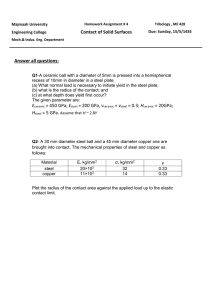

Reg. No. :

R 3438

B.E./B.Tech.

DEGREEEXAMINATION,NOVEMBER/DECEMBER

2007.

Seventh Semester

(Regulation 2004)

Mechanical Engineering

ME 1OO7- PROCESSPLANNING AND COST ESTIMATION

co

m

(Common to Production Engineering)

(Common to B.E. (Part-Time) Sixth Semester Regulation 2005)

N.

Time : Three hours

Maximum : 100 marks

va

Answer ALL questions.

aa

na

PARTA-(fO x2=20 marks)

Define method studv.

2.

Write down any two important applications of work measurement.

3.

Briefabout scopeofprocessplanning.

4.

What are the documents used in processplanning?

5.

What is manufacturing logic?

6.

Define costing.

7.

List the types of estimates.

8.

Brief about indirect material cost.

9.

What is administrative overhead?

ww

w.

M

1.

10. Find the weight of steel sphere of diameter 140mm taking steel density as

7150 Kg/ns.

PARTB-(5x16=80marks)

11.

(a)

State and explain major principles of motion economy.

(16)

Or

(b)

72. (a)

(i)

Describe the procedurefor stop watch time study.

(8)

(ii)

Explain the applications of ergonomics.

(8)

List and explain processplanning activities.

(16)

Or

Describe material selectionparameters"

(ii)

Determine the time to face mill a C.I. casting 7.2 m long and

266.7 mm wide, considering start and end allowances.Assume the

following:

No. of teeth in the cutter

32

Cutter diameter

375mm

75 rpm

Spindle speed

:

287.5mm per minute-

N.

Table feed

(i)

State and explain objectives of cost estimation'

(ii)

What are different classifications of cost? Explain.

va

13. (a)

(6)

(i)

co

m

(b)

(10)

(8)

(8)

(b)

15. (a)

(8)

(ii)

Explain major elements of cost.

(8)

Explain various methods of estimates.

M

(a)

Describe cost accounting with an example.

(i)

w.

1A

a=

(i)

(16)

Or

Discuss data requirements and sources for cost estimation.

ww

(b)

aa

na

Or

(10)

(6)

(ii)

Write short notes on cost allowances in estimation.

(i)

For manufacture of 1000 bolts and nuts per hour, a factory incurs

following expenses:

Direct Material cost

Rs.350

Direct labour cost

Rs.200

Direct expenses

Rs.75

Factory over heads

I50Vooflabour cost

Office overheads

307oof factory cost

Determine whether the factory is makrng profit or loss in seliing

(8)

one set of bolt and nut for Rs.1.

R 3438

(ii )

A welded platform top is made by 20 mm steel plates requiring

10 joints of 1 metre length each.Welding is done on one side only by

arc welding process.Labour chargesare Rs.15 per hour. Electrode

required per metre run in 2.5 m and costs Rs.6 per metre. Power

consumption is 6 Kwhr per metre of the weld and cost

Rs. 3 per Kwhr. Time for welding 1 m length is 18 min. Assuming

(8)

over heads as Rs.10per hour, calculatewelding expenses.

Or

(i)

Determine selling price of a component made from steel bar 50 mm

long and 20 mm in diameter machining time u. f ] hour.

Assume the following:

Steel cost

Rs.60/Kg

Labour cost

Rs.15/hour

Overheads

7007oof labour cost

Profit

207ooftotal cost

co

m

8000 Kglm3

(6)

N.

150 piecesofa stepped shaft are to be drop forged from raw stock of

20 mm diameter. Estimate the cost assuming the foilowing:

Shaft size : Step on left :10 mm diameter x 75 mm long

Step in the middle :20 mm diameter x

125 mm long

Step on right : 10 mm diameter x 75 mm long

(2)

Material cost : Rs.200metre

(3)

Cost of forging : Rs.1200per sq.metreof forged surface

(4)

Over heads:I007oof forging cost.

