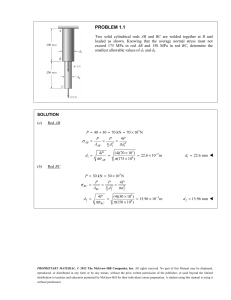

Torsion Apparatus Experiment TORSION APPARATUS EXPERIMENT (The Modulus of Rigidity) Student's Guide Laboratory Manual 1 and Workbook (2014) Torsion Apparatus Experiment List of Equipment 1. Torsion Apparatus Machine 2. Metal Test Rods (Test Specimens with Different Diameters) 2.1. Steel (Diameter: 3.0mm, Length:100cm) 2.2. Steel (Diameter: 4.0mm, Length:100cm) 2.3. Brass (Diameter: 3.0mm, Length:100cm) 2.4. Brass (Diameter: 4.0mm, Length:100cm) 3. Wheel (Diameter:17cm) 4. Masses (8 Pieces) 5. 4.1. Mass:4x400gr 4.2. Mass:2x200gr 4.3. Mass:1x100gr 4.4. Mass:1x50gr String 2 Torsion Apparatus Experiment Purpose: The objective of this experiment is to analyze and determine the rigidity modulus of the various metal rods. Introduction: The torsion apparatus is used to determine the modulus of rigidity (or shear modulus) of the materials. When under application of an external force, the shape of a solid material changes without change in its volume, and the solid material is said to be shared. This deformation happens when a tangential force (F ) is applied to one of the faces of the object. In the case of the rigidity modulus, suppose a rigid block whose lower face is fixed and a known tangential force (F ) is applied to its upper face as seen in the Figure-(1). This external force Figure-1: Deformation of a solid object under shear stress. causes the parallel layers to the lower face to slip through a distance of x from the fixed face of the solid block such that the upper face shifts and the Here, A is the area of the upper face of the solid solid material takes a new form while its volume block. The unit of stress is the Pascal (1 Pascal=1 remaining unchanged. The strain produced in this Pa=1N/m ). 2 material by the stress is measured by the angle Figure-(1) shows that one side of the object under ( ) called the shearing strain (or simply shear). x shear stress is displaced by a distance Due to this shearing of the solid material, a relative to the opposite side. If the displacement tangential restoring force is developed in the solid (x) is the deformation of the object, we can object which is equal and opposite to the external define applied force. shear displacement strain as the ratio of the x to the transverse dimension, h : Since shear stress is a force per unit area, we define the shear stress as the force (F ) acting Shear strain tangent to the surface, divided by the area ( A) on which it acts: x h (2) Shear strain is a dimensionless number with a ratio of two lengths. F Shear stress A (1) 3 Torsion Apparatus Experiment The ratio of shear stress (tangential stress) to shear strain is called rigidity modulus (or shear modulus) : F/A x/h (3) Note that the concepts of the shear stress, shear strain and shear modulus apply to solid materials only. The reason is that the shear force in the Figure-(1) is required to deform the (a) solid object, and the object tends to return to its original shape if the shear force is removed. The corresponding elastic modulus (ratio of shear stress to shear strain) is given by the shear modulus. Similar to the solid block, when a torque ( ) is applied to a rigid rod (shaft) with length () and (b) radius (r ) , the torque deforms the rod by twisting Figure-2: The shearing of a circular solid metal rod by the it through a small angle ( ) . Torsion occurs applied torque. when a solid material (or shaft) is subjected to a In the geometry given by the Figure-(2), it can be torque ( ) . Here, torsion refers to the twisting of a seen that one end of the rigid rod will rotate about shaft loaded by the applied torque. the longitudinal axis with respect to the other end Consider a horizontal line drawn along the length during twisting. The magnitude of this rotation is of a given metal rod. The rod is fixed at one end measured in terms of the angle and twisted at the other end due to the action of which, one end rotates relative to the other end. torque . This applied torque will cause the one The angle (in radians) by is called the angle of twist. face of the circular cylinder (rigid rod) to be twisted through an angle ( ) at the length Since the end of the metal rod is twisted, the . radial line on the end face of the rod rotates When twisted, the horizontal line moves through an angle through the angle and the line BC will be shifted to AC . The length of the arc BA produced at the outside edge of the rod is the through the angle ( ) . The length of the arc BA deformation distance (corresponding to produced is (Figure-2a). x given in the Figure-1) and will be also equal to r (Figure-2b). 