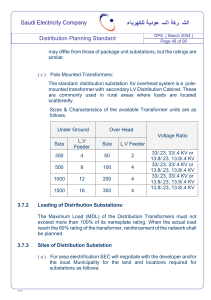

Control Instruments and Accessories for Transformers CONTROL MONITORING PROTECTION C O NTENTS Our Company 1 Engineering, Design, Research and Development Department 2 Quality Department 2 Manufacturing Department 2 Sales Department 3 Integral Quality Management 3 Liquid Level, Pressure Vacuum and Temperature Indicators 4 Deenergized Tap Changers and Accessories 5 Liquid Level Indicators 6 Direct Mount Temperature Indicators 7 Capillary Temperature Indicators 8 Thermal Image 9 Smart Gauge System (SGS) 10 Pressure Relief Device (PRD) 11 Pressure Relief and Arc Detector (INFORMANT) 12 Resistance Temperature Detector (RTD) 13 Sudden Pressure Relay (SPR), Accumulated Gas Indicator 14 Block Connections, Flow Indicator 15 New Generation of On-Line Transformer Monitors 16 Series 1500 and 1700: Specification Table 17 Monitoring Systems Structure 18 Series 1500 and 1700: Flow Chart 19 Special Applications 19 Geomagnetic Induced Current Sensor (GICS) 20 GENERAL OFFIC ES / MANUFAC T URING Prol. J. M. Morelos 702 Ocotepec, C.P. 62220 Cuernavaca, Morelos México Tel: +52 777 416 65 82 Tel: +52 777 416 65 29 E-mail: ventas@orto.mx www.orto.mx D IREC TO RY General Manager Javier Hernandez javier.hernandez@orto.mx President Alan Boege alan.boege@ orto.mx Engineering and Quality Manager Adrián Rivera adrian.rivera@orto.mx R&D Manager Juan José Lopez juanjose.lopez@orto.mx Marketing Manager Héctor Garza hector.garza@ orto.mx Manufacturing Manager Adrián Juarez adrian.juarez@orto.mx GENERAL OFFIC ES / MANUFAC T URING Prol. J. M. Morelos 702 Ocotepec, C.P. 62220 Cuernavaca, Morelos México Tel: +52 777 416 65 82 Tel: +52 777 416 65 29 E-mail: ventas@orto.mx www.orto.mx O UR C O MPANY O RTO , manufacturer of monitoring systems, control instruments and accessories for transformers, began its operation in Mexico City in 1971. Now, its Research and Development facilities, Manufacturing, Quality, Engineering and Sales offices are located in Cuernavaca, state of Morelos, a city 60 km south of Mexico - City. For more than one generation, O RTO has gained a reputation as a reliable supplier. ORTO’s integral quality system is based upon a clear and well defined policy, philosophy and mission. All the people in ORTO are responsible for the quality of the products, and this quality means the long lasting satisfaction of its customers. ORTO’s mission is to protect transformers by detecting failures, or even anticipating them, constantly monitoring liquid temperature, liquid level and pressure or vacuum that exists in an electrical distribution or power transformer. To do this, O RTO has conventional instruments, monitoring devices for diverse variables, such as temperature, current, oil level and pressure-vacuum, and its accessories such as pressure relief valves, oil drain valves, tap changers, sight glasses, feedthrough connections for current transformers, and other special equipment manufactured according to customer’s requests. 1 E NGINEERING, DESIGN, RESEARC H & DEVELO PMENT DEPARTMENT O RTO ’s Engineering Department has a permanent goal to improve processes and products, and to design and develop customer’s requirements for new or special instruments and accessories. It keeps the technical information for manufacturing up to date. Engineering is also responsible for evaluating standards and specifications from our customers, Official Mexican Standards, and international standards which apply to our instruments and accessories, to verify that our products comply with any requirement from the standards.The Engineering group. Engineering Department is in charge of making specifications, drawings, and manufacturing plans with which our instruments are manufactured.The area of research and development carries out the design of new products including development activities in the fields of electronics and software. Q UALITY DEPARTMENT The Quality Assurance Control team is responsible for planning and executing techniques and activities so that R & D Team. ORTO’s manufacturing systems, as well as their suppliers’, meet the quality standards specified in its Quality System.W hen the manufacturing process is finished, Quality Control makes a Quality Certificate of the product.This