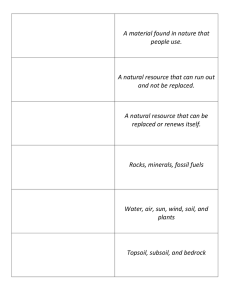

CLIENT PROJECT COMPANY EPC CONTRACTOR Zuluf Water Treatment Plant HSE Construction Plan Appendix B3 – Envir.Impacts of the Project and Mitigation Measures Proj. nº: WT2201 Doc nº: WT2201-FIT-HS-PLN-000-0001 Rev 1 Page 1 of 4 Appendix B3 Environmental Impacts of the Project and Mitigation Measures CLIENT PROJECT COMPANY EPC CONTRACTOR Zuluf Water Treatment Plant HSE Construction Plan Appendix B3 – Envir.Impacts of the Project and Mitigation Measures Proj. nº: WT2201 Doc nº: WT2201-FIT-HS-PLN-000-0001 Rev 1 Page 2 of 4 Appendix B3 – Environmental Impacts of the Project and Mitigation Measures Issue Excavation, construction, demolition wastes Stripped vegetal topsoil Soil pollution impact and mitigation measures Traffic Soil erosion Impact on Ecosystem Protection of the utilities Noise and vibration Environmental Impacts of the Project and Mitigation Measures Mitigation Measure • Some part of excavation earth will be stored in the construction site to be used in stuffing. .Storage areas of excavation earth will be determined before Works by applying the Local Authorities. • Remaining excavation earth and demolition wastes will be carried by licensed persons or companies to areas designated by relevant municipalities. • Site specific Waste Management Plan will be prepared and implemented which will include, among the others, planning and required permits on surplus excavation soil disposal area. • Vegetal topsoil stripped before excavation works will be temporarily stored in a suitable place in the construction site, and transferred to the agricultural and pasture fields which is the local government will be allowed. • Topsoil will be recovered using appropriate equipment. Depending on compaction and recovery rates, deep ripping may be required to maximize topsoil recovery with care taken not to mix topsoil with sodic subsoil. It should be arranged that any excavated topsoil, where practical, shall be stored and reused. The more fertile topsoil will later be deposited to form a superficial layer conducive to seedling establishment. The rest of topsoil shall be utilized for other purposes working in coordination with local authorities and any other public interest to restore eroded land and/or re-forestation in the vicinity of the route. • Sedimentation - Erosion Control and topsoil will be implemented properly. • Contaminated soils will be managed according to the regulations during excavation and handling of soils. • Cleared areas will be stabilized in order to avoid sediment release. • Excavated contaminated materials might be transported or stored in a safe manner on site, before their transportation towards other sites. • Temporary occupied lands will be restored to their normal use after the completion of the construction Works. • In the event of any spoil or debris from construction works being deposited on adjacent land or any silt washed down to any area, then all such spoil, debris or material and silt will be immediately removed and the affected land and areas restored to their natural state. • Permit requirements will be identified for abnormal loads. • The routes will be identified with the estimated numbers of traffic movements, speed and times of travel. • The following speed limits must be respected, except emergency vehicles only at the time of emergency: 20 km/h on the site roads; 10 km/h near and inside construction areas. • Dust and mud control will be identified. • The routes should pass through residential areas that ensure the safety of the community and minimize the nuisance impact of traffic movements. • Existing road development plans will have been taken into account for route and road restoration plans. • Identification of the work shall be undertaken on the roads prior to construction activities, to upgrade or stabilize the roads or any bridges or culverts to accommodate abnormal loads. • Road closures and diversions required will be identified and planned. • A traffic management plan will be prepared and implemented. • All long-term topsoil material stockpiles will be located outside the active construction site and away from drainage lines. Drainage from higher areas will be diverted around stockpile areas to prevent erosion. As required, sediment controls will be installed downstream of stockpile areas to collect any run-off. • Soil erosion will be controlled through use of dikes, fiber mats, mulches, grasses, slope, drains and other devices. • A gutter or trough interceptor drain will be constructed at the top of the cut slopes to prevent the soil erosion by precipitation. • Disturbance areas will be stripped progressively, as required, in order to reduce erosion and sediment generation, to reduce the extent of topsoil stockpiles and to utilize stripped topsoil as soon as possible for rehabilitation. Rehabilitation of disturbed areas, such as • roads, embankments, will be undertaken as soon as practicable after these structures are completed or as areas are no longer required for operational purposes. • Sedimentation and Erosion Control, Top Soil Management will be detailed with management plans and implemented. • Protection and renovation of ecosystem will be assured by studies. • A survey will be established to determine the location of all utilities affected by the Works. • Where either temporary or permanent works are to be undertaken in the vicinity of utilities appropriate construction methods will be adopted to provide adequate protective devices and take precautionary measures, in order to avoid damage to the utilities. • . • Regular and effective maintenance of construction machines will be made; • During the