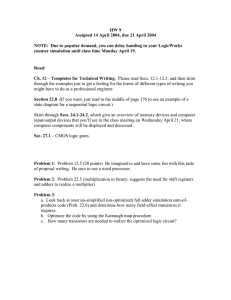

UNIVERSITY OF SUNDERLAND FACULTY OF TECHNOLOGY SCHOOL OF ENGINEERING MODULE CODE: MODULE TITLE: MODULE ASSESSOR: ASSESSMENT: TITLE OF ASSESSMENT: MODERATED: ENX300 Manufacturing Systems Design Dr Ken Robson One of one Assignment 1 – Individual Assignment October 2023 PLEASE READ ALL INSTRUCTIONS AND INFORMATION CAREFULLY. This assignment contributes 30% to your final module mark. Please ensure that you retain a duplicate of your assignment. We are required to send samples of student work to the external examiners for moderation purposes. It will also safeguard in the unlikely event of your work going astray. THE FOLLOWING LEARNING OUTCOMES WILL BE ASSESSED: To be able to critically appraise the various sub-elements of the Lean/JIT methodology and their linkages IMPORTANT INFORMATION You are required to submit your work within the bounds of the University Infringement of Assessment Regulations (see Student academic integrity at https://sunderlandac.sharepoint.com/sites/cs_Academic-Registry/SitePages/AcademicMisconduct.aspx Your work may be subject to checks for originality. Where you are asked to submit an individual piece of work, the work must be entirely your own. The safety of your assessments is your responsibility. You must not permit another student access to your work. Submission Date and Time Submission Location 20th November 2023 23:59pm Via CANVAS Question 1 a) ‘Smoothtools’ manufacturing company want to enter the ‘woodworking tools’ market and one of the first products it has decided to manufacture is a general purpose smoothing plane. (See Figure Q1a - parts view). After ‘reverse engineering’ the wood plane, the planning department have arrived at a build sequence and timings for each task which is shown in Table Q1a (i). Furthermore, the marketing department at ‘Smoothtools’ have produced a sales forecast for the new planes. This is shown in Table Q1a(ii)]. Assuming staff work a 35 hour week for 48 weeks per year you are required to determine the following: i) ii) iii) iv) Design a product layout (Long thin) for the assembly operation (including the fly press) which meets the requirements of the 1st quarter production (15 Marks) Using this layout, how many people are required to manufacture/assemble the product? What is the balance loss and potential output of this arrangement? (6 Marks) st If a ‘short fat’ layout is used in the 1 quarter, how many people would be required to assemble the products? What is the balance loss and potential output of this arrangement? (6 (6 Marks) Which layout is needed to meet the increasing demand in Year 1 and why? (8 Marks) v) What are the advantages and disadvantages of both ‘long thin’ and ‘short fat’ layouts? (15 Marks) Figure Q1a Exploded view of wood plane TASK ELEMENT TIME (Seconds) PRESS OPERATIONS A Build poke sub-assembly 7 secs B Fit poke assembly to frog 6 secs C Rivet adjusting lever to frog 9 secs D Press adjusting nut screw to frog 5 secs TOTAL PRESS OPERATIONS 27 secs BENCH OPERATIONS E Fit adjusting nut to frog 9 secs F Fit frog screw to frog 3 secs G Fit knob to base 9 secs H Fit handle to base 10 secs I Fit frog sub-assembly to base 9 secs J Assemble blade sub-assembly 5 secs K Assemble blade sub-assembly , clamp and label to base and adjust/inspect 12 secs L Make up box and wrap plane, pack and stock 12 secs TOTAL ASSEMBLY AND PACK TIME 69 secs Table Q1a(i) Standard time for each task and build sequence Period Year 1 Units 1st quarter 98000 2nd quarter 140000 3rd quarter 140000 4th quarter 230000 Table Q1a(ii) Sales forecast Year 1 Question 2 a) The Directors of ‘Smoothtools Ltd’ are considering the introduction of Lean Manufacturing to the plant but have number of queries about the concepts involved. As a result they have requested that you write a short report which clearly explains the following: (i) What is the difference between ‘push’, ‘pull’ and ‘Theory of constraints’ approaches to planning and control? Explain using diagrams, highlighting the pros and cons of each. (15 marks) (ii) What is ‘level scheduling’? and what might be the pre-requisites before we can introduce it? (Explain using diagrams where necessary) (10 marks) (iii) Will the ‘Autocratic’ culture of the company fit with the philosophy of ‘Lean’? What is the ‘Lean Philosophy’ in relation to people ? and what ‘working practices’ need to be put in place in order to move to a Lean environment? (10 marks) (iv) Recommend and describe a tool or technique which can be used to analyse and improve the performance of ‘Smoothtools’ manufacturing systems e.g. Rankorder clustering, Ishikawa diagrams, value stream mapping etc. and explain its basic principle, how it would be applied, the potential benefits and inhibitors to implementation (15 marks) (The expected Word count and references for each part should be: 400 words +/- 10%. 2-3 Harvard references) [TOTAL 50 marks] End of Assignment