Journal of Cleaner Production 51 (2013) 34e46

Contents lists available at SciVerse ScienceDirect

Journal of Cleaner Production

journal homepage: www.elsevier.com/locate/jclepro

Evaluation of green maintenance initiatives in design and

development of mechanical systems using an integrated approach

V.N. Ajukumar*, O.P. Gandhi

Industrial Tribology, Machine Dynamics and Maintenance Engineering Centre, Indian Institute of Technology, New Delhi 110016, India

a r t i c l e i n f o

a b s t r a c t

Article history:

Received 20 April 2012

Received in revised form

4 January 2013

Accepted 7 January 2013

Available online 29 January 2013

The growing public concern on global environmental degradation is forcing many industries to undertake environmentally conscious policies for product design, manufacturing, service and end-of-life

activities. Maintenance is a critical activity carried out in the use phase of the product life cycle to prolong

system availability. The increasing amount of repairs and maintenance of machinery has become a

burden on the environment. Therefore, green maintenance driven product design and maintenance

actions are critically important; and organizations are now looking for methods and tools to assess the

sustainability aspects of their design and operation. This paper presents an objective approach to evaluate green maintenance aspects of mechanical systems at its design stage and rank the design alternatives. It takes into consideration the green maintenance requirements, environment conscious

attributes and their interrelationships. The evaluation problem is formulated as a multi-attribute decision-making model and solved using analytical hierarchy process (AHP) and the technique for order

preference by similarity to ideal solution (TOPSIS) approach. The proposed approach starts with applying

AHP method to evaluate the importance of green maintenance requirements during maintenance. Then

the relationships between the requirements and design characteristics are established and the TOPSIS

method is adopted to rank the design alternatives.

Ó 2013 Elsevier Ltd. All rights reserved.

Keywords:

Design for environment

Green maintenance

Multi-criteria decision making

Green product design

Digraph

1. Introduction

Maintenance is a desirable activity in plant operation and it is

the most efficient way to retain or restore the system to a desired

level of performance. In addition to fulfilling the requirements of

equipment inspection, lubrication and repair, it has an added

responsibility of plant protection, pollution prevention, personnel

safety and waste disposal. The increasing requirements of maintenance in the unproductive use phase of the product life cycle of

mechanical systems produce significant impact on the environment; as defective parts, used oils, grease and cleaning agents are

discarded into the environment. In this context, the designers and

practising maintenance personnel are facing the challenge in

responding: how to do the necessary maintenance, with minimum

negative environmental impact? Moreover, various environmental

regulations/policies have put pressures on the organizations to

service, repair and dispose of their equipment in an environmentally friendly manner. Green maintenance enabled design of

* Corresponding author. Tel.: þ91 9495925959.

E-mail address: vnaju@yahoo.com (V.N. Ajukumar).

0959-6526/$ e see front matter Ó 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.jclepro.2013.01.010

equipment and sustainable maintenance practices emerge as a

solution to the problem.

Green maintenance is an attempt to make maintenance more

environmentally benign by eliminating all waste streams associated with maintenance. Its activities involve the integration of

product design issues with issues of maintenance planning and

execution aimed at minimizing negative environmental effect;

while at the same time ensuring health and safety of the personnel

involved. This demand for understanding the green maintenance

requirements during operation phase of maintenance and how

these can be mapped onto design characteristics at the design

stage. The challenge is to alter conventional design process to

anticipate and assess environmental impacts during maintenance

and to incorporate the green considerations systematically and

effectively. This is significant as the environmental impact of

maintenance associated with equipment is primarily decided at the

design stage and secondarily, by the policies and steps followed

during the operation phase of maintenance. Designers must

therefore, be aware of the interrelationships between process and

product design issues, and incorporate green aspects into design for

eco-friendly maintenance, in addition to the conventional design

variables.

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

Researchers have tried to minimize the negative impact of

products on the environment by focusing on design for environment (DFE), as design is the process in which the most factors of the

product life cycle are determined. Santos-Reyes and Lawlor-Wright

(2001) described a structured approach to DFE for addressing the

problem of integrating green concerns at an early product design

phase. The approach suggested eco-principles and the measures of

eco-performance that can be useful to choose alternative options

for improving and quantifying product environmental performance. Madu et al. (2002) introduced a step-by-step approach for

environmentally conscious design. Kuo et al. (2006) presented a

green fuzzy design analysis (GFDA) to evaluate product design

alternatives based on environmental consideration using fuzzy

logic.

Efforts have also been made to analyze the environmental

impact using various approaches during the stages of manufacturing, servicing and disposal. Life-cycle assessment (LCA) is one

such approach, which identifies the environmental burden that

arises from a product at its various stages of life cycle (Ishi, 1995).

Hundal (1998) carried out the detailed analysis of various aspects of

life cycle to be considered at the product development process. It

was revealed that consideration of eco-design and waste prevention at the design stage is useful for successful development of

the product. Yang (2007) developed an LCA based sustainable

product design for eco-design support and for product LCA analysis

at early design stages, using which the designers can compare

material and energy consumptions, and to assess environmental

impacts of different end-of-life treatment options.

Masui et al. (2003) presented a methodology for applying

Quality Function Deployment (QFD) for environmentally conscious

design in the early stage of product development. Watkins et al.

(1995) developed the EcoSys system that integrates design information and expert system to perform environmental impact analyses during product design and manufacturing processes. As

sustainability assessment principles, strategies and tools are on the

rise, it is a challenge to integrate systems and sustainability perspectives into product design, manufacturing and delivering decisions (Wage, 2007). Fukushige et al. (2012) developed a

representational scheme using which the life-cycle scenarios can

be represented and the designer can easily derive requirements for

product and process design to take care of later processes of lifecycle design. Recently, Anand and Wani (2010) presented an evaluation procedure for product life-cycle design at the conceptual

stage in terms of life-cycle design index.

It is clear from the above that although maintenance being a

significant contributor in prolonging the use phase of product life,

particularly with mechanical systems, yet its role on negative

environmental impact has not been adequately addressed. Existence of strong gap between green maintenance requirements and

35

existing design practices is another matter to be taken care of.

However, there are not many effective tools available either in

assessing how the design can be altered in bringing and accommodating sustainability aspects in maintenance. Therefore, it is

required to provide designers with appropriate tools to analyze and

predict the impact at the early stages of the design. Such an

assessment will help in devising design modifications and proposing maintenance policies/strategies catering to the design. This

paper presents an approach that integrates AHP and TOPSIS to

assist designers in identifying and incorporating green maintenance requirements with design characteristics, and help to

achieve an effective evaluation of the final design. AHP will be used

to evaluate the priority indices of the required green maintenance

requirements. These green maintenance requirements are then

correlated with the design characteristics to highlight the critical

design features that must be included in the equipment design. The

interrelationships among the design characteristics are also analyzed using graph theoretic techniques. On the other hand, TOPSIS

will be used to evaluate the best design alternative by taking into

consideration the extent to which each alternative is capable of

meeting the green maintenance requirements. The paper is

organized as follows. The green maintenance aspects, its issues,

challenges and enabling features are explained briefly in Section 2.

A brief description regarding the integrated approach of AHP and

TOPSIS is presented in Section 3. An example is included to illustrate the application of the methodology in Section 4. Finally, Section 5 summarizes the results of this paper.

2. Green maintenance e features and characteristics

This section discusses the impact of maintenance on environment and the issues involved in incorporating environmentally

benign features during design and operation. It also elaborates the

features of green maintenance and identification of environment

conscious attributes facilitating sustainable maintenance.

