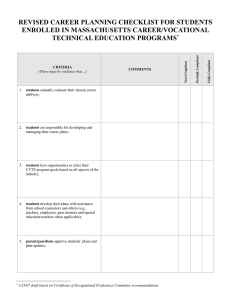

A review on design and synthesis of compliant mechanism for micro actuation ARSHAD JAVED* Graduate Student, Mechanical Engineering, Birla Institute of Technology and Science, Pilani-333031, arshadjaved@rediffmail.com Dr. BIJAY KUMAR ROUT Asst. Professor, Mechanical Engineering Group, Birla Institute of Technology and Science, Pilani 333031 Prof. R. K. MITTAL Dean, ARCD, BITS-Pilani, Birla Institute of Technology and Science, Pilani 333031 Abstract At micro scale, joint frictions of mechanism become highly influencing parameter. Thus the mechanism at this scale must avoid joints causing friction. A compliant mechanism is a mechanism that gets its mobility from the flexibility of some or all of its members and eliminates the need of frictional joints. Though it exists at macro level but it finds its larger application in MEMS. In this paper the study of compliant mechanism and its applications in MEMS is carried out. Design and synthesis of compliant mechanisms is entirely different from the conventional open or close loop mechanisms. Few approaches are developed by researchers and few other methods are in development stage. In all these methodologies topology optimization is a major step as it decides the final shape and structure of the mechanism. In the present work various topology optimization for compliant mechanisms are reviewed, and study of its influence on the final design is been presented. Keywords: Compliant mechanisms, Topology optimization, Micro-actuators 1. MICROACTUATORS In recent years, enormous progress has been made in the design, fabrication, and commercialization of Microsystems. Some of these microsystems require micro actuation to fulfill desired activity. An actuator is a device that transforms a form of energy (mechanical, electrical or thermal energy) into controllable motion. Similar to macro devices, MEMS also require micro actuation in terms of suspension, rotary, intermittent and linear motion. At micro level the task become very challenging as the offered form of energy and the required motion both are in terms of micron. Again, the requirement is to produce not just a motion but an “accurate motion”. At this juncture the traditional actuator methodology/principals seem to be failing due to error and difficulty in manufacturing. 1.1 TYPES OF MICROACTUATORS: Various techniques are used to generate micro actuation in MEMS devices. The challenge is to find out an efficient relationship between motion and energy input. Commonly theses are driven by electrostatic forces, thermal phase change, shape-memory alloy, magnetic and piezoelectric forces. Each of these has its own working methodology and their working principle is discussed briefly. Electrostatic microactuators have been constructed of metal or doped semiconductors and designed with flexures, rotary bearing surfaces and linear bearing surfaces. Typically tens to hundreds of volts are needed to generate a few µN forces to achieve actuation on the order of a few micrometers. Range of motion is increased in some improved designs [13]. The two well known designs are the lateral comb drive [14] and the rotary micromotor [12]. The major difficulty is to provide comparatively large voltage. Again high voltages on small scale create high electric field gradients that attract dust particles. Also, it will not function in conductive fluids. Other electrostatic actuator is scratch drive stepper motor [15] which can work for few µN forces and can travel distances in range of 6 mm. This is used to assemble complex hinged three-dimensional microstructures that are used for optical applications [16]. 1 In thermal microactuators motion is amplified by thermal expansion of thin members. These members are heated by passing a current through them. The thermal actuator design used in recent work is the thermo mechanical in-plane microactuator (TIM). These actuators use bi-morph designs that take advantage of a considerable difference in the thermal expansion coefficient of each material in the device [17]. Some other methods of micro thermal actuation are nonsymmetrical heating of a single layer of patterned material [18]; force generated during the phase change from liquid to vapor [19]; shape-memory alloys; phase change from a low-temperature and weak martensite crystal phase to a higher-temperature and very rigid austenite crystal phase [20, 21]. In Magnetic microactuators straight macroscopic designs may be one of the solution of despite the significant challenge involved in integrating