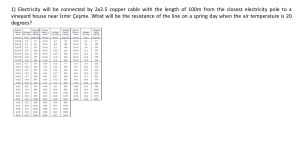

1. A refrigerating plant for an air-conditioning system removes 10,000 Btu/min from the air. The plant circulates 170 lb of refrigerant/min and the internal power delivered by its compressor is 60 horsepower. The refrigerant evaporation temperature is 40F, and its condensation temperature is 100·F. Calculate : From: Freon table Attached :Appendix P1= P2 = 26.51 psia P3 = P4 = 107.9 psia t 2 = 14F A. the capacity of the plant, tons; B. the refrigerating effect, Btuflb; C. the coefficient of performance of the actual plant; and D . the coefficient of performance of the equivalent Carnot cycle. B. m' = C. Wnet heat absorbed(Btu/min) 10,000 = = 50 tons 200 Btu/min-ton 200 heat absorbed(Btu/min) 10, 000 B. RE = = = 58.8 Btu/lb mass of Refrigerant (lb/min) 170 D. COP = J x RE 58.8 COP = = = 3.93 Wnet 14.97 T (40 460) D. COPcarnot = L 8.33 TH -TL (100 460) (40 460) 2. A r e f r i g e r a t i n g plant circulates 23 lb Freon-12 per minute and is assumed to operate on a cycle similar to that of the figure . The pressure in the evaporator coil is 50 psia, the temperature of the Freon-12 entering the compressor is 50" F, the pressure in the condenser is 120 psia and the temperature of the liquid refrigerant entering the expansion valve is 86F. Calculate or determine: A. the evaporation temperature, • F; B. the condensation temperature, F; C. the refrigerating effect, Btu/lb; D. the capacity of the plant, tons; E. the power required to compress the Freon-12, hp; and F. the coefficient of performance. . heat absorbed 200xCapacity 50(200) 183.6 RE RE 54.48 = h3 - h2 = 91.13 - 80.04 = 11.09 Btu/lb h -h RE 54.48 = 2 1 = = 4.91 Wnet h3 - h 2 11.09 m'freon-12 Wnet E. Wnet/ton = x 60 2545 x capacity F. QR m'freon-12 ( h3 - h4 ) = 183.6 (91.13 - 25.56) = 12,040 Btu/min m'freon-12 2 where : G. PD = Capacity 183.6 1.516 PD = 2 1.516 ft 3 /lb = 5.57 ft 3 /min.ton 50 4. An air compression refrigeration system is to have an air pressure of 100 psia in the brine tank and an allowable air temperature increase of 60F. For standard vapor compression cycle temperatures of 77F entering the expansion cylinder and 14 F entering the compression cylinder, calculate: A. the coefficient of performance; B. the mass of air circulated per ton of refrigeration; C. the required piston displacement of the compressor cylinder, neglecting volumetric efficiency. P P=C S=C S= S=C T P=C P 183.6 x 11.09 x 60 0.96 2545 x 50 = E Wnet (Hp)(2545 Btu/Hp-min) 60 x2545 = = 14.97Btu/min J mass of Refrigerant x 60 170(60) C. A. RE = h2 - h1 = 80.04 - 25.56 = 54.48 Btu/lb PRESSUR A. Capacity = t 4 = 77F S2 S3 0.17317 Btu/lb ; h2 = 80.04 and h3 = 91.13 Btu/lb P=C C P= C P=C V h h4 = h1 = 27.72 Btu/lb h2 = 84.24 Btu/lb S2 =S3 =0.17187 h3 =91.31 Btu/lb See Attached Appendix: A. Evaporation temperature = 38.3F B. Condensation temperature = 93.4 F C. RE = h2 – h1 = 84.24 – 27.72 = 56.52 Btu/lb m'(RE) 23(56.52) = = 6.5 tons 200 200 m' h3 - h2 23 56.52 E. Wnet = = = 3.83 Hp 42.42 42.42 h -h RE 84.24 - 27.72 F. COP = = 2 1 = = 7.99 Wnet h3 - h2 91.31 - 84.24 D. Capacity ' = 3. A cooling plant using Freon-12 as the refrigerant is to have a capacity of 50 tons when operating on the refrigerant rating cycle. For this ideal plant cycle determine: D. E. F. G. . T4 = 77 + 460 = 537R T2 = 14 + 460 = 474R T2 - T1 = 60F T1 = 474 - 60 = 414R Since: Processes 3-4 and 1-2 are constant pressure: Use:Attached Figure A. B. C. S the refrigerating effect, Btu/lb; the rate of Freon-12 circulation, lb/min; the net work required per:pound of Freon-12 circulated, Btu/lb; the coefficient of performance; the power required per ton of refrigeration, hp/ton; the heat rejected by the condenser, Btu/min; and the compressor piston displacement, ft3/min·ton of refrigeration. P3 P4 and P2 P1 P4 P1 k 1 k = T T4 = 3 T1 T2 T 537 T3 = T2 4 = 474 = 615°R 414 T1 Cp T2 -T1 60 A. COP = = = 3.33 Cp T3 -T4 - Cp T2 - T1 615-537 - 60 B. RE - Cp T2 -T1 = 0.24(60) = 14.4 Btu/lb 200 Btu/min.ton =13.9 lb/min.ton 14.4 Btu/lb m'RT2 C. Piston Displacement = V2 = P2 m'air = 13.9(53.3)(474) = 24.4 ft 3 /min.ton 144 x 100 5. A simplified line diagram and TS plot for one section of a cooling system for a large aircraft