBH (solid line), xDL

(dash-dotted line), and set points (dotted

line).

– 12S-41–

In contrast, the response of the LSR configuration to the same disturbance, shown in Figure

12S.20, settles in about half the time, with significantly less undershoot in xDL. This is because the

controllers are significantly less bandwidth-limited, as predicted by the DC contour maps in Figure

12S.17. Furthermore, the settling time of the LSR configuration is comparable to that for the single

column, as predicted by the DC analysis. These simulation results can be reproduced using the

METH_LSR.HSC file on available on the Wiley web site.

It should be emphasized that the DC contour maps are based on the assumption of perfect

control, assuming that there are no stability limitations to increases in the controller gain. In

practice, when single-loop controllers are implemented, the controller gains are limited, as in this

example, by process interactions, or by single-loop stability limitations such as delay times. As a

result, the bandwidth limitations are usually underestimated by the DC contour maps, but usually

not sufficiently to affect their diagnoses when used to screen alternative designs. Note that the

prediction that the FS configuration provides significantly worse disturbance rejection compared

with that of the LSR configuration has been verified by simulation. Clearly, the LSR design is

preferable based on energy-efficiency and controllability.

This approach has been used successfully for screening more complex heat-integrated

flowsheets (Weitz, 1994), exothermic reactors (Naot and Lewin, 1995), and polymerization

reactors (Lewin and Bogle, 1996). In all cases, the projections were confirmed using rigorous

dynamic models. To further illustrate this screening technique, Section 12S.5 provides three case

studies, involving exothermic reactors in series, heat-exchanger networks, and a recycle process.

– 12S-42–

12S.4 CONTROLLER LOOP DEFINITION AND TUNING

Since the regulatory loops use PI controllers for verification of the C&R analysis, a brief summary

of their configuration and tuning is provided in this section.

Definition of PID Control Loop.

This involves specifying:

1. The process variable to be controlled, PV; that is, any stream- or operation-related variable

in the flowsheet (e.g., pressure, temperature, liquid level, species mass or mole fraction,

mass or molar flow rate). The minimum and maximum values of the PV are used to express

the PV as a percentage of its full range:

PV − PVmin

PV ( % ) =

× 100

PVmax − PVmin

(12S.62)

2. The controller output, OP, to be manipulated by the controller, as a percentage of its full

range. This variable is usually either a stream flow rate or the rate of heat transfer of an

energy stream. Generally, its minimum value is specified as zero and its maximum is taken

as twice its nominal value. Note that occasionally the nominal value is not positioned

midway between the minimum and maximum values (e.g., when the nominal flow rate of a

bypass stream lies near its maximum or minimum flow rate).

3. The controller action, either direct or reverse acting, which defines the direction of its

effect. For a direct-acting controller, when the PV rises above the setpoint (SP), the OP

increases, and vice versa. In these cases, the static process gain is negative, as illustrated for

a level controller in Figure 12S.21(a). Here, the liquid level is the PV, the flow rate of the

effluent stream, Qo, is the OP, and the controller action is set to Direct. In contrast, for a

reverse-acting controller, when the PV rises above the SP, the OP decreases, and vice versa.

In these cases, the static process gain is positive, as illustrated in Figure 12S.21(b), which

shows a different controller configuration for the surge tank. Here, the flow rate of the feed

stream, Qi, is the OP, and the controller action is set to reverse.

– 12S - 43 –

Figure 12S.21 Level-control configurations for a surge tank:

(a) Direct acting; (b) Reverse acting

4. The tuning parameters. For a PID controller, the output, OP(t), is a function of the tracking

error, E(t):

OP{t} = OPSS + K C E{t} + 1

τi

t

∫0

E{θ}dθ + τ d

dE{t}

dt

(12S.63)

where OPSS is the bias, or controller output at zero error, and KC, τi and τd are the

proportional gain, integral time constant (or reset time), and derivative time constant (or rate

time) of the controller. The tracking error at time t, E(t), is the difference between the set

point and the process variable:

E{t} = SP{t} − PV {t}

(12S.64)

As mentioned above, SP, PV and OP are expressed as percentages of their full ranges.

Consequently, the controller gain, KC, is dimensionless, and represents the percentage

change in OP for a one-percent change in PV. In the absence of other information, factory

settings are used: KC = 1, τi = 10 min. and τd = 0. These are tuned for improved

performance, as discussed in the next section.

Controller Tuning.

The PID (Proportional-Integral-Derivative) controller is the most commonly used feedback