certificate guarantees the customer that the instrument or accessory has been manufactured according to the applicable standards, as ISO 9001:2008 and its Mexican equivalent NMX -CC-9001-IMNC-2008. MANUFAC TURING DEPARTMENT Manufacturing department. The manufacturing processes in ORTO are desinged so that quality is controlled from the receiving of raw material to the packaging and shipment of the final product. All these processes are strictly regulated from the manufacturing of pieces and components to the final assembly of the product, by the manufacturing plans.These plans are based on modern systems of continuous improvement, ISO 9001:2008, and the experience of more than one generation in manufacturing. APG Process. 2 S ALES DEPARTMENT The Technical Sales Department seeks to satisfy all of ORTO’s customers’ requests and needs through a constant and close communication with the Engineering and Manufacturing Departments.We have a large customer base, and our customers are located in México, U.S.A., Canada, France, Belgium, Colombia, Ecuador, Paraguay, Chile, Peru,Argentina, Dominican Republic, Guatemala, Nicaragua, Phillipines, Singapore, Indonesia and Korea. For any technical question, do not hesitate to contact us! C ANADA EUROPE U.S.A. C ENT RAL AMERIC A ASIA SOUT H AMERIC A Sales department. INTEGRAL Q UALITY MANAGEMENT Orto de México relies on an This supports and strengthens our Integral Quality Management which strategic business approach, our integrates four dimensions: results and the care for our customers. REC O GNITIO NS National Technology Recognition C ERTIFIC ATES Quality Management System ISO 9001:2008 Environmental Management System ISO 14001:2015 C ertificate of C lean Industry Ethic and Values in the Industry Innovation and C ompetitivity Recognition State of Nuevo León Safe Industry C ertificate All Inclusive C ertificate for Exportation Personnel C ertificate “ Yacatecuhtli” Social Responsibility C ertificate Innovation and C ompetitivity Recognition State of Morelos 3 L IQ UID LEVEL INDIC ATO RS for distribution transformers The liquid level indicators for distribution transformers are designed to measure the liquid level inside the tank.The gauge is weatherproof, and it can be used in extreme climates which may vary from -50 to 80 °C. It does not require maintenance. Liquid Level Indicators. PRESSURE VAC UUM INDIC ATO R for distribution transformers This instrument is used to measure pressure or vacuum for sealed tank distribution and power transformers. If required, it can be provided with vacuum or pressure micro switches for control. The materials of this instrument allow indoor or outdoor use, and it does not require any maintenance. All internal components are made with corrosion resistance materials. These instruments have a scale ranging from -100 to +100 kPa (-12 to 12 psi).The accuracy is 3% full scale. T EMPERATURE INDIC ATO RS Pressure Vacuum Indicators. for distribution transformers The temperature indicators for distribution transformers are designed to measure the liquid temperature of the transformer. These indicators are available with different dial ranges: Liquid Temperature (0 to 120 ºC) Liquid Temperature (0 to 160 ºC) Dial texts can be in English, Spanish or Bilingual. Under request, other languages can be provided. 4 Temperature Indicators. D EENERGIZ ED TAP C HANGERS for distribution transformers The externally operated single phase or three phase tap changers are designed for distribution transformers from 15 kV to 34.5 kV, and with current rates of 100 A, 120 A or 150 A, maximum continuous current. Its terminal studs are made of copper tinned.The copper wire from the coils can be crimped, soldered or screwed on to the studs.The components of the tap changers are compatible with transformer oil, and have proper contact resistance.The body, shaft, Distribution. nut, nameplate and dust-knob cap are made of a thermoplastic material with high strength, weathers-resistant, UV grade and reinforced with fiberglass.The tap changers are available in several deck-configurations for maximum versatility. D EENERGIZ ED TAP C HANGERS for small and medium power transformers The externally operated three phase tap changer for small and medium power