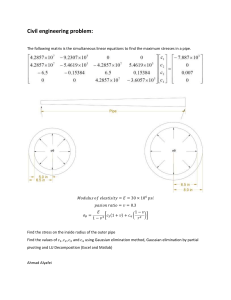

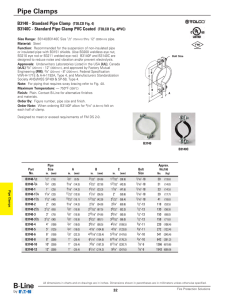

Int. J. Pres. Ves. & Piping 26 (1986) 145-166 ASME Code Classification of Pipe Stresses: A Simplified Elastic Procedure A. K. Dhalla Westinghouse Electric Corporation, Advanced Energy Systems Division, Madison, PA, USA and G. L. Jones O'Donnell and Associates, Inc., Pittsburgh, PA, USA (Received: 8 March, 1986) A BSTRA CT Liquid Metal Fast Breeder Reactor (LMFBR) plants utilize thin-walled components to minimize thermal stresses due to coolant temperature transients. A non-integral, insulated pipe clamp is generally used to support high temperature pipes and minimize thermal interaction between the piping and the support system. The resultant clamp-induced pipe stresses require consistent classification into primary and secondary stress categories as defined by the A S M E Code. A simplified stress classification procedure is proposed in this paper to split the clamp-induced pipe stresses into primary and secondary categories. INTRODUCTION The pressure vessel components and piping systems in a Liquid Metal Fast Breeder Reactor (LMFBR) plant are considerably thinner than those designed for the Pressurized Water Reactor (PWR) plant. The nominal thickness of the PWR structural components is primarily dictated by the internal pressure loading. In contrast, the internal 145 Int. J. Pres. Ves. & Piping 0308-0161/86/$03.50 © Elsevier Applied Science Publishers Ltd, England, 1986. Printed in Great Britain 146 A. K. Dhalla, G. L. Jones pressure in an L M F B R (loop type) plant is considerably smaller than in a PWR, hence the structural components are designed to be as thin as possible to minimize thermal effects. Typically, the nominal radius-to-thickness ratios of these LMFBR structural components range from 25 to 70, hence they may be realistically thought of as thin-walled structures. For example, the pipes considered in the present study are large radius (0.457 m and 0.305 m) thin-walled (12.7mm) pipes which transport liquid sodium, at elevated temperatures (546°C-585°C), in the Primary Heat Transport System (PHTS). The predominant displacement-controlled loading in these thin-walled piping systems is due to the thermal movements of the system and the thermal transients postulated for these plants. Thus, theoretically, to minimize thermal stresses, it is beneficial to reduce the pipe thicknesses and to design flexible piping loops. However, due to the interaction between a relatively thin LMFBR pipe and a stiff clamp, an evaluation is required of the local stresses at pipe supports. However, in applying the ASME Code t'2 acceptance criteria, it is not clear whether these local pipe stresses should be considered as primary or secondary. The purpose of this paper is to present a simplified procedure to classify local stresses, induced by the piping restraint assembly, into the primary and the secondary categories designated in the ASME Code. 1.2 The example used to illustrate the simplified stress classification procedure is that of a pipe clamp structural assembly used in the Clinch River Breeder Reactor Plant (CRBRP). The simplified method presented here was originally developed in Ref. 3 and was successfully used in Ref. 4 to quantify primary stress due to elastic follow-up in the CRBRP piping system. In the Fast Flex Test Facility (FFTF) the clamp-induced pipe stresses were conservatively designated as primary. In the CRBRP the clamp preloads as well as the hanger and snubber loads are significantly higher than those in the FFTF. Consequently, it was not possible to assume the local clamp-induced pipe stresses to be primary and still comply with ASME Code 1'2 primary stress limits. Additional analyses were performed to understand and evaluate the pipe response due to preloads and external loads imposed on the pipe clamp. The two- and threedimensional finite element models to represent the pipe clamp geometry were presented in earlier papers. 