M

aa

na

va

(1)

w.

(ii)

Steel Density

Consider scale loss, shear loss, flash loss, tong hold loss and

(10)

sprue loss whiie making required assumptions.

ww

(b)

R 3438

Reg. No. :

v 4234

B.E./B.Tech. DEGREE EXAMINATION, APRIIIMAY 2008.

Eighth Semester

(Regulation 2004)

Mechanical Engineering

ME 1015 - PRODUCTION PLANNING AND CONTROL

co

m

(Common to B.E (Part Time) Seventh SemesterRegulation 2005)

Maximum : 100 marks

Time : Three hours

N.

Answer ALL the questions.

va

PARTA-(10 x2=20 marks)

Define continuous production.

2.

What is meant by Break even Analysis?

3.

Define method study.

4.

What is work measurement?

5.

List the pre-requiste information neededfor processplanning.

6.

How is the quality determined in batch production?

7.

Define Kanban svstem.

8.

What is manufacturing lead time?

9.

Write the uses of two bin system.

10.

What is ABC analysis?

ww

w.

M

aa

na

1.

PARTB-(5x16=80marks)

11. (a)

(16)

Discuss the ten functions of production planning cycle.

Or

(b)

12. (a)

(6+5+5)

Write detailed notes on :

(i)

Standardization

(ii)

Simplification

(iii)

Specialization.

(i)

Explain the various steps for time study.

Discuss predetermined motion time standard.

(ii)

(8)

(8)

Or

Explain micro motion and memo motion study?

(8)

(ii)

Discuss the advantagesand disadvantagesof work sampling.

(8)

Discuss in detaii the different phases of applying value analysis.

Or

(a)

(8+8)

Processplanning.

(i)

Describe the information flow for master scheduling .

(ii)

With an example explain Gantt chart.

(8 + 8)

w.

Or

Write detailed notes on :

(i)

Flow production scheduling

(8+8)

ww

ft)

(16)

va

(ii)

M

14.

Explain the steps involved in :

(i)

Productplanning

aa

na

ft)

co

m

13. (a)

(i)

N.

(b)

15.

(a)

(b)

(ii)

Batch production scheduling.

(i)

Discuss the different costs associatedwith Inventory.

(ii)

Derive an expression for EOQ with uniform demand rate without

(10)

sfiortages.

Discussin detail

(i)

JIT

(ii)

ERP.

(6)

(8+8)

v 4234

A 1400

B.E./B.Tech.

DEGREEEXAMINATION,MAY/JUNE 200?.

SeventhSemester

MechanicalEngineering

MF 441- PROCESSPT,ANNINGAND COSTESTIMATION

fime : Three hours

Maximum : 100marks

Answer ALL questions.

x2=20 marks)

co

m

PARTA-(10

Definestandardization.

2.

What is Break Even Analvsis?

3.

What are the aims of costing?

4.

Define Estimation.

5.

List out the different components of Cost.

6.

What are the factory expenses?

7.,

What are the lossesin forging?

8.

What are the Different types of labour cost involved in welding?

L

Define standard time. Write formula for standard time"

10.

What are the different types of milling operations?

ww

w.

M

aa

na

va

N.

1.

PARTB-(5x16=B0marks)

11" (a)

(i)

What is the scopeof processplanning?

(ii)

Explain process planning for parts and process planning for

(10)

assembiies.

Or

(6)

(b)

12.

(6)

(i)

what are the benefitsof computeraidedprocessplanning?

(ii)

List out the types of computeraidedprocessplanning.Explain.

(10)

(8)

Describethe various costinvolvedin the estimatingprocedure'

(a) (i)

(ii)

What are the functions of estimating?

(4)

(iii)

Differentiate costing and estimation'

(4)

Or

(2)

What is the importance of costing?