transformers are designed to change the taps of the high voltage coil of the transformer. It can be used in 15, 25 and 34.5 kV voltage class and maximum continuous current of 150 amperes. Small and Medium Power. The support and shaft are made of a fiberglass reinforced material. The bases are made with polyester reinforced with fiberglass and copper or brass tined terminals. D EENERGIZ ED TAP C HANGERS for power transformers Other models for deenergized tap changers with 115 kV voltage class, 650 kV BIL and 250 A are available for power transformers. Power. A C C ESSO RIES for distribution transformers Different accessories, such as pressure relief valves, draining valves and sight glasses are available. Grounding connectors for distribution and power transformers are also available. Accessories. 5 L IQ UID LEVEL INDIC ATO RS for medium and high power transformers The liquid level indicators with micro switches for control are designed to measure the liquid level inside the transformer tank.The indicators include the necessary control and alarm circuits for a safe and efficient transformer operation.The instrument is weatherproof, and it can be used in extreme climates, which may vary from artic to tropical. It requires no maintenance. Under request, special Flying Leads. paint for marine and corrosive environments can be provided. MICRO SWITCHES: From factory, the indicator has a micro switch adjusted to operate at minimum (MIN) level. Under customer request, two more micro switches can be added to operate at maximum (MAX ) or minimum (MIN) liquid levels. Activation Axial Type of the micro switches occurs when the liquid reaches its highest or lowest specified level. LIQUID LEVEL TYPES: The liquid level indicators can be manufactured with a radial or axial float, depending on the customer requirements.Two options for the center bolt are available (3.125” or 4”). Radial Type SC ADA O UTPUT: For the SCADA models, electronic circuits are added to convert the liquid level value into a 4-20 mA output analog signal. LANGUAGE: Dial texts can be in English, Spanish or Bilingual. Under request, other languages can be provided. Scada Output. 6 D IREC T MO UNT TEMPERATURE INDIC ATO RS for medium power and power transformers The bimetal temperature indicators are designed to measure the liquid or winding temperature of the transformer.They include the control, alarm and trip micro switches necessary for secure and efficient transformer operation. Under request, LiquidTemperature. special paint for marine and corrosive environments can be provided. SC ALE: The bimetal temperature indicators are available with different dial ranges: 0-120 °C 0-160 °C to measure liquid or winding temperature 0-180 °C Scale in °F can be provided under request. MICRO SWITCHES: WindingTemperature. The micro switches activate when the set alarm temperatures are reached.The instrument can be specified with 1, 2, 3 or 4 micro switches. SC ADA O UTPUT: For the SCADA models, electronic circuits are added to convert the temperature value into a commutable 4-20 / 0-1 Scada Output. mA analog output, or RTD output.These instruments are manufactured to operate in any environment and guarantees accuracy and repeatability within +/- 2% full scale. LANGUAGE: Dial texts can be in English, Spanish or Bilingual. Under request, other languages can be provided. 7 C APILLARY TEMPERATURE INDIC ATO RS for medium and high power transformers The remote temperature indicators with capillary tube are designed to measure the liquid or winding temperature of the transformer.They include the control, alarm and trip micro switches necessary for secure and efficient transformer operation. Under request, special paint for marine and corrosive environments can be provided. WindingTemperature. SC ALE: The capillary temperature indicators are available with different dial ranges: 0-120 °C 0-160 °C to measure liquid or winding temperature Scada Output. 