3'5 The local stresses used in this paper were obtained from a three-dimensional finite element model presented in Ref. 5. ASME code classification of pipe stresses 147 TYPICAL PIPING RESTRAINT ASSEMBLY Figure 1 shows a typical piping restraint assembly used in the CRBRP. The external loads at the hanger and snubber locations are transmitted by the pipeline clamps attached to the pipe. The design parameters and loadings imposed on the piping have dictated specialized design features for the CRBRP pipe clamps to support long horizontal and vertical runs of pipe. These aspects of design are discussed in detail in Refs 6 and 7. A brief description of the clamp is as follows. To minimize the potential for local discontinuity stresses in the liquid metal piping, a non-integral insulated pipe clamp was designed to serve as an attachment point for load hangers and seismic restraints. The clamp is composed of two semicircular bands with bolt flanges, gussets and attachment lugs welded to the bands, as shown in Fig. 1. In addition to these metal outer bands, there are two semicircular bands of sheathed 24" PI CLAM SNUBBER Fig. 1. Typical 24in pipe restraint assembly for CRBRP. 148 A. K. Dhalla, G. L. Jones Fig. 2. Full three-dimensional clamp/pipe interaction model. ASME code classification of pipe stresses 149 load-bearing insulation attached to the inner surface of the clamp from the pipe. The assembly is held in place by bolts and Belleville spring stackups that are preloaded at assembly. This produces an initial contact pressure between the clamp assembly and the surface of the pipe. The Belleville spring stackups are designed to accommodate thermal expansion of the pipe without introducing large changes in the bolt or spring loads or the contact pressure at the pipe/clamp interface. BACKGROUND Prior work included preparation of two- and three-dimensional finite element models to examine parametrically different load combinations and to evaluate pipe/clamp interaction effects. 4'5 The final threedimensional pipe/clamp interaction model used in the present study is shown in Fig. 2. To reduce computation cost only a quarter model was used to represent the pipe and the clamp geometry. The two planes of ATZ=4.211cm AT Z = 0.0 em /~ 4,400N / 2,200N~ f f CENTER OFCLAMP ATZ- 13.2cm AT Z" 15.2 ¢m 4 , 4 0 0 N ~ 4 , 4 0 0 N EDGE OF Fig. 3. CLAMP Interface load distribution for 178 000N preload. A . K . Dhalla, G. L. Jones 150 125 100 75 A so E I-- a. 25 0 0 X PRELOAD -25 -50 50 ~ A 25 ~ ul ,,r ~ BENDING 0 EMBRANE X I -25 0 I I 50 100 I II 150 200 I 250 300 350 PRELOAD (kN) Fig. 4. Pipe wall stress c o m p o n e n t s as a function o f preload with an assumed initial gap distribution. ASME code classification of pipe stresses 151 symmetry used in analysis are: (a) a longitudinal plane through the clamp split line along the length of the pipe, and (b) a transverse plane through the center of the clamp band. For nonlinear elastic analysis, the initial gap distribution was based upon the worst case tolerance stackups between the corresponding maximum/minimum radii of the pipe O.D., the insulation band I.D./O.D., and the clamp band I.D. Figure 3 shows the interface loads on the pipe due to the clamp preload of 178 kN, which is the design preload for this clamp configuration. The load distribution at different axial locations in the pipe shows that the interface loads are high under the outer gusset plate at z = 13.2 cm, and these interface loads decrease away from the gusset. The preloaded bolts as positioned on the clamp thus impose significant line loads on the thin circular pipe, which deforms and redistributes the stresses as more gaps are closed around the circumference and along the length of the pipe. Interestingly, the maximum stress occurs not at the outer gusset, but at the clamp center line where the largest pipe deformations are present. The stresses at the outer gusset are high but not as high as at the center line. Figure 4 shows the variation of maximum hoop and axial stresses as the preload is increased. The peak membrane and bending stresses occur at different preloads, because of the change in interface loads (on the pipe) due to the change in gap distribution. Thus, from the point of view of application of the ASME Code it is difficult to classify these stresses arbitrarily: e.g., the local bending stress as secondary and local membrane stress as primary. Furthermore, the clamp is subjected to external loads which may change the gap distribution and, consequently, the