ferromagnetic cores, rotors and copper coils around the cores [22, 23]. Magnetic actuation has an advantage over electrostatics actuation as it can achieve larger forces over larger gaps than their electrostatic counterparts. Magnetic actuation can operate in conductive fluids and the lower electric field gradients present in magnetic microactuators and it will not attract appreciable quantities of dust particles. Magnetic microactuators can generate torque and large out-of-plane deflections (e.g., more than 90◦) useful for microphotonic and millimeter wave applications [24, 25]. Magnetostrictive materials can also be used for micro actuation, which experience a mechanical strain when magnetized. Piezoelectric microactuators use piezoelectric materials that generate large forces over small displacement. .MEMS devices for example accelerometer sensors and micro actuators are frequently use micro-fabricated piezoelectric devices that convert a mechanical displacement to an electric signal.They also transform electric signals to mechanical displacement with an inverse piezoelectric effect. Piezoelectric materials are used to generate large forces over small displacements. Some piezoelectric materials like, ZnO and PZT are used for the devices in surgical applications like a smart force-feedback knife [26], and an ultrasonic cutting tool [27]. 2. MICRO-MECHANISM AND COMPLIANT MECHANISM The function and requirement of a micro-actuator has been described earlier. Micro-mechanism is a part of micro actuator. It basically modifies (amplify or reduce) or generates the desired motion in the system. There are few basic elements in micro mechanism like Pits, grooves and channels, Microflexures and Microbearing surfaces. Combination of these building blocks, bring new mechanisms at micro level. Pits, grooves and channels are created by bulk micro machining. Microflexures are used to achieve simple kind of motion [28]. In many other applications, combination of micro flexural elements is used. These basic elements are cantilever beams, bridges, torsion bars, plates and membrane. A dry release etch (e.g., plasma etching, XeF2 etc) is used to fabricate these since it does not have a fluid meniscus and will not generate surface tension forces [29]. Microbearing surfaces are nothing but the base surface for rotation and translation motion to enable fully free structures capable of unlimited rotation. Major problem in these are wear and relatively small life [30]. New methods are also developed to improve the bearing materials and they are partially successful [31] But in all the cases requirement is to produce a specific motion with certain range and predefined behavior just like macro mechanism. Also there is a requirement to reduce or amplify the motion in a desired manner. Due to limitations in manufacturing, assembly methods, and friction it is difficult to fabricate mechanism at micro level [1]. In such situation compliance mechanism is the effective solution. It is a single part mechanism providing a limited deflection that is used as amplified or modified motion. The concept of compliant mechanisms is not new [4]. Basically it is a structure with zero degree of freedom. But the links are not rigid and shows small deflections when force is applied. Combination of different deflection of each links creates a specific motion with respect to an input force, and it works as macro mechanism. Thus, compliant mechanisms function as a synergistic combination of a structure and a mechanism, or as a “structure with mobility” [5]. The links are having no apparent joint as in the case of conventional macro mechanism. Compliant mechanisms are require fewer parts; are easy to fabricate; have less wear, and backlash; have no need for lubrication; and have built-in restoring force [2, 3]. Hence it reduces the major problem of friction, fabrication of micro joints, and reliability. A compliant mechanism is a mechanism that gains its mobility from the flexibility of some or all of its members, as opposed to its more conventional rigid body counterpart [6] The application of compliant mechanism in MEMS device is shown in Fig. 1. It shows a compliant suspension to guide the shuttle mass of a micro-linear electrostatic actuator (comb-drive actuator) [43]. This suspension provides a very low stiffness (highly compliant) in the direction of motion and higher stiffness in the direction perpendicular to the motion. 