2.1. Maintenance and its impact on environment

Products impact the environment at various stages of its life

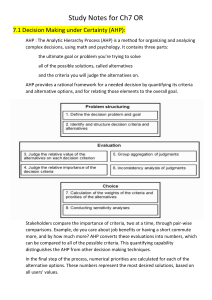

cycle including during maintenance. Fig. 1 represents the stages in a

product life cycle, starting from design to end-of-life activities. The

environmental impact of the product at major stages of life cycle

(EIlc) is expressed by Sy and Mascle (2011) as

EIlc ¼ EImat þ EImanuf þ EIuse þ EIeol

where EImat, EImanuf, EIuse and EIeol are, the environmental impact of

the material needed to produce the component, the impact

Feed back to rectify and optimize the product

Product

design

Materials extraction

and processing

Product

manufacturing

(1)

Marketing and

distribution

Product use (Productive

operation phase and

non-productive

maintenance phase)

Waste management to

tackle:

• Landfill problems

• Ground water

contamination

• Air toxicity

Fig. 1. Life-cycle stages of a product.

End of life

36

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

associated with the manufacturing processes, environmental

impact of use and end-of-life impacts respectively.

In the current work, the attention is focussed only on the impact

of equipment maintenance, which comes under the use phase of

product life cycle (shaded portion in Fig. 1). Environmental impact

in the use phase of product life cycle, EIuse, can be split into two, i.e.

during the operation phase, EIop, and that during the maintenance

phase, EImaint, i.e. EIuse ¼ EIop þ EImaint.

In the maintenance of equipment, it is expected that the

defective items will be serviced by trained technicians and brought

back to working condition using the available resources and energy.

Fig. 2 shows a typical maintenance scenario, where the variables

influencing maintenance work is depicted. The quality of maintenance work and its environmental impact are determined by the

energy and resource utilization, guided by environmental regulations. It is also dependent on the maintenance policies adopted as

well as on the expertise of the maintenance technician. As the

equipment becomes complex, the more resource intensive are

likely the maintenance steps, and consequently the more environmental impact it may create.

2.2. Issues and challenges

The decisions taken during early design stage determines

whether a product is sustainable or not (Ramani et al., 2010). In

addition to this, environmentally benign maintenance processes

and procedures also got a greater role to play in reducing environmental impact, particularly with the mechanical systems.

Therefore, it is essential to identify the design characteristics that

can be incorporated at the design stage; as well as the factors that

facilitate green maintenance for the likely repair actions as part of

maintenance. These two domains under green maintenance, i.e.

environmentally conscious equipment/system design, and environmentally conscious maintenance process design are highlighted

in Fig. 3. The task of incorporating environmental compatibility

during design and maintenance involves the following challenges:

Optimization of critical design characteristics, which are having a greater role in reducing negative environmental impact.

Incorporating those features in design, without impairing the

functionality of the product or in conflict with other Design for

‘X’ (DFX) parameters (‘X’ can be Disassembly/Assembly (D/A),

Maintainability (M) or Recyclability).

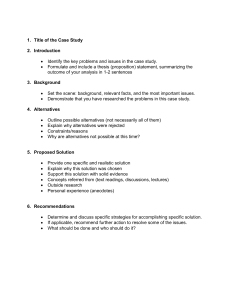

2.3. Green maintenance requirements and their facilitating factors

Understanding of comprehensive green maintenance requirements and green maintenance processes becomes critical, as sustainable design and eco-friendly operations have become the

mainstream among industrialists and academicians. Therefore,

identification of green maintenance requirements is the starting

point of green maintenance enabled design. Fig. 4 shows the green

Environmental regulations/

standards

Material, energy and labour

inputs

Product to be

serviced

Serviced product +

maintenance waste

+ energy wastage

Maintenance

Maintenance strategies/

policies

Maintenance

technician’s capability

Fig. 2. Maintenance and its constraints.

maintenance requirements; categorized in the form of a hierarchical tree. Of all the requirements, the ones which are shown in

shaded rectangles in the figure can be fulfilled, if taken care of at the

design stage. The rest of the requirements are the ones, which can

be taken care of during the operation phase of maintenance.

Good mapping between the green maintenance requirements

and facilitating environmentally conscious design characteristics

should be established to achieve a sustainable product, as equipment design and associated maintenance processes are closely

interrelated. Table 1 shows the features enabling green maintenance of mechanical systems from the view point of design and

operation. Its requirements and facilitating features are listed in the

second and third columns of the table respectively. Environmentally conscious attributes derived out of facilitating green

maintenance parameters are shown as fourth column of table. The

significance of the distinguished environmental characteristics in

the context of green maintenance is explained in the following subsections.

2.3.1. Tribo-design and practices

Tribological inputs in design and effective tribo-practices during

service/repair have significant influence in improving the quality of

maintenance of the system. The effects of improvements in tribology have positive effects on maintenance; as tribology and

maintenance share causeeconsequence relationship (Babi

c, 2001).

According to Kato (2011), tribology is expected to support the

technologies of sustainability and zero emission by developing its

science and technology for the demand of new values of industrial

products. Holmberg (2001) explored the role of tribology and different tribology-related methods to improve reliability design,

component life time, condition monitoring and diagnostics. Xue

et al. (2007) have stressed the need for tribological investigation

in decreasing environmental pollution, tribological measures for

controlling noise and limiting discharge of harmful dust. Tribologists are increasingly utilizing surface treatments and coatings to

reduce or control friction and wear (Holmberg and Mathews,

2009). Eco-tribology through progress in surface modification is

seen to be an effective engineering technology that can contribute

very much for sustainable societies (Sasaki, 2010). Therefore, surface modification technology such as surface texturing and coating

will help components perform their duty for a longer duration of

time.

Nosonovsky and Bhushan (2010) discussed the concept of green

tribology and its relation to other ‘green’ disciplines namely; green

engineering and green chemistry. The authors defined three areas

of green tribology: (i) biometrics for tribology applications, (ii)

environment-friendly lubrication, and (iii) the tribology of renewable energy application. The authors also mentioned the twelve

principles of green tribology e minimization of heat and energy

dissipation; minimization of wear; reduction or complete elimination of lubrication and self lubrication; natural lubrication; biodegradable lubrication; sustainable chemistry and green principles

for tribological applications, coatings and lubricants; biomimetic

approaches; surface texturing; environmental implications of

coatings and other methods of surface modification; design for

degradation of surfaces; real time monitoring; and sustainable

energy applications.

As part of the maintenance, machines are periodically cleaned

and lubricated. Degreasers, detergents and other surfactants

(cleansers) found in waste water are derived as its consequence.

Vast quantities of used oils, wash waters, greases, cleaning solvents,

anti-freeze agents and air-conditioning refrigerant are finding their

way into water streams altering the physical, chemical and biological nature (Sangodoyin, 1991) and being toxic to numerous

aquatic organisms. The pollutants also contain suspended solids,

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

37

Green maintenance

Environmentally compatible system

design

Environmentally compatible maintenance

process design

• Equipment design including tribo-design

features

• Plant layout and design

• Safety features

• Tribo practices

• Maintenance policies and strategies

• Organizational support

Fig. 3. Domains under green maintenance.

both degradable and non-bio-degradable organics; heavy metal

ions; dissolved inorganics; acids, bases and coloring compounds

(Ijeoma and Achi, 2011), with long-term implications on ecosystem

functioning. Sometimes, cleaning may be carried out using hazardous solvents having volatile organic compounds which contain

a range of air pollutants as well. Similarly, repair also produces

wastes in the form of filters, used gloves, hoses, grease containers,

packing materials and discarded components creating landfill

problems. The cumulative hazardous effects of these pollutants

cause climate change, loss of natural resources and adverse health

impacts.