4 Torsion Apparatus Experiment As the external axial torque twists the rod, a In the case of the applied torque, the relationship section perpendicular to the axis at a given between the torque and the twist angle is given distance rotates through the angle . If we by the torsion equation as: assume that the two arcs are the same, it follows that: BA r where r J (9) (4) where (5) J is polar moment of inertia for a solid cylindrical specimen. The polar moment of inertia for a solid circular shaft with the diameter (d ) is the shear strain (the angle of the can be calculated as: shear) on the outer surface of the solid rod. d4 J The modulus of rigidity (or shear modulus) is given by: (6) (10) 32 By combining Equation-(8) and Equation-(9), we get the general torsion equation as: where, : The applied shear stress, : The resulting shear strain. J r (11) Substituting Equation-(5) into Equation-(6), we Using Equation-(11), we can rewrite the shear get: modulus (or rigidity modulus) at the end of the metal rod as follows: r (7) (8) J (12) or, where, : r Shear modulus (or rigidity modulus), : Length of the metal test rod (shaft) over which the angle of twist is measured, shear stress, shear modulus and angle of twist for J: Polar moment of inertia, a given circular shaft. Applied torque, The Equation-(8) uses the relationship in the : : 5 Angle of twist in radians. Torsion Apparatus Experiment where, : Applied torque, F : The constant applied force due to gravity acting on the hanging mass, R : Radius of the wheel on the torsion apparatus, M : Hanging mass. Figure-3: The cross-section of a solid circular shaft. If we use the applied torque moment of inertia Assume that the circular shaft has a uniform and the polar J for a given circular shaft in the Equation-(12), we can also rewrite the rigidity cross-section along its length () , it is straight modulus ( ) as a function of the mass (load): and the torque is constant along its length. Then we can state that a cross-section normal to the longitudinal axis is planar before the torque 2MgR r4 (15) application and it will remain planar after twisting by the angle (Figure-3). If the torque and the degree of rotation where r is the radius of the circular shaft such that d 2r . are known in a given torsion experiment, the rigidity By plotting a graph of torque ( ) versus the of the any test specimen can be angle of twist ( ) , the rigidity modulus can be determined. In the torsion apparatus, the torque determined from the slope of the graph. So, ( ) is supplied by hanging masses (M ) Equation-(12) can be written as follows; modulus attached to a string wrapped around a vertical wheel with radius (R) . This radius is (Slope) J (16) perpendicular to the applied force (F ) which is the tension in the string wrapped around the wheel. Therefore, the applied torque ( ) in the Therefore, knowing () and (J ) of any metal torsion apparatus can be calculated as: test rod for a particular experiment, and then measuring the slope of corresponding FR (13) MgR (14) graph, Equation-(16) will give the rigidity modulus ( ) of the metal rod experimentally. 6 Torsion Apparatus Experiment Description of the Torsion Apparatus (a) (b) Figure-4: Schematic representation of the torsion apparatus (a) and the cylindrical shaft (metal rod) under applied torsional loading (b). 7 Torsion Apparatus Experiment The torsion apparatus consists of a wheel, metal Experimental Procedure test rods and masses with different weights. The Part-I metal rods include brass with 3.0mm and 4.0mm in diameter (d ) ; the other test rods are steel with The torsion experiment looks at the shear the diameters of 3.0mm and 4.0mm. deformation of a cylindrical shaft (metal rod) The torsion test is performed by mounting the under applied torsional loading. metal rod specimen into a torsion testing machine and then applying the twisting moment (or torque) In the first part of the experiment, the deformation to the material. The metal rod is held horizontal test of the each metal rod is carried out to and rigidly mounted into the end sockets of determine if the deformation remains linear torsion apparatus (Figure-4a). elastic or not. In order to study the response of materials The large wheel contains a socket to hold one under the torsional force, test specimens are mounted between the two sockets end of the metal rod such that this side of the rod of the torsion testing machine and then twisted. is subjected to a torque produced by the vertical Each of the specimens should be elastically wheel. A light string around the groove of the 0 deformed (0 wheel carries masses to produce the torque. 