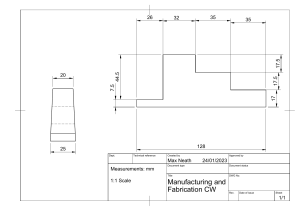

B THIS DRAWING AND ITS ESPECIFICATIONS ARE OF EXCLUSIVE USE OF GALILEO TECHNOLOGIES; ITS COPY, DIFUSSION, AND/OR USE WITHOUT ESPECIFIC AUTORIZATION IS PROHIBITED. EL PRESENTE PLANO Y SUS ESPECIFICACIONES SON DE USO EXCLUSIVO DE GALILEO TECHNOLOGIES; SU REPRODUCCI N, DIFUSI N, Y/O UTILIZACI N SIN AUTORIZACION EXPRESA ESTA PROHIBIDA Y DARA LUGAR A ACCIONES LEGALES. A C D ASSEMBLY SEQUENCE COOLER UNIT ( 1 : 30 ) STEP 1: LIFT THE COOLER UNIT INTO POSITION AND DISASSEMBLE ALL LIFTING EQUIPMENT. COMPRESSOR UNIT ( 1 : 30 ) STEP 2: TAKE APART THE REMOVABLE PIPE RUNS ON THE COMPRESSOR UNIT (DETAILS A & B). PLEASE TAKE INTO CONSIDERATION THAT OTHER PIPE RUNS (BESIDES THE REMOVABLE ONES) MIGHT REQUIRE TO BE TAKEN APART TOO (DETAILS C & D). STEP 2 DETAIL A REMOVABLE PIPE RUNS ( 1 : 10 ) STEP 3: LIFT THE COMPRESSOR UNIT RIGHT NEXT TO THE COOLER UNIT, FACING BOTH PAIRS OF ASSEMBLY PLATES WITH EACH OTHER (DETAILS E & F). CENTERING BOTH UNITS IS LEFT TO THE LIFTING ACTION, USING THE ASSEMBLY PLATES AS A REFERENCE. ADDITIONAL CENTERING DEVICES CAN BE USED IF THEY GUARANTEE THE ALIGNMENT OF THE ASSEMBLY PLATES. 1 STEP 2 DETAIL C TAKE APART IF NEEDED ( 1 : 10 ) STEP 2 DETAIL D TAKE APART IF NEEDED ( 1 : 10 ) A F D 1 STEP 5: INSTALL BACK THE PIPE RUNS TAKEN APART PREVIOUSLY. STEP 6: CONNECT THE WATER PIPES (DETAIL H) THROUGH A HOSE TIGHTENED BY CLAMPS (DETAIL I). E C STEP 4: BOLT THE 2 UNITS TOGETHER THROUGH THE ASSEMBLY PLATES, IT IS SUGGESTED TO FOLLOW THE INDICATED TIGHTENING PATTERN AND TORQUE SPECS (DETAIL G). THIS ACTION SHOULD LEVEL BOTH UNITS BETWEEN THEM AND ALIGN THE PIPE RUNS, SO THAT THERE IS NO TENSION PRESENT WHEN BOLTING THEM BACK TOGETHER. STEP 3 DETAIL F DRILLED ASSEMBLY PLATES ( 1 : 10 ) B TERRAIN MUST BE PLAIN, LEVELED AND CLEAR OF ANY OBSTACLES. DEPENDING ON THE FINISHING DEGREE ACHIEVED ON THE TERRAIN, THE USE OF CENTERING AND LEVELING DEVICES MIGHT BE REQUIRED. STEP 2 DETAIL B REMOVABLE PIPE RUNS ( 1 : 10 ) STEP 3 DETAIL E THREADED ASSEMBLY PLATES ( 1 : 10 ) 2 STEP 6 DETAIL H WATER PIPE CONNECTION ( 1 : 10 ) STEP 4 DETAIL G COMPRESSOR UNIT TIGHTENING PATTERN TORQUE TO 53 N.m ( 1 : 15 ) 9 1 12 15 8 13 7 16 3 11 5 2 STEP 6 DETAIL I HOSE AND CLAMPS H 4 14 Ver f rmula c digo/See code formule: 6 Iso E 10 Rev. Descripci n A 2 B A.I. C Fecha Aprob 00 EMISION Rev. Descripci n F.L. 31/10/2023 P.D.C. A.I. Fecha Aprob Material: Steel, Mild MCP4753180110WG00 Esc: Nombre/Name Fecha/Date Dib./Dra. F.L. 31/10/2023 Rev./Rev. M.E.G. 31/10/2023 Apr./App. P.D.C. 31/10/2023 Sin otra especificaci n/Otherwise specified T tulo: MCP - PROCESS WELLHEAD - MCP 637-3-1800-15-90 - 3 ET CATERPILLAR G3412C - MX400 - 1800 RPM - MAWP: VARIABLE Title: M quina: Machine: HOJA 1 DE 1 D Peso / Weight: N/A A1 Plano N : Draw N : Rev MCP4753180110WG00 00 R.01 EN005INTCOR0023 R.03 R.02 R.01 R.02/R.03 INTERCONNECTIONS TAG F.L. F.L. 31/10/2023 P.D.C. M.E.G. 31/10/2023 31/10/2023 31/10/2023

![Avoiding Trafficked Labor [English]](http://s2.studylib.net/store/data/027039054_1-3047401815af88cce843a8404da043fb-300x300.png)