Research on decreasing the detrimental impact of lubricants on

the environment, recommends the use of bio-degradable oils,

vegetable oils and process fluid lubrication like water lubrication.

Bronshteyn and Kreiner (1999) estimated that approximately 5e8%

energy savings are achievable by using energy efficient viscosityindex improved industrial lubricants by reducing churning and

friction losses. Synthetic lubricants, particularly synthetic ester

lubricants, derived from renewable resources give frictional benefits which offer positive energy reduction and considerable cost

savings (Lea, 2007). Effective tribological practices significantly

reduce the wear, extend the lubrication frequencies and reduce the

lubricant consumption. This will lead to energy savings through

reduced downtime, and with fewer waste disposal concerns. In this

way, improvements in tribological design and practices can reduce

the maintenance requirements and thereby, contributing to

sustainability.

2.3.2. Equipment design

The way the equipment is maintained is largely decided by its

design. Proper design facilitates an early assessment of maintenance environmental impact and helps in devising design modifications or in planning maintenance strategies. There are various

design attributes directly and indirectly deciding the ecofriendliness of the system; the important among these being

maintainability, reliability and material characteristics.

Incorporating maintainability into the system at the design

stage reduces the maintenance requirements. In this context,

design attributes like accessibility, modularity, disassemblability/

assemblability, simplicity and standardization gains importance.

Features of tribology such as longevity lubricants, long life lubrication, self-lubricating materials and coatings can significantly

improve maintainability of the systems (Wani and Gandhi, 2002).

Bringing simplicity in design by reducing weight and volume,

results in less intensive maintenance steps. Modular design helps in

maintenance as it reduces the repair time. Not only that, functional

upgradation is easier to achieve with modular products. Upgradeability of equipment equips the system to perform the added

Green maintenance requirements

Environmental

compatibility

Energy efficiency

Leakage prevention

Ease of maintenance

Minimum landfill

problems

Synthetic lubricants

derived from renewable

resources

Bio-degradable

lubricants and cleaning

agents

Upgradability during

maintenance

Waste treatment policy

Longevity materials

Tribo-materials, energy

efficient bearings and

lubricants

Paperless maintenance

management system

Minimizing unnecessary

travel and easy to

transport

Fig. 4. Green maintenance requirements.

Human health and

safety risks

Enforcing rules and

regulations

Proper lighting and

ventilation

Easy to follow and

safe maintenance

steps

Use of non-toxic

lubricants and

solvents

38

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

Table 1

Green maintenance requirements and environmentally conscious attributes.

S.No.

Requirements for green maintenance

Facilitating parameters of green maintenance

Environmentally conscious attributes

1

Low friction, noise and heat dissipation; minimum

requirement of lubricants; no leakage through

joints and seals; no ground water contamination.

Design of joints and seals, long life

bio-degradable oils; tribo-compatible

materials.

2

Ease of maintenance; remanufacturing

upgradeability; finished surfaces for low wear;

availability of bio-degradable components as

replacements

3

Minimum resource consumption; minimum

transportation requirements; paperless

maintenance management system;

4

Practice of environmental guidelines/standards;

waste disposal programs; availability of

maintenance support in the form of tools,

spares and personnel.

Long life lubricants; tribo-compatible materials with

self-lubricating property; energy efficient bearings;

bio-degradable lubricants; process fluid lubricants;

minimum/efficient joints to prevent leakage and use

of right gaskets and seals; filtering and reuse of used oils;

non-chlorinated and organic solvents for cleaning.

Maintainability enhancing attributes; use of standard

joining techniques; diagnosability; low material variety in

design; ergonomic work condition; biomimetic materials

with self-lubricating properties; design upgradable

components; treating and finishing surfaces; chemical

deposition techniques and use of surface coatings like

Diamond like Carbon (DLC) coating; reuse of used

materials; substitution with non-hazardous materials.

Plant layout catering to maintenance workflow; use of

natural lighting; maximize use of chain pulley blocks,

which can be mounted on jib cranes at several locations

in the maintenance area; use of natural drafts for

maintenance area ventilation; material handling facilities;

use of electronic work orders; use of color coding to

segregate preventive maintenance and emergency work

orders; use of remanufactured components as substituents.

Commitment to enforce regulations/standards; waste

treatment policy; auditing the impact of maintenance

activities on environment; availability of skilled technicians;

adequate training and motivation; consistent communication

on sustainable maintenance practices; computers in

inventory management; recycling policy.

requirements. Design for disassembly has been used as one of the

strategy for reducing environmental impact of product and disassembly is increasingly important in most industries due to significant increase in the quantity of used products being repaired or

serviced. Ease of disassembly enhances the serviceability and helps

in energy saving. For example, identification of optimum disassembly sequence reduces the total time of disassembly and

number of parts discarded into the environment, as otherwise

improper disassembly techniques damages the components to be

repaired, thereby increasing scrap rate. With advancement in

manufacturing technologies, complex products with miniaturized

components are introduced, which makes disassembly complicated; consuming greater amount of time and resources. In this

context, disassemblability of equipment assumes great significance

for products which are to be serviced frequently.

The selection of materials is also significant in reducing the

environmental load. For example, bio-degradable components and

components with self-lubricating properties enhance green design.

Materials with high recoverability rate, which are safe, reliable and

environmentally friendly, should be used. Efforts are on to have a

lower coefficient of friction and thereby lower energy consumption,

through the use of biomimetic materials and appropriate surface

morphological techniques. Incorporation of the mentioned design

features during the design stage has tremendous influence in

achieving green maintenance.

2.3.3. Plant design and layout

Plant layout and design is significant in reducing the overall

energy requirements during maintenance. Features like use of

overhead cranes will assist the transfer of assemblies/subassemblies with minimum energy requirement. Proper layout

will also reduce the transportation requirement. The plant should

be designed in such a way to utilize the maximum amount of

natural lighting and use of natural drafts for maintenance area

ventilation. It should also be designed for effective flow of maintenance waste. Potential impact factors regarding health of maintenance workers should be identified. With proper design of

Accessibility; disassemblability;

simplicity; modularity; surface

coating/texturing; remanufacturing

upgradeability.

Plant layout design features; electronic

work orders.

Management commitment;

communication, training and

motivation.

equipment and layout, maintenance time can be reduced significantly resulting in considerable saving of energy.

2.3.4. Manufacturing aspects of the product

Manufacturers can no longer continue to produce products

without considering how their products are maintained during its

service life. This aspect has been recognized by researchers and

consequently, the concepts of Environmentally Responsible Manufacturing (ERM) and Environmentally Conscious Manufacturing

(ECM) have evolved over the years. The ERM is intended for the

reduction and elimination of waste streams associated with the

design, manufacture, use and disposal of products and materials

(Melnyk and Handfield, 1995), while the ECM is concerned with

developing methods for manufacturing new products from conceptual design to final delivery and ultimately to the end-of-life

(EOL) disposal such that the environmental standards and

requirements are satisfied (Gungor and Gupta, 1999). During repair,

proper care has to be taken to segregate those components that can

be recycled. The recycled materials can again be used for manufacturing and this will reduce the requirement of fresh inventory.

Use of environmentally relevant materials also enhances green

options under maintenance. Compatibility of materials used is

another aspect, which needs to be considered much before manufacturing the equipment. The energy requirement for disassembly/assembly depends on the compatibility of mating

materials. All these point to the importance of manufacturing

aspects of a product in ensuring its green maintenance.