0-180 °C Scale in °F can be provided under request. MICRO SWITCHES: The micro switches activate when the set alarm temperatures are reached.The instrument can be specified with 1, 2, 3, 4 or 5 micro switches. C APILLARY LENGTH: The length of the stainless-steel armored capillary tube can be 3,658 mm (144”) or 8,000 mm (314”). SC ADA O UTPUT: For the SCADA models, electronic circuits are added to convert the temperature value into a commutable 4-20 mA or 0-1 mA analog output.These instruments are manufactured to operate in any environment and guarantees accuracy and repeatability within +/- 2% full scale. LANGUAGE: Dial texts can be in English, Spanish or Bilingual. Under request, other languages can be provided. 8 LiquidTemperature. T HERMAL IMAGE for industrial, medium and high power transformers C O NNEC TIO N DIAGRAM C alibration Resistanc e 25 Watts (1,2,3,5 Ω) The thermal Image is normally used in combination with the winding temperature indicator in the majorities of liquid-filled Power transformers. It simulates the winding temperature using a heating resistance connected to Heater Resistanc e A One thermowell with feedthough cables. the secondary of the transformer CT, as B shown in the connection diagram. C urrent input 0-5 Amp between A and B The temperature gradient over liquid temperature, obtained in the thermal image, is proportional to the applied TC secondary One thermowell standard. current, according to the following figure: Temperature Gradient over Top O il 70° C 60° C 50° C O il Temp. 25° C 40° C Two thermowells. 30° C 20° C 10° C O il Temp. 100° C 0° C 0 1 2 3 4 5 6 Current in heater element 7 Amp Three thermowells. THERMOWELL O PTIO NS: One thermowell for winding temperature ( with or without feedthrough cables). Two or three thermowells with any combination of liquid and winding temperature. C ALIBRATIO N O PTIO NS: Calibration resistance mounted inside the thermal image or mounted in the control cabinet of the transformer (1Ω suggested resistance). Balancing transformer for current calibration. Balancing transformer. Calibration resistance. 9 S MART GAUGE SYSTEM (SGS) The Smart Gauge System provides a cost-effective method for the temperature monitoring of liquid-filled transformers. For this case, typically, two gauges are needed: one to measure liquid temperature and other one to measure winding temperature.The Smart Gauge System is a two-in-one instrument that displays both temperatures in the same dial. Instead of a digital display, it uses the traditional gauge type display which customers are used to, and facilitates readings under sunlight conditions.The sensor is mounted directly in a thermowell and there is no need to use the thermal image. Liquid temperature is measured through an RTD. Instead of the standard thermal image used to simulate the winding temperature, it includes an external split core CT to measure the load current, and calculate the winding temperature.The mathematical model also calculates the loss of life of the transformer. Maximum temperatures are stored in a nonvolatile memory and displayed in the gauge dial when needed. It includes 5 Relays of 6A / 250 VAC , to activate the cooling stages and provide alarm and trip functions.These relays can be configured in fail safe mode to activate the cooling system of the transformer in case of power loss or damage of the device.Two communication protocols are available in this instrument: DNP3.0 and Modbus. Devices installed in different transformers in the same substation can interconnect in a daisy chain configuration, thus permitting simultaneous monitoring of several transformers. Frontal View MAIN FEATURES SGS APPLIC ATIO N O n-line tempera ture 10 USE O utdoor MEASURED/C ALC ULATED VARIABLES RELAY O UTPUTS DISPLAY C O MMUNIC ATIO N 1 RTD liquid tempera ture sensor 5 Solid Sta te Rela ys Ga uge type Seria l Fiber O ptic, RS-485 monitor for power 1 Split core C T loa d current sensor (6A/250 VAC ) displa y for liquid a nd USB ports tra nsformers 2 ca lcula ted va ria bles: Winding tempera ture a nd winding DNP3.0 a nd Modbus Protocol & Loss of life tempera ture PRESSURE RELIEF DEVIC E (PRD) for industrial, medium and high power transformers The pressure relief device is used to release the pressure generated inside a transformer in the event of an internal short circuit. Pressure release is complemented with the operation of an electrical contact that sends the trip signal to the breaker, thus preventing the occurrence of major damage (explosion of the tank and fire).The materials used in the