Subject Code: CHE-513

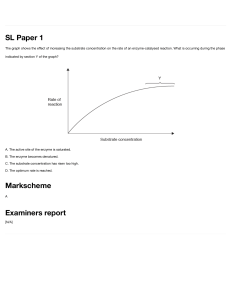

Course Title: Biochemical Engineering

Relative

Weightage

CWS 20-35

Credits: 4

MTE 20-30

ETE 40-50

Lectures: 3/week

Tutorial : 1/week

2

Course Content

S. No.

Content

1.

Introduction

2.

Microbiology

3.

Biochemistry

4.

Kinetics of Enzyme Catalysed Reactions

5.

Microbial Fermentation Kinetics

6.

Sterilization

7.

Aeration and Agitation

8.

Scale-up of Bioreactors

9.

Aerobic and Anaerobic Fermentations

10.

Downstream Processing

3

Suggested books

S. No.

Authors / Name of Book / Publisher

Year of

Publication

1.

Bailey J.E. and Olis D.F., “Biochemical Engineering

Fundamentals”,2nd Ed., McGraw-Hill.

1987

2.

Doble M. and Gummadi S.N., “Biochemical Engineering”,

Prentice Hall.

2007

3.

Schuler M.L. and Kargi F., “Bioprocess Engineering”, 2nd

Ed., Prentice Hall.

2002

4

Chapter 1

S. No.

Content

1

Introduction

1.1

History of Biochemical Engineering

1.1.1

Early Development of Biochemical Engineering

1.1.2

Renewed and Expanded Efforts on Biomass Conversion

1.2

Biochemical Engineering Fundamentals

1.3

Role of biochemical engineering in the biochemical product synthesis

1.3.1

Biochemical Engineer’s Responsibilities

1.3.2

Further Advances in Biochemical Engineering

1.4

Bioprocess Economics

1.4.1

Process Economics

1.4.2

Bioproduct Regulation

1.4.3

General Fermentation Process Economics

5

1 Introduction

Biochemical engineering, also known as bioprocess engineering, is a field

of study with roots stemming from chemical engineering and biological

engineering

Processing of biological materials and processing using biological agents

such as cells, enzymes, or antibodies are the central domains of biochemical

engineering.

Success in biochemical engineering requires integrated knowledge of

governing biological properties and principles, and of chemical engineering

methodology and strategy.

Work at the forefront captures the latest, best information and technology

from both areas and accomplishes new syntheses for bioprocess design,

operation, analysis, and optimization. Reaching this objective clearly requires

years of careful study and practice.

6

Biotechnology and biochemical engineering

Biotechnology is "the integration of natural sciences and engineering sciences in

order to achieve the application of organisms, cells, parts thereof and molecular

analogues for products and services"

Biotechnology is technology based on biology - biotechnology harnesses

cellular and biomolecular processes to develop technologies and products that help

improve our lives and the health of our planet.

Biochemical engineering, mainly deals with the design, construction, and

advancement of unit processes that involve biological organisms or organic

molecules and has various applications in areas of interest such as biofuels,

food, pharmaceuticals, biotechnology, and water treatment processes.[1][2]

The role of a biochemical engineer is to take findings developed by biologists and

chemists in a laboratory and translate that to a large-scale manufacturing process.

7

Continued…

Cells

Enzyme

Antibody

8

• Antibody, also called immunoglobulin, a protective protein produced

by the immune system in response to the presence of a foreign substance,

called an antigen. Antibodies recognize and latch onto antigens in order to

remove them from the body. A wide range of substances are regarded by

the body as antigens, including disease-causing organisms and toxic

materials such as insect venom.

• When an alien substance enters the body, the immune system is able to

recognize it as foreign because molecules on the surface of the antigen

differ from those found in the body. To eliminate the invader, the immune

system calls on a number of mechanisms, including one of the most

important—antibody production.

• Antibodies are produced by specialized white blood cells called

B lymphocytes (or B cells). When an antigen binds to the B-cell surface, it

stimulates the B cell to divide and mature into a group of identical cells

called a clone.

• The mature B cells, called plasma cells, secrete millions of antibodies into

the bloodstream and lymphatic system.

Vaccine production

Vaccine production has several stages. Process of vaccine manufacture has the

following steps:

oInactivation – This involves making of the antigen preparation

oPurification – The isolated antigen is purified

oFormulation – The purified antigen is combined with adjuvants, stabilizers and

preservatives to form the final vaccine preparation.

The initial production involves generation of the antigen from the microbe. For this the

virus or microbe is grown either on primary cells such as chicken eggs (e.g. in

influenza) or on cell lines or cultured human cells (e.g. Hepatitis A).

Bacteria against which the vaccines are developed may be grown in bioreactors (e.g.

Haemophilus influenzae type b).

The antigen may also be a toxin or toxoid from the organism (e.g. Diphtheria or

tetanus) or it may be part of the microorganism as well.

Proteins or parts from the organism can be generated in yeast, bacteria, or cell

cultures.

Bacteria or viruses may be weakened using chemicals or heat to make the vaccine

(e.g. polio vaccine).

After the antigen is generated, it is isolated from the cells used to

generate it.

For weakened or attenuated viruses no further purification may

be required.

Recombinant proteins need many operations involving

ultrafiltration and column chromatography for purification before

they are ready for administration

11

1.1 History of Biochemical Engineering

The phrase, “biochemical engineering”, first appeared in the late 1940s

and early 1950s. That was the time shortly after aerobic submerged

culture was launched as a way of increasing the production capacity of

penicillin, used to cure battle wounds of World War II (Shuler and Kargi

1992).

Commercial scale biological processing of biomass materials is an

activity as old as human civilization.

In more recent years, utilization of lignocellulosic biomass has become

an actively pursued subject, because of the concerns of future exhaustion

of non-renewable fossil fuels.

Since the energy crisis caused by the oil embargo by the OPEC countries

in 1974, there have been expanded efforts in research and development

aimed at improved conversion efficiency of lignocellulosics as an

alternative material resource. The future payoff from successful

utilization of lignocellulosics will be enormous.

12

1.1.1 Early Development of Biochemical

Engineering

Following the commercialization of penicillin, a large number of

antibiotics were also discovered from extensive screening programs by

many pharmaceutical companies worldwide in the 1950s and 1960s.

There was a strong demand for better designs of aeration systems and

deeper understanding of the process of oxygen transfer in biological

systems so that many new drugs could be manufactured efficiently.

Oxygen transfer became in those years a popular subject for biochemical

engineers to engage in.

In those years, one of the most important references in oxygen transfer is

the comprehensive review by Professor Robert Finn (1954).

13

1.1.2 Renewed and Expanded Efforts on

Biomass Conversion

Renewable biomass and coal were looked upon for possible replacement

of fuels and chemicals from petroleum.

At the time, George Tsao was on assignment at the U.S. National Science

Foundation, on leave from Iowa State University, managing several

funding programs as a part of the RANN (Research Applied to National

Needs) initiatives.

Recognizing the need for biomass research, George Tsao invited

Professor Charles R.Wilke of the University of California at Berkeley to

conduct a conference on the use of cellulose as a potential alternative

resource of fuels and chemicals.

It took place in 1974 and the proceedings of that conference were later

published as a special volume of Biotechnology and Bioengineering

(Wilke 1975).

14

Continued…

That conference served an important function in stimulating renewed

interest in the conversion of biomass into fuels and chemicals. In 1978,

the first of a series of conferences on Biotechnology for Fuels and

Chemicals was organized by researchers of the Oak Ridge National

Laboratory, Oak Ridge, Tennessee, under the leadership of Dr. Charles D.

Scott. Later, researchers of the National Renewable Energy Laboratory,

Golden, Colorado also joined the effort and this series of conferences has

been held annually ever since.

15

1.2 Biochemical Engineering Fundamentals

Biology is amazing at transforming one

chemical to another, Biochemical Engineering

is the harnessing of this process to make

products on an industrial scale.

One of the earliest examples was brewing

where

humankind took grain and water and

used yeast to change it into beer.