750 ) and the recovery of the specimen to its original shape must be The Figure-(4b) shows a shaft fixed at one end possible if the specimen is unloaded ( 00 ) . and twisted at the other end due to the action of a The deformation is measured by the angle of torque . The masses (M ) are chosen for each rod so that the torsion angle (angle of twist) twist, at the length, of the metal rod. never increases beyond 75 and the deformation To test the deformation of the specimen: must remain linear elastic. Different cylindrical 1. 0 rods are loaded with external torque and then the Measure the diameter of the first specimen to be tested as torsion angle ( ) measured at the end () of the 2. metal rod. Using the data set of the load (torque) d d1 . Clamp the test specimen into the torsion testing machine using the sockets and make and the corresponding angular twist, the rigidity sure the specimen is firmly mounted and modulus of the different cylindrical rods is twist angle, is zero determined. (0 0 ) . 3. Load the masses one by one in order to deform the test specimen elastically until the rod is twisted about 750 of the rotation. Note that the magnitude of torque applied to the specimen must be such that the resulting stress remains in the elastic region. 8 Torsion Apparatus Experiment 4. Remove the weights in the same order in 4. which they were added. Now, the reading of twist angle should be again zero (0 0 essential to make sure that the twist angle is zero (0 ) . Note that the twist angle must be zero each time when the rod is relaxed (the 5. torque ) . If not, set the angle to zero. Now, load the rod with a torque by using torsion angle clockwise and anti-clockwise direction. 6. Record the at the end () of the rod. applied torque and the If the angle of twist is not zero after removing corresponding angle of twist in the data the added weights, the rod is not deformed table. Note that for every load increment; you elastically and the following conditions may should record the torque exist: ( ) with the corresponding angular displacement ( ) . 5.1. The fixed rod is not straight and 4.1. Repeat until enough measurements are horizontal along the end sockets. taken to draw a graph of applied torque 5.2. The rod is not firmly clamped into the as a function of twist angle. end sockets so it is slipping. 6. 0 masses and measure the corresponding unloaded). This procedure is done both in 5. Before loading the masses for torque, it is 7. Before proceeding with the experiment, Plot a graph of the applied torque ( ) repeat the deformation test for the each against the twist angle ( ) of rotation. In the specimen graph, angle of twist should be in radians. with different materials and diameters. 8. Draw the best straight line through the points in the graph and determine the slope. 6.1. By the slope of torque-twist angle Part-II graph, find and record the ratio of the applied torque to the angle of twist. In this part of the experiment, different solid 6.2. Using the slope, the rod diameter (d1 ) cylindrical rods will be subjected to a torsional and load. Then, the modulus of rigidity will be rigidity determined for the cylindrical materials. 1. 9. diameter (d1 ) of the test rod. Also record the 2. 3. length () , modulus ( ) determine of the the test specimen from Equation-(16). For the first test piece, determine the length as rod Compare the experimental value of the rigidity modulus with the accepted value. 1.0m where the angle of twist 10. Carried out the experiment on the rods of the ( ) will be measured. steel and brass of the same diameter Measure the radius (R) of the loading (4.0mm) using the length, 0.5m until wheel in the torsion apparatus. the each rod is twisted about Calculate and record polar moment of inertia by using the corresponding diameter the test piece as J 450 . 11. Repeat the experiment to find the rigidity modulus ( ) (d1 ) of J1 . of the different metal rods under applied torsional loading. 