PRD guarantee a high resistance to the UV rays and corrosive environments. O RDERING O PTIO NS: From 4 up to 20 psi operating pressure (± 1 psi), according to customer specifications. Standard PRD. From 1 to 4 simultaneously operating switches SPDT, 15 A , 125/250 VAC . Special switches for 10 A, 125 VDC. Sealed box and female connector with 8 pins (standard), 9 pins ANSI style or terminal box NEMA 4/6, IP 56/68, with gland connector PG-16. W ith or without flag for long distance view of device operation. Sealed female plug with cable SOOW, female plug with ½”-14 NPS thread (for conduit tube) or flying leads. Small PRD. Viton gasket and O ring (-29 to 204 °C) or low temperature Neoprene gasket and O ring (-54 to 149 °C). Painted stainless steel springs. Zinc plated and painted cover (standard), hot dipped galvanized and painted cover or stainless steel painted cover. W ith or without mounting gasket. MO DELS: Three different models of PRD’s are available: STANDARD SMALL MO UNTING DIAMETER 235 mm (9.25”) 125 mm (4.921”) TOTAL DIAMETER 265 mm (10.433”) 164 mm (6.456”) DIREC TED FLO W 235 mm (9.25”) 324 mm (12.76”) Directed Flow PRD. 11 PRESSURE RELIEF AND ARC DETEC TO R (INFO RMANT) DEVICE CHARACTERISTICS The main function of the pressure relief and arc detector (INFORMANT) is to trigger a flag when arcing is occuring inside the tranformer tank.The flag announces that a transformer fault has occurred and that should not be reenergized, since there is a risk of explosion and fire.The device is sensitive enough to detect pressure increase due to internal low energy arcing (partial discharges) or high energy arcs due to short circuits between phases or between phase and ground. This INFORMANT will never activate the flag during transformer testing or during transport or installation. It includes a pressure valve to release the internal pressure of the tank manually or automatically. TESTING The INFORMANT works with a bellow mechanism resistant to vibration and tempertures ranging from -20 to 120 °C. Each device is individually tested with five consecutive tests at three different pressure rates (1.5, 5.0 and 14.0 psi/sec). The INFORMANT can be used in pole mounted and pad mounted distribution transformers. INSTALATIO N The INFORMANT is installed outside the transformer, so there is no need to modify its internal design. Cost increase due to replacement of bushings or modification of the tank dimensions will not be needed. It is installed in the airspace above the maximum operating oil level.To mount the INFORMANT simply screw it to the tank. The installation of the device in existing transformers can be done in the field, using the same tank hole of the standard pressure valve.This allows an easy retrofit for transformers in service. MAINTENANCE The INFORMANT is maintenance-free and does not require any field calibration or configuration. 12 RESISTANC E TEMPERATURE DETEC TO R (RTD) for industrial, medium and high power transformers Ambient temperature. The resistance temperature detector (RTD) is used to measure the liquid or winding temperature of a transformer or to measure ambient temperature, depending on the device mounting.The device includes a passive element which converts the temperature value to a resistance value proportional to temperature.The RTD´s have a high exactitude and repeatability and are manufactured Winding temperature thermowell. weatherproof for use in extreme climates, which can vary from artic to tropic. RTD 4-20 / 0-1 mA output. APPLIC ATIO NS: •Liquid temperature when mounted in a thermowell. •W inding temperature when mounted in a thermal image. •Ambient temperature when mounted with an ambient RTD resistance output. protector. O UTPUT O PTIO NS: Liquid temperature thermowell. •Platinum 100 Ω (Pt100) resistance output •Copper 10 Ω (Cu10) resistance output •Analog output 4-20 mA or 0-1 mA C URRENT TRANSFO RMER The current transformer provides a 4-20 mA output, which is proportional to the RMS value of the incoming alternating current.The controlled output current is not affected by variations in the supply voltage or by the burden (within Current transformer. specified limits). Standard scales are 5, 10, 30 and 50 A with an accuracy is ± 0.5 % on the whole scale. PRESSURE SENSO R The pressure sensor provides a 4-20 mA output, which is proportional to the pressure inside the transformer tank. Standard scale is 0 to 15 psi. Other scales are available under request. Pressure sensor. 