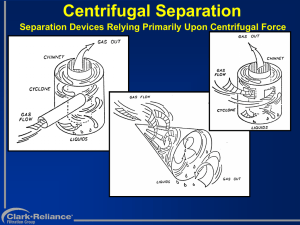

2023-10-26 Alicia Wendt Department of Economic History EKHB90 - The Firm in a Historical Setting Word count: 1603 Alfa Laval and the centrifugal separator Case 2 - Businesses and Changing Societies 1 Introduction Businesses have gone from solely existing with the approval of a government and being strictly controlled by it to being seen as an institution on its own with the ability to impact societies. Research is done continuously on the extent of this impact with the help of statistics for example, how much of a nation's GDP per capita originates in the business sector. This essay aims to survey the impact Alfa Laval has had, as a driver of innovation, on economic growth. “It is taken as axiomatic that innovative activity has been the single, most important component of long-term economic growth[…].” (Rosenberg, 2006). This essay will specifically focus on the centrifugal separator that was invented by the Swedish inventor Carl Gustaf de Laval in 1879. It will also explain the development of the centrifugal separator within different industries such as the food industry, marine industry, pharmaceutical industry, and chemical industry. 1 2 From R&D to Innovation and Economic Growth Investment in Research and Development is the main driver of innovation (Bilbao-Osorio & Rodrígues-Pose, 2004). Innovation, in this case, refers to the systematic practice of inventing or improving a product or service. Innovativeness leads to the invention of new products and services, which in turn leads to an increase in business activity which then leads to job creation and a rise in incomes (Sioufi, 2023). Innovation also leads to a greater output with the same, or less, input. Economic growth refers to the positive development of a nation's wealth over time, based on the goods and services produced. Therefore an increase in innovativeness can explain the increase of a nation's wealth. Gross Domestic Product per capita is widely used to measure and compare nations' wealth and economic growth. GDP per capita describes the value of a nation's output in a particular year divided by the population (Cambridge Dictionary, n.d). Figure 1 Research has shown that there is a positive correlation between the amount of patents and both the level and growth rate of GDP per capita in a nation (Ulku, 2004). The correlation between GDP per capita and the Global Innovation Index is shown in Figure 1 where each of the dots describes a country's GDP per capita and GII score. The line shows the trend beteende the GDP per capita and the GII. As the GII score increases the GDP per capita also increases. This graph can therefore describe the correlation between innovativeness and a nation's wealth. (Stancu & Raluca Bucur, 2017) 3 The history of the centrifugal separator Before the centrifugal separator was introduced to the dairy industry, milk and cream separation was very time-consuming (Magnusson, 1986). In his book, Magnusson (1986) mentions three methods which all took around 10-36 hours per batch, compared to Gustaf de Laval's centrifugal separator that was introduced in 1879 and only took an hour per batch. He also acknowledges that Gustaf de Laval was not the first to experiment with centrifugal force as a way to separate milk from cream. The author continues to write that it was the inspiration from the German 2 Wilhelm Lefeldt that started it all. 11 years later Alfa Laval introduced the first separator made with the so-called Alfa discs, invented by the German inventor Clemens von Bechtolsheim, which improved the separator's capacity (Alfa Laval, n.d). The first separator was made for the dairy industry but as the innovation evolved, the areas in which it could be used also increased. In cooperation with Eric Nylén, Alfa Laval designed a centrifugal separator meant for separating the yeast from the liquid it was cultured in (Magnusson, 1986). An additional variation of the separator mentioned in the book is the oil purification separator that was created as a response to the high price and shortage of lubricating oils during the First World War. These separators later also inspired the development of purification separators used for clarifying alcohol (Magnusson, 1986). Lastly, Magnusson (1986) also mentions the introduction of the first separators for industrial use in 1920 as well as the first self-cleaning separators in 1951. 4 Centrifugal separators today 4.1 The food industry The use of the centrifugal separator has expanded since the 20th century and it is now used in every factory where separation of two liquids of different densities or separation of liquid and solids is required. The main example of a centrifugal separator within the food industry is the dairy industry for which it was created. The separator efficiently separates the milk and cream and reduces the time for separation to only one hour per batch while at the same time ensuring a high-quality product (Magnusson, 1986). According to Tetra Pak (n.d), the improved invention also saved farmers 3-5 dollars per cow when first introduced. Along with this it also enables farmers to extract creams with different fat content by adjusting the settings on the separator (Jana, 2018). The yeast separator has also evolved and is now used in both brewing and distilling. This technique of separation of yeast in the beer industry has led to a more efficient production process without significantly increasing the cost of the facilities (Graham, 2010). The author also argues that it has improved the overall quality as well as the flavor stability of the beer. Furthermore, he mentions that centrifugal separators also have improved the efficiency of alcohol production. Ferrando, Güell, and Lopez (1998) continue on this track in their comparative article on wine making and even states that the centrifugal separation technique is superior to the other clarification techniques mentioned due to its ability to maintain wine quality and reduce negative environmental impacts. Lastly, the oil separator is widely used in today's edible oil industry. Compared to settling methods, the disc stack centrifuge is more suitable for larger production scales (Costagli, 2018). In his concluding thoughts, he describes the disc stack centrifuge as the superior machine as it is “able to ensure quality and efficiency on industrial scale production” (Costagli, 2018) in the 3 virgin olive oil industry. Other areas of use for the centrifugal separator are the juice extraction process and the extraction of plant-based protein (Alfa Laval, n.d). 