Over the last hundred years the challenge has

been translating discoveries into processes,

such as taking an exciting discovery like

antibiotics and finding a way to manufacture

them on a large scale. Without a viable way of

making antibiotics quickly, safely and cheaply

they would never have saved as many lives as

they have.

16

Continued…

Biochemical engineering involves the use of a catalyst, either an enzyme

or whole cell, which is either freely suspended in an aqueous medium or

“immobilized” in a gel or attached to a solid surface.

In contrast to an enzyme, whose activity decreases over time, cells are

autocatalytic (dx/dt = μx, where x = cell concentration and μ = growth

rate, t–1) and can grow exponentially with excess nutrients.

17

1.3 Role of Biochemical Engineering in the

Biochemical Product Synthesis

Biochemical engineering is concerned with conducting biological

processes on an industrial scale. This area links biological sciences

with chemical engineering. The role of biochemical engineers has

become more important in recent years due to the dramatic

developments of biotechnology.

We need to design an effective bioreactor to cultivate the cells in the

most optimum conditions. Therefore, biochemical engineering is one

of the major areas in biotechnology important to its

commercialization.

Biochemical engineers research and develop processes to use

microbial organisms and enzyme systems for manufacturing

chemical products. It is necessary to have advanced knowledge of

biochemistry, microbiology and chemical engineering to work in this

field. By understanding the exact duties of biochemical engineers.

18

Continued…

Figure 1.1: To illustrate the role of a biochemical engineer, let's look at a typical

biological process (bioprocess) involving microbial cells as shown.

19

Continued…

To carry out a bioprocess on a large scale, biochemical engineers need to

work together with biological scientists:

1. To obtain the best biological catalyst (microorganism, animal cell,

plant cell, or enzyme) for a desired process.

2. To create the best possible environment for the catalyst to perform by

designing the bioreactor and operating it in the most efficient way.

3. To separate the desired products from the reaction mixture in the most

economical way.

20

Continued…

Biochemical engineers follow strict safety protocols since they work with

potentially dangerous chemicals, materials and equipment. They may

assist with creating safety regulations to ensure product manufacturing

safety. Some of the places that employ biochemical engineers are:

o Hospitals

o Aerospace companies

o Research centres

o Chemical companies

o Universities

o Petrochemical engineering

companies

o Textile companies

o Medical instrumentation

companies

o Food companies

o Mining companies

o Paper companies

o Oil and natural gas companies

o Plastics companies

o Pharmaceutical companies

21

1.3.1 Biochemical Engineer’s Responsibilities

The work responsibilities of biochemical engineers can vary by the industry

they work in and their experience level and skills. Some of the typical duties

include the following:

Researching interactions of biological materials in different environments

and ways to inhibit or promote their growth.

Predicting material interaction results by using computer simulation and

statistical models and replicating the results in the laboratory.

Studying cells, proteins, enzymes and other biological materials and

using them to build compounds for public consumption.

Preparing, overseeing, directing and recording laboratory experiments

and writing technical reports on research findings.

Training staff and providing technical support in the use of biomedical

equipment and evaluating its safety and effectiveness.

22

Continued…

Working in collaboration with biologists, chemists, research staff and

manufacturing personnel to develop new products and technologies.

Designing equipment with computer-aided design (CAD) software,

developing production processes and preparing budgets.

Checking the accuracy of information about products and product

development processes and preparing operating manuals for mass

production.

Publishing research papers, applying for patents, making research

recommendations and presenting research findings.

Maintaining a research database and staying updated on the latest

industry research and scientific and technological developments.

23

1.3.2 Further Advances in Biochemical

Engineering

The required engineering expertise in manufacture of ethanol and bulk

chemicals is somewhat different from that in producing high priced

health products. For low value products, the required efficiency is

important in determining the overall process economics.

For pharmaceuticals, assurance of the product purity and safety is of top

priority. The price of a new drug can always be properly adjusted to give

manufacturers the desired profit. For products like ethanol, process

efficiency requirements stimulated a great deal of engineering research

and development work over the years.

In order to improve reactor efficiency, multiple stage, fed batch reaction

systems with internal cell recycle has been developed for ethanol

production in the industry. For reducing energy cost spent in dehydration

of ethanol to produce fuel grade products, the technique of adsorption by

corn grits was invented (Ladisch 1984).

24

Continued…

Biological agents almost always suffer from product feedback inhibition.

The SSF (simultaneous saccharification and degradation) concept avoids

the feedback inhibition of cellulase activities.

For ethanol, a number of techniques were proposed and tested, including,

for instance, membrane separation of the ethanol product (Matsumuro

1986), evaporation of ethanol from processing beer by gas stripping

(Dale 1985, Zhang 1992), pervaporation (Mori 1990), solvent extraction

(Bruce 1992), and others.

25

Fed-batch culture is, in the broadest sense, defined as an operational technique in

biotechnological processes where one or more nutrients (substrates) are fed

(supplied) to the bioreactor during cultivation and in which the product(s) remain in

the bioreactor until the end of the run.[1]

An alternative description of the method is that of a culture in which "a base medium

supports initial cell culture and a feed medium is added to prevent nutrient

depletion".[2]

It is also a type of semi-batch culture.

In some cases, all the nutrients are fed into the bioreactor. The advantage of the fedbatch culture is that one can control concentration of fed-substrate in the culture

liquid at arbitrarily desired levels (in many cases, at low levels).

Generally speaking, fed-batch culture is superior to conventional batch culture when

controlling concentrations of a nutrient (or nutrients) affects the yield or productivity

of the desired metabolite.

26

1.4 Bioprocess Economics

We examine the continuing role which economics plays bioprocess

research, development, and commercialization.

Subsequently, characteristic features of particular fermentation processes

are discussed, including fine chemicals, bulk chemicals, and single cell

protein in the examples, the relative cost importance of substrate

feedstocks, equipment, utilities, and bioreactor vs. recovery sections will

be examined, since identification of major cost areas frequently pinpoints

process economic weaknesses and thereby indicates whether an

engineering process improvement and/or strain development would be

most logical to pursue in process optimization.

Ethanol from biomass processes include not only fermentation and

recovery sections but may also requires substantial pre-treatment process

to hydrolyze and solubilize the biomass components.

27

Continued…

Moreover, different countries (including the United States) have

developed various forms of tax subsidies or credits for ethanol plants:

such device have a clear impact on process economics.

Biological waste treatment provides the main process example for which

substrate conversion (rather than biomass production or product

formation) is the operating goal; here, biomass (cell sludge) disposal is

responsible for a major fraction of plant operating costs.

28

1.4.1 Process Economics

For a project which eventually achieves commercialization, these stages

include inception of process or product idea, a preliminary evaluation of

economics and markets, the development of any additional data needed

for final detailed design.

Inception may arise from any source: a sales department suggestion,

emergence of a competing product, a customer request, an offshoot of a

current process, or a new idea from research and development.

If the preliminary evaluations are promising, the development of data

necessary for final design normally follows. This development includes

both market and cost refinement.

29

Continued…

Table 1.1 Stages in plant design project

1. Inception

2. Preliminary evaluation of economics and market

3. Development of data necessary for final design

4. Final economic analysis

5. Detailed engineering design

6. Procurement

7. Construction

8. Start-up and trial runs

9. Production

30

1.4.2 Bioproduct Regulation

Involvement of government in bioproduct regulation stems from

legislated agency responsibility for worker health and safety, consumer

safety, environmental statutes applicable to biotechnology

Specific regulations concerning newer aspects of biotechnology

(recombinant DNA in particular).

The three most important U.S. agencies in regulation are the Food and

Drug Administration (FDA), the U.S. Department of Agriculture

(USDA), and the Environmental Protection Agency (EPA).

31

Continued…

Table 1.2 U.S. Agencies involved in biotechnology regulation

1. FDA

(a) Office of New Drug Evaluation (all new drugs require animal and human testing; any rDNA

drug products are all "new").

(b) Office of Biologics: clinical trials required, followed by licensing of both product and

producer.