13 S UDDEN PRESSURE RELAY (SPR) for medium and high power transformers UR rec ognized by UL The sudden pressure relay is an instrument designed for Seal-in relay. responding to a sudden increase of pressure, usually generated by an internal fault of the transformer. It reacts quickly and has a micro switch that can be connected to the breaker trip, to reduce damage in the transformer tank. MECHANIC AL SPR The mechanical rapid pressure relay is used in combination with a seal-in relay to maintain the alarm and trip circuits active, when the momentary contact of the SPR operates.This condition remains until the reset button of the seal-in relay is pressed to return the device to its initial condition.A red LED located in the upper right part of the device lights on, while the seal-in relay is in the alarm or trip condition. Mechanical SPR. ELECTRO NIC SPR This device also responds to slow pressure rise and includes a SC ADA switchable output (0-1 mA or 4-20 mA) for the remote monitoring of the transformer tank pressure. It also includes an additional relay that is activated by a certain pressure level adjustable by the user. It is composed of two main parts: a pressure sensor and a control panel. Electronic SPR. A C C UMULATED GAS INDIC ATO R for medium and high power transformers The accumulated gas indicator with micro switch and SC ADA output is designed to measure the volume of gas that has been exchanged between the instrument casing and the inside of the transformer.The presence of gas indicates the possibility of a failure. The gas volume scale is from 0 to 450 cm3 and the micro switch is adjusted to produce an alarm at a value of 200 cm3. 14 Accumulated Gas Indicator. BLO C K C O NNEC TIO NS for medium and high power transformers The block connection is a transformer accessory used to connect the internal electrical devices of the transformer with the external control system. It is weather proof and requires no maintenance. The block connection is manufactured with an epoxy resin for temperature range from -20°C to 100°C .W ith an APG process, the temperature range increases (-55°C to +155° C ). The block connection has a numeric identification for every stud or terminal on each side of the product. This accessory is manufactured in different models Block Connections. depending on the number of studs, to satisfy our customer requirements. F LO W INDIC ATO R for medium and high power transformers This instrument is designed to indicate if the liquid is flowing in the pump tubing. One micro switch for control is included in all models. The instrument vane can be adjusted according to the flow direction. The vane size can be designed for different tube diameters from 1.5” to 8”. Flow Indicator. 15 N EW GENERATIO N O F O N- LINE TRANSFO RMER MO NITO RS SERIES 1500 AND 1700 The series 1500 and 1700 Electronic Monitors are feasibly-priced devices, designed for monitoring distribution, power, dry-type and wind farm transformers.The monitors optionally include 6 A, 250 V relays that are programmable by the user and may be configured for automatic fan control, alarm activation, or to automatically trip the transformer off line. Contact status (open or closed) is indicated by LEDs located in the front panel. All models include one USB and one RS-485 port for remote communication with a master station, using DNP 3.0 or Modbus protocols.The rail mount modular design allows a serial port daisy-chain arrangement to interconnect several modules, thus increasing the number of input and output signals of the system to satisfy end-user requirements. S IGNAL C O NVERTER for power and distribution transformers SERIES 1501 The series 1501 signal converter is a feasibly-priced device, designed for monitoring liquid-filled transformers. It is capable of processing up to 12 analog inputs of 4-20 or 0-1 mA. The device’s function is as a signal converter that measures and digitizes analog Series 1501 values, and forwards them to a remote terminal. For this reason, it is not equipped with