2 Fig. 1 Compliant mechanism based motion amplifier [43] 2.1 DESIGN METHODOLOGY OF COMPLIANT MECHANISMS A compliant mechanism has the characteristics of both structures and kinematic chain. Therefore, design method can have two approaches: (i) taking it as a structure with some definite range of deflection, known as structure optimization method [34-37] and (ii) taking it as a kinematic chain having flexible links and joints, known as kinematic synthesis approach [32,33]. Analysis of compliant mechanism can be complex, often requiring nonlinear finite-element analysis, a possible way is a pseudo-rigid-body model, which helps to simplify the analysis and improve understanding of how compliant bi-stable mechanisms behave [44-63]. In other words design of compliant mechanisms can be classified into two types: lumped and distributed compliant mechanisms. Lumped compliant mechanisms are based on rigid-body kinematic synthesis, and distributed compliant mechanisms are based on of continuum topology optimization [6, 38]. Lumped compliant mechanisms are typically analyzed by using the pseudo-rigid-body approaches [40]. In this approach some part of the mechanism is considered as rigid while material near to the flexible joint is taken as flexible. But lumped compliant mechanisms are not very suitable as it undergone unsymmetrical over strain around hinges [42]. Thus distributed compliance is the remaining method in which compliance is distributed through structure. This method was described through topology optimization by Ananthasuresh [41]. Distributed compliant mechanisms are basically structure and obtaining their flexibility from topology and shape of the material continuum. They are suitable for mechanisms at microscale with the characteristics of continuous and monolithic structures. To adequately design a compliant mechanism, these criteria should be addressed [8, 11]. The criteria are, required kinematic motion, desired mechanical or geometrical advantage, required stiffness to an external load, material properties, stress limitations, weight limitations, buckling instabilities, dynamics and actuator characteristics. Distributed compliant mechanisms synthesis eliminates the problems of load concentrations and poor lifetimes by distributing the strain energy throughout the mechanism. Hence each member undergoes an elastic deformation and transferring energy from the input to the output. This synthesis process is not exactly same as the traditional kinetic synthesis process, as the links are not rigid. The synthesis process is typically completed in two steps [9-11]. The first step is to construct a kinematic geometry that generates the desired displacement and force output for a given input. This process is called topology synthesis which takes the form of a multi-criteria optimization problem. The second step in the design of compliant mechanisms is size and shape optimization. In this step the shape of the individual elements is optimized to ensure that the mechanism achieves prescribed performance specifications such as maximum stress, motion amplification or force amplification etc [11]. In an additional step one can also enforce local constraints for the minimization of buckling instabilities, enforcement of stress limitations to ensure the operation envelope of the device is within the elastic regime, minimization of stress concentrations, as well as enforcement of fabrication and weight limitations[9-11]. 3. TOPOLOGY SYNTHESIS AND OPTIMIZATION Topology synthesis is the process in which a kinematic layout is created that is capable of giving the prescribed output with respect to the input force and displacement. It also decides sufficient stiffness to with stand against external loads. Topology optimization provides qualitative results, thus it provides a kinematically functional mechanism. 3 In microstructures topology optimization has been applied in continuum structures [1] in recent years particularly in compliant mechanism in micro structures [1-6]. Different approaches are chosen by different researchers to find the optimum solution. Most of the effort has been spent in developing techniques for optimization and associated difficulties. These techniques are summaries below: 3.1 DESIGN BASED ON DIFFERENT APPROACHES: Few researchers tried to change the basic approach of designing. Initially researchers attempted to solve these problems by taking lumped and distributed system as discussed in section 2.1, few others advancements in these approaches are discussed below, On of these approach is Energy based formulation [8]. In this approach objective function is selected to maximize the