(c) National Center for Devices and Radiologic Health: regulates medical devices and medical

diagnostics (including monoclonal antibody diagnostics, except those related to blood bank

operation). Monoclonal antibody (MAb) systems currently must demonstrate performance

equivalence to prior product, rather than safety and efficacy.

2. USDA

Primary regulatory authority over animal biologics, with FDA secondary. MAb and rDNA open

grey areas of agency responsibility uncertainty (eg, USDA regulates interstate marketing, but

FDA may regulate intrastate conditions.)

3. EPA

Authority "to identify and evaluate potential hazards and then to regulate the production, use,

distribution, and disposal of these substances, including chemicals, herbicides, and pesticides."

4. OSHA (Occupational Safety and Health Administration.)

Responsible for worker health and safety regulation. As of 1984, no bioprocess standards issued,

nor regulatory stance toward biotechnology declared.

32

Food Safety and Standards Authority of India (FSSAI) : It is a statutory body

established under the Ministry of Health & Family Welfare, Government of India. The

FSSAI has been established under the Food Safety and Standards Act, 2006, which

is a consolidating statue related to food safety and regulation in India.

The Central Drugs Standard Control Organisation(CDSCO): It is the

National Regulatory Authority (NRA) of India under Directorate General of

Health Services, Ministry of Health & Family Welfare, Government of India.

CPCB

1.4.3 General Fermentation Process

Economics

While considerable differences clearly exist between different

fermentations, the plant design is most easily discussed from a common

flow sheet, given in Fig. 1.2. This simple diagram indicates that the

process is largely divisible into fermentation (or bioreaction) section, and

a product recovery section.

34

Continued…

Figure 1.2: Generalized process flow sheet.

35

Thanks

Chapter 2

S. No.

Content

S. No.

Content

2

Microbiology

2.3.6

Difference Between Plant cell and Animal cell

2.1

Cell theory

2.4

RDNA Technology

2.1.1

Importance of the Cell Theory

2.4.1

Enzymes for Manipulating DNA

2.2

Structure of Microbial Cells

2.4.2

Vectors for Escherichia coli

2.2.1

Procaryotic Cells

2.4.3

Characterization of Cloned DNAs

2.2.2

Eucaryotic Cells

2.4.4

Expression of Eucaryotic Proteins in E. coli

2.2.3

Cell Fractionation

2.4.5

Genetic Engineering Using Other Host

Organisms

2.3

Cell Types

2.4.6

Concluding Remarks

2.3.1

Bacteria

2.5

Genetically Engineered Microbes

2.3.2

Yeasts

2.5.1

Virus and Phages: Lysogeny and Transduction

2.3.3

Molds

2.5.2

Commercial Applications of Microbial

Genetics and Mutant Populations

2.3.4

Algae and Protozoa

2.5.3

Utilization of Auxotrophic Mutants

2.3.5

Animal and Plant Cells

2.5.4

Mutants with Altered Regulatory Systems

2

2. Microbiology

Microbiology is the study of living organisms too small to be seen clearly

by the naked eye. As a rough rule of thumb, most microorganisms have a

diameter of 0.1 mm or less.

Many conclusions have been reached in numerous experimental studies

involving methods adapted from the physical sciences.

Since this approach has proved so fruitful, the applicability of the

principles of chemistry and physics to biological systems is now a

widespread working hypothesis within the life sciences.

3

2.1 Cell Theory

A development critical to the understanding of living systems started in

1838, when Schleiden and Schwann first proposed the cell theory.

This theory stated that all living systems are composed of cells and their

products.

This notion of a common denominator permits an important

decomposition in the analysis of living systems: first the component

parts, the cells, can be studied, and then this knowledge is used to try to

understand the complete organism.

The value of this decomposition rests on the fact that cells from a wide

variety of organisms share many common features in their structure and

function.

All cells are not alike. Muscle cells are clearly different from those found

in the eye or brain.

4

Continued…

Equally, there are many different types of single-celled organisms.

These in turn can be classified in terms of the two major types of cellular

organization.

The cell theory definition states that cells are the building blocks of life.

Cells both make up all living things and run the processes needed for life.

Hair, skin, organs, etc. are all made up of cells.

In fact, each person is estimated to be made up of nearly 40 trillion cells!

Each part of a cell has a different function, and cells are responsible for

taking in nutrients, turning nutrients into energy, removing waste, and

more. Basically, everything what body does, it does because cells are

directing the action.

5

2.1.1 Importance of the Cell Theory

Knowing that all living things are made up of cells allows us to

understand how organisms are created, grow, and die. That

information helps us understand how new life is created, why organisms

take the form they do, how cancer spreads, how diseases can be

managed, and more.

Cells even help us understand fundamental issues such as life and death:

an organism whose cells are living is considered alive, while one whose

cells are dead is considered dead

Before the cell theory existed, people had a very different view of

biology. Many believed in spontaneous generation, the idea that living

organisms can arise from non-living matter. An example of this would be

a piece of rotten meat creating flies because flies often appear around

rotten meat.

6

Continued…

Additionally, before cells and the cell theory were known, it wasn’t

understood that humans, as well as all other living organisms, were made

up of billions and trillions of tiny building blocks that controlled all our

biological processes.

7

2.2 Structure of Microbial Cells

Cells

Procaryotic Cells

Eucaryotic Cells

8

2.2.1 Procaryotic Cells

Procaryotic cells, or procaryotes, do not contain a membrane-enclosed

nucleus. Procaryotes are relatively small and simple cells.

They usually exist alone, not associated with other cells. The typical

dimension of these cells, which may be spherical, rodlike, or spiral, is

from 0.5 to 3 um.

In order to gain a qualitative feel for such dimensions, it is instructive to

compare the relative sizes of cells with other components of the universe.

9

Angstrom

units, Å

1036

Distance seen by

200-in telescope

Figure 2.1:

Characteristic

dimensions of the

universe. The biological

world encompasses

abroad spectrum of sizes

−109 light years

Angstrom

units, Å

Our galaxy

1030

Cosmic world

1012

−1 light year

Length of man

Radius of an amino

Solar system

109

1020

Radius of giant algal cell

Earth

106 - 100 μm radius of giant amoeba

1010

20 μm

Biological world

1 μm

Radius

of most

cells

Eucaryotes

Procaryotes

Resolution of light microscope

0

10

Hydrogen atoms

103 - Radius of smallest bacterium

Molecular world

Unit membrane thickness

Resolution of electron microscope

Atomic nucleus

10−6

Atomic world

100

Radius of an amino acid

Continued…

Microorganisms of this type grow rapidly and are widespread in the bio

sphere. Some, for example, can double in size, mass, and number in 20

min.

Typically, procaryotes are biochemically versatile; i.e, they often can

accept a wide variety of nutrients and further are capable of selecting the

best nutrient from among several available in their environment.

The rapid growth and biochemical versatility of procaryotes make them

obvious choices for biological research and biochemical processing.

In Fig. 2.2 the basic features of a procaryotic cell are illustrated.

11

Continued…

Cell Membrane

70 A

Cell wall

200 A

Ribosome

Nuclear region

Figure 2.2: Electron micrograph of a procaryote, (Bacillus subtilis)

12

Continued…

The cell is surrounded by a rigid wall, approximately 200 A thick.

This wall lends structural strength to the cell to preserve its integrity in a

wide variety of external surroundings.

Immediately inside this wall is the cell membrane, which typically has a

thickness of about 70 A. It is sometimes called a plasma membrane.

These membranes play a critical role: they largely determine which

chemical species can be transferred between the cell and its environment

as well as the net rate of such transfer.

Within the cell is a large, ill-defined region called the nuclear zone,

which is the dominant control center for cell operation.

13

Continued…

The grainy dark spots apparent in the cell interior are the ribosomes, the

sites of important biochemical reactions.

The cytoplasm is the fluid material occupying the remainder of the cell.

Not evident here but visible in some photographs are clear, bubblelike

regions called storage granules.