stress distribution at different load levels. Therefore, in the following sections a simple procedure based upon elastic analyses is presented to classify clamp-induced stresses (in the pipe) as primary or secondary as implied philosophically in the ASME Code. The proposed method uses the CRBRP clamp for illustration, but it does not depend upon any specific clamp configuration. CLASSIFICATION OF LOAD-CONTROLLED A N D D I S P L A C E M E N T - C O N T R O L L E D QUANTITIES The design of reasonably conservative piping systems requires careful classification of induced stresses into primary (P) and secondary (Q) stress categories. The basic characteristic of a primary stress is that it 152 A. K. Dhalla, G. L. Jones is not self-limiting (see NB-3213.8 of Ref. l). Primary stress is not redistributed or relieved by inelastic deformation. The structural response is equilibrium-controlled or load-controlled, hence primary stresses may be alternatively described as equilibrium-controlled or loadcontrolled stresses. The basic characteristic of a secondary stress is that it is self-limiting (see NB-3213.9 of Ref. 1). Secondary stress is caused by displacement constraints and is redistributed or relieved by inelastic deformation. These inelastic deformations may be in the form of time-independent plastic strains or time-dependent creep strains. The structural response is predominantly compatibility-controlled or deformation-controlled, hence secondary stresses may be alternatively described as compatibility-controlled or deformation-controlled stresses. Primary stresses which can result in failure from a single application of load are limited to relatively low allowable values. Secondary stresses which can result in failure only from repeated load cycles are less severely limited. It is the range and the number of cycles of secondary stress (rather than the level of stress) that are of particular importance in preventing failure by exhaustion of ductility or gross distortion, or due to creep-fatigue interaction. Thus, the importance attached to the ASME Code classification of stresses, into primary and secondary categories, derives from their relationship to modes of failure. Elastic secant modulus procedure If the local stress due to pipe/clamp interaction is redistributed then that stress may be considered secondary. This redistribution may occur due to material nonlinearity (plasticity and creep) or due to geometric nonlinearity (gap redistribution). An inelastic analysis would show how this redistribution proceeds as the clamp preload is increased. Unfortunately, such an inelastic analysis is quite expensive, and it is difficult to quantify the primary-secondary split even if an inelastic analysis is performed. Therefore an elastic secant modulus approach, discussed below, was developed to quantify the primary-secondary split. The elastic analysis procedure is based on the concept that the local material flexibility in the plastic (or creep) region can be simulated by lowering the elastic modulus of the pipe. This is illustrated schematically in Fig. 5, which shows a plot of the generalized local stress versus the local strain experienced by a pipe subjected to clamp preload. If the clamp preload were to produce a purely load-controlled situation, then 153 A S M E code classification of pipe stresses / / ! G9 / J / / N ! E1 E2 I / Controlled II'•r•'•---100% Deformation Controlled el E2 Generalized Local Strain Fig. 5. Load-controlled and deformation-controlledresponses. a change in elastic modulus from E 1 t o E 2 would not affect the initial local stress o-1, but strain would increase from e 1 to e2 as represented by the horizontal line AB in Fig. 5. On the other hand, if the preload were primarily a displacement-controlled loading, then the change in elastic modulus would not affect the initial local strain el, but the initial local stress would drop from 0"1 to a 2 represented by the vertical line AC in Fig. 5. Figure 6 shows the inelastic response predicted by the pipe/clamp interaction model, s The applied preload is plotted against the local effective strain, ee, at the most highly loaded location in the pipe. At loads above 80 kN the material nonlinearity increases significantly