display and control relays. It includes 2 communication ports (USB and RS-485) which transmit data to a master station (not included), through Modbus or DNP 3.0 protocols. SML 1701 The din-rail mount design facilitates the interconnection of multiple converters in a daisy chain configuration, thus permitting simultaneous monitoring of several transformers. O N- LINE DRY-TYPE TRANSFO RMER MO NITO R SERIES 1701 The series 1701 Monitor is a feasibly-priced device, designed for temperature Series 1701 panel mount. monitoring and control in dry type transformers. It includes 3 RTD (Pt100 type) inputs for monitoring the temperature of the three coils and an additional RTD to monitor the ambient temperature.The 4-digit display is easy to read even in high luminosity conditions.The monitor is equipped with 6 relay outputs configurable by the user, providing for cooling control and for alarm and trip functions.This model includes 2 communication ports (USB and RS-485 which transmit data to a master station (not included), through Modbus or DNP 3.0 protocols.The din-rail mount design of the equipment makes possible the interconnection of multiple monitors in a daisy chain, thus permitting the monitoring of several transformers concurrently. 16 Series 1701 din-rail mount. S PEC IFIC ATIO N MO DEL 1 501 TABLE SERIES 1 500 AND 1 700 APPLIC ATIO N USE O n-line monitoring Indoor for distribution a nd a nd power tra nsformers O utdoor INPUTS 12 sensor inputs RELAY O UTPUTS Not a va ila ble DISPLAY Not a va ila ble C O MMUNIC ATIO NS Seria l RS-485 a nd USB ports per module (4-20 mA DNP3.0 a nd or 0-1 mA), Modbus Protocol expa nda ble in multiples of 12 See selec tion guide (*) 1 701 1 702 Tempera ture 4 RTD (type pt100) 6 progra mma ble C oil tempera ture in mea surement a nd inputs for rela ys (6 A, 250 V), pha se A, pha se B, control for dry-type tempera ture for cooling control, pha se C a nd DNP3.0 a nd tra nsformers mea surement of a la rm a nd trip a mbient tempera ture Modbus Protocol coils a nd a mbient functions Seria l RS-485 a nd USB ports Indoor Efficiency ca lcula tion Seria l RS-485 a nd USB ports Indoor 3 volta ge inputs 1 progra mma ble Efficiency a nd core for distribution a nd a nd (240V), 3 current rela y (6 A, 250 V), tempera ture power tra nsformers O utdoor inputs (5A) a nd 1 for high core DNP3.0 a nd RTD (type pt100) tempera ture a la rm Modbus Protocol input for core tempera ture mea surement 1 703 O n-line monitoring 1 RTD (type pt100) 6 progra mma ble O il tempera ture, for wind fa rm input for oil rela y (6 A, 250 V), Liquid level a nd ta nk tra nsformers tempera ture, for a la rm a nd trip pressure 1 liquid level sensor functions Indoor Seria l RS-485 a nd USB ports DNP3.0 a nd Modbus Protocol input a nd 1 pressure sensor input 1 704 O n-line monitoring Indoor for distribution a nd a nd power tra nsformers O utdoor 4 sensor inputs per module (4-20 mA See selec tion guide (*) Depending on Seria l RS-485 a nd USB ports selected sensors or 0-1 mA), DNP3.0 a nd expa nda ble in Modbus Protocol multiples of 4 See selec tion guide (*) (*) Sensor and relay selec tion guide: Top Oil Temperature Bottom Oil Temperature Vibrations Bushing Leakage Current LTC Position LTC Oil Temperature Liquid Level Tank Pressure Dissolved Gas Moisture in Oil Fan or Pump Current Stage 1 Fan or Pump Current Stage 2 Fan or Pump Current Stage 3 Load Current Phase A Load Current Phase B Load Current Phase C WindingTemperature Phase A WindingTemperature Phase B WindingTemperature Phase C 17 MO NITO RING SYSTEMS STRUC TURE TRANSFO RMER DIAGNO STICS The structure of the Monitoring Systems focusses on four main areas: Hardware, Software, Communications and Q ualified Staff, which depend from each other and overlap themselves. TRANSFO RMER HARDWARE HARDWARE C OMMUNICATIONS SO FTWARE Protoc ols: Modbus TC P/IP DNP 3.0 Therma l a na lysis Bushing a na lysis Liquid level LTC a na lysis O thers Sensors: Winding temp. Liquid temp. Line current Liquid level O thers Fiber optic s Radio DIAGNO STIC S SO FTWARE MO DEL REQ UIRED SENSO RS THERMAL ANALYSIS (based on IEEE and IEC spec s.) Ports: RS-232 RS-485 Ethernet Shielded c able Q UALIFIED STAFF GSM Satellite PREVENTIO N, PROTEC TIO N AND C O NTRO L FUNC TIO NS Ambient tempera