14

2.2.2 Eucaryotic Cells

Eucaryotic cells, or eucaryotes, make up the other major class of cell

types. Eucaryotes may be defined most concisely as cells which possess a

membrane enclosed nucleus.

As a rule these cells are significantly larger than procaryotes. All cells of

higher organisms belong to this family.

The internal structure of eucaryotes is considerably more complex than

that of procaryotic cells, as can be seen in Figure 2.3. The internal region

is divided into a number of distinct compartments.

They have special structures and functions for conducting the activities

of the cell. The cell is surrounded by a plasma, or unit, membrane similar

to that found in procaryotes. On the exterior surface of this membrane

may be a cell coat, or wall. The nature of the outer covering depends on

the particular cell.

15

Continued…

Figure 2.3: A typical eucaryotic cell

16

Continued…

Important to the internal specialization of eucaryotic cells is the presence

of unit membranes within the cell.

A complex, convoluted membrane system, called the endoplasmic

reticulum, leads from the cell membrane into the cell. The nucleus here is

surrounded by a porous membrane.

Ribosomes, biochemical reaction sites seen before in procaryotes, are

embedded in the surface of much of the endo plasmic reticulum.

A major function of the nucleus is to control the catalytic activity at the

ribosomes.

The nucleus is one of several interior regions surrounded by unit

membranes. These specialized membrane-enclosed domains are known

collectively as organ ells.

17

Continued…

The mitochondria are organelles with an extremely specialized and

organized internal structure.

They are found in all eucaryotic cells which utilize oxygen in the

process of energy generation.

Chloroplasts and mitochondria are the sites of many other

important biochemical reactions in addition to their role in energy

production.

The Golgi complex, lysosomes, and vacuoles are the remaining

organelles illustrated in Figure. 2.3.

In general, they serve to isolate chemical reactions or certain

chemical compounds from the cytoplasm.

18

2.2.3 Cell Fractionation

A major problem in analyzing the characteristics of a particular organelle

from a given type of cell is obtaining a sufficient quantity of the

organelle for subsequent biochemical analysis. Typically this requires

that a large number of organelles be isolated from a large number of

cells, or a cell population.

Let us follow a common procedure for this purpose: First a cell

suspension is homogenized in a special solution using either a rotating

pestle within a tube or ultrasonic sound.

Here an attempt is made to break the cells apart without significantly

disturbing or disrupting the organelles within. Fractionation of the

resulting suspension, which now ideally contains a variety of isolated

intact organelles, is the next step.

As process engineers, we know that any separation process is based upon

exploitation of differences in the physical and/or chemical properties of

the components to be isolated.

19

Continued…

The standard centrifugation techniques for fractionating cell organelles

rely upon physical characteristics: size, shape, and density. A rudimentary

analysis of centrifugation is presented in the following example.

Example 2.1: Analysis of particle motion in a centrifuge. Suppose that a

spherical particle of radius r and density 𝜌𝑝 , is placed in a centrifuge tube

containing fluid medium of density 𝜌𝑓 , and viscosity 𝜇𝑐 . If this tube is then

placed in a centrifuge and spun at angular velocity 𝜔 (see Fig. 1E1.1), we

may calculate the particle motion employing the following force balance

(what approximations have been invoked here?):

Solution:

Drag Force on particle = bouncy force

4𝜋𝑟 3

6𝜋𝜇𝑐 𝑟𝜇𝑟 =

𝐺(𝜌𝑝 − 𝜌𝑓 )

3

2.1

20

Continued…

Figure 2.1.1: When a centrifuge is spun at high speed, particles suspended in the

centrifuge tubes move away from the centrifuge axis. Since the rate of movement of

these particles depends on their size, shape, and density, particles differing in these

properties can be separated in a centrifuge.

21

Continued…

where u, is the particle velocity in the r direction

𝑑𝑟

𝑢𝑟 =

𝑑𝑡

2.2

and G is the acceleration due to centrifugal forces

𝐺 = 𝜔2 𝑟

2.3

Stokes' law has been used in Eq. (2.1) to express the drag force since particle

velocities (and therefore particle Reynolds numbers) are usually very low in this

situation. The usual gravitational force term does not appear in Eq. (2.1) because the

direction in Fig. 2.1.1 is normal to the gravity force. Rotation of the centrifuge at

high speed, however, produces an acceleration G usually many times larger than the

acceleration of gravity g; for example, G = 600-600,000 g. Integration of this

expression gives the time required for movement of the particle from position 𝑟1 to

𝑟2 :

22

Continued…

9

𝜇𝑐

𝑟2

𝑡=

𝑙𝑛

2 𝜔 2 𝑅2 (𝜌𝑝 − 𝜌𝑓 ) 𝑟1

Spheres with different sizes and/or densities will take different times to

traverse the same distance in the centrifuge tube. This is the basis for the

method of differential centrifugation.

Since the larger particles such as nuclei and unbroken cells sediment more

rapidly, they can be collected as a precipitate by spinning the suspension for

a limited time at relatively low velocities.

The supernatant suspension is then subjected to additional centrifugation at

higher rotor speeds for a short time, and another precipitate containing

mitochondria is isolated. By continuing this procedure a series of cell

fractions can be obtained.

The overall process is illustrated schematically in Fig. 2.1.2. More

sophisticated centrifugation methods employ liquid media with density

gradients along the centrifuge tube.

23

Continued…

These techniques are also applicable for continued subdivision and

fractionation of smaller cell constituents such as particular types of

macromolecules. RPM to RCF conversion

Centrifuge rotor speed is often expressed as

Relative centrifugal field (RCF)

RCF in units of gravity (x g)

G = (1.118 x 10-5) R S2

where R is the rotor

radius (cm) and S is

the speed (RPM):

Speeds range from

0-7,500 RPM for low-speed

centrifuges, all the way to

20,000 RPM or higher

Figure 2.1.2: The steps in a typical differential centrifugation separation of

cell constituents. Smaller components are isolated as the process proceeds.

24

2.3 Cell Types

Taxonomy is the art of biological classification. The basic unit in this

classification scheme is the species which is characterized by a high

degree of similarity in physical and biochemical properties and

significant differences from the properties of related organisms.

Procaryotes

Bacteria

Table: 2.1

Classification of

microorganisms

belonging to the

kingdom of protists

Eucaryotes

PROTIST

KINGDOM

Blue-green

algae

Fungi

Molds

Algae

Protozoa

Yeasts

25

2.3.1 Bacteria

Bacteria are typically unicellular, but they may exist in three basic

morphological forms (Fig. 2.4). Most can not utilize light energy, are

capable of motion and reproduce by division into two daughter cells

(binary fusion).

There are many subdivisions of bacteria: some of the general groups of

bacteria and some of their distinguishing characteristics are given in

Table 2.2.

Figure 2.4: The three forms of bacteria

26

Table 2.2:

Dominant

Morphologic

al form

Some

nutritional

habits

Common

habitat

Most members

require 𝑶𝟐

(aerobic)

Pho

tosy

nth

etic

Form

s

endos

pores

Gram

reactio

n

Acetic acid

bacteria

Rods

Often consume

alcohol

Decaying plants

Yes

No

No

Negative

Bacillus

Rods

Versatile

Soil

Yes

No

Yes

Positive

Clostridium

Irregular form

Many varieties

Soil

Most species

cannot tolerate 𝑶𝟐

No

Yes

Positive

Corynebacte

rium

Rods

Simple

requirements

Soil, human

body

No, but use 𝑶𝟐 if

present

No

Yes

Positive

Enteric or

coliform

bacteria

Rods or cocci

Simple organic

compounds

Naturally in

intestine of

higher animals

No, but can use

𝑶𝟐 if present

No

No

Negative

Lactic acid

Rods

Species acidtolerant

Plants

No

No

No

Positive

Pseudomona

s

Rods

Some extremely

versatile

Soil, water

Yes

No

No

Negative

Rhizobium

Rods

Fixes nitrogen

Soil, Plants

Yes

No

No

Negative

Rhodospirill

ium

Rods, spirals

Can fix 𝑵𝟐 or

produce 𝑯𝟐

Specialized

aqueous

environment

No

Yes

No

Negative

Zymomonas

Rods

Ferments glucose

to ethanol

Soil

No, can tolerate

𝑶𝟐

No

No

Negative

Group

27

Continued…

The aerobic Bacillus species are extremely widespread and adaptable.