2.3.5. Maintenance practices including safety concerns

Success of green maintenance goes beyond the technical features of the equipment and is dependent on the maintenance

practices as well. Unhealthy practices followed in the maintenance

shop floor are a matter of concern for green maintenance enthusiast. Used gloves, gaskets, oil seals and filters, hoses, oil and grease

containers often creates landfill problems and should be disposed

of in approved disposal area. Degreasers, detergents and cleaning

agents resulting from cleaning should be prevented from flowing

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

into sewers, sinks, floor drains and water drainage systems. In

addition, there should be efforts at source reduction; through

housekeeping, followed by qualitative and quantitative characterization of waste streams to select appropriate treatment technology. Another aspect is to estimate the energy wastage in the

maintenance actions being carried out. Eco-friendly, readily biodegradable and non-toxic fluids are being regularly introduced into

the market. Along with this, life time lubrication or use of long life

lubricants will also go a long way in protecting the environment.

Following an effective environment-friendly preventive maintenance routine is a positive step toward the objective.

Green maintenance also has the responsibility of keeping the

work environment safe and reliable. Each repair step has to be

performed in a safe way, with appropriate protection of maintenance workers and others present in the workplace. Inadequate

and ill-timed maintenance may contribute to large-scale disasters,

with damaging consequences to human and environment.

Eco-friendly maintenance has the potential to reduce the

resource consumed during repair, but it may not change the condition of product retiring from the market because of technology

renovation (Sheng and Jukun, 2007). This results in discarding so

many technically obsolete components into the environment.

Remanufacturing is an effective way to reduce the environmental

impacts by upgrading the performance and in value recovery to

prolong product life. Remanufacturing is defined as manufacturing

process of recycling a machine or part by disassembling and

cleaning to a predetermined standard with defective components

being replaced by new, or reprocessed components (Berko-Boateng

et al., 1993). In remanufacturing, the products are completely disassembled and some parts are machined to like-new condition,

which sometimes include cosmetic operations (Ilgin and Gupta,

2010). With remanufacture, the performance of a system can be

upgraded in restoring value and therefore, remanufacturing capability should be considered as an essential step toward reducing the

negative environmental effect owing to technological obsolescence.

2.3.6. Management support

The recent standards of ISO-14040 (2006) have made it mandatory for manufacturers to carry out environmental implications

of their product at all stages of its life cycle to reduce environmental

hazards created due to solid waste and disposal, as well as on

methods to recycle the products. It also suggests the methods to be

adopted at the design stage for designing eco-friendly products.

Based on these, organizations are establishing policies concerning

the environmental impact in the matters of product design and on

maintenance activities to accommodate the green maintenance

concerns. In addition to these, integration is required in matters of

management commitment, employee empowerment, rewards,

feedback and review, and environmental performance. Management should be committed, in general, in implementing the environmental standards, involving employees in policy making,

communicating with them the environmental targets and imparting them proper training and education. They should define and

communicate with the staff, the policies and procedures that

develop a green culture toward waste reduction during maintenance. In addition, they should also monitor performance, carry

out environmental audit and take appropriate corrective actions

based on environmental efficiency. The organization should also

have a structure in place to enhance the reduction of waste generated during repair. Dismantled and discarded components should

be collected, classified, and stored and there should be a proper

mechanism to dispose the waste, keeping the plant environment

safe from environmental disaster. This is crucial in the current

scenario, where maintenance is to be completed in shorter downtime and with optimum use of resources.

39

3. Proposed integrated methodology of AHP, graph theory

and TOPSIS

The selection of an optimal design from green maintenance point

of view among a set of alternatives on the basis of environmentally

conscious attributes is a multiple attribute decision-making

(MADM) problem. Numerous techniques for MADM are in use like

AHP, TOPSIS, SAW and ELECTRE. Of these methods, TOPSIS and AHP

are the widely used decision-making methods. AHP is a decision

support procedure developed by Saaty (1994) for dealing with

complex, unstructured and multiple-criteria decisions. AHP is used

to arrive at a consensus decision in situations involving several

decision makers with different conflicting objectives and helps to

systematically compare and determine the priorities of the criteria

and sub-criteria (Tam and Tummala, 2001). The model enables the

problem to be structured in a hierarchical manner in terms of criteria and sub-criteria. Hwang and Yoon (1981) developed TOPSIS to

assess the alternatives, considering how far is each alternative from

ideal and negative ideal solution, and selecting the closest, relative

to the ideal solution as the best alternative.

In the literature, there are numerous applications of integrated

AHP-TOPSIS, which have been used for variety of analysis like; optimum maintenance strategy in textile industry (Shyjith et al., 2008),

evaluation of hazardous waste transportation firms (Gumus, 2009),

performance evaluation of Turkish cement firms (Ertugrul and

Karakasoglu, 2009), machine tool selection (Yurdakul and Tansel,

2009) weapon selection (Dagdeviren et al., 2009), customer-driven

product design process (Lin et al., 2008), aero-engine health assessment (Wang et al., 2010), operating system selection (Balli and

lu, 2009) and selection of environmentally conscious manuKorukog

facturing program (Sutapa and Panjaintan, 2011). In this work, an

integrated methodology of AHP, graph theory and TOPSIS has been

proposed with the objective of ranking design alternatives. AHP prioritizes the identified green maintenance requirements. Digraph

approach is used to establish the interrelationships among the identified design characteristics. TOPSIS evaluates design alternatives

based on environmental compatibility. Three major steps of the proposed integrated methodology are shown in Fig. 5.

The three steps (Fig. 5) are developed as follows:

Step 1 e Prioritization of green maintenance requirements

1.1 Consider a product/system which is to be designed and maintained with green maintenance perspective as the main objective.

1.2 Identify the green maintenance requirements for the system to

have eco-friendly maintenance.

1.3 Use AHP to evaluate the priority measure of green maintenance

requirements. The implementation procedure is described

stepwise as under.

1.3.1 Conduct the pair-wise comparisons of green maintainability

requirements by using the relative scale measurement shown in

Table 2 (Saaty, 1980). A total number of n(n 1)/2 pair-wise

comparisons is to be evaluated with n green maintainability

requirements. Let A represent an n n pair-wise comparison

matrix.

2

1

6 a21

6

A ¼ 6

6 /

4 /

an1

a12

1

/

/

an2

/

/

/

/

/

/

/

/

/

/

3

a1n

a2n 7

7

/ 7

7

/ 5

1

(2)

The matrix element aij (i, j ¼ 1, 2, ., n), represents the relative preference of the ith requirement over jth requirement.

The diagonal elements in the matrix A, are self-compared to

the green maintainability requirements, and thus aij ¼ 1. The

40

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

with i, j ¼ 1, 2, ., n.

1.3.3 This matrix is checked for consistency to ensure that the pairwise judgment is reasonable and acceptable. Let C denote an

n-dimensional column vector describing the sum of the

weighted values for the importance degree of the requirements, then

C ¼ [Ci]n 1 ¼ AWT, i ¼ 1, 2, ., n where;

Step 1

System considered for green maintenance

Identification of green maintenance requirements

Prioritization of green maintenance requirements

AHP

2

AW T

Identification of design characteristics facilitating

green maintenance

Graph theory

Step 2

Establish relationships between design

characteristics

Normalization

procedure

lmax ¼

Step 3

Obtain rating of design alternatives based on green

maintenance requirements using linguistic variables

TOPSIS

CI ¼

Ranking of design alternatives

Fig. 5. Roadmap of the methodology as illustrated in the paper.

values of off diagonal elements represent the strength of the

relative importance degree of the ith requirement compared

to the jth requirement. The relative importance of jth

requirement over ith requirement is given by, aji ¼ 1/aij,

where aij > 0, i s j.