with the increase in load. This inelastic response can also be simulated by using an elastic secant modulus, E s, for pipe material under the clamp. Two preload cases (178 kN and 267 kN) were analyzed using appropriate secant moduli with zero initial gap distribution. The secant modulus values for these two cases were calculated from the ratio of the effective 154 A. K. Dhalla, G. L. Jones 60 Elastic / Analysis-~t/ 50 / / I / Secant - ~ l Modulus E2 = 88 GPa I n e l a s t i c ~ Analysis for 40 Preload = 267 kN / / / Secant Modulus, E1 = 130 GPa for Preload = 178 kN @, l 30 2O lo Elastic Modulus Eo = 194 GPa 2 4 6 8 10 12 Effective Strain, Ceff (10 .4 in/in) Fig. 6. Comparison of inelastic and secant modulus elastic analyses. stress to the effective strain at the most highly stressed location in the pipe for the corresponding preload. The effective strains obtained from the elastic secant modulus analyses are also plotted in Fig. 6. The close correspondence in this figure between the points obtained from elastic secant modulus analyses and the curve obtained from inelastic analysis suggests that the pipe flexibility can be reasonably represented by either elastic-plastic material properties in inelastic analysis or by reducing the elastic modulus in an elastic analysis. Of course this simplified procedure would estimate local responses at the highly loaded locations reasonably well. At stress levels less than 25% of the maximum stress the predictions would be unsatisfactory. However, this shortcoming of the simplified procedure is only of academic interest because to comply with the ASME Code rules, an analyst generally selects the most highly loaded locations and ignores the lower stressed regions in the structure. ASME code classification of pipe stresses 155 The results presented in Fig. 6 were obtained using secant modulus for pipe material directly under the clamp, and elastic modulus for the rest of the pipe/clamp assembly. The rationale for this selection is as follows. At load levels higher than the design preload, redistribution of local plasticity and/or initial gaps reduce the clamp-induced pipe bending stresses (Fig. 4), and the interface load distribution becomes more uniform (Fig. 3). Thus, the basic characteristic of secondary stress is realized, that is the clamp-induced pipe stresses cannot precipitate failure in a single load application. Although a detailed sensitivity study to select the appropriate pipe length for reduced secant modulus was not performed, a good correlation between detailed inelastic and secant modulus (elastic) analysis confirms the adequacy of the simplified procedure proposed in this paper. In summary, if the local stresses induced in the pipe are purely deformation-controlled quantities (secondary) then the corresponding stress ratio (ax/a2) would vary in direct proportion to the material flexibility ratio (El~E2), and the correspondence strains would be constant. That is, a--! =--El when ~1 = g2 (1) E2 O"2 On the other hand, if the local stresses are predominantly loadcontrolled, then the corresponding strain ratio would vary inversely with the material flexibility ratio and the correspondence stresses would be constant. That is, e2 ~1 - El E2 when o l = o-z (2) P R E L O A D E D C L A M P - I N D U C E D PIPE STRESSES In a practical problem, neither eqn (1) nor eqn (2) could be satisfied based upon the actual numerical values predicted by elastic secant modulus analyses. The numerical difference between the exact satisfaction of eqns (1) and (2) and the actual stress and strain ratio predictions would provide a measure of local stress that is considered primary. This is illustrated in Fig. 7, where normalized equivalent or effective stress at the outside surface of the clamp is plotted against the normalized equivalent effective strain. The numerical values are based upon four 156 A. K. Dhalla, G. L. Jones 100% Load-Cont rolled 2 %- %o 0P u = 30 o. 0P I = 0 o Upper Bound Percent Primary = 33% Lower Bound Percent Primary = 0% ~6~ g Symbol Modtrtus Ratio E/El ~8~ Z (3 1 O A 2 3 O 10 10 - - tE • !