Several Clostridium species, which normally function under anaerobic

conditions, die in the presence of oxygen in the vegetative state but form

spores unaffected by oxygen.

Some bacteria whose vegetative forms are rapidly killed at 45°C can

form spores which survive boiling in water for several hours.

Therefore, when we are attempting to kill microorganisms by heating

(heat sterilization) the spore forming capability of bacteria demands use

of higher temperatures, typically achieved by boiling under pressure in

an autoclave to give T > 120 °C.

28

2.3.2 Yeasts

Yeasts form one of the important subgroups of fungi.

Fungi, like bacteria, are widespread in nature although they usually live

in the soil and in regions of lower relative humidity than bacteria.

They are unable to extract energy from sunlight and usually are freeliving.

Although most fungi have a relatively complex morphology, yeasts are

distinguished by their usual existence as single, small cells from 5 to 30

μm long and from 1 to 5 μm wide.

The various paths of reproduction of yeasts are asexual (budding and

fission) as shown in Fig. 2.7, and sexual.

In budding, a small offspring cell begins to grow on the side of the

original cell; physical separation of mature offspring from the parent may

not be immediate.

29

Continued…

Example 2.2: Yeast cells grow in the exponential phase. The cell mass

concentrations are given in Table 4.4. Calculate the specific growth rate,

𝜇𝑚𝑎𝑥 .

Time (h)

0

5

10

15

20

25

Cell concentration, 𝐶𝑥

0.5

1.3

4.0

10.2

24,0

52.5

Kg dry cell 𝑚−3 medium.

Solution:

A plot of a 𝐶𝑥 /𝐶𝑥𝑜 against cultivation time (Figure 4.2) gives a straight

line, the slope of which can be used to evaluate 𝜇𝑚𝑎𝑥 .

𝜇𝑚𝑎𝑥 = 0.20 ℎ−1

30

Continued…

Figure E2.2: Determination of a specific growth rate in the exponential growth phase.

31

2.3.3 Molds

Molds are higher fungi with a vegetative structure called a mycelium. As

illustrated in Fig. 2.6, the mycelium is a highly branched system of tubes.

Within these enclosing tubes is a mobile mass of cytoplasm containing

many nuclei.

The mycelium may consist of more than one cell of related types. The

long, thin filaments of cells within the mycelium are called hyphae.

In some cases the mycelium may be very dense. Molds, like yeasts, do

not contain chlorophyll, and they are generally non motile.

Reproduction, which may be sexual or asexual, is typically accomplished

by means of spores.

32

Continued…

Figure 2.6: The mycelial structure of molds

33

Continued…

The most important classes of molds industrially are Aspergillus and

Penicillium (Fig. 2.7). Major useful products of these organisms include

antibiotics ,organic acids, and biological catalysts.

Penicillium

Figure 2.7: The hyphae of Aspergillus and Penicillium

Aspergillus

34

2.3.4 Algae and Protozoa

These relatively large eucaryotes have sophisticated and highly organized

structures.

For example, Euglena has flagella for locomotion, lacks a rigid wall, and

has an eyespot sensitive to light,

Considerable commercial interest in algae is concentrated on their

possible exploitation as foodstuffs and food supplements.

In Japan, several processes for algae food cultivation are in operation

today. Also important in Asia is use of seaweed in the human diet.

Just as algae may be viewed as primitive plants, protozoa, which cannot

exploit sunlight's energy, are in a sense primitive animals.

Although protozoa are not now employed for industrial manufacture of

either cells or products, their activities are significant among the

microorganisms which participate in biological waste treatment.

35

2.3.5 Animal and Plant Cells

Many vaccines and other useful biochemicals are produced by growth of

animal cells in process reactors; i.e., by cell propagation outside of the

whole animal.

Improvements in cultivation techniques for these tissue-derived cells and

emerging methods for genetic manipulation of animal and plant cells

offer great potential for expanded commercial utilization of these higher

cells.

When a piece of animal tissue, perhaps after disruption to break the cells

apart, is placed in appropriate nutrient liquid, many cell types, such as

blood cells, die within a few days, weeks, or months. Other cells multiply

and are called primary cell lines.

36

Continued…

It is also possible to grow certain plant cells in culture, either as a callus

or as aggregated cells in suspension.

Cell line designation

Animal

Tissue

HeLa (CCL 2)

Human

Cervix carcinoma

HLM

Human

Fetal liver

FS-4

Human

Foreskin fibroblast

MK2

Monkey

Kidney

CHO (CCL 61)

Chinese hamster

Ovary

L-M (CCL 2)

Mouse

Connective tissue

Table: 2.3 A

sampling of

standard

animal cell

lines and their

origins

Since plants produce many commercially important compounds including

perfumes, dyes, medicinals, and opiates, there is significant potential for

future applications of plant cell culture.

Cultured plant cells have several potential agricultural applications including

whole plant regeneration.

37

2.3.6 Difference Between Plant cell and

Animal cell

Unicellular organisms are believed to be one of the earliest forms of life

on earth. Eventually, more complex multicellular organisms evolved

from these unicellular life forms over the aeons. Multicellular organisms

have specialized cells with complicated cell organelles, which unicellular

organisms typically lack.

In an ecosystem, plants have the role of producers while animals have

taken the role of consumers. Hence, their daily activities and functions

vary, so do their cell structure. Cell structure and organelles vary in

plants and animals, and they are primarily classified based on their

function. The difference in their cell composition is the reason behind the

difference between plants and animals, their structure and functions.

Each cell organelle has a particular function to perform. Some of the cell

organelles are present in both plant cell and the animal cell, while others

are unique to just one. Most of the earth’s higher organisms are

eukaryotes, including all plant and animals. Hence, these cells share

some similarities typically associated with eukaryotes.

38

Continued…

For example, all eukaryotic cells consist of a nucleus, plasma membrane,

cytoplasm, peroxisomes, mitochondria, ribosomes and other cell

organelles.

Plant cell

Animal cell

Figure 2.8: Plant cell vs Animal cell

39

2.4 RDNA Technology

Recombinant DNA technology provides carefully controlled and novel

genetic alterations in certain organisms.

This approach has made possible manufacture of valuable animal

products (proteins) in simple bacteria.

These examples indicate the central importance of genetics to the

biochemical engineer.

This subject occupies a large fraction of the present efforts in both

university and industrial biological research.

The practical importance of designing genetic modifications (or, in other

situations, of avoiding such changes) emphasizes the need for close

cooperation between engineers, biologists, and biochemists in

biochemical process design and evaluation.

40

Continued…

A brief schematic of a method for cloning a segment of DNA shown in

Fig. 2.9. Here cloning means obtaining a colony of genetically identical

cells which contain the DNA segment of interest.

This segment, called "foreign DNA" in Fig. 2.9, is obtained by cutting a

larger piece of DNA into fragments using specific endonuclease enzymes

or by enzymatic or chemical synthesis.

The foreign DNA is joined in the test tube (in vitro) to a vector or vehicle

which will carry the foreign DNA as a passenger into a bacterial cell.

In this example the vector is a bacterial plasmid which has been

manipulated to facilitate the cloning process. The recombinant DNA

molecule formed by the foreign DNA-plasmid construct is then

introduced into a bacterial cell by transformation.

41

Continued…

Figure 2.9: Schematic illustration of the major steps in cloning a

foreign DNA segment.

42

2.4.1 Enzymes for Manipulating DNA

One key to recent breakthroughs in genetic engineering is the discovery and

the subsequent commercial supply of several enzymes which can be used to

cut, alter, and join DNA molecules in the test tube.