4.2 The marine industry The marine industry has also been impacted by the centrifugal separator. These separators are used both to clean the bilge water and to purify lube oil and fuel onboard ships. Bilge water is, according to the Cambridge Dictionary, “the dirty water that collects in the bottom inside part of a ship” (Cambridge Dictionary, n.d). The bilge water has to be discharged as a part of the operational practice, but it is not allowed to discharge water containing a certain percentage of oil, and this is where the PureBilge is important (Alfa Laval, n.d). This innovation is described by Alfa Laval as a cleaning system specifically for bilge water on board ships. In addition to this, the centrifugal separator was also used to purify lubricating oils and fuel so that they could be reused (Magnusson, 1986). The author explained that with this innovation ships were able to reduce the cost to one third of the previous expenditure. It is also brought up in the book that this technique was introduced to aircrafts and cars as well. Alfa Laval still provides centrifuges for this purpose and they have also expanded their portfolio to newer forms of fuel (Alfa Laval, n.d). 4.3 Pharmaceutical and chemical industry Other uses for centrifugal separators are within the chemical and pharmaceutical industries. Gas separators are for example used for uranium enrichment. This is achieved by separating the uranium used in power plants from the other molecules in the gas (NRC, 2020). Additionally, Alfa Laval also provides centrifuges for separating impurities from liquids as explained in the previous subheading, but they also provide machines for separating different chemicals, cell harvesting, separation of the different components in the blood, and processing cell cultures (Alfa Laval, n.d). 5 Conclusion This essay aimed to survey the impact Alfa Laval has had on economic growth through the invention of the centrifugal separator. Since its introduction 144 years ago it has been improved upon a substantial amount of times, not only by Alfa Laval but also by other scientists and inventors throughout the world. The success of the first centrifugal separator inspired others to continue to develop it and expand the area of application. In this essay alone three inventors outside of Alfa Laval are mentioned as important in the development of the centrifugal separators before 1951, not including all the people continuing the development after that. Because of this inspiration, the centrifugal separator has been able to improve efficiency, not only in the dairy industry which it was originally invented for but within all the industries that require separation. This led to increased competitiveness in the dairy industry as well as an 4 expansion to new markets, which in turn led to an increase in output both for the companies that produce the separators and the companies that use the separators. Today centrifugal separators are being used in all industries where there is a need for the separation of solids from liquids or the separation of two liquids with different densities. Alfa Laval has improved efficiency within every industry in which the separators are being used. This has then led to an increase in output without companies having to substantially increase input. It is with this innovativeness and the invention of the centrifugal separator that Alfa Laval has been able to increase efficiency, in its own and other production processes, which increased the output in many industries as well as positively impacted economic growth. 5 References: Alfa Laval. (n.d). https://www.alfalaval.com/about-us/our-company/history-of-alfa-laval/ https://www.alfalaval.com/products/process-solutions/protein-solutions/pl ant-based-protein-and-vegetable-processing-systems/ https://www.alfalaval.com/globalassets/documents/products/separation/centrifugal-separators/alf a-laval-purebilge-white-paper.pdf https://www.alfalaval.com/products/separation/biopharma-hss/ https://www.alfalaval.com/products/separation/centrifugal-separators/separators/separators-for-c hemical-and-manufacturing-industries/separators-for-chemical-and-manufacturing-industries/ [All accessed 24 October 2023] Bilbao-Osorio. B., & Rodrígues-Pose. A. (2004). From R&D to Innovation and Economic Growth in the EU. Growth and Change, vol. 35, no. 4, pp. 434-455 Cambridge Dictionary. (n.d). GDP per capita. https://dictionary.cambridge.org/dictionary/english/gdp-per-capita https://dictionary.cambridge.org/dictionary/english/bilge-water [All accessed 23 October 2023] Costalgi. G. (2018) The use of disc stack centrifuge in the virgin olive oil industry. Journal of Agricultural Engineering, vol. 49, no. 2, pp. 75-80 Ferrando. M., Güell. C., & López. F. (1998). Industrial Wine Making: Comparison of Muts Clarification Treatments. Journal of Agricultural and Food Chemistry, vol. 46, no. 4, pp. 1523-1528 Graham. S. G. (2010). High-Gravity Brewing and Distilling – Past Experiences and Future Prospects. Journal of the American Society of Brewing Chemists, vol. 68, no. 1, pp. 1-9 Jana. A. (2018). Technology of Milk and Milk Products, [e-book] INFLIBNET Centre Magnusson. B. (1986). From Gustaf de Laval’s cream skimmer to industrial processing, Alfa-Laval AB United States Nuclear Regulatory Commission. (2020). Uranium Enrichment, https://www.nrc.gov/materials/fuel-cycle-fac/ur-enrichment.html [Accessed 24 October 2023] Rosenberg, N. 2006. Chapter 3: Innovation and economic growth. In OECD, Innovation and economic growth in tourism (pp. 43-52). OECD Publishing Sioufi, N. (2023). Innovation as a driver of growth, https://www.gpca.org.ae/2023/06/24/innovation-as-a-driver-of-growth/ [Accessed 23 October 2023] Stancu. A., & Bucur. C. R. (2017). The Correlation Between Innovative Capabilities and Economic Development. Economic insights - Trends and challenges, vol. 6. No, 4, pp. 5-12 Tetra Pak. (n.d). The cream of the crop: how the separator sparked a dairy revolution, https://www.tetrapak.com/en-cz/insights/cases-articles/separator-dairy-revolution [Accessed 23 October 2023] Ulku. H. 2004. R&D, Innovation and Economic Growth: an Empirical Analysis, working paper, no. 2004-185, International Monetary Fund.