~"-- 12 0 (:oe = ee 2I 100% Deformation-Contro,led 4I 6I 8 10 Normalized Equivalent Strain (6ie/foe) Fig. 7. Primary-secondary split based upon equivalent elastic analysis for preloaded case (outside surface). elastic analyses with E o / E i = 1, 2, 3 and 10. The purpose of performing more than three elastic analyses is to establish a trend of stress relaxation with respect to the reduction o f secant modulus. Figure 7 is a normalized plot so that the portion that can be designated as primary can be represented by the relative position of the line A D with respect to the 100% load- and deformation-controlled lines. The angle 0 p, between the 100% deformation-controlled line AC and ASME code classification of pipe stresses 157 the equivalent elastic stress-strain response represented by line AD, measures the deviation from 100% displacement-controlled loading. For example, if the predicted stress ratio had increased in direct proportion to the moduli ratio, and if the corresponding strains remained constant, then 0p would be zero and the primary stress contribution due to clamp/pipe interaction would be 0%. In contrast, if 0p were 90 ° then the primary stress contribution would be 100%. A linear variation may be assumed in between these two extremes. For example, an upper bound primary stress contribution due to the pipe/clamp interaction as obtained from Fig. 7 is given by 0p 0-7 x 100 = 33% (3) In subsequent discussion, eqn (3) will be used to classify the local clampinduced stresses into primary and secondary categories. Conceptually, the primary-secondary split based upon elastic secant modulus analyses is straightforward. However, when numerical values are plotted in Fig. 7, for Eo/E l = 1 to 10, the elastic stress and strain predictions do not fall on the straight line AD. This nonlinear behavior is due to changes in gap distribution, which alter the interface loads and the clamp-induced pipe stresses. As pipe becomes more flexible, the strains remain nearly constant, and the response plotted in Fig. 7, at E/Ei greater than 3, is closer to the deformation-controlled line. Thus, if the clamp is overloaded during faulted condition, the mode of failure will be similar to that due to the application of a secondary stress as implied in the ASME Code. In Fig. 7, two values of primary stress split are presented: (a) a conservative upper bound value defined by the solid line AD, and (b) a reasonable lower bound value defined by the dotted line AE. The lower bound value of clamp-induced primary pipe stress is considered reasonable because (a) it accounts for the stress reduction due to plasticity and redistribution of interaction loads, and (b) one application of such clamp-induced stresses would not cause failure in the pipe. However, in some cases a designer might neglect the stress relief due to material or geometric (gap redistribution) flexibility offered by the clamp design and use a conservative upper bound value presented in Fig. 7 for clamp-induced primary pipe stress. The rationale for limiting the elastic moduli I(E/Ei) ratio to 10 is presented in Fig. 8. This figure shows the isochronous stress-strain curves, at t = 0 and t = 200 000 h, for the piping material. The life of 158 A. K. Dhalla, G. L. Jones 24 ~ E/E 1 = 1 t I 20 t =2x105 = 0 hrs. hrs.- E/E 2 = 2 ,>"// - E/E 3 = 3 / / / 16 I\ / ." 12 I \ I / \ D t f / / / // / / / / / / / // // // /'~--- E/E,=,o / / / / 0 I I I I ] 0.2 0.4 0.6 0.8 1.0 Strain (%) Fig. 8. lsochronous stress-strain curves for 316SS piping material. the CRBR plant is about 200000h, hence the material flexibility represented by E / E l = 10 corresponds to a strain of about 1%. In a piping system the pipe/clamp interaction stress is only a part of the total bending strain experienced by the pipe at the most highly loaded location. Limiting the total bending strain to 1% due to pipe/clamp interaction is a reasonable assumption. The inelastic strain limits specified in Code Case N-47 are 2% for bending and 1% for membrane A S M E code classification of pipe stresses 159 strains. Therefore, it is sufficient to limit the elastic analyses to E / E l = 10 to obtain reasonable classification of the pipe/clamp interaction stress. Local stresses for preloaded clamp reevaluated The example shown in Fig. 7 represents the case of a clamp preloaded to the maximum design preload. The primary-secondary split illustrated ! I I _ ._A_ ~A~,~ B ,~Obn " 4 g f~ ~ O~u ~ ~eb._ ~ D Symbol ~AIt~ I ~ 10 c; i 2 Component Membrane Rending I I I 4 6 8 10 Normalized Strain, % = ~i / ~:o Bending Component Split Membrane Component Split 0 PU=370 ,0P1=230 OPm = 90 ° , Percent Primary = 100% Upper Bound Percent Primary = 41% Lower Bound Percent Primary = 26% Fig. 9. Primary-secondary stress split for membrane and bending stress components (preload case). A. K. Dhalla, G. L. Jones 160 in Fig. 7 is based upon the surface stress at the most highly stressed location at the split line of the pipe (point A in Fig. 2). The surface stress in ASME Code terminology includes the primary membrane ( e m ) ' primary and secondary bending (Pb and Q), and peak (F) stress components. Consequently, the primary-secondary stress categorization at the inside and outside surface would be different if the primarysecondary split were calculated as shown in Fig. 7. For example, Fig. 4 shows that the membrane stress components (at the same split line location) increase nearly proportionately with the increase in the preload applied to the clamp. In contrast, the bending stress components increase up to the design load and then decrease with further increase in preload. In order to include the interaction of membrane and bending components and to evaluate their redistribution as the pipe becomes more flexible, it was necessary to calculate the primary-secondary split separately for the membrane and the bending stress components. Figure 9 shows the membrane and the bending stress component plots, respectively, for the preload case with zero initial gap distribution. These plots are based upon four elastic analysis results, where the elastic modulus in the pipe under the clamp is reduced ( E / E i = 1, 2, 3 and 10), to simulate redistribution of stresses in the inelastic range when the pipe becomes more flexible. Although the plots at various axial and circumferential locations in the pipe are not shown, the observed trend TABLE 1 C l a m p - I n d u c e d Pipe Stresses and Strains due to a Preload o f 40 Kips (Location: center o f clamp, underneath clamp split line) Normalized modulus Equivalent stress (psi) Equivalent strain (in~in) Normalized stress Normalized strain Membrane components 1 2 3 10 3500 3980 3840 3 160 1.24 2.84 4.08 11-3 x × x x 10 -4 10 4 10 -4 10 -4 1.0 0.88 0.91 1.11 1.0 2.29 3.29 9.11 4.89x 6.84 x 8.02 x 12.0 x 10 4 10 4 10 -4 10 -4 1.0 1.44 1.82 4.27 1.0 1.40 1.64 2-45 Bending components I 2 3 10 13760 9580 7540 3220 ASME code classification of pipe stresses 161 is similar to that shown here at the most highly stressed location. The numerical values presented in Table 1 show that the membrane stresses are basically primary in nature, because the membrane stresses are nearly constant for E / E t varying from 1 to 10. In contrast the bending stresses are predominantly secondary in nature, because they redistribute as the pipe becomes more flexible. In Fig. 9, the conservative upper bound clamp-induced primary stress in the pipe may be considered to be 41%, whereas a more reasonable lower bound primary stress is considered to be 26%. E X T E R N A L LOADS A P P L I E D TO P R E L O A D E D C L A M P Local stresses for externally loaded clamp When the pipe clamp is connected to a snubber, the clamp would transmit an external seismic load to the pipe. Without a three-dimensional interaction model (Fig. 2) it is not possible to calculate the local clamp/pipe interaction stresses during such seismic events. Traditionally, only the nominal beam stress (Mc/I, where M is the m o m e n t applied to a pipe of a m o m e n t of inertia, I, and c is the distance of the extreme fiber from the pipe neutral axis) is calculated and the clamp/pipe interaction effects are ignored. However, for the thin-walled L M F B R piping it is necessary to calculate these local interaction stresses to properly evaluate the primary stress limits specified in the ASME Code. To reduce the computation costs, a quarter symmetry model (180 ° Sector, Fig. 2) was utilized for symmetric (split line) external load cases. Two load cases were investigated: (a) vertical tensile external load, and (b) vertical compressive external load. These load cases are sketched in Fig. 10, wherein