Prominent among these crucial enzymes are the restriction endonucleases

which recognize and cut specific nucleotide sequences within the DNA

molecule. For example the restriction enzyme called EcoRI recognizes the

double-stranded six-nucleotide sequence

∙ ∙ ∙ −G − A − A − T − T − C − ∙ ∙ ∙

∙ ∙ ∙ −C − T − T − A − A − G − ∙ ∙ ∙

and cleaves each strand between the G and A residues as marked above by

arrows. The two ends may then separate

∙ ∙ ∙ −G

∙ ∙ ∙ −C − T − T − A − A

A−A−T−T−C−∙∙∙

G−∙∙∙

43

Continued…

Notice that in this case each end contains a short single-stranded

segment. These are called "sticky ends" or "cohesive termini" since the

two ends are complementary single-stranded nucleotide sequences which

will naturally tend to base pair and to join, by hydrogen bonding, to each

other.

Whether or not these hydrogen bonded sequences tend to stay together or

separate can be adjusted by manipulating the temperature or the pH of

the solution.

More than 100 different restriction enzymes have now been identified.

Some of the more commonly used ones, their recognition sites, and the

points of DNA backbone hydrolysis are listed in Table 2.4. We should

observe here that not all restriction enzymes leave sticky ends.

44

Continued…

Table 2.4: Recognition sites and rage points (arrows) for some on endonuclease enzymes

Enzymes

Target site

BumHΙ

G G A T C C

C C T A G G

BglΙΙ

A G A T C T

T C T A G A

EcoRΙ

G A A T T C

C T T A A G

HaeΙΙΙ

G G C C

C C G G

HindΙΙΙ

A A G C T T

T T C G A A

HpaΙ

G T T A A C

C A A T T G

PstΙ

C T G C A G

G A C G T C

45

Continued…

Suppose the sticky ends obtained by earlier EcoRI hydrolysis of different

DNA molecules are allowed to anneal-to come together and base pair.

This configuration is not covalently closed: the phosphodiester bonds

(indicated by dashes) are missing between the G and A residues in both

strands. DNA ligase catalyzes the condensation of a 3’− hydroxyl group

with a 5'−phosphate group to add these missing links. Annealed fragments

∙ ∙ ∙ −G

A−A−T−T−C−∙∙∙

∙ ∙ ∙ −C − T − T − A − A

G−∙∙∙

are covalently closed by DNA ligase

∙ ∙ ∙ −G − A − A − T − T − C − ∙ ∙ ∙

∙ ∙ ∙ −C − T − T − A − A − G − ∙ ∙ ∙

46

2.4.2 Vectors for Escherichia coli

Vectors are DNA molecules which provide propagation of a DNA

fragment in a growing cell population. A useful vector for cloning should

have the following properties:

1. Ability to replicate in the host cell

2. Ability to accommodate foreign DNA of various sizes without damage

to replication functions

3. Easy insertion in host cell after in vitro DNA manipulations

4. Contains a selection marker to facilitate rapid, positive selection of cells

which contain the vector

5. Contains only one target site for one or more different restriction

endonucleases

Two different classes of vectors-plasmids and bacteriophages have been

developed for cloning DNA in E. coli. We will concentrate here on plasmid

vectors.

47

Continued…

Selection markers are also important. By including, for example, a gene

for antibiotic resistance in the plasmid, we can rapidly and positively

select for cells containing plasmids.

This is done by growing the cells on medium containing a level of the

antibiotic which kills plasmid-free cells but which allows growth of cells

containing plasmids and hence the antibiotic resistance gene.

Another common strategy for selection is to use a mutant host lacking an

enzyme required for growth in a particular medium and to include on the

recombinant plasmid the normal gene for that enzyme.

Plasmid vectors for cloning in E. coli have been highly developed in

recent years. Among the more popular plasmids is pBR322 (Fig. 2.13)

which includes a number of unique restriction enzyme sites, genes for

tetracycline and for ampicillin resistance, and an origin of replication

which allows amplification of the plasmid.

48

Continued…

Here "amplification" means a large increase in the ratio of plasmid to

chromosomal DNA. Amplification is possible using pBR322 and related

plasmids since the plasmid can replicate in the absence of protein

synthesis in the host cell but the chromosome cannot.

Figure 2.11: Map of the plasmid pBR322 showing genetic loci and

some of the unique restriction enzyme sites. The complete nucleotide

sequence of the 4362 base-pair plasmid is known.

49

2.4.3 Characterization of Cloned DNAs

First, we can distinguish between clones which have plasmids with

inserts and those which contain only reclosed plasmids by applying

insertional inactivation during the cloning procedure. Suppose, for

example, that DNA fragments were inserted at the PstΙ restriction

enzyme site in plasmid pBR322.

Since inserts this position interrupt the gene for ampicillin resistance,

cells containing recombinant plasmids will be ampicillin sensitive and

tetracycline resistant. On the other hand, cells with insert-free plasmids

will be resistant to both ampicillin and tetracycline.

Screening for specific nucleotide sequences in the clone may be

accomplished by several different procedures which are all based on

hybridization of denatured (ie, single-stranded) DNA from the clone with

a nucleic acid probe, typically labelled with 3 2𝑃 to make it radioactive.

50

Continued…

In the in situ colony hybridization method, a replica plate of the clones

is grown on nitrocellulose paper laid over the Petri plate with nutrient

medium. Cells are then lysed by treatment with lysozyme, and NaOH is

used to denature the DNA. The filter paper is then removed, contacted

with the probe, washed, and exposed to x-ray film. Spots appear on the

film where probe hybridization to complementary DNA has occurred,

identifying interesting clones for further study.

A probe is a nucleic acid which has been labeled i.e., chemically modified in

some way which allows it and hence anything it hybridizes to, to be

detected. There are three major types of probe: Oligonucleotide

probes, DNA probes and. cRNA probes (riboprobes)

51

In the Southern blotting method, the DNA in the gel is

denatured with alkali, and the gel is covered with cellulose

nitrate filter paper. Buffer solution drawn from moist filter

paper below this sandwich to dry filter paper above it carries

DNA the gel to cellulose nitrate where binds. The bound,

denatured DNA then probe and film before to identify

complementary that the probe.

52

Continued…

In the Maxam-Gilbert method, the double-stranded DNA is first

labelled radioactively at one end of each strand. The DNA is then

denatured, and a preparation of one of the two types of strands is divided

into four aliquots, each which is treated with different chemicals. Each of

the four chemical treatments destroys selectively one or two bases and

cleaves the DNA at those points. It is critical to the method that this

destruction be incomplete-ideally the chemical treatment to cleave each

strand only once. The fragments resulting from these four parallel

treatments are then run on a long polyacrylamide g Gel band positions

are visualized by exposure to x-ray film.

53

Continued…

Figure

2.12:

MaxamGilbert DNA sequencing:

application of four different

reagents

which

attack

different bases gives a

mixture of fragments with

relative

lengths

corresponding

to

the

destroyed

bases.

The

pattern of bands on the four

lane gel permit direct

reading

of

the

corresponding nucleotide

sequence running, from top

to bottom, toward the

labelled end of the starting

oligonucleotide.

54

Continued…

The Sanger DNA sequencing method, There are three main steps to

Sanger sequencing.

1. DNA Sequence For Chain Termination PCR. The DNA sequence of

interest is used as a template for a special type of PCR called chaintermination PCR.

2. Size Separation by Gel Electrophoresis.

3. Gel Analysis & Determination of DNA Sequence.

55

2.4.4 Expression of Eucaryotic Proteins in

E. coli

Procaryotes such as E. coli do not possess the biochemical machinery to

do RNA splicing Accordingly, a eucaryotic gene placed directly in E. coli

(with appropriate bacterial expression controls to be discussed next) will

not be properly expressed.

There are two quite different strategies for accomplishing this. The first

is chemical synthesis of the desired nucleotide sequence. While details of

chemical synthesis of genes are best left for the references, we should

observe that DNA synthesis chemistry as of this writing does not permit

direct synthesis of the entire gene. Instead, overlapping oligonucleotides

are designed which will tend to self-assemble by base pairing into a

complete double stranded coding sequence.

