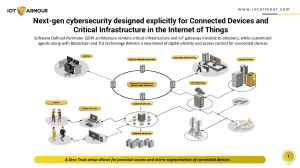

INDUSTRY 4.0 Need and Reason for Adopting Industry 4.0: Economic Drivers: Globalization: As markets become global, there's a need to be more competitive and efficient. Firms are pressured to optimize operations and cater to diverse demands from different markets. Cost Efficiency: Automation and digitization can lead to significant cost savings, especially in labor-intensive tasks and sectors with high energy consumption. Customization: The modern consumer demands customization. Industry 4.0 allows for flexible manufacturing systems that cater to individual needs without compromising on efficiency. Technological Drivers: Evolution of the Internet: The proliferation of internet connectivity, both in terms of reach and speed, has allowed devices across the globe to communicate seamlessly. Miniaturization of Hardware: Devices are getting smaller and more powerful, allowing for decentralized decision-making in manufacturing processes. Advances in Software: From AI to complex simulation software, modern applications can process vast amounts of data and make real-time decisions. Socio-Economic Drivers: Urbanization: As cities grow, there's an increasing demand for smarter infrastructure, from utilities to transportation. Changing Labor Market: As more repetitive tasks get automated, the nature of jobs changes, requiring a shift in skillsets. Definition of Industry 4.0: Industry 4.0 is the integration of advanced manufacturing techniques with information technology, data, and analytics. It involves the use of large-scale M2M and IoT deployments, alongside the use of autonomous robotics, simulation, and other advanced technologies, making the factories smarter and more efficient. Goals and Design Principles of Industry 4.0: Goals: Efficiency and Productivity: By digitizing and automating, companies can produce more in less time with fewer resources. Customization: Catering to specific customer needs even in mass production. Improved Decision Making: With real-time data, companies can make informed decisions instantly. Innovation: Fostering a culture of continuous improvement and innovation. Design Principles: Interoperability: Machines, devices, sensors, and people must connect and communicate seamlessly. Information Transparency: Operators should have all the required information available at their fingertips. Technical Assistance: Systems should be able to support humans in making informed decisions and solving emergencies. Decentralized Decisions: If something goes wrong, the system should be able to rectify it, or at least mitigate its effects without human intervention. Technologies of Industry 4.0: 1.Internet of Things (IoT): IoT is at the core of Industry 4.0. Connected devices across the production process collect data that can be used to optimize operations. 2. Big Data Analytics: As data is collected, it's crucial to interpret it correctly. Big data analytics tools can identify patterns, predicting faults before they occur, and ensuring everything runs smoothly. 3. Augmented Reality: These tools can offer real-time data overlays, assisting operators in maintenance or even complex production tasks. 4. Robotics: Robots have been a part of the manufacturing industry for decades, but they're getting smarter. With AI integration, they can make decisions based on real-time data. 5. Cloud Computing and Cybersecurity: As data becomes more crucial, so does its storage and security. Cloud platforms allow companies to store data offsite, reducing costs, and improving resilience. Cybersecurity ensures this data is safe from breaches. 6. Artificial Intelligence: AI can process the vast amounts of data Industry 4.0 systems produce, making real-time decisions to optimize production. 7. 3D Printing: This technology allows for rapid prototyping, ensuring that production can be more flexible and cater to specific demands without the need for lengthy changeovers. 8. Digital Twin: By creating a digital representation of a physical asset, companies can test changes and potential improvements in a virtual environment before implementing them. Big Data Definition: Big Data is a term that describes extremely large datasets that can be analyzed to reveal patterns, trends, and associations, particularly relating to human behavior and interactions. Key Components: Data Generation: Devices such as mobile devices, cameras, and sensors continuously produce vast amounts of data. Data Storage: Systems like Hadoop and cloud storage options have emerged to store these colossal datasets. Data Analysis: Tools and frameworks, such as Spark and Python libraries, help analyze this data. Benefits: Strategic Decision Making: Big data offers insights to drive strategic business decisions. Customer Insights: Helps in understanding consumer behavior. Operational Efficiency: Optimizes operations, reducing time and costs. Challenges: Storage Issues: Storing vast amounts of data can be a challenge, especially on-premises. Complex Analysis: Requires sophisticated tools and expertise. Privacy Concerns: Storing and analyzing data can lead to privacy issues. Artificial Intelligence (AI) Definition: AI involves creating algorithms that allow computers to perform tasks that typically require human intelligence. Key Components: Algorithms: Sets of rules or instructions that solve problems. Neural Networks: Mimic the human brain to process data. Training Data: Large datasets used to train AI models. Benefits: Automation: Increases efficiency. Predictive Analysis: Can predict future trends based on data. Personalization: Offers customized experiences to users. Challenges: Ethical Issues: Such as bias in AI. High Costs: Implementing AI can be expensive. Dependence: Over-reliance can lead to reduced human decision-making. Industrial Internet of Things (IIoT) Definition: A network of interconnected devices used in industrial sectors, integrated with computer systems to gather and analyze data. Key Components: Sensors/Devices: Collect data from the environment or machines. Connectivity: Devices connect to a central system or to each other using technologies like Wi-Fi, Bluetooth, or proprietary protocols. Data Processing: Once data is collected, it's processed either at the edge (on the device) or in a centralized system. Benefits: Real-time Monitoring: Immediate feedback on industrial processes. Predictive Maintenance: Detect issues in machinery before they become major problems. Efficiency: Optimized production and reduced waste. Challenges: Integration: Integrating IIoT devices with legacy systems. Security: Potential for breaches leading to industrial espionage or sabotage. Data Overload: Managing vast amounts of data. Cybersecurity Definition: Cybersecurity encompasses practices, technologies, and processes designed to protect data, networks, and systems from cyber-attacks. Key Components: Firewalls: Shield internal networks from malicious attacks. Encryption: Scrambles data to make it unreadable without a specific cryptographic key. Authentication: Ensures that individuals are who they claim to be. Benefits: Protection: Safeguard against data breaches and unauthorized access. Business Continuity: Ensure that operations continue even under attack. Customer Trust: Secure handling of customer data builds trust. Challenges: Sophisticated Attacks: Cyberattacks are becoming more sophisticated. Costly: Implementing robust cybersecurity can be expensive. Rapid Technological Changes: New technologies can introduce new vulnerabilities. Cloud Definition: Cloud computing is the provision of computing services, including storage, processing, and networking, over the internet. Key Components: Data Centers: Physical or virtual infrastructure used by enterprises to house computer, server, and networking systems. Virtual Machines: An emulation of a computer system. Service Models: IaaS, PaaS, SaaS, etc. Benefits: Flexibility: Scale up or down based on demand. Cost-Effective: No need for on-premises infrastructure. Remote Access: Access from anywhere with internet connectivity. Challenges: Latency Issues: Delays in data processing can occur. Security Concerns: Storing sensitive data off-premises can be a concern. Vendor Lock-in: Difficult to migrate from one service provider to another. Augmented Reality (AR): Definition: AR overlays digital content on the real world, enhancing what we see, hear, and feel. Key Components: Cameras and Sensors: Collect real-world interactions. Projection: Projects digital information onto a surface. Processing: Requires powerful processors to integrate and display AR in real-time. Benefits: Interactive Training: From medicine to mechanics, AR offers hands-on training. Enhanced Shopping: Customers can visualize products before purchasing. Navigation: Real-world path overlays in real-time. Challenges: Hardware Limitations: Requires powerful, often bulky, hardware. Privacy Concerns: Continuous scanning of the environment could invade privacy. Development Complexity: Creating AR applications can be complex.