energy throughput the structure to optimizing the performance [8, 11] (discussed in 2.1) of a compliant mechanism. It is based on distributed compliance. These formulations can be implemented for topology synthesis as well as size and shape refinement. This formulation can incorporate other energy domain like electric, magnetic etc also. The next approach is Methodology based on flexible building blocks [72]. It combines the kinematic and structural approach. A multi objective genetic algorithm is used for global optimization of compliant building blocks assemblies. This algorithm allows discrete variables such as buildingblocks variables or boundary conditions variables in design problem. And different discrete possibilities can be explored such as materials possibilities, fixed frames locations, actuators locations, and contacts locations. 3.2 DESIGN BASED ON DIFFERENT OPTIMIZATION TECHNIQUES: By changing the mathematical techniques of optimization, various solutions are possible. Starting with Multi physics Optimization Topology [65], It is a methodology to implement structural topology optimization via a fully-coupled partial differential equation (PDE) expression. The multiphysical structural optimization capability is integrated through specially derived Lagrange-Euler equations. Subsequently Wavelet-based interpolation algorithm [66] was devised by Fu and Zhang. It is a methodology to implement structure topology optimization via a fully-coupled partial differential equation (PDE) expression. The multiphysical structural optimization capability is integrated through specially derived Lagrange-Euler equations. In most of the topology result checkerboard pattern comes out. Checkerboard is a pattern, in which solid and void elements alternate in a periodic fashion, are frequently encountered in the solutions to the topology optimization design. Such patterns make topology extraction and subsequent fabrication very difficult. The methodology combining topology and reliability based design optimization [67] for compliant design was proposed by Maute and Frangpol. This method provides a stochastic method for compliant MEMS design. Topology optimization problem is also solved by traditional optimization techniques [68]. The method of moving asymptotes is applied to solve the optimization problem. It is classified to the sequential convex programming methods. To prevent numerical singularities density filtering approach can also be applied. This method can handle problems such as checkerboards, mesh-dependency and one-node connected hinges in resulting mechanisms. Another method is Multi criterion Optimization technique. Initially optimization problems were solved utilizing the homogenization approach, later, several objective functions were investigated, including a weighted-sum multicriteria approach based on maximizing the flexibility of a mechanism while simultaneously maximizing the stiffness. Larsen et al. [78] posed an objective based on maximizing the flexibility of a mechanism while obtaining a specific mechanical advantage. Frecker et al. [77] reformulated the flexibility and stiffness criterion as a ratio while using ground truss structure for topology synthesis. Nishiwaki et al. [79] also posed the two criteria as ratios, but additionally used the homogenization approach and expanded the formulation for plural multi-flexibility cases. This topology optimization is also solved using level set methods [76]. In this methodology a level-set method for designing monolithic compliant mechanisms made of multiple materials as an optimization of continuum heterogeneous structures was given. Also the formation of de facto hinges was dealt based on the shape gradient information. Use of a random guided search method for multiobjective optimization of compliant mechanisms through genetic programming techniques [73] is also attempted. Features that exploit the implementation of genetic algorithms to compliant mechanism design, such as multiple criteria specification and multiple-design parameter variation. The optimization of topology is attempted by suppressing intermediate density [74]. This technique uses a constraint of explicit penalty with variable bound to suppress intermediate density in topology optimization of compliant mechanisms, to ensure mesh independent and not to complicate the non convex objective function in compliant design. The topology optimization using Sequential Convex Programming was attempted by Ying and Luo [69]. To overcome the shortcomings of weighting methods, this