56

Continued…

The other way to obtain a bacterial gene for a eucaryotic protein is to

work backward from the mature, spliced eucaryotic messenger RNA. As

shown schematically in Fig. 2.15, the mRNA for the desired protein

provides a template from which the enzyme reverse transcriptase can

synthesize a complementary DNA strand.

After separating the mRNA and single DNA strand, the complementary

DNA strand is added using DNA polymerase, and the enzyme S1

nuclease then serves to clip off a small single-stranded loop at one end.

57

Continued…

Figure 2.13: In eucaryotic

gene expression, the primary

transcript mRNA is spliced

to obtain the mature mRNA

which is translated. An

abbreviated hypothetical

example is shown here.

58

2.4.5 Genetic Engineering Using Other Host

Organisms

There is great interest in developing cloning and expression systems for

organisms other than E. coli. In all cases it is important to keep in mind the

following potential barriers to expression of a foreign gene:

1. Host cell nuclease attack on foreign DNA or RNA

2. Vector replication malfunction

3. Poor activity of promoter or transcription terminator

4. Incomplete mRNA splicing

5. Inefficient translation

6. Protease attack.

Also, we need an efficient procedure for introducing the vector into host

cells. with high yields.

59

Continued…

Methods exist for molecular coloning and gene expression in several

bacteria. Perhaps the most extensively studied is Bacillus subtilis, a gram

positive nonpathogenic, nonparasitic, industrial microorganism used

before the advent of genetic engineering to manufacture several enzymes

and polypeptide antibiotics B. subtilis secretes some of its proteins into

the surrounding medium.

Several plasmids and bacteriophages are available for cloning in B.

subtilis Transformation, transduction, and protoplast fusion methods can

be used to introduce foreign DNA.

In transformation, a bacterium takes up a piece of DNA floating in its

environment. In transduction, DNA is accidentally moved from one bacterium

to another by a virus. In conjugation, DNA is transferred between bacteria through a

tube between cells.

Somatic fusion, also called protoplast fusion, is a type of genetic modification in

plants by which two distinct species of plants are fused together to form a new

hybrid plant with the characteristics of both, a somatic hybrid

60

Continued…

Several mammalian proteins including insulin and interferons have been

successfully expressed in B. subtilis, but, as of this writing export of foreign

proteins from B. subtilis remains problematic.

Cloning technology is also available for several Pseudomonas and

Streptomyces strains. A combination of genetic engineering and

mutation/selection methods has generated Pseudomonas species with

new metabolic capabilities-for example, the ability to grow on ordinarily

toxic chlorinated hydrocarbons as their sole carbon source.

The last examples introduce a new theme-metabolic engineering-which

de serves further comment. With genetic engineering we can not only

produce proteins useful in their own right, but we can also add to a living

cell more of some particular enzymes, regulatory proteins, permeases, or

any other protein.

Further, we may be able to give to the cell completely new enzymatic,

regulatory, or transport activity which we would never expect to find in

nature or through use of random mutagenesis.

61

Continued…

Because of all the available methodology and its rapid growth, E. coli re

mains the organism of choice for cloning and characterizing DNAs.

Thus, when the final objective is to propagate the vector and express its

genes in another organism, it is convenient to construct and to utilize a

shuttle vector which can be propagated both in E. coli and in the other

organism of choice.

Clearly, a shuttle vector must contain two origins of replication-one for

each host organism. Shown in Fig. 2.17 is the shuttle vector developed to

express immune interferon (INF-y) in monkey cells.

62

Continued…

Figure 2.17: Diagram of the shuttle vector for E. coli and monkey cells

which gives expression and secretion of immune interferon in monkey cells

63

2.4.6 Concluding Remarks

Given the potential significance of recombinant DNA technology in

future activities in biotechnology, further study of the underlying

molecular biology and methods is essential to the biochemical engineer.

Gene expression levels, intracellular protease activities, genetic stability,

and other factors which determine the productivity of recombinant

populations all depend on the nucleotide sequence of the vector, on the

genetic properties of the host cell, on medium composition, and on

bioreactor configuration and operating conditions.

Combined efforts of biochemical engineers and molecular biologists are

essential to understanding causes and effects and interactions in

genetically engineered organisms.

64

2.5 Genetically Engineered Microbes

The use of genetically engineered microorganisms (GEMs, often referred

to as Genetically Modified Microorganisms or GMMs) has become

widespread in the production of food processing aids and other food

ingredients.

GEMs are advancing food production by increasing efficiency, reducing

waste and resource requirements, and ultimately enabling beneficial

innovations such as the cost-effective fortification of food with essential

nutrients, vitamins, and amino acids, and delivery of tailored enzymes to

achieve unique food processing capabilities.

In addition to mutation, a variety of processes change the genetic

material within a cell. These have both positive and negative implications

from the standpoint of industrial biotechnology.

65

Continued…

From the former perspective, any method for altering a cell's DNA

content provides an opportunity for development of more productive

strains. On the other hand, an unplanned modification of a desired

species' DNA can cause expensive failures of industrial bioprocesses.

Much of what follows pertains only to bacteria, E. coli serving as the

subject of most research on these topics

66

Thank you

Chapter 3

S. No.

Content

S. No.

Content

3

Biochemistry

3.3.1

Building Blocks, an Energy Carrier, and

Coenzymes

3.1

Lipids

3.3.2

Biological Information Storage

3.1.1

Properties of Lipids

3.4

Amino Acids into Proteins

3.1.2

Lipid Structure

3.4.1

Amino Acid Building Blocks and Polypeptides

3.1.3

Classification of Lipids

3.4.2

Protein Structure

3.1.4

Fatty Acids and Related Lipids

3.4.3

Primary Structure

3.1.5

Fat soluble Vitamins, steroids and

Other Lipids

3.4.4

Three-Dimensional Conformation: Secondary

and Tertiary Structure

3.2

Sugars and Polysaccharides

3.4.5

Quaternary Structure and Biological

Regulation

3.2.1

D-Glucose and Other

Monosaccharides

3.5

Hybrid Biochemicals

3.2.2

Disaccharides to Polysaccharides

3.5.1

Cell Envelopes: Peptidoglycan and

Lipopolysaccharides

3.2.3

Cellulose

3.5.2

Antibodies and Other Glycoproteins

3.3

From Nucleotides to RNA and DNA

2

3. Biochemistry

The four main classes of polymeric cell compounds are the fats and

lipids, the polysaccharides (cellulose, starch, etc.), the informationencoded polydeoxyribonucleic and polyribonucleic acids (DNA, RNA),

and proteins.

The various biological polymers may be usefully regarded as being either

repetitive or nonrepetitive in structure.

Repetitive biological polymers contain one kind of monomeric subunit.

The major function of repetitive polymers in the cell is to provide

structures with the desired mechanical strength, chemical inertness, and

permeability.

Repetitive polymers also provide a means of nutrient storage.

In the latter function, for example, a 1 M glucose solution can be stored

as the polymer glycogen, a cell polysaccharide reserve, with a concurrent

reduction in molarity by a factor of 10,000 or greater.

3

Continued…

Nonrepetitive polymers may contain from several up to 20 different

monomer species.

The predominant elements (hydrogen, oxygen, nitrogen, and carbon)

form chemical bonds by completing their outer shells with one, two,

three, and four electrons, respectively.

They are the lightest elements in the periodic table with such properties,

and (except for hydrogen) they can form multiple bonds as well.

The variety of chemicals which can be assembled from these four

elements include, if we add a little phosphorus and sulfur, the four major

biopolymer classes.

An addition to variety, the biochemical compounds assembled from these

elements are quite stable, reacting only slowly with each other, water,

and other cellular compounds.

4

Continued…

Chemical reactions involving such compounds are catalyzed by

biological catalysts: proteins which are called enzymes (recall that a

catalyst is a substance which allows an increase in a reaction rate without

itself undergoing a permanent change).