a constant preload was maintained during application of the external loading. Four elastic analyses with E / E I = l, 2, 3 and 10 were performed for these two load cases. We are interested in the local membrane and bending stress caused by the pipe/clamp interaction. These local stresses are in addition to the nominal beam type bending stresses where the pipe section is assumed to be circular. Thus, the final primary stress limit checks would include not only the nominal beam type stresses but also the primary local stresses as calculated by the equivalent elastic analysis procedure described earlier. The numerical values tabulated in Tables 2 and 3 are used to arrive 162 A. K. Dhalla, G. L. Jones q~ Vertical, Compressive (VC) Vertical, Tensile (VT) Fig. 10. External load cases examined. at the primary-secondary split shown in Fig. 11 for the external load cases. This figure shows the membrane and the bending stress component plots for the external vertical tension and vertical compression. Both these cases include a design preload that would be experienced by this clamp. The effective stress results separated into membrane and bending parts show similar trends as those observed earlier for the preload clamp without external load. Once again, the membrane stresses could be conservatively considered as primary for the A S M E Code type calculations. At higher load levels, substantial stress redistribution is experienced by the pipe due to higher material flexibility (E/E~ greater than 3); and the clamp-induced local bending stresses, shown in Figs 9 and 1 l, are closer to the deformation-controlled line than to the load-controlled line. For these external load cases a conservative upper bound local bending stress may be considered as 56% primary. On the other hand, a reasonably local bending stress for design may be considered as 41% A S M E code classification of pipe stresses 163 TABLE 2 C l a m p - I n d u c e d Pipe Stresses a n d Strains Due to a n External Vertical C o m p r e s s i o n L o a d o f 40 Kips a n d a Preload of 40 Kips (Location: center o f clamp, u n d e r n e a t h c l a m p split line) Normalized modulus Equivalent stress (psi) Equivalent strain (in~in) Normalized stress Normalized strain Membrane components 1 2 3 10 4430 3890 3670 3340 1.58 2-78 3.91 11.9 x x x x 10 -4 10 - 4 10 - 4 10 - 4 1-0 1.14 1.21 1.33 1.0 1-76 2-47 7-53 9780 6630 5240 2310 3.48 4.74 5'58 8'25 x × x x 10 - 4 10 - 4 10 - 4 10 - 4 1.0 1.48 1.87 4.23 1-0 1.36 1-60 2.37 Bending components 1 2 3 10 TABLE 3 C l a m p - I n d u c e d Pipe Stresses a n d Strains Due to an External Vertical Tension Load o f 40 Kips a n d a Preload o f 40 Kips (Location: c e n t e r o f clamp, u n d e r n e a t h clamp split line) Normalized modulus Equivalent stress (psi) Equivalent strain (in~in) Normalized stress Normalized strain Membrane components ! 2 3 10 7250 6440 5820 4090 2"58 4"59 6-19 14"6 × x x × 10 -4 10 -4 10 - 4 10 -4 1-0 1-13 1"25 1-77 1.0 1.78 2'40 5'66 23 160 17200 14030 6650 8.24 12.3 14.9 23.8 x x x x 10 - 4 10 - 4 10 -4 10 -4 !.0 1-35 1.65 3.48 1.0 1.49 1.81 2-89 Bending components ! 2 3 10 A. K. Dhalla, G. L. Jones 164 m ,, I I I I +I A bn ii c 6 D Symbol Component Load Case A Membrane Vertical Compression 0 Bending Membrane [] 10 c Vertical Tension Bending I I I 1 2 4 6 8 10 6 n = ~-i/~o Bending Component Split Membrane Component Split 0 Co 0~ * = 500 0 CI = a?o ,no Percent Primo. = 100~ Upper bound percent primary = 56% Lower bound percent primary = 41% F i g . 11. Primary and secondary stress split for membrane and bending stress components (external load case). primary as indicated by the dotted line in Fig. 11. These observations have been confirmed by similar results plotted for various axial and circumferential locations in the pipe. It should be emphasized that Fig. l l shows just one of a number of locations investigated in the present study. Special post-processing programs were written to evaluate the simplified elastic analysis results. Thus, the upper and lower bound percent primary stress values shown in Fig. 11 envelop the data generated ASME code classification of pipe stresses 165 in the present study. Additional conservatism built into the present recommendation for primary-secondary