Predetermined Time Systems: MTM Analysis & Standards

advertisement

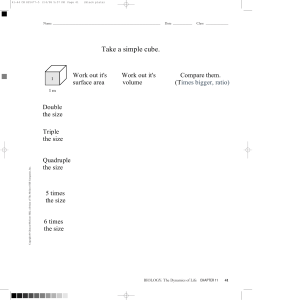

Chapter 13

Predetermined Time

Systems

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Ch.13 – Predetermined Time Systems

Key Points:

• Use predetermined time systems to predict

standard times for new jobs or improve

methods analysis

• They are a database of basic motion times

• Consider interactions with other motions

• Accurate systems require more effort

• Quick, simple systems are less accurate

2

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Predetermined Time Systems

PTS – technique for obtaining a standard

time (vs. time study, work sampling) via:

1) Analyze and subdivide a task into

elemental motions (therbligs)

2) Assign pre-set time values for these

elements

3) Summate times to obtain a standard time

for whole task (no direct timing)

3

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

History of PTS

•

•

•

•

•

Based on Gilbreths’ therbligs

Time added in for each therblig

First – Work Factor in 1930’s

Now over 200 PTS systems

Focus on MTM based ones

4

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

13.1 Methods Time Measurement

(MTM)

• Maynard, Stegemerten, Schwab in 1940s

• Westinghouse jobs, broken down into

elements, rated, timed

• Time Measurement Unit (TMU) = 0.00001

hr = 0.0006 min = 0.036 sec

• Main variations: tradeoff of speed &

accuracy = MTM-1, 2, 3

• Specialized variations for jobs: MTM-C for

clerical, MTM-V for machines, MTM-M for

magnification

Ch.13

5

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Comparison of MTM-1,-2,-3

6

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Accuracy vs. Length of Cycle

7

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Use MTM-2 When:

1)

2)

3)

4)

Cycle time > 1,600 TMUs (~ 1 min)

Cycle is not highly repetitive

No complex finger motions used

Ex: dealing a deck of 52 cards

•

•

•

Time =

Repetitive =

Finger motions =

8

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

9 Elemental Motions

1) GET (G): gain control of object

•

•

•

Reach for an object

Grasp object

(eventually) Release object

2) PUT (P) = move object (when under

control) to new location

•

•

Move object to new location

Position object to proper location

9

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Variations of GET & PUT

• Case = type of grasping or correcting

motion, amount of control needed

• Distance reached

• Weight of object or resistance

• Type of PUT

– Insertion difficulty (one object into another)

– Surface alignment

10

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Cases

for

GET(G)

11

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Cases for PUT (P)

12

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Clearances (in.) for

Insertion vs. Alignment PUT

PA

PB

PC

Insertion

>0.4

<0.4

Tight fit

Alignment

>0.25

<0.25

>0.0625

<0.0625

13

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Distance Code

Range (in)

Code

Classification

0-2

2

1-finger

2-6

6

2-wrist

6-12

12

3-forearm

12-18

18

4-arm

18-32*

32

5-torso

* >32 → step

14

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Weight Factor

• If significant weight moved, additional time

is needed

• GET Weight (GW) = + 1 TMU for each 2

lbs up to 40 lbs

• Values are per hand (20 lb box → 5 TMU)

• PUT Weight (PW) = + 1 TMU for each 10

lbs (above 4 lbs) up to 40 lbs

• Resistance: Ffriction = 0.4 N

15

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Other Elemental Motions - 1

3) Apply Pressure (A) = 14 TMU

•

•

•

Exert muscular force on object

Without moving it (otherwise G or P)

Ex: push button

4) Regrasp (R) = 6 TMU

•

•

•

Change position of object

Without relinquishing control (otherwise G)

Ex: reorient tool

16

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Other 7 Elemental Motions - 2

5) Eye Action (E) = 7 TMU

•

•

•

Recognize an object or

Shift line of sight out of normal area of vision

Don’t over do, G and P have already

6) Crank (C) = 15 TMU/rev

•

•

•

•

Hand/fingers move in circular path > ½ rev

If < ½ rev, use G and/or P

May need GW to overcome stiction

May need PW for sticky crank

17

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Other 7 Elemental Motions - 3

7) Steps (S) = 18 TMU/step

•

•

Leg motion to move body,

Distance > 12”

8) Foot Motion (F) = 9 TMU

•

•

Short foot motion, to press pedal

Distance < 12”

9) Bend & Arise (B) = 61 TMU

•

•

•

Vertical displacement of body

Squat, stoop, kneel on one knee

Kneel on both knees = 2B

18

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

MTM-2 Application

1)

2)

3)

4)

5)

Use MTM Methods Analysis Chart

Summarize motions by hand (L & R)

Add TMUs (no ratings needed)

Add allowances

Consider special cases

19

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Summary of MTM-2 Data

20

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Insertion vs. Alignment PUT

RH

TMU

P

P

21

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Continuous vs. Intermittent Crank

Continuous C

GB 18

18

GW 10

5

3C

45

3PW 10

3

Total

71

Intermittent C

22

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

1) Simultaneous Motion

• Simo difficult motions

require more time

• Add a penalty

Ch.13

23

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Other Special Cases

2) Principle of limiting motion

– For two different motions for each hand

– Use the longer time

3) Principle of combined motion

– For two combined motion in one hand

– Use longer time

4) R is included in C-type motions

24

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Examples

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

25

Sources of Error

• Discreteness – tabular data

– No interpolation

– Hopefully, this averages out

• Synthesis assumes correct process

• Need correct application - practice

26

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Ex #1: U-bolt (Cable

clamp) assembly

27

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

28

Ex #2: Flashlight assembly

29

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Comparison of

MTM and Time Study

30

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.

Ch. 13 Summary

• Use predetermined time systems to predict

standard times for new jobs or improve

methods analysis

• They are a database of basic motion times

• Consider interactions with other motions

• Accurate systems require more effort

• Quick, simple systems are less accurate

31

Ch.13

Copyright {c} 2014 by the McGraw-Hill Companies, Inc. All rights Reserved.