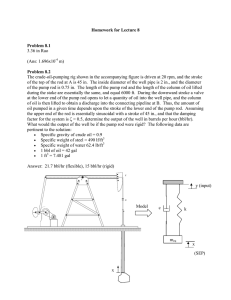

Title Slides 02 Topic Characteristics 04 Problem Statement 05 Research Objectives 06 Literature Review 07 Methodology 08 Timeline 11 Impact 12 References 13 Thesis Presentation Outline Topic Characteristics 01 Conducting a research study for recognize operation conditions of sucker rod pump Using Semisupervised learning 02 Novelty approach for automatic well failure analysis for the sucker rod pumping systems 03 This study based on monthly historical real data for different fields Problem Statement Monitoring the working conditions of the sucker rod pumping system is important to sustain acceptable productivity levels in oil and gas industry. In the case of the analysis of working conditions of hundreds or thousands of wells in the same field, it is humanly unfeasible and ineffective to perform visual classification, in addition to requiring large experience. Also with high frequency and streaming of sensors data (data change every 5 minutes) it will generate big number of unlabeled dyno card shapes per day. Labeling those shapes will consume time and cost in case of anomaly detection the rod pump. Therefore, it is essential to develop algorithm to recognize huge number of unlabeled shapes to identify events of interest, and consequently, improve asset management. Sucker rod pump Competent The main components of sucker-rod pumping wells are the prime mover, the pumping unit, the rod string and the downhole pump. The pumping unit transforms the rotary motion of the prime mover into the reciprocating motion necessary to operate the downhole pump . The rod string connects the downhole pump with the pumping unit. The downhole pump works on the positive displacement principle and consists of a working barrel (cylinder) and plunger (piston). The plunger contains the discharge valve (traveling valve) and the working barrel contains the suction valve (standing valve). The two valves operate on the ball-and-seat principle and work like check valves Sucker rod pump How it work Problem Statement Dynamometer cards Dynamometer cards are one of the main tools for rod-pumping well performance analysis as mentioned by Gibbs and Neely(1966) [1] By plotting the load (force) on the y-axis and position (usually measured in stroke length or percent of the pump cycle) on the x-axis. Normal Condition Gas Interference Ideal downhole dynometer card Fluid Pound Objective #1 Design a robust framework that incorporates both labeled and unlabeled data for rod pump failure analysis Semi-Supervised Learning Implement advanced anomaly detection algorithms that can identify Framework subtle deviations from normal rod pump operation using the labeled Objective #2 and unlabeled data. This will contribute to the early detection of potential failures. Objective #3 Employ semi-supervised classification techniques to categorize different types of failures once they are detected. The classification model should be able to differentiate between various failure modes, such as mechanical, fluid-related, and operational failures Objective #4 Quantitatively assess the performance of the proposed semi-supervised learning approach by comparing it with traditional supervised methods such as CNN, VGG16 and Alexnet . Metrics such as accuracy, precision, recall, and F1-score will be used for evaluation Research Objectives Literature review A study by Ramez Abdalla and Ahmed El-Banbi (2019) [2] used downhole dynamometer cards as input to ANN with Genetic algorithms to identify the sucker rod pumping system conditions . 01 It used historical data 4,467 dynamometer cards as numerical values for oil wells from an offshore oil field in Egyptian western desert and china. It depend on SME which label dynamometer card samples to categorize the pump failure with for normal operating conditions and 12 common rod pump failures. A study by Sayed Ali Sharaf and Patrick Bangert at (2019) [3] proposed approach Beam Pump Dynamometer Card Classification Using Gradient Boosting Machines (GBM) Classifier . 02 Another study by Haibo Chenget at. (2020) [4] used a AlexNet-SVM algorithm Automatic Recognition of Sucker-Rod Pumping System Working Conditions. 03 The study using raw data which is collected from a real oilfield in northern China from sensors of load and displacement to plot dyno card shapes and generate images which transferred to AlexNetbased transfer learning technique to classify 8 common rod pump failures . 04 The study used a dataset of wells from Bahrain fields with 5,380,163 different cards from 297 beam pumps and 35,292 cards are manually labelled by experts into twelve (12)classes. A study by João Nascimento et at (2021) [5] proposed a approach for Diagnostic of Operation Conditions of Sucker-Rod Pumping Wells. The study used 50,000 dynamometer cards from 38 wells in the Mossoró, RN, Brazil. Features are numerical representations derived from the available data and are linked to the model. It use three algorithms (decision tree, random forest and XGBoost), three descriptors (Fourier, wavelet and card load values Literature review 05 A different study by Yi Peng(2019) [6] build a general model that generates the dynamometer card from electrical power parameter using state-of-art deep learning algorithms It collect more than 200,000 labeled images from petro china. It depend on SME which label dynamometer card samples to categorize the pump failure with for normal operating conditions and 12 common rod pump failures. 06 , 07 Another study by Jeremy Liu at. (2015) [8] used SVM and auto-encoder to Classify and Predicted Well Failures Feature sets are typically selected by subjectmatter experts through experience. 