method adopts the compromise programming to convert the multi-criteria problem to one single problem. The fundamental idea of the CP methods is to define the scalarized objective function to be minimized by metric form. In this method 4 both the mechanical functionality and the structural stiffness are considered as optimization objective functions. This topology optimization problem was dealt as a Multiobjective topology optimization problem [70] which is based on minimal structural compliance and maximal structural output displacement of MEMS actuators. Topological synthesis of compliant mechanisms was carried out using Linear Beam Elements concepts [71]. This study employs a multi-criteria objective function comprised of mutual potential energy (MPE) and strain energy (SE) to full ground truss structures. 3.3 DESIGN BASED ON DIFFERENT TYPE OF MATERIALS Compliant mechanism should be designed for more realistic situations in which non linearity present in the material and some special actuators. Topology optimization design of Flextensional Actuators (piezo-ceramic attached to a fexible mechanical structure) [64] is based on the homogenization design method. The objective is to determine the optimal material property (via material volume fraction) and structural topology to maximize the performance of the structure in a given application. Essentially, the method consists of finding the optimal material distribution in a perforated domain with infinite micro scale voids. This method can be applied to 3-D model also. The design using general displacement functional with non-linear material model is used in the topology optimization formulation [75]. Sensitivity analysis of this displacement functional is derived from the adjoint method and the optimization problem is solved iteratively by the generalized convex approximation. 30 25 20 15 10 5 2007 2006 2005 2004 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 1993 1992 1991 1990 1966-90 0 Fig. 2 Year-wise publication in international journals Fig.2 shows the number of research publication in the area of compliant mechanism particularly. The thrust of research has started in the year 1994 and further exploration is continuing recently. 4. CONCLUSION AND FUTURE SCOPE In this paper, the need of micro-actuator in MEMS is discussed. The compliant mechanism needed and issues involved to fulfill this requirement are presented. Various topology optimization methods used in compliant mechanism have been stated. The purpose of these methods is to tackle the real time difficulty in the design process like de facto hinge, checker-board, non linear material problems etc. And thus provide an effective methodology which can generate the optimum solution with respect to simplicity, computation time etc. Not only MEMS, but most of the commonly used macro-mechanism are renovated using this concept. The design based on energy formulation, incorporating thermal, magnetic, electrostatic and piezo-actuator with a compliant micro-mechanism has been discussed. The future scope lies in considering non-linearities due to large deformation, and dynamic aspects of micromechanical structures. The life and fatigue failure of these mechanisms are not investigated so far. Though MEMS always deal with planner compliant mechanism but 3D compliant micro mechanism may be an advancement which will open new frontier. 5 References [1] G.K Ananthasuresh, S. Kota and Y. Gianchandani, “A Methodical Approach to the Design of Compliant Micromechanisms,” Proceedings of the Solid-State Sensor and Actuator Workshop, Hilton Head Island, SC, 189-192, 1994. [2] N.M. Sevak and C.W. McLarnan, “Optimal synthesis of flexible link mechanisms with large static deflections,” J. Eng. Ind., 97, 520–526, May 1975. [3] I. Her and A. Midha, “A compliance numberconcept for compliant mechanisms and type synthesis,” Journal of Mechanisms. Transmissions and Automation in Design. Transactions of the ASME, 109(3), 348-355, 1987. [4] R.H. Bums and F. R. E. Crossley, “Kinetostatic synthesis of flexible link mechanisms,” ASME-Paper No. 68-Mech-36 1968. [5] J. Jinyong, S. Kota, and N. Kikuchi, “Topological Synthesis of Compliant Mechanisms Using Linear Beam Elements,” Journal of Mechanics Based Design of Structures and Machines, 28(4), 245 – 280, Nov. 2000 [6] O. Sigmund,”On the Design of Compliant Mechanisms Using Topology Optimization ', Mechanics Based Design of Structures and Machines, 25(4), 493 – 524, Jan. 1997. [7] J.W. Wittwer, “Simulation-Based Design Under Uncertainty for Compliant Microelectromechanical