1.3.2 The normalization of the geometric mean method is used to

determine the priority measure of the considered green

maintenance requirements. The priority weight, Wi, of the ith

requirement is given by

Wi ¼

11

n

aij A

j¼1

Pn

n

Y

i¼1

(3)

11

n

aij A

j¼1

Table 2

Numerical scale of relative judgment (aij) (Saaty, 1980).

Ratings

Judgment/preference

9

Extremely preferred

7

Very strongly preferred

5

Strongly preferred

3

Moderately preferred

1

Equally preferred

2, 4, 6 and 8 are used as intermittent values

3

a1n

a2n 7

7½ W

/ 5 1

1

/

/

Wn (4)

Pn

i¼1

cvi

(5)

n

With lmax value, a consistency index (CI) is estimated by

Calculate negative and positive ideal solutions and

separation measures

n

Y

/

/

/

/

The consistency values for the requirements are represented

by the vector V ¼ [cvi]1 x n with a typical element cvi defined

as cvi ¼ ci/Wi (i ¼ 1, 2, ., n). However, to avoid inconsistency

in the pair-wise comparison matrix, Saaty (1980) suggested

the use of the maximum eigenvalue, lmax, which can be

determined as

Establish relationship between green maintenance

requirements and design characteristics

Develop relative weightage of design characteristics

with respect to the requirements

1 a12

6 a21

1

¼ 6

4 /

/

an1 an2

2 3

c1

6/7

7

¼ 6

4/5

cn

lmax n

(6)

n1

If CI ¼ 0, the evaluation for the pair-wise comparison matrix

is implied to be perfectly consistent. The closer the maximum eigenvalue lmax is to n, the more consistent is the

evaluation. Judgment consistency is checked by the consistency ratio (CR), given by CR ¼ CI/RI, where RI is the random consistency index for matrices of size n, shown in

Table 3 (proposed by Saaty, 1980). This consistency checking

is important as it is normal that no two individuals may make

the same decision regarding comparison values. The pairwise comparison matrix is acceptable, if CR does not

exceed a value of 0.10. If it is more, the judgment matrix is

inconsistent and judgments should be retrieved and

improved to obtain a consistent matrix.

Step 2 e Relative weights of design characteristics

2.1 Identify the design characteristics which help in fulfilling the

green maintenance requirements.

2.2 Establish the relationships among the design characteristics.

This is required as the design characteristics critical in effecting

green maintenance are interlinked. Their interactions and

interrelationships can be easily represented through digraph.

This digraph consists of set of nodes N ¼ {ni}, with i ¼ 1, 2, ., M

and a set of directed edges E ¼ {eij}, where nodes represent the

design characteristics and the directed edges represent the way

in which they are linked to each other. For example, if design

characteristic represented by node ‘n1’ influence the design

characteristic represented by node ‘n2’, then a directed edge is

drawn from node ‘n1’ to node ‘n2’. In case, if both the features

are related to each other, then directed edges are drawn toward

Table 3

Average random consistency values (RI) (Saaty, 1980).

Size of matrix

Random consistency

1

0

2

0

3

0.58

4

0.9

5

1.12

6

1.24

7

1.32

8

1.41

9

1.45

10

1.49

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

each other. The digraph can be easily converted to matrix form

for mathematical processing (Jurkat and Ryser, 1966). The

strength of these interrelations can also be quantitatively

estimated using appropriate numerical scale.

2.3 Establish the relationships between green maintainability

requirements and design characteristics and prioritize the

design characteristics using a normalization procedure. The

interaction relationships between green maintainability

requirements and design characteristics provide designers

with an efficient means of designing systems with minimum

environmental impact during maintenance. Design characteristics are assessed based on the information regarding the

priority weights of green maintenance requirements, the

relationships between green maintenance requirements and

design characteristics, and the interrelationships among the

design characteristics. The normalized values show the correlation of the requirements with the design characteristics. Let

Qij denote the set of quantified relationship values between the

ith green maintenance requirements and the jth design characteristics. Normalization procedure as explained by

Wasserman (1993), is done as per Eq. (7).

Pm

k ¼ 1 Rik Ckj

Pm

i¼1

k ¼ 1 Rik Ckj

Qij ¼ Pn

(7)

where Ri,k denotes the relational coefficient corresponding to

the inter-dependency relationship between the ith maintenance requirement, i ¼ 1,2, ., n, and the kth design characteristics, k ¼ 1, 2, ., m, Ck,j denotes the value

corresponding to the closeness relationship between the kth

and jth design characteristics, k, j ¼ 1, 2, ., m. The weights

determined through Q, represent the importance of green

maintenance requirements to each design characteristics.

This is interpreted as the degree of attention that a designer

must reserve for each technical design characteristic while

developing the product. The design parameters having the

highest numerical values assume great significance in

determining the outcome of green maintenance. In this way,

the critical design parameters to be incorporated at the

design stage can be identified.

2.4 Develop the relative weightage of design characteristics. The

relative importance degrees of design characteristics for any

factor j can then be determined as

Xj ¼

n

X

Wi Qij

(8)

i¼1

The larger the value of X, the greater is the impact of design

characteristics on the environmental impact. The results of the

degrees of relative importance of design characteristics indicate

that the membership function of design characteristics, D, can

~ ¼ fX =D g, j ¼ 1,2, ., m, where Dj represents the

be written as D

j

j

jth design characteristic associated with a product.Step 3 e

Ranking of design alternatives.

The selection of competent design alternative is a complex job

and TOPSIS method based on the principles of multiple-criteria

decision making (MCDM) is employed. For this, the conceptual

design alternatives based on the identified relationships

between green maintenance requirements and design alternatives are to be rated. The rating is assigned using linguistic

variables to assess the design alternatives against all green

maintenance requirements. This is essential as performance

may not be precisely assessed, as unquantifiable and incomplete

information are more often involved. The linguistic variables

41

and their membership functions enable decision makers to deal

with uncertain, qualitative, and non-numerical judgments.

The decision matrix is shown in Table 4. It shows the alternatives, DAr (for r ¼ 1, 2, ., s), green maintenance requirements, Ri

(for i ¼ 1, 2, ., n), and the measures of performance of alternatives,

kri (for r ¼ 1, 2, ., s; i ¼ 1, 2, ., n).

In order to rate the performance of design alternatives against

all the green maintenance requirements, the linguistic variables are

defined. The membership functions express the degrees of membership of the corresponding linguistic variables. Chen and Hwang

(1992) proposed a numerical approximation system to systematically convert linguistic terms to their corresponding fuzzy numbers.

Based on this, Rao (2008) and Venkataswamy and Agrawal (1997),

used similar approach with an eleven point scale as shown in

Table 5.

The development steps of the TOPSIS method in ranking design

alternatives are explained as follows:

3.1 Establish a normalized decision matrix. Let U denote a normalized decision matrix representing the relative performance

of the generated design alternatives, with typical element Uri.

kri

Uri ¼ qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

Ps

2

r ¼ 1 kri

(9)

3.2 Calculate the weighted decision matrix. Let V denote a weighted decision matrix, then V ¼ {bri, i ¼ 1,2, ., n; r ¼ 1, 2, ., s},

bri ¼ Wi Uri

(10)

Wi is the importance degree for the ith green maintenance

requirement.

3.3 Determine the positive ideal solution (Sþ) and the negative

ideal solution (S) according to the weighted decision matrix.