(iii)

Describethe detail procedureof estimating'

( 10 )

co

m

(ii)

design in the

A firm producing air circulator wants to place an improved

keeping the

market. suggest a selling price covering the on cost and

will cost

previous profit proportions on sales.The materials in new model

frgures

Rs. 350 and the direct wages would be Rs. 200. The foliowing

(16)

relate to the Previous Year'

Stockof material on 1't April 1976=' Rs' 25,000

aa

na

va

N.

13. (a)

( 4)

What is the aims of estimating?

{b) (i)

Stockof material on 31't March 19?5= Rs' 27,000

Purchaseof raw materials in this period = Rs' 50,000

M

Manufacturing wages = Rs. 15,000

w.

Works on cost = Rs. 7,500

Administrative and sales on cost = 7,500'

ww

Salesduring the Year = Rs. 95,000

(b)

Or

are Rs' 2'00 per

In a production concern the variabie overhead charges

Rs' 35,000' It is

article and the fixed overhead charges per month are

under normal

estimated that 65,000 articles are produced each month

conditions Find :

(i)

The normal overhead cost per article'

charges

If the factory cost drops to 85Voproduction. The overhead

that are unrecovered'

these

(iii) If the production is increased to l30%o by what amount

(16)

chargeswill be over recovered'

(ii)

A 1400

74. (a)

1000 steppedbolts of size shown in Fig. are to be made by machine

forging.Estimate net weight, grossweight and number of bars required.

If m.s bars are availablein 5 metre length and 20 mm diameter. Take

( 16)

the density of m.s bar 7.868gm/cm3.

co

m

ALL DIM IN MM.

what is the material cost of welding two plates of size 300 mm

iength and 150 mm with 8 mm thickness to make a piece

300 x 300 mm approximately? Use rightward technique with no

edge,preparation costs.Take over all cost ofoxygen as Rs.0.70 per

cu.meter, cost of acetyieneat Rs. 7.00 per cu.metre, cost of filler

metal Rs. 2.50 per kg. and 1 cu,cm of frller metal weighs 11.28gms.

va

(i)

aa

na

(b)

N.

Or

M

(L2)

A lap joint is to be preparedin 9.5 mm. M.S. steel sheet using flat

rvelding position and 6 mm electrode.current used is 250 amps and

30 volts. welding speedis 12 m/hr. and 0.3 kg of metal is deposited

ww

(ii)

w.

Assume weld as rightward'

per metre length ofjoint.

Labour costs Rs. 1.50/hr, power Rs. 0.2/I{ST{ and electrode

Rs. 4/kg. Effrciency of machine is 50vo and operating factor is 60vo'

Calculate the cost of labour, power and electrodeper metre of weld'

(4)

15. (a)

(i)

Estimate the time taken to prepare a job as shown in fig. From mild

steel stock bar 4.00 cm in diameter and 7.5 cm long. Assume the

(72)

following data.

Cutting speed for turning and boring operations = 20 m/min

A 1400

Cutting speed for drilling operations = 30 m/min.

Feed for turning and boring operation = 0.2 mm./rev.

Feed for 20 mm drill = 0.23 mm/rev.

co

m

Depth of cut not to exceed3 mm in any operation.

Estimate the time required for tapping a hole with 2 cm diameter

tap (3 mm pitch) to a depth of 5 cm in mild steel. The return speed

of the tap is to be 3 times the cutting speedwhich is to be 10 metres

per minute.

(4)

aa

na

va

(ii)

N.

ALL DIMENSIONS IN MM.

Or

A cast iron block of size 20 cm x 7.5 cm is required to be shaped to

reduce the thickness from 2 cm to 1.8 cm in one cut. Determine the

time required for shapping if cutting speedis 20 m/min. and feed is

0.2 mm per stroke and the cutting time ratio is 3/5.

(8)

(ii)

w.

M

(i)

ww

(b)

Calculate the time required to rough gnnd a steel shaft of 3.?5 cm

diarneter to 3.7 cm diameter size using a grinding wheel of 5 cm

face and assuming a cutting speedof 12 metre/rninute and deptl: cf

(S)

cut 0.0025 cm. Length of shaft to tre ground is 25 crn.

A 1400