Systems,” Report for the degree of Doctor of Philosophy, Brigham Young University, April 2005 [8] S. Kota, J. Hetrick, Z. Li, and L. Saggere, “Tailoring Unconventional Actuators Using Compliant Transmissions: Design Methods and Applications,” IEEE/ASME Transactions on Mechatronics, 4(4), 396-408, Dec. 1999. [9] G.K. Ananthasuresh, and S. Kota. “Designing compliant mechanisms,” ASME J. Mechanical Engineering, 117, 93-96, Nov. 1995. [10] S. Kota. “Compliant systems using monolithic mechanisms,” Smart Materials Bulletin. Elsevier Science Ltd., 36, 7-10, March 2001. [11] S. Kota, J. Joo, Z. Li, S. Rodgers and J. Sniegowski. “Design of Compliant Mechanisms: Applications to MEMS,” Analog Integrated Circuits and Signal Processing, 29. 7-15, 2003. [12] L-S. Fan, Y-C. Tai and R.S. Muller, “IC-processed electrostatic micro-motors,” International Technical Digest Electron Devices Meeting, IEDM '88, 666-669,1988. [13] J.D. Grade, H. Jerman and T.W. Kenny, “A large-deflection electrostatic actuator for optical switching applications,” Solid-State Sensor and Actuator Workshop Technical Digest,Hilton Head Island, SC, 97–100, 2000. [14] W.C. Tang, T.-C.H Nguyen and R.T. Howel, “Laterally driven polysilicon resonant microstructures,” Proceedings of Micro Electro Mechanical Systems, An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots'. IEEE, 53-59, Feb 1989. [15] T. Akiyama, D. Collard and H. Fujita, “Scratch drive actuator with mechanical links for self-assembly of threedimensional MEMS,” J. Microelectromech. Syst., 6, 7-10, 1997 [16] M.C. Wu, “Micromachining for optical and optoelectronic systems,” Proceedings of the IEEE, 85(11), 1833-1856, Nov. 1997. [17] G.T.A. Kovacs, “Micromachined Transducers Sourcebook,” Boston, McGraw-Hill, 1998 [18] H. Guckel, J. Klein, T. Christension, K. Skrobis,M. Laudon and E. Lovell, “Thermo-magnetic metal flexure actuators,” Solid-State Sensor and Actuator Workshop Technical Digest, Hilton Head Island, SC, 73–5,1992 [19] M.J. Zdeblick, “Integrated, microminiature electric to fluidic valve,” US Patent 4 824 073, 1989 [20] A.D. Johnson, “Vacuum-deposited TiNi shape memory film: characterization and applications in microdevices’” J. Micromech. Microeng., 1, 34–41, 1991 [21] A.P. Lee, D.R. Ciarlo, P.A. Krulevitch, S. Lehew, J. Trevino and M.A. Northrup, “A practical microgripper by fine alignment, eutectic bonding and SMA actuation,” Proc. Int. Solid-State Sensors and Actuators Conf., Transducers ’95, Stockholm, 368–71, 1995 [22] C.H. Ahn, Y.J. Kim and M.G. Allen, “A planar variable reluctance magnetic micromotor with fully Integrated stator and wrapped coils,” MEMS ‘93: Proc. IEEE Micro Electro Mechanical Systems, Fort Lauderdale, 1–6, 1993 [23] H. Guckel, T.R. Christenson, H.J. Skrobis, T.S. Jung, J. Klein, K.V. Hartojo and I. Widjaja, “A first functional current excited planar rotational magnetic micromotor,” MEMS ‘93: Proc. IEEE Micro Electro Mechanical Systems, Fort Lauderdale, 7–11, 1993 [24] J.W. Judy, R.S. Muller and H.H. Zappe, “Magnetic microactuation of polysilicon flexure structures,” IEEE J. Microelectromech. Syst., 4, 162–169, 1995 [25] J.W. Judy and R.S. Muller, “Magnetically actuated, addressable microstructures,” J. Microelectromech. Syst., 6, 249– 256, 1997 [26] D.L. Polla, D.J. Peichel, A.G. Erdman and J.A. Costin, “Piezoelectric microactuator useful in a force-balanced scalpel,” US Patent 5 629 577 [27] A. Lal, “Silicon-based ultrasonic surgical actuators,” Proc. 20th Annu. Int. Conf. of the IEEE Engineering in Medicine and Biology Society, Hong Kong, 20, 2785–2790, 1998 [28] H.C. Nathanson, W. E. Newell, R.A. Wickstrom and J.R. Davis , “The resonant gate transistor,” IEEE Trans. Electron Devices, 14(2) 117-133, 1967 6 [29] Y.I. Lee, K-H. Park, J. Lee, C-S Lee, H. J. Yoo, C-J Kim and Y-S Yoon, “Dry release for surface micromachining with HF vapor-phase etching,” J. Microelectromech. Syst., 6, 226–233, 1997 [30] K. Deng, V.R. Dhuler, M. Mehregany and E. W. Jansen, “Measurement of micromotor dynamics in lubricating fluids,” Proc. Micro Electro Mechanical Systems , Fort Lauderdale, 260–4, 1993 [31] M.R. Houston, R. Maboudian and R.T. Howe, “Self-assembled monolayer films as durable anti-stiction coatings for polysilicon microstructures,” Technical Digest Solid-State Sensor and Actuator Workshop, Hilton Head Island, 42–7, 1996 [32] L.L. Howell and A. Midha, “A Loop-Closure Theory for the Analysis and Synthesis of Compliant Mechanisms,” ASME Journal of Mechanical Design, 118, 121-125, 1996. [33] L.L. Howell, A. Midha, and T.W. Norton, “Evaluation