The ideal solution is the best practical solution or it is made of

all the best performance scores. The Sþ and S are defined as

Sþ ¼ fðmax bri ; iεJÞorðmin bri ; iεJ 0 Þ; r ¼ 1; 2; .; sg

þ

þ

¼ bþ

1 ; b2 ; .; bn

(11)

S ¼ fðmax bri ; iεJÞorðmin bri ; iεJ 0 Þ; r ¼ 1; 2; .; sg

¼ b

1 ; b2 ; .; bn

(12)

where J ¼ {i ¼ 1,2, ., n and i is associated with the beneficial

requirements of bri}, and J0 ¼ {i ¼ 1, 2, ., n and i is associated

with non-beneficial requirements of bri}. Beneficial requirements are the one whose higher values are preferred for a given

application and non-beneficial requirements are the one whose

lower values are preferred.

Table 4

Decision matrix.

Alternatives

Green maintenance requirements

R1

R2

.

.

Rn

DA1

DA2

.

.

DAs

k11

k21

.

.

ks1

k12

k22

.

.

ks2

.

.

.

.

.

.

.

.

.

.

k1n

k2n

.

.

ksn

42

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

Table 5

Value of green maintenance requirements.

Qualitative measure of fulfillment

of green maintenance requirements

Assigned

values (kri)

Exceptionally low

Extremely low

Very low

Low

Below average

Average

Above average

High

Very high

Extremely high

Exceptionally high

0.045

0.135

0.255

0.335

0.410

0.500

0.590

0.665

0.745

0.865

0.955

Ir ¼

vffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

u n 2

uX

bri bþ

¼ t

i

; r ¼ 1; 2; .; s:

(13)

vffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

u n 2

uX

¼ t

bri b

i

; r ¼ 1; 2; .; s:

(14)

i¼1

bþ

r

i¼1

b

r

bþ

r þ br

; r ¼ 1; 2; .; s and 0 Ir 1:

(15)

3.6 Rank the preference order of competitive design alternatives

according to their relative closeness to the ideal solution. The

greater value of relative closeness represents a higher ranking

order among competitive design alternatives and will be

chosen as a recommended design alternative.

3.4 Measure the separation distance of each competitive design

alternative from the Sþ and the S. The distance of the considered design from ideal and non-ideal solution is considered

as a measure of similarity of this design to ideal and non-ideal

solution. A Euclidean distance method is used in this research.

Let bþ

r and br represent the distance of the ith design alternative from the Sþ and S, respectively.

bþ

r

3.5 Calculate the relative closeness or similarity degree to the ideal

solution for each design alternative. Let I denote an s-dimensional column vector describing the coefficient of relative

closeness to the ideal solution for competitive design alternatives, with typical element,

4. Demonstration of the methodology

An example of automotive valve operating mechanism is considered for illustrating the methodology. Valves, valve seats, valve

guides, and other accessories do require continuous monitoring

and upkeep, as their life is comparatively shorter than the overall

life of the engines and some other parts of the automobile that

require early replacement, which in turn may cause additional

burden on the environment. Three design alternatives of a valve

driving system considered as shown in Fig. 6 are: (a) overhead valve

arrangement, (b) overhead camshaft operated by twin-rockers

(rockers are set up on each side of the cam to operate inlet and

exhaust valve), and (c) overhead camshaft with direct acting valves.

In overhead valve arrangement, the intake and exhaust valves are

Fig. 6. Three alternatives of valve operating mechanism.

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

located in the cylinder head, while the camshaft and lifters are

located in the engine block. Valve train components of this design

include lifters, pushrods, and rocker arms. In the overhead camshaft operated valve trains, the intake and exhaust valves are

located in the cylinder head along with the camshaft. The valves are

operated directly by the camshaft and follower, thereby eliminating

many of the moving parts required in the overhead valve engine.

Maintenance/repair work carried out, in general, in the valve

operating mechanism is checking of the valve lash (clearance

between the rocker arm and the tip of the valve stem when the

valve is fully closed). This clearance is desired to accommodate the

expansion of components in the valve train, as these heats up from

engine normal running. In addition, the valve mechanism is

repaired for other problems like sticking valves, bent valves, worn

or scored parts of valve train and excessive damage/cutting of

valves and valve seats. All these likely problems contribute to

excessive oil consumption, compression leak and valve train noise.

Maintenance procedures involved use of solvents, lubricants,

cleaning agents and procedures/resources to upgrade the performance or to conduct repair.

The maintenance of valve trains involves mainly servicing of

valves, valve guides and valve seats. These tasks further necessitate

cleaning, refacing or grinding valves, refacing valve stem tips,

replacement of worn out parts, valve spring inspection, etc. Based

on the discussion in Section 2, the green maintenance requirements

for the valve operating mechanism are identified, which are grouped under five generic requirements as under:

Leakage prevention to prevent soil and water contamination

(R1)

Minimum landfill problems (R2)

Maximum use of degradable, and less eco-toxic lubricants and

cleaning agents (R3)

Upgradation of performance during repair (R4)

Minimum energy and resource consumption, and maximum

time efficiency (R5)

These green maintenance requirements are prioritized to

identify the more important of requirements from the less significant ones using the AHP approach explained in step 1.3, Section

3. Matrix, Eq. (16), shows the pair-wise comparison matrix, where

the requirements are compared against each other on a numerical

scale (Table 2) according to relative importance. Refer sub-step 1.3.1

of Section 3 for details.

2

1

61

6

A ¼ 6

63

42

5

1

1

2

2

3

1=3

1=2

1

1=3

4

1=2

1=2

3

1

3

43

comparison matrix is checked for its consistency based on procedure mentioned in sub-step 1.3.3. The consistency ratio obtained is

0.0586, which is less than the acceptable standard of 0.10. Therefore, the consistency matrix is acceptable with the priority weights

valid and consistent.

The objective of reduced negative environmental impact cannot

be materialized unless the designers are responsive toward the

green maintenance requirements. It is expected that they will

properly map the requirements with the design characteristics and

bridge the gap. These design characteristics are intended to represent features of the design directly controllable by the designers

or practicing engineers. The design characteristics, which help in

fulfilling the above mentioned requirements have been identified

in the next step (i.e. step 2.1, Section 3). The identified design

characteristics are: Design of joints and seals (D1), Ease of access to

parts and assemblies (D2), Reduced material diversity (D3), Long life

bio-degradable oils (D4), Reliable and durable materials and

materials with tribo-compatibility (D5), Diagnosability (D6), Simplicity in design (D7), Surface coating/texturing (D8) and Ease of

disassembly/assembly (D9).

These design characteristics (D1eD9) are interlinked or interdependent, i.e. one design characteristic has got the influence on

the others. The interrelationship digraph (Fig. 7) has been developed as per step 2.2, Section 3 and it shows the interrelationships

among the nine design characteristics. The strength of the interrelationships is assessed on a scale of 1, 3 and 5 (linear interval scale

e Franceschini and Rupil, 1999), which represents weak, medium

and strong interactions respectively. Table 7 shows all such interactive characteristics quantified on the chosen scale.

It is desirable to see the role of design characteristics in meeting

the green maintenance requirements, which will help to reduce the

negative environmental effect. Therefore, the relationships

between the design characteristics and the requirements must be

established. The effect of the identified design characteristics in

meeting the requirements has been quantified using the earlier

adopted scale of 1, 3 and 5, where 1 represents weak influence, 3

medium and 5 strong influences respectively. Table 8 shows the

influence characteristics matrix.

Normalization procedure is applied to values shown in influence

characteristics matrix as explained in step 2.3, Section 3. Table 9

shows result of the normalization.

D8

D9

3

1=5

1=3 7

7

1=4 7

7

1=3 5

1

(16)

D1

D7

The weightages for the five identified requirements are evaluated based on Eq. (3) and are shown in the last column of Table 6.

Refer sub-step 1.3.2 of Section 3 for the details. The pair-wise

Table 6

Requirements and their weightage.

D2

S.No.