Element

% of dry weight

Element

% of dry weight

Carbon

50

Sodium

1

Oxygen

20

Calcium

0.5

Nitrogen

14

Magnesium

0.5

Hydrogen

8

Chlorine

0.5

Phosphorus

3

Iron

0.2

Sulfur

1

All other

≈ 0.3

Potassium

1

Table 3.1: The elemental composition of E.coli (Escherichia coli)

5

3.1 Lipids

By definition, lipids are biological compounds which are soluble in

nonpolar solvents such as benzene, chloroform, and ether, and are

practically insoluble in water.

Consequently, these molecules are diverse in their chemical structure and

their biological function.

Fats, which simply serve as polymeric biological fuel storage, are lipids,

as are several important mediators of biological activity.

Lipids also constitute portions of more complex molecules such as

lipoproteins and liposaccharides, which again appear predominantly in

biological membranes of cells and the external walls of some viruses.

The hydrocarbon chain is nearly insoluble in water, but the carboxyl

group is very hydrophilic.

6

Continued…

Figure 3.1: Lipids

7

3.1.1 Properties of Lipids

Lipids are a family of organic compounds, composed of fats and oils. These

molecules yield high energy and are responsible for different functions

within the human body. Listed below are some important characteristics

of Lipids.

1. Lipids are oily or greasy nonpolar molecules, stored in the adipose

tissue of the body.

2. Lipids are a heterogeneous group of compounds, mainly composed of

hydrocarbon chains.

3. Lipids are energy-rich organic molecules, which provide energy for

different life processes.

4. Lipids are a class of compounds characterised by their solubility in

nonpolar solvents and insolubility in water.

5. Lipids are significant in biological systems as they form a mechanical

barrier dividing a cell from the external environment known as the

cell membrane.

8

3.1.2 Lipid Structure

Lipids are the polymers of fatty acids that contain a long, non-polar

hydrocarbon chain with a small polar region containing oxygen. The lipid

structure is explained in the diagram below:

Figure 3.2: Lipid Structure – Saturated and Unsaturated Fatty Acids

9

3.1.3 Classification of Lipids

Lipids can be classified into two main classes:

1. Non-saponifiable lipids

2. Saponifiable lipids

Non-saponifiable Lipids

A nonsaponifiable lipid cannot be disintegrated into smaller molecules

through hydrolysis. Nonsaponifiable lipids include cholesterol,

prostaglandins, etc.

Saponifiable Lipids

A saponifiable lipid comprises one or more ester groups, enabling it to

undergo hydrolysis in the presence of a base, acid, or enzymes, including

waxes, triglycerides, sphingolipids and phospholipids.

Phospholipids and sphingolipids are two classes of lipids mainly found in the cell membrane

of all living organisms.

10

3.1.4 Fatty Acids and Related Lipids

• The main difference between phospholipids and sphingolipids is that phospholipids consist of

a glycerol backbone whereas sphingolipids consist of a sphingosine backbone. (Sphingosine (2amino-4-trans-octadecene-1,3-diol) is an 18-carbon amino alcohol with an

unsaturated hydrocarbon chain,)

• Furthermore, phospholipids are the major component of lipids in the cell membrane while

sphingolipids are the second major component of lipids in the cell membrane.

Saturated fatty acids are relatively simple lipids with the general formula:

𝑂

𝐶𝐻3 − 𝐶𝐻2

𝑛

−𝐶

𝑂𝐻

The hydrocarbon chain is constructed from identical two-carbon

monomers, so that fatty acids may be regarded as noninformational

biopolymers with a terminal carboxylic group.

The value of n is typically between 12 and 20 (even numbers) in biological

systems.

11

Continued…

Unsaturated fatty acids are formed upon replacement of a saturated

(−𝐶 − 𝐶−) bond by a double bond (−𝐶 = 𝐶−).

For example, oleic acid is the unsaturated counterpart of stearic acid (n =

16).

𝐶𝐻3 − (𝐶𝐻₂)16 −𝐶𝑂𝑂𝐻

Stearic acid

𝐶𝐻3 − (𝐶𝐻2 )7 −𝐻𝐶 = 𝐶𝐻 − (𝐶𝐻2 )7 − 𝐶𝑂𝑂𝐻

Oleic acid

12

Continued…

Lipid monolayer at an air-water interface

Lipid micelle in water

Figure 3.3: Some stable configurations of fatty acids in water

These hydrophilic-hydrophobic lipid molecules possess very small

solubilities: elevation of the solution concentration above the

monomolecular solubility limit results in the condensation of excess

solutes into larger ordered structures called micelles (Fig. 3.3).

13

Continued…

Important as reservoirs of fuel, fats are esters formed by condensation of

fatty acids with glycerol.

𝑂

𝐶𝐻₂𝑂𝐻

𝐻𝑂 − 𝑂𝐶 𝐶𝐻2

𝑛1

− 𝐶𝐻3

𝐶𝐻𝑂𝐻

+

𝐻𝑂 − 𝑂𝐶 𝐶𝐻2

𝑛2

− 𝐶𝐻3

𝑛3

− 𝐶𝐻3

+

−3𝐻2 𝑂

𝐶𝐻2 𝑂 − 𝐶 − 𝐶𝐻2

𝑂

𝑛1

− 𝐶𝐻3

𝐶𝐻2 𝑂 − 𝐶 − 𝐶𝐻2

𝑂

𝑛2

− 𝐶𝐻3

𝐶𝐻2 𝑂 − 𝐶 − 𝐶𝐻2

𝑛3

− 𝐶𝐻3

+

𝐶𝐻₂𝑂𝐻

Glycerol

𝐻𝑂 − 𝑂𝐶 𝐶𝐻2

Fatty acids

A Fat

14

3.1.5 Fat soluble Vitamins, steroids and

Other Lipids

A vitamin is an organic substance which is required in trace amounts for

normal cell function.

The vitamins which cannot be synthesized internally by an organism are

termed essential vitamins: in their absence in the external medium, the

cell cannot survive.

The water-soluble vitamins such as vitamin C (ascorbic acid) are not

lipids by definition.

However, vitamins A, E, K, and D are water-insoluble and dissolve in

organic solvents. Consequently these vitamins are classified as lipids.

Steroids are a class of lipid biochemicals with the general structure

shown in Fig.3.4(a).

Of these, a subgroup (hormones) constitutes some of the extremely

potent controllers of biological reaction rates: hormones may be effective

at levels of 10−8 M in human tissue.

15

Continued…

Steroids

Our bodies possess chemical messengers known as hormones, which are

basically organic compounds synthesized in glands and transported by

the bloodstream to various tissues in order to trigger or hinder the desired

process.

Steroids are a kind of hormone that is typically recognized by their

tetracyclic skeleton, composed of three fused six-membered and one

five-membered ring, as seen above.

The four rings are assigned as A, B, C & D as observed in the shade blue,

while the numbers in red indicate the carbons.

Related sterol compounds have been shown to alter cell plasma

membrane permeabilities.

16

Continued…

a)

General steroid base: perhydroxycyclopentano

phenathrene

𝐶𝐻3

b)

O

C

𝐶𝐻3

Progesterone

𝐶𝐻3

𝐶𝐻3

O

C

𝐶𝐻3

c)

HC

O

(𝐶𝐻2 )3 −𝐶𝐻(𝐶𝐻3 )2

O

OH

𝐶𝐻3

Cholesterol

𝐶𝐻3

𝐶𝐻3

𝐶𝐻3

Cortisone

O

HO

progesterone can be converted into cortisone in a two step

process (microbial, then chemical) (Fig. 3.4b).

Figure 3.4: Some examples of steroid structure

17

Examples of Lipids

Waxes

Waxes are “esters” (an organic compound made by replacing the

hydrogen with acid by an alkyl or another organic group) formed from

long-alcohols and long-chain carboxylic acids.

Waxes are found almost everywhere. The fruits and leaves of many

plants possess waxy coatings, that can safeguard them from small

predators and dehydration.

Fur of a few animals and the feathers of birds possess the same coatings

serving as water repellents.

Carnauba wax is known for its water resistance and toughness

(significant for car wax).

18

Continued…

Cholesterol