ture C ooling control Unba la nced current a la rm O il tempera ture C ooling fa ilure a la rm Loss of life Winding tempera ture High oil or winding tempera ture a la rm Hottest spot tempera ture Line current O verloa d a la rm C ooling system current LTC ANALYSIS LIQ UID LEVEL Ma in ta nk oil tempera ture Tempera ture differentia l a la rm LTC tempera ture C onta ct wea r Ma in ta nk Low level a la rm LTC ta nk OTHERS O THERS STATISTIC S AND FAILURE MEC HANISMS FAILURE MEC HANISMS REQ UIRED SENSO RS Insula tion a ging of the tra nsformer Winding tempera ture, liquid tempera ture, line current, a mbient tempera ture Insula tion a ging of the bushings Lea ka ge current in ca pa citive ta p Loss of dielectric strength due to insufficient insula ting liquid Liquid level LTC conta ct wea r Tempera ture differentia l between ma in ta nk a nd LTC ta nk O thers 18 O THERS O N- LINE MO NITO RING Moisture O il SYSTEM1 500 AND 1 700: FLO W C HART Dissolved Gas Sudden Pressure Relay Liquid Level Geomagnetic Induc ed C urrent Load C urrent Bushing Leakage C urrent Fan/Pump C urrent Top O il Temp. LTC Temp. Partial Disc harges Bottom O il Temp. Vibrations SENSOR... n SERIES 1 500/1 700 C O NTRO L RO O M 4- 20 mA 0- 1 mA 4- 20 mA 0- 1 mA All Series 1500 and 1700 monitors can be connected together in a Daisy Chain connection through their RS-485 serial ports. Serial Port RS- 232 Serial Port RS- 4 85 DNP 3.0 Protoc ol Modbus Modular system expandible according to the user’s ORTO can also provide a Linux based workstation Series 1600, to store requirements. During the service time, it can be and analyze the data provided by the monitors. It includes aWeb Server equipped with up to 8 options, starting with just one. and a database to generate reports and graphs. S PEC IAL APPLIC ATIO NS The real time monitoring systems manufactured by O RTO are flexible and can handle any type of sensor with an output of 4-20 mA or 0-10 Volts.That makes it possible to monitor transformers as well as other power equipments. O RTO has developed real time monitoring systems for a variety of applications, such as: Real T ime Monitoring for Generators These systems use sensors that measure the temperature at different parts of Real Time Monitoring for Generators the stator to detect excessive heating problems. Real T ime Monitoring for Electrical C ircuits These systems use sensors to measure voltage, current, power, energy, billing, power factor and harmonic distortion for voltage and current.W ith the combination of these sensors it is possible to detect problems such as voltages out of the specified tolerance range, power peaks, harmonic distortion, consoles that are out of service, as well as the verification of values such as peak demand, consumed energy and billing. Real Time Monitoring for Electrical Circuits 19 G EO MAGNETIC INDUC ED C URRENT SENSO R SO LAR EXPLO SIO NS Solar explosions radiate electromagnetic interference that comes to the Earth. ELEC TRO MAGNETIC RADIATIO N INDUC ES AN ELEC TRIC C URRENT GIC GIC Transformer GIC Transformer GIC GIC GIC The electromagnetic radiation from the Sun, induces an electric current (quasi DC) in the transmission line, which passes through the coils of the transformer. MAGNETIC FLUX IN A TRANSFO RMER C ore Mutual Flux I1 C O RE SATURATIO N- HARMO NIC S The Geomagnetic Induced Current Sensor measures the value of the quasi DC current circulating in the transformer windings.The copper rod is connected between the neutral bushing of the transformer and the ground connection. TRANSFO RMER FAILURE I2 V 2 Load V1 Leakage Flux The geomagnetic current flowing through Core saturation produces harmonics the coils of the transformer, saturates the due to the increased demand of The temperature increases in core increasing the leakage flux which excitation current.The value of reactive metals, oil and windings, and may heats the metal parts (coils, metal fittings, power increases as well, and may lead to cause accelerated aging of the tank, etc.). a breaker trip. insulation and transformer failure. 20 GENERAL OFFIC ES / MANUFAC T URING Prol. J. M. Morelos 702 Ocotepec, C.P. 62220 Cuernavaca, Morelos México Tel: +52 777 416 65 82 Tel: +52 777 416 65 29 E-mail: ventas@orto.mx www.orto.mx