are shown below. When it is used for cooling on the ground, the following Fahrenheit temperatures are experienced at the numbered points on the diagrams: T 1 3 8. A refrigerating plant for an air-conditioning system is to have a capacity of 10 tons and a coefficient of performance of 2.50 when operating With a refrigerating effect of 61.4 Btu/lb of refrigerant. Calculate : A. the refrigerant flow rate, lb/min; B. the work done on the refrigerant by the compressor, Btu/lb C. the compressor internal horsepower, hp; and D. the rate of heat rejection from the system, Btu/min. 2 5 S t (• F) 1 2 3 4 5 342 142 252 145 35 For a situation where the air flow rate through the system is 65 lb/min, specific heat of the air is assumed constant and the compressor and expander processes are assumed isentropic, calculate: (A) the heat transferred to the atmospheric air supply, Btu/min; (B) the power developed by the expander, hp; and (C) the heat transferred from auxiliary power unit compressor bleed, expressed in tons of refrigeration. A. Q1-4 =m'Cp t1 - t 2 t 3 - t 4 = 65(0.24) 342 - 142 252 - 145 = 4789.2 Btu/min m' h4 - h5 65(0.24)(145 - 35) B. Wnet = = = 40.45 hp 42.42 42.42 Q 4789.2 C. REFRIG = 1-4 = = 23.95 tons 200 200 6 . An ideal Freon-12 refrigerating system has a capacity of 50 tons. The condenser pressure is 180 psia, and the Freon12 temperature leaving the condenser is 120° F. The pressure leaving the expansion valve is 44 psia, and the temperature of the Freon-12 leaving the succeeding coil is 40° F. Circulating water enters the condenser at a temperature of 100° F and leaves it at 1 1 5 F. Determine: the mass of Freon-12 circulated, lb/hr; the compressor power for isentropic compression, Btu/hr the heat capacity of the system, Btu/hr the mass of water circulated through the condenser and heating system, lb/hr E. the useful heat furnished per Btu of compressor work (heating performance ratio) A. B. C. D. See Freon-12 table s attached Appendix/Figure: h1 = h4 = 36.16 Btu/lb h2 = 83.03 Btu/lb S2 = S3 0.17142 Btu/lb h3 = 94.31 Btu/lb 12,000 x capacity A. m = h2 -h1 ' 12,000(50) = 12,800lb/hr 83.03-36.16 B. Compressor Power = m'Wnet ' = = m' h3 - h2 = 12,800(94.31-83.03) = 144,400 Btu/hr C. Heating Effect : QR = h3 - h4 = 94.31 - 36.16 = 58.15 Btu/lb Heat Capacity = HC = m'(RE) = 12,800(58.15) = 744,300 Btu/hr HC 744,300 D. mcirculating water = = = 49,620 lb/hr C t out - tin 1(115 100) E. Heating Performance = A. 50 percent; B. 25 percent; and C. 12.5 percent. Answers: (A) 4.71 hp; (B) 1.57 hp; (C) 0.673 hp 4 point 7. Calculate the horsepower required per ton of refrigeration produced by the reversal of a Carnot cycle having a thermal efficiency of HC 744, 300 5.15 Compressor Power 144, 400 Answers: (A) 32.6lb/min; (B) 24.6 Btu/lb; (C) 18.9 hp; (D) 2800 Btu/min 9. A refrigeration system has a capacity of 25 tons and rejects heat at the rate of 6560 Btu/min. Calculate: (A) the rate of heat absorption by the refrigerant, Btu/min; (B) the power required as input to the system, Btu/min; and (C) the coefficient of performance for the system. Answers: (A) 5,000 Btu/min; (B) 1560 Btu/min; (C) 3.2 10. A modified Rankine refrigerating cycle operates with an evaporator pressure of 21.4 psia and a condenser pressure of 141 psia. Refrigerant is Freon-12 circulating through the system at 30 lb/min. Liquid refrigerant at 141 psia and 100" F enters the expansion valve, and surerheated vapor at 21.4 psia and 5" F enters the compressor. Calculate: (A) the refrigerating effect, Btu/lb; (B) the plant capacity in tons of refrigeration; (C) the power required to compress the refrigerant, hp; and (D) the plant coefficient of performance. Answers: (A) 47.86 Btu/lb; (B) 7.18 tons; (C) 10.66 hp; (D) 3.17 11. In an ideal (reversed Joule cycle) air-refrigerating system the temperature of the air entering the compression cylinder is 50F, the temperature entering the after-cooler is 160° F. and the temperature entering the brine tank is 0F. Calculate: (A) the temperature of the air leaving the after-cooler (B) the coefficient of performance; (C) the mass of air which must be circulated per ton of refrigeration, lb/min. Answers: (A) 99F (B) 4.54 (C) 16.7 lb/min CNS 04 MDSP/MESL