Requirement list

Weightage

1

Leakage prevention to prevent soil and

water contamination

Landfill problems

Degradable and less eco-toxic lubricants

and cleaning agents

Upgrading performance during repair

Minimum energy and resource consumption

and maximum time efficiency

0.0778

2

3

4

5

D6

D3

D5

0.0960

0.2263

D4

0.1361

0.4638

Fig. 7. Interrelationship digraph.

44

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

Table 7

Design dependence matrix (Cik values in Eq. (7)).

D1

D2

D3

D4

D5

D6

D7

D8

D9

D1

D2

D3

D4

D5

D6

D7

D8

D9

0

0

0

0

1

0

0

0

0

1

0

0

0

0

0

3

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

1

0

1

3

0

0

0

0

3

0

5

1

0

1

0

0

0

0

0

0

0

1

0

1

0

0

1

0

0

3

5

3

0

0

0

5

0

0

Table 8

Influence characteristics matrix (Rik values in Eq. (7)).

R1

R2

R3

R4

R5

2

0:335

P ¼ 4 0:590

0:500

D1

D2

D3

D4

D5

D6

D7

D8

D9

5

0

0

0

3

0

1

0

3

3

0

3

0

1

3

5

1

3

1

1

0

3

0

1

1

0

1

0

1

3

3

3

0

3

5

0

0

0

3

1

0

1

0

5

5

0:3975

U ¼ 4 0:7000

0:5933

0:590

0:590

0:665

0:500

0:335

0:590

3

0:255

0:335 5

0:500

(17)

0:5355

0:5355

0:6531

0:5530

0:5530

0:6232

0:5933

0:3975

0:7000

3

0:3901

0:5125 5

0:7650

(18)

The weighted normalized decision matrix, V, is also established

by multiplying the normalized decision matrix by its associated

weights. This is as per Eq. (10), step 3.2, Section 3.

2

Determination of the relative importance measures of design

characteristics (X) is based on the priority weights of green maintenance requirements, and the normalized correlation coefficients

between green maintenance requirements and design characteristics. The relative importance degree of a design characteristic

represents the influence of that design characteristic in satisfying

the green maintenance requirement. The value of X for each of the

design characteristics D1, D2, ., D9 is obtained based on Eq. (8)

(Refer step 2.4, Section 3) and these are 0.0032, 0.0568, 0.0032,

0.0032, 0.0032, 0.1641, 0.0189, 0.0284 and 0.1830, respectively.

Here, Ease of Disassembly/Assembly, (D9), is having the highest

relative importance measure. A larger the value of X indicates a

greater impact of the design characteristics on the environmental

load. This relative importance measure is a significant parameter

for the designer in taking effective steps to reduce negative environmental effect.

In a design environment, various design alternatives can be

developed that meet the functional needs and the designer will

select the best design alternative. Here, the objective is to select the

design alternative, which will leave minimum negative environmental impact during maintenance. Therefore, the design alternatives are evaluated based on their performance with respect to

the green maintenance requirements. Decision matrix is prepared

as a first step in this regard. The structure of the decision matrix is

as follows and is based on Table 4.

DAr represents the design alternatives, with r ¼ 1, 2 and 3

(Fig. 6(a)e(c)); Ri represents the ith green maintenance requirements, i ¼ 1e5, related to rth alternative. The numerical values

represent the performance rating of each alternative DAr with

respect to each green maintenance requirement. The numerical

0:410

0:410

0:500

The TOPSIS method is applied to evaluate the three design

alternatives. The normalized decision matrix, U, is established using

Eq. (9), given in step 3.1, Section 3 and the resultant matrix is shown

as Eq. (18).

2

Design characteristics

Green maintenance

requirements

values are assigned as per linguistic qualitative measure, Table 5.

The use of linguistic variable makes the evaluation process more

realistic and has been implemented by various researchers (Rao,

2006; Rao and Davim, 2008). The developed decision matrix, P, is

shown as matrix, Eq. (17).

0:0309

V ¼ 4 0:0545

0:0462

0:0514

0:0514

0:0627

0:1251

0:1251

0:1410

0:0807

0:0541

0:0953

3

0:1809

0:2377 5

0:3548

(19)

Based on the results of V, the positive ideal solution is obtained

as {0.0545, 0.0627, 0.1410, 0.0953 and 0.3548}; while negative ideal

solution is obtained as {0.0309, 0.0514, 0.1251, 0.0541 and 0.1809}.

Refer Eqs. (11) and (12) in step 3.2, Section 3 for the details. The

separation distance measures, bþ

r and br , of each design alternative

from the positive and negative ideal solutions are respectively

(0.1772, 0.1257, 0.0083) and (0.0266, 0.0615, 0.1804). These are

based on Eqs. (13) and (14) respectively, as explained in step 3.4,

Section 3. The relative closeness, Ir, for each design alternative to

the ideal solution is also determined using Eq. (15), step 3.5, Section

3, which is: (0.1305, 0.3285, 0.9560). The evaluation of green

maintenance characteristics of the design alternatives is done

based on the relative closeness values. The ranking of the alternatives are DA3eDA2eDA1, from most preferable to the least. If the

best one is needed to be selected, then the alternative DA3 must be

chosen because of having the highest Ir value.

The proposed approach is capable of helping designers to systematically consider relevant eco-friendly design information and

effectively determine the key objectives and optimum conceptual

alternatives. It takes into consideration, the design characteristics,

their interrelationships and attempts to map the green maintenance requirements with the relevant design features. The procedure further evaluates and identifies the design characteristics

that are critical to a specific set of green maintenance requirements.

The overall relationships of green maintenance requirements to all

design characteristics were compared and ranked to determine the

most suitable set of design characteristics for a recommended

design alternative. In this way, the adopted procedure helps in

Table 9

Normalized influence characteristics matrix (NVij values).

Requirements

R1

R2

R3

R4

R5

Design characteristics

D1

D2

D3

D4

D5

D6

D7

D8

D9

0

0.0435

0

0.0099

0.0068

0.1972

0.1304

0

0.0891

0.1224

0

0.0435

0

0.0099

0.0068

0

0

0.2381

0.0197

0.0065

0

0

0.2381

0.0197

0.0065

0.1972

0.2464

0

0.4257

0.3537

0.0704

0.0435

0

0.0099

0.0408

0.1127

0.0725

1

0.0693

0.0612

0.4225

0.4203

0

0.3267

0.3946

V.N. Ajukumar, O.P. Gandhi / Journal of Cleaner Production 51 (2013) 34e46

identifying the critical design parameters which are relevant in

minimizing the negative environmental impact and it is quite

practical to implement at the design stage. But, it is to be noted that

all features essential to have an effective green maintenance cannot

be incorporated at the design stage, as design is mostly a trade-off

between various design options under a constrained environment.

Therefore, a comprehensive approach is desirable considering the

operational aspects of maintenance including the maintenance

strategies adopted, waste treatment/disposal policies, energy utilization/wastage in repair steps and other organizational practices.

5. Conclusions

In this work, an integrated approach involving; AHP, graph

theory and TOPSIS, is applied to evaluate a set of suitable design

alternatives of a mechanical system for a specific set of requirements with green maintenance as an objective. The evaluation

outcome helps in choosing a more suitable design alternative for a

specific set of green maintenance requirements with minimal

environmental impact and helps in assessing the level to which

green maintenance aspects are incorporated in the design. It also

shows how the green maintenance requirements can be taken care

of by prioritizing the design characteristics and focusing attention

on these. This paper emphasizes that the strategy for a product

design should not be centered only on functionality, but should also

take into account important issue such as environmental compatibility during maintenance. But it is difficult to integrate all factors

in a design model as holistic approach is preferred in design and not

to focus on any one aspect, be it, design for maintainability, design

for environment or any other DFX parameter. Therefore, it is necessary during maintenance that certain checklists or environmental

guidelines be followed. In this way, the green maintenance enabled

design and operations can bring considerable reductions in energy

consumption and waste generation during maintenance, which

will help in the development of sustainable products and enable

the future generation to survive and prosper.