split is the fact that the highest pipe stress due to operative mechanical and seismic loading does not occur at the same location as the highest clamp-induced primary stress. C O N C L U D I N G REMARKS Piping restraints or clamps are routinely used to support thermal expansion loops (piping runs) used in an LMFBR plant. However, clamp/pipe interaction effects are not analyzed routinely for these thinwalled (25 < r/t < 70) piping systems. A three-dimensional finite element clamp/pipe interaction model was developed to evaluate the effect of clamp on pipe. Inelastic as well as nonlinear elastic analyses were performed to calculate the local stresses induced in the pipe due to preloading of the clamp. To comply with the ASME Code requirements it is necessary to classify these clamp-induced local stresses into primary and secondary categories. Unfortunately, inelastic analysis is expensive and it cannot be used to quantify the primary-secondary split of the local stresses induced in the pipe. However, inelastic analysis is useful in evaluating the deformation response of the pipe to distinguish qualitatively a load-controlled primary loading from a deformationcontrolled secondary loading. An elastic secant modulus procedure was developed to classify the local stresses into primary and secondary categories. This simplified procedure requires local stress predictions from at least three elastic secant modulus analyses, with different (more flexible) elastic moduli, to simulate the material and/or geometric nonlinearity in the clamp/pipe structural model. The adequacy of this approach was confirmed by comparing the elastic secant modulus analysis results with those obtained by a detailed inelastic analysis. The simplified equivalent elastic procedure does not depend upon the specific clamp design or the pipe geometry. The classification of stresses into primary and secondary categories is based upon the ASME Code definition of the load-controlled and the deformation-controlled structural response. The local stresses due to clamp/pipe interaction can be categorized as follows: (a) the membrane stress components are predominantly primary; (b) the bending stress components are only 30-50% primary. 166 A. K. Dhalla, G. L. Jones At loads higher than the design load levels substantial local stress redistribution is experienced by the pipe due to higher material flexibility ( E / E i greater than 3), and gap redistribution between the clamp and the pipe. A C K N O W L E D G E M ENTS This paper is based on work performed under subcontract to Westinghouse Electric Corporation, Advanced Reactors Division, on US Department o f Energy Contract EY-76-15-2395. The authors wish to express their appreciation for the technical contributions made by R. M. Mello, L. P. Pollono and Dr R. H. Mallett. REFERENCES 1. A S M E Boiler and Pressure Vessel Code, Rules of Construction of Nuclear Power Plant Components, Section III, Division 1, American Society of Mechanical Engineers, New York, 1977. 2. A S M E Boiler and Pressure Vessel Code Case N-47 (1592), Class 1 Components in Elevated Temperature Service, Section III, Division 1, American Society of Mechanical Engineers, New York, 1977. 3. Jones, G. L., An evaluation of clamp effects on LMFBR piping systems, in Effects of piping restraints on piping integrity, PVP-40, pp. 201 17, American Society of Mechanical Engineers, New York, 1980. 4. Dhalla, A. K., Verification of an elastic procedure to estimate elastic followup, in Design of elevated temperature piping, PVP-Vol. 86, pp. 81-96, American Society of Mechanical Engineers, New York, 1984. 5. Jones, G. L. and Dhalla, A. K., Classification of clamp induced stresses in thin-wailed pipe, ASME paper 81-PVP-I 7, American Society of Mechanical Engineers, New York, June 1981. 6. Pollono, L. P. and Mello, R. M., Design considerations for CRBRP heat transport system piping operating at elevated temperatures, ASME paper 79-NE-5, American Society of Mechanical Engineers, New York, 1979. 7. Pollono, L. P. and Mello, R. M., Design and testing of CRBRP insulated horizontal and vertical pipe clamps, in Effects of piping restraints on piping integrity, PVP-40, pp. 177-200, American Society of Mechanical Engineers, New York, 1980.