of Equivalent Spring Stiffness for Use in a Pseudo-Rigid-Body Model of Large-Deflection Compliant Mechanisms”, ASME Journal of Mechanical Design, 118, 126-131, 1996. [34] G.K. Anathasuresh, S. Kota, and N. Kikushi, “Strategies for Systematic Synthesis of Compliant MEMS”, ASME Winter Annual Meeting, Chicago, Illinois, USA, DSC-55(2), 677-686, 1994. [35] M.I. Frecker, “Optimal Design of Compliant Mechanisms”, Ph.D. Dissertation, Department of Mechanical Engineering, University of Michigan, Ann Arbor, Michigan, USA, 1997. [36] J.A. Hetrick and S. Kota, “An Energy Formulation for Parametric Size and Shape Optimization of CompliantMechanisms,” Journal of Mechanical Design, 121, 229-234, 1999. [37] J. Joo, S. Kota, and N. Kikuchi, “Nonlinear Synthesis of Compliant Mechanisms: Topology Design”, Proceedings of 2000 ASME Biannual Mechanism Design Conference, PA, 1-6, 2001 [38] O. Sigmund, "On the design of compliant mechanisms using topology optimization," Mechanics of Structures and Machines, 25(4), 493-524, 1997 [39] O. Sigmund, "Design of Multiphysics Actuator using Topology Optimization – Part: One, Material Structure," Computational Methods in Applied Mechanics and Engineering, 190(49-50), 6577-6604, 2001, [40] L.L. Howell, "Compliant mechanisms," John Wiley &Sons, Inc., New York, 2001. [41] G.K. Ananthasuresh, L. Yin, "A novel topology design scheme for the multi-physics problems of electro-thermally compliant micromechanisms". Sensors and Actors, Series A: physical, (97-98), 599-609, 2002 [42] H. Ying, H. Xu, “Topology Optimization of Compliant Mechanisms Using Sequential Convex Programming,” Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 4388-4392, Oct. 2006 [43] S. Nishiwaki, S. Min, S. Ejima, and N. Kikuchi, “Structural optimization considering flexibility,” ASME Int. J., 41(3),476–484, 1998. [44] P. Opdahl, B.D. Jensen, and L.L. Howell, “An Investigation into Compliant Bistable Mechanisms,” Proceedings of the 1998 ASME Design Engineering Technical Conferences, DETC98/DAC-5914, 1998 [45] M. Saif, “On a Tunable Bistable MEMS-Theory and Experiment,” Journal of Microelectromechanical Systems, 9(2), 157-170, 2000 [46] M. Vangbo, M., “An Analytical Analysis of a Compressed Bistable Buckled Beam,” Sensors and Actuators A, 69(3), 212-216, 1998. [47] Y.J. Yang and C-J Kim, “Dynamics of a Bistable Snapping Microactuator,” Proceedings of SPIE, 2443, 754-762, 1995 [48] Y-J. Yang and C-J. Kim, “Testing and Characterization of a Bistable SnappingMicroactuator Based on ThermoMechanical Analysis,” Digest of Technical Papers / International Conference on Solid-State Sensors and Actuators, 2, 337-340, 1995 [49] B. Hälg, “On a Nonvolatile Memory Cell Based on Micro-Electro-Mechanics,” Proceedings - IEEE Micro Electro Mechanical Systems: An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots, Napa Valley, CA, 172-176, 1990 [50] M. Capanu, J.G. Boyd and P.J. Hesketh, “Design, Fabrication, and Testing of a Bistable Electromagnetically Actuated Microvalve,” Journal of Microelectromechanical Systems, 9(2), 181-189., 2000. [51] C. Goll, W. Bacher, B. Bstgens, D. Maas, W. Menz and W.K. Schomburg, “Microvalves with bistable buckled polymer diaphragms,” Journal of Micromechanics and Microengineering, 6(1), 77-79, 1996 [52] B. Wagner, H.J. Quenzer, S. Hoerschelmann, T. Lisec, and M. Juerss, “BistableMicrovalve with Pneumatically Coupled Membranes,” Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS), San Diego, CA, 384-388., Feb. 1996 [53] J. Qiu, J.H. Lang, and A.H. Slocum, “A Curved-Beam Bistable Mechanism,” Journal of Microelectromechanical Systems, 13(2), 137-146, 2004 [54] N.D. Masters, and L.L. and Howell, “A Three Degree of Freedom Pseudo-Rigid-Body Model for the Design of a Fully Compliant Bistable Micromechanism,” Proceedings of the 2002 ASME Design Engineering Technical Conferences, DETC2002/MECH-34202, 2002 [55] L. Que, L. Otradovec, A.D. Oliver and Y.B. Gianchandani, “Pulse and DC Operation Lifetimes of Bent-Beam ElectroThermal Actuators,” Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS), 570-573, 2001. 