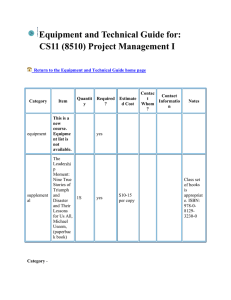

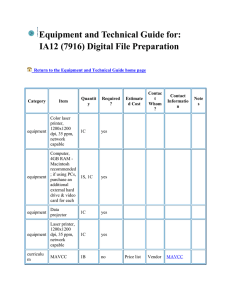

School of Science and Engineering Fall 2022 Meng 4448 – Facilities Planning Line Balancing Class Activity Submitted to: Dr. Ahmed Mohib Submitted by: Omar Attia 900181034, Mark Nabih 900182589, Fady Bassily 900172913, Abdelrahman Ehab 900160897, Abdelrahman Moussa 900172112 (Different Group) 4th December 2022 1 Table of Contents Introduction ............................................................................................... 3 Calculation ................................................................................................. 3 Measurements ............................................................................................ 4 Precedence Diagram .................................................................................. 4 Conclusion ................................................................................................. 6 2 Introduction Line Balancing is the method used to divide and assign different work elements on say a production like to different workstations. This is done based on multiple criteria, most importantly the takt time and the work element cycle time. Work elements must then be grouped and divided in a way that they do not exceed the takt time required to meet the expected demand of the product. In this activity, we worked on assembling the components of an electric plug to reach the final product. Each operation time was recorded and then they were grouped accordingly into different workstations. Calculation The required takt time can be obtained as follows: 𝐺𝑖𝑣𝑒𝑛 𝐷𝑒𝑚𝑎𝑛𝑑 = 30𝑝𝑐 3𝑝𝑐 0.05𝑝𝑐 1𝑝𝑐 = = = 10𝑚𝑖𝑛𝑠 𝑚𝑖𝑛 𝑠𝑒𝑐 20𝑠𝑒𝑐 Therefore, in order to create 30 electric plugs in 10 minutes, 1 plug must be created every 20 seconds. This is the takt time which is derived from the demand and it sets the limit on the time of each workstation where every workstation should no exceed 20 seconds cycle time otherwise the demand will not be met. Figure 1: Electric Plug diagram 3 Measurements Work Element Task Description Time (sec) Predecessor A Insert and connect the Earth terminal 5.5 B Insert and connect the Live Terminal 5.7 A C Insert and connect the Neutral Terminal 5.4 A D Insert Cable grip and fix with 1 bolt 11.5 B, C E Fix cable grip with second bolt 8.1 D F Insert Fuse 5.2 G Install Plastic Back cover 14.8 F H Install Paper cover 1.3 G Precedence Diagram B A 5.7 5.5 C D 11.5 E 8.1 5.4 F G H 5.2 14.8 1.3 4 There were five of us in the group so we can start by dividing the tasks into five workstations, and the maximum cycle time for each workstation is 20 seconds. Therefore, we can divide the tasks accordingly. 𝐸𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 = 57.5 ∗ 100 = 57.5% 5 ∗ 20 The efficiency is low because there is overstaff (we don’t need 5 workstations). So if we only use 4 workstations, the efficiency will improve as follows. 5 𝐸𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 = 57.5 ∗ 100 = 72% 4 ∗ 20 Workstation Time WS1 10.7 WS2 11.1 WS3 19.6 WS4 16.1 Line Balancing 25 20 15 10 5 0 WS1 WS2 WS3 WS4 Conclusion This time the efficiency improved to 72%, while much better than the previous attempt, it is still not high enough, this is because as shown in the chart, WS3 is the most overloaded station as it is very close to the 20 second cycle time limit. Usually, it would be better to take off tasks from WS 3 and add them to other workstations, but in this case it would be difficult to do so and still satisfy the precedence requirements. So, the workstations can function as done for now. 6