08 A novel study by Lu Chen at (2020) [7] using the motor power and XGBoost to diagnose working states of a sucker rod pump In this study, the motor power curves of seven working states are obtained by transforming the dynamometer cards into motor power curves The study used a dataset of wells from Bahrain fields with 5,380,163 different cards from 297 beam pumps and 35,292 cards are manually labelled by experts into twelve (12)classes. A Conference Paper · January 2009 et shows that by using Artificial Neural Network (ANN) system one can establishes pattern classes and sets standards for training and validation in Dynamometer Card in oil well rod pump systems . Literature review 09 In this paper [12] Semisupervised generative adversarial network (GAN) approaches are used to learn from limited labeled data alongside larger unlabeled datasets in Medical Images. 10 Also GAN are used in semisupervised learning on graphs [13] . This paper investigates the potential of generative adversarial nets (GANs) for semi-supervised learning over graphs and present a novel method GraphSGAN. In the domain of Internet of thing (IoT) especially in smart 11 homes Semi-Supervised Learning with GANs are used for Device-Free Fingerprinting Indoor Localization [14]. This paper proposes a method called semi-supervised deep convolutional generative adversarial network (DCGAN) model for device-free fingerprinting indoor localization. The performance of semi-supervised DCGAN is compared with supervised CNN When trained with sufficient labeled data (e.g., 3200 or 6400 labeled real CSI samples), both DCGAN and CNN achieve comparable performance, around 87% accuracy. When trained with reduced amount of labeled data, CNN attains suffered performance while DCGAN retains the performance 12 Another Paper [15] use Triple Generative Adversarial Networks for enhance the performance of classification of well-known image net dataset (MNIST, SVHN, CIFAR10 and Tiny Image net data) in the semi-supervised learning problem. The results show that performance of this method is outperform the performance of 13-layer CNN classifier. Methodology Work Flow for pattern recognition of pumping system Raw Data acquisition (SCADA System) Data Preprocessing Dyno Card image Generation Image Normalization Training set Labeled & unlabeled Testing set Labeled & unlabeled General Adversarial Network Model Pump operation condition Semi-supervised general adversarial networks Study Timeline Lorem Ipsum 2017Lorem Ipsum Literature 2021Lorem Ipsum 2019 Data Review 1- 2 months Comparative analysis 1 month Preparation and analysis 1 week Lorem Ipsum Data collection 1 week 2018 Lorem Ipsum Experimental design & implementation 20203-6 months Lorem Ipsum Results and Conclusion 1 week Expected Contributions 01 The proposed approach will provide a novel method for Rod Pump failure analysis Enhanced Failure Analysis: The proposed 02 approach has the potential to improve the accuracy of rod pump failure detection and classification, thereby reducing downtime and maintenance costs. Reduced Data Labeling Costs and time: By leveraging unlabeled data, the reliance on 03 labeled failure instances can be reduced, which is particularly valuable considering the scarcity and cost of such data and reduce the time consuming for this failure analysis References Beam Pump Dynamometer Card Classification Using Machine Learning 1 3 Identification of Downhole Conditions in Sucker Rod Pumped Wells Using Deep Neural Networks and Genetic Algorithms Ramez Abdalla , Ahmed El-Banbi https://doi.org/10.2118/200494-PA Automatic Recognition of Sucker-Rod Pumping System Working Conditions Using Dynamometer Cards with Transfer Learning and SVM 2 Sayed Ali Sharaf, Tatweer Petroleum; Patrick Bangert, Algorithmica Technologies; Mohamed Fardan, Khalil Alqassab, Mohamed Abubakr, and Mahmood Ahmed, Tatweer Petroleum https://doi.org/10.2118/194949-MS 4 Diagnostic of Operation Conditions and Sensor Faults Using Machine Learning in Sucker-Rod Pumping Wells João Nascimento , André Maitelli , Carla Maitelli and Anderson Cavalcanti Haibo Cheng, Haibin Yu, Peng Zeng , Evgeny Osipov , Shichao Li and Valeriy Vyatkin https://doi.org/10.3390/s20195659 https://doi.org/10.3390/s21134546 References 5 Artificial Intelligence Applied in Sucker Rod Pumping Wells: Intelligent Dynamometer Card Generation, Diagnosis, and Failure Detection Using Deep Neural Networks 6 Using the motor power and XGBoost to diagnose working states of a sucker rod pump Lu Chen , Xianwen Gao , Xiangyu Li https://doi.org/10.1016/j.petrol.2020.108329 Yi Peng, PetroChina Riped https://doi.org/10.2118/196159-MS 7 Autoencoder-Derived Features as Inputs to Classification Algorithms for Predicting Well Failures Jeremy Liu; Ayush Jaiswal; Ke-Thia Yao; Cauligi S. Raghavendra https://doi.org/10.2118/174015-MS 8 Pattern Recognition for Downhole Dynamometer Card in Oil Rod Pump System using Artificial Neural Networks. A. M. Felippe de Souza,Marco A. D. Bezerra, M. de A. Barreto Filho, Leizer Schnitman https://www.researchgate.net/publication/220710225_Patte rn_Recognition_for_Downhole_Dynamometer_Card_in_Oil _Rod_Pump_System_using_Artificial_Neural_Networks References 9 Semi-Supervised Deep Learning for Abnormality Classification in Retinal Images 11 Kevin M. Chen and Ronald Y. Chang Bruno Lecouat, Ken Chang, Chuan-Sheng Foo, Balagopal Unnikrishnan https://arxiv.org/pdf/1812.07832v1.pdf 10 Semi-supervised Learning on Graphs with Generative Adversarial Nets Ming Ding , Jie Tang , Jie Zhang https://doi.org/10.1145/3269206.3271768 Semi-Supervised Learning with GANs for DeviceFree Fingerprinting Indoor Localization https://arxiv.org/pdf/2008.07111v1.pdf 12 Triple Generative Adversarial Networks Chongxuan Li, Kun Xu, Jiashuo Liu, Jun Zhu, Member, IEEE, and Bo Zhang https://arxiv.org/pdf/1912.09784v2.pdf QUESTIONS THANK YOU !