7 [56] H. Chang, J. Tsay and C. Sung, “Design of a fully compliant bistable micromechanism for switching devices,” Proceedings of SPIE - The International Society for Optical Engineering, 4593, 97-108, 2001. [57] M.B Parkinson,., Jensen, B.D., and Roach, G.M., 2000, “Optimization-Based Design of a Fully-Compliant Bistable Micromechanism,” ASME Design Engineering Technical Conferences and Computer and Information in Engineering Conference, Baltimore, Maryland, 2000 [58] B.D. Jensen, F. Bitsie, and M. de Boer, “Interferometric Measurement for Improved Understanding of Boundary Effects in Micromachined Beams,” Proceedings of SPIE - The International Society for Optical Engineering, 3875, 6172, 1999 [59] B.D. Jensen, L. L. Howell and L. G. Salmon, “Introduction of Two-Link In-Plane, Bistable Compliant MEMS,” Proceeding of the 1998 ASME Design Engineering Technical Conferences, DETC98/MECH-5837, 1998. [60] E.J.J. Kruglick, and K. S.J. Pister, “Bistable MEMS Relays and Contact Characterization,” IEEE Solid-State Sensor and Actuator Workshop, Hilton Head Island, South Carolina, 333-337, June 1998 [61] L.L Howell., and A. Midha, and M.D., Murphy, 1994d, “Dimensional Synthesis of Compliant Constant-Force Slider Mechanisms,” American Society of Mechanical Engineers,Design Engineering Division (Publication) DE, 23rd Biennial Mechanisms Conference, 71, 509-515, 1994 [62] J.W. Wittwer, and L.L. Howell, “Design of a Functionally Binary Pinned-Pinned Segment For Use as a TensionCompression Spring in Compliant Mechanisms,” Proceedings of IMECE 2002, ASME International Mechanical Engineering Congress & Exposition, New Orleans, 17-22, Nov.2002. [63] M.S. Baker, S.M. Lyon, and L.L. Howell, “A Linear Displacement Bistable Micromechanism,” Proceedings of the 2000 ASME Design Engineering Technical Conferences, DETC2000/MECH-14117, 1-7, 2000 [64] E.C.N. Silva, S. Nishiwaki and Noboru Kikuchi, “Topology Optimization Design of Flextensional Actuators,” IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 47(3), 657-671, May 2000. [65] J.G. Korvink and Z. Liu, “Multiphysics for Topology Optimization in MEMS,” Proceedings of the 6th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Micro-Electronics and MicroSystems, EuroSimE, 214- 218, April 2005 [66] Y. Fu, and X. Zhang, “Wavelet-Based Interpolation Algorithm for Topology Extraction of Compliant Mechanisms,” Proceedings of the Fourth International Conference on Machine Learning and Cybernetics, Guangzhou, 2802-2807, August 2005. [67] K. Maute and D.M. Frangopol, “Reliability-based design of MEMS mechanisms by topology optimization,” Comput. Structures, 81, 813–824, 2003. [68] J. Liu, and Y.C.Z. Luo, “Design of Monolithic Compliant Mechanisms for Microactuator Using Topology Optimization Schemes,” Proceedings of the 6th World Congress on Intelligent Control and Automation, Dalian, China, 6465-6469, 2006 [69] H. Ying, and H.X.Z. Luo, “Topology Optimization of Compliant Mechanisms Using Sequential Convex Programming,” Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 4366-4392, 2006 [70] K. Zuo, Y. Zhao, Y. Xie and L. Chen, “Design MEMS Actuators with Topology Optimization Method,” Proceedings of the 1st IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Zhuhai, China, 15171522,2006 [71] J. Joo, S. Kota and N, Kikuchi, “Topological Synthesis of Compliant Mechanisms Using Linear Beam Elements,” International Journal of Mechanics Based Design of Structures and Machines, 28(4), 245-280, Nov. 2000. [72] P. Bernardoni, P. Bidaud, C. Bidard and F. Gosselin, “A new compliant mechanism design methodology based on flexible building blocks,” Proceedings of SPIE, Smart Structures and Materials 2004: Modeling, Signal Processing, and Control, 5383, 244-254, July 2004. [73] R. Parsons and S. L. Canfield, “Developing genetic programming techniques for the design of compliant mechanisms,” Journal of Structural and Multidisciplinary Optimization, 25(1),78-89,Aug.2002. [74] G.K. Lau, H. Du, M. K. Lim, “Techniques to suppress intermediate density in topology optimization of compliant mechanism,” Computational Mechanics, 27(5), 426-435, 2001. [75] D. Jung and h. C. Gea, “Compliant mechanism design with non-linear materials using topology optimization,” International Journal of Mechanics and Materials in Design, 1(2), 157–171, 2004. [76] M.Y. Wang, S. Chen, X. Wang, and Yulin Mei, “Design of Multimaterial Compliant Mechanisms Using Level-Set Methods,” Journal of Mechanical Design, 127, 941-947, 2005. [77] M.I. Frecker, G.K. Ananthasuresh, S. Nishikawi, N. Kikuchi, and S. Kota, “Topological synthesis ofcompliant mechanisms using multi-criteria optimization,” Journal of Mech. design, 119, 238–245, 1997. [78] U.D. Larsen, O. Sigmund, and S. Bouwstra, “Design and fabrication of compliant micromechanisms and structures with negative Poisson’s ratio,” J. Microelectromech. Syst., vol. 6, no. 2, pp. 99–106, June 1997. [79] S. Nishiwaki, S. Min, S. Ejima, and N. Kikuchi, “Structural optimization considering flexibility,” JSME Int. J., vol. 41, no. 3, pp. 476–484, 1998. 8