References

Anand, A., Wani, M.F., 2010. Product life-cycle modelling and evaluation at the

conceptual design stage: a digraph and matrix approach. Transactions of the

ASME, Journal of Mechanical Design 132, 091010e091019.

Babi

c, M., 2001. Nature of tribology e maintenance relation. Tribology in Industry

23 (1,2), 21e27.

lu, S., 2009. Operating system selection using fuzzy AHP and TOPSIS

Balli, S., Korukog

methods. Mathematical and Computational Applications 14 (2), 119e130.

Berko-Boateng, V.B., Azar, J., DeJong, E., Yander, G.A., 1993. Asset recycle management e a total approach to product design for the environment. In: International Symposium on Electronics and the Environment. IEEE, Arlington, VA,

pp. 19e31.

Bronshteyn, L.A., Kreiner, J.H., 1999. Energy efficiency of industrial oils. Tribology

Transactions 42 (4), 771e776.

Chen, S.J., Hwang, C.L., 1992. Fuzzy Multiple Attribute Decision Making: Methods

and Applications. In: Lecture Notes in Economics and Mathematical Systems.

Springer-Verlag, Berlin.

Dagdeviren, M., Yavuz, S., Kılınç, N., 2009. Weapon selection using the AHP and

TOPSIS methods under fuzzy environment. Expert Systems with Applications

36 (4), 8143e8151.

Ertugrul, I., Karakasoglu, N., 2009. Performance evaluation of Turkish cement firms

with fuzzy analytic hierarchy process and TOPSIS methods. Expert Systems

with Applications 36 (1), 702e715.

Franceschini, F., Rupil, A., 1999. Rating scale and prioritization in QFD. International

Journal of Quality and Reliability Management 16 (1), 85e97.

Fukushige, S., Yamamoto, K., Umeda, Y., 2012. Lifecycle scenario design for product

end-of-life strategy. Journal of Remanufacturing 2 (1), 1e15.

Gumus, A.T., 2009. Evaluation of hazardous waste transportation firms by using a

step fuzzy AHP and TOPSIS methodology. Expert Systems with Applications 36

(2), 4067e4074.

Gungor, A., Gupta, S.M., 1999. Issues in environmentally conscious manufacturing

and product recovery: a survey. Computers and Industrial Engineering 36 (4),

811e853.

Holmberg, K., 2001. Reliability aspects of tribology. Tribology International 34,

801e808.

45

Holmberg, K., Mathews, A., 2009. In: Briswe, B.J. (Ed.), Coatings tribology e properties, mechanisms, techniques and applications in surface engineeringTribology and Interface Engineering Series, second ed., vol. 56.

Hundal, M.S., 1998. Electrical Appliances: Safety and Human Considerations. Second

Nord Design 98 Seminar on Engineering Design. KTH, Stockholm, pp. 299e304.

Hwang, C.L., Yoon, K., 1981. Multiple Attribute Decision Making: Method and

Applications. Springer-Verlag, New York, NY.

Ijeoma, K., Achi, O.K., 2011. Industrial effluents and their impact on water quality of

receiving rivers in Nigeria. Journal of Applied Technology in Environmental

Sanitation 1 (1), 75e86.

Ilgin, M.A., Gupta, S.M., 2010. Environmentally conscious manufacturing and

product recovery (ECMPRO): a review of the state of the art. Journal of Environmental Management 91, 563e591.

Ishi, K., 1995. Life-cycle engineering design. Transactions of the ASME, Journal of

Mechanical Design 117, 42e47.

ISO-14040, 2006. Environment Management-life Cycle Assessment e Principles and

Framework. www.iso.org.

Jurkat, W.B., Ryser, H.J., 1966. Matrix factorization of determinants and permanents.

Journal of Algebra 3, 1e11.

Kato, K., 2011. Industrial tribology in the past and future. Tribology Online 6 (1), 1e9.

Kuo, T.C., Chang, S.H., Huang, S.H., 2006. Environmentally conscious design by using

fuzzy multi-attribute decision-making. International Journal of Advanced

Manufacturing Technology 29, 209e215.

Lea, C., 2007. Energy savings through use of advanced biodegradable lubricants.

Industrial Lubricants and Tribology 59 (3), 132e136.

Lin, M.C., Wang, C.C., Chen, M.S., Chang, C.A., 2008. Using AHP and TOPSIS

approaches in customer driven product design process. Computers in Industry

59, 17e31.

Madu, C.N., Kuei, C., Madu, I.E., 2002. A hierarchic metric approach for integration of

green issues in manufacturing: a paper recycling application. Journal of Environmental Management 64, 261e272.

Masui, K., Sakao, T., Kobayashi, M., Inaba, A., 2003. Applying quality function

deployment to environmentally conscious design. International Journal of

Quality and Reliability Management 20 (1), 90e106.

Melnyk, S.A., Handfield, R.B., 1995. Environmentally responsible manufacturing. In:

APICS Conference, Orlando, USA.

Nosonovsky, M., Bhushan, B., 2010. Green tribology: principles, research areas and

challenges. Philosophical Transactions of the Royal Society of London, Series A:

Mathematical, Physical & Engineering Sciences 368 (1929), 4677e4694.

Ramani, K., Ramanujan, D., Bernstein, W.Z., Zhao, F., Sutherland, J.W., Handwerker, C.,

Choi, J.K., Kim, H., Thurston, D., 2010. Integrated sustainable life cycle design: a

review. Transactions of the ASME, Journal of Mechanical Design 132 (9), 091004.

Rao, R.V., 2006. A material selection model using graph theory and matrix

approach. Materials Science and Engineering: A 431, 248e255.

Rao, R.V., 2008. Evaluation of environmentally conscious manufacturing programs

using multiple attribute decision making methods. Proceedings of the IMechE,

Part B: Journal of Engineering Manufacture 222, 441e451.

Rao, R.V., Davim, J.P., 2008. A decision-making framework model for material

selection using a combined multiple attribute decision-making method. International Journal of Manufacturing Technology 35, 751e760.

Saaty, T.L., 1980. Analytic Hierarchy Process. McGraw Hill, New York, NY.

Saaty, T.L., 1994. How to make a decision: the analytic hierarchy process. Interfaces

24 (6), 19e43.

Sangodoyin, A.Y., 1991. Groundwater and surface pollution by open refuse dump in

Ibadan, Nigeria. Journal of Discovery and Innovations 3 (1), 24e31.

Santos-Reyes, D.E., Lawlor-Wright, T., 2001. A design for the environment methodology to support an environmental management system. Integrated Manufacturing Systems 12 (5), 323e332.

Sasaki, S., 2010. Environmental friendly tribology (eco-tribology). Journal of

Mechanical Science and Technology 24, 67e71.

Sheng, Z., Jukun, Y., 2007. Remanufacturing Upgrade for Green Maintenance.

Remanufacturing Technology Committee of CAPE, Beijing 100072.

Shyjith, K., Ilangkumaran, M., Kumanan, S., 2008. Multi-criteria decision-making

approach to evaluate optimum maintenance strategy in textile industry. Journal of Quality in Maintenance Engineering 14 (4), 375e386.

Sutapa, I.N., Panjaintan, T.W.S., 2011. Selection of environmentally conscious manufacturing’s program using multi-criteria decision making: a case study in