9 Torsion Apparatus Experiment LABORATORY REPORT Name Department Student No Date Material Type: . . . . . Length of Metal Rod, (m) : . . . . . Metal Rod Diameter, d1 (m) : Polar Moment of Inertia, . . . . . J 1 (m 4 ) : . . . . . Table-1: Experimental data values for the rigidity modulus of the metal test rod in the diameter, d 1 . (m) M (kg) (Deg ) (Rad ) ( N .m) Slope (N / m2 ) Measured Measured Measured Experimental Experimental Calculated Experimental 0.0 0.0 0.0 0.0 ….. ….. ….. ….. ….. ….. ….. 1.0 ….. ….. ….. ….. ….. (m) : Test length of the metal rod, M (kg) : Hanging mass, (Deg ) : Twist angle in degrees measured experimentally at the test length () , (Rad ) : Angle of twist in radians, ( N .m) : Applied torque, (N / m2 ) : The modulus of rigidity. 10 Torsion Apparatus Experiment Graph-1: Applied torque as a function of twist angle for the metal rod with diameter (d1 ) at 1.0m . 11 Torsion Apparatus Experiment Material Type: . . . . . Length of Metal Rod, (m) : . . . . . Metal Rod Diameter, d 2 (m) : Polar Moment of Inertia, . . . . . J 2 (m 4 ) : . . . . . Table-2: The rigidity modulus of the metal test rod with the diameter, d 2 . (m) M (kg) (Deg ) (Rad ) ( N .m) Slope (N / m2 ) Measured Measured Measured Experimental Experimental Calculated Experimental 0.0 0.0 0.0 0.0 ….. ….. ….. ….. ….. ….. 1.0 ….. ….. ….. ….. ….. Graph-2: Applied torque as a function of twist angle for the metal rod diameter (d 2 ) at 1.0m . 12 Torsion Apparatus Experiment Material Type: . . . . . Length of Metal Rod, (m) : . . . . . Metal Rod Diameter, d 3 (m) : . . . . . 4 Polar Moment of Inertia, J 3 (m ) : . . . . . Table-3: The rigidity modulus of the metal test rod with the diameter, d 3 . (m) M (kg) (Deg ) (Rad ) ( N .m) Slope (N / m2 ) Measured Measured Measured Experimental Experimental Calculated Experimental 0.0 0.0 0.0 0.0 ….. ….. ….. ….. ….. ….. 1.0 ….. ….. ….. ….. ….. ….. Graph-3: Applied torque as a function of twist angle for the metal rod diameter (d 3 ) at 1.0m. 13 Torsion Apparatus Experiment Material Type: . . . . . Length of Metal Rod, (m) : . . . . . Metal Rod Diameter, d 4 (m) : Polar Moment of Inertia, . . . . . J 4 (m 4 ) : . . . . . Table-4: The rigidity modulus of the metal test rod with the diameter, d 4 . (m) M (kg) (Deg ) (Rad ) ( N .m) Slope (N / m2 ) Measured Measured Measured Experimental Experimental Calculated Experimental 0.0 0.0 0.0 0.0 ….. ….. ….. ….. ….. 1.0 ….. ….. ….. ….. ….. ….. Graph-4: Applied torque as a function of twist angle for the metal rod diameter (d 4 ) at 1.0m . 14 Torsion Apparatus Experiment Material Type: . . . . . Length of Metal Rod, (m) : . . . . . Metal Rod Diameter, d (m) : . . . . . Polar Moment of Inertia, J (m 4 ) : . . . . . Table-5: The rigidity modulus of the steel with the diameter, d 4.0mm at 0.5m . (m) M (kg) (Deg ) (Rad ) ( N .m) Slope (N / m2 ) Measured Measured Measured Experimental Experimental Calculated Experimental 0.0 0.0 0.0 0.0 ….. ….. ….. ….. ….. 0.5 ….. ….. ….. ….. ….. ….. Graph-5: Applied torque as a function of twist angle for the steel rod diameter (d 4.0mm) at 0.5m . 15 Torsion Apparatus Experiment Material Type: . . . . . Length of Metal Rod, (m) : . . . . . Metal Rod Diameter, d (m) : . . . . . Polar Moment of Inertia, J (m 4 ) : . . . . . Table-6: The rigidity modulus of the brass with the diameter, d 4.0mm at 0.5m . (m) M (kg) (Deg ) (Rad ) ( N .m) Slope (N / m2 ) Measured Measured Measured Experimental Experimental Calculated Experimental 0.0 0.0 0.0 0.0 ….. ….. ….. ….. ….. 0.5 ….. ….. ….. ….. ….. ….. Graph-6: Applied torque as a function of twist angle for the brass rod diameter (d 4.0mm) at 16 0.5m . Torsion Apparatus Experiment Table-7: Comparison of the experimental and expected values of the rigidity modulus corresponding to material type. Material Diameter Steel ….. Steel ….. Brass ….. Brass ….. Rigidity Modulus Rigidity Modulus (N / m2 ) (N / m2 ) Experimental Expected %Error () The test length () of the each metal rod is set to 1.0m ± 0.001m in the torsion apparatus. Table-8: Comparison of the experimental rigidity modulus with the expected value of the metal rods (steel and brass). Material Diameter Steel ….. Brass ….. Rigidity Modulus Rigidity Modulus (N / m2 ) (N / m2 ) Experimental Expected %Error () The test length () of the each metal rod is set to 0.5m ± 0.001m in the torsion apparatus. 17