construction, background noise and vibration measurements will be carried out repeatedly and measures will be taken such as sound barriers, mufflers of equipments, if necessary. CLIENT PROJECT COMPANY EPC CONTRACTOR Zuluf Water Treatment Plant HSE Construction Plan Appendix B3 – Envir.Impacts of the Project and Mitigation Measures Issue Water Quality Air Quality Domestic solid waste Proj. nº: WT2201 Doc nº: WT2201-FIT-HS-PLN-000-0001 Rev 1 Page 3 of 4 Environmental Impacts of the Project and Mitigation Measures Mitigation Measure • The contractor will be responsible for designing and construct (etc. Semi-permeable fencing, Noise barriers) the project to ensure that during its operational phase noise levels do not exceed the relevant noise level standards for daytime and nighttime as specified in the EIES. • Silent crossings will be developed in residential areas to reduce horn use in residential areas. • All powered mechanical equipment used in the Works will be effectively sound reduced using the most modern techniques. Acoustic screens or enclosures will be constructed around any parts of the Works from which excessive noise may be generated. • The equipments will be switched off when it is not used; • Keep haul / access roads in close proximity to the Project well maintained. • Rubber linings will be used for dumpers to reduce noise impact. • Minimising drop height of materials; • The plant and vehicles will be started-up sequentially rather than all together; • Reversing alarms will be used that do not have a tonal component (i.e. broadband), if necessary. In this type of alarm, the sound energy would be spread homogenously across the frequency spectrum minimising the possibility of acoustic feature in the reversing alarm. • Sources of significant noise will be enclosed, as far as reasonably possible; Loading and unloading should be done away from noise-sensitive areas, where possible; • Any stationary plant will be located (i.e. pumps, compressor, concrete mixing, etc.) away from noise-sensitive receptors, where possible. • Temporary local noise barriers will be installed for noisy equipment. • Low or non-vibratory piling equipment should be selected such as rotary or bored piling. • To reduce the requirement for vibratory compaction, use static force compaction, such as smooth-wheeled or sheepsfoot rollers. • Vibratory plant not to be start up or shut-down within 50m of receptors. • The reduction of working hours to during less sensitive hours during the day. • Retention works will be used to prevent soil and sediment accumulation in the water resources. • Landscaping or excavation work near the watercourses will not be carried out during high tidal periods or heavy rains. • No tools and machinery will be cleaned in any water source or areas that drain into an existing watercourse, stream, or canal. • Equipments will be checked weekly for oil and lubrication leaks. • Equipment oil and lubrication replacements will be performed only in maintenance and repair areas. • Chemicals and concrete agitator washings will not be deposited into watercourses. • Retention equipments, such as, sedimentation traps will be installed in work areas to settle out sediment (particles) in suspension in water column. • Before any pumped water discharge in the natural environment, chemical analyses (screening parameters) will be carried out according to the local and environmental law and regulations. • All existing stream courses and drains within, and adjacent to the site will be kept safe and free from any debris and any excavated materials, arising from the works. • All water and waste products that will be produced on the site shall be collected and removed from the site via a suitable and properly designed temporary drainage system and disposed of at a location and in a manner that will cause neither pollution nor noise. • Road transport and material stocks will be carefully managed in order to decrease the risk of material and dust that are ventilated by the effect of wind to the minimum level (for example; proper covering materials will be used). • The construction site that are exposed to the over traffic will be humidified by implementing water sprays (for example by water pump) in a controlled way. • Materials stored in piles will be retained a high level of humidity by frequently spraying them during the periods (approximately three times a day). • On dry weather conditions, while working nearby of the settlement areas or detached domiciles, special attention would be given to the matter of preventing dust movements within the broad of the study or on construction sites. • Spray/water unpaved surfaces which are exposed to winds and erosion, as often as necessary (several times a day) using watering trucks to ensure a high humidity level of the soil, thus minimizing dust. • Areas having firm ground onto which heavy vehicles will park will be regularly audited and they will become free of all materials having mud and dust. • No waste resulting from the construction activities will be combusted on site. • Domestic wastes will be recycled and reused as much as possible to minimize waste. • Different waste streams will be collected separately and disposed/transferred by authorized staff to the final disposal location/facility. • A site specific Waste Management Plan will be prepared and implemented. CLIENT PROJECT COMPANY EPC CONTRACTOR Zuluf Water Treatment Plant HSE Construction Plan Appendix B3 – Envir.Impacts of the Project and Mitigation Measures Issue Hazardous Waste Construction camps Liquid waste and accidental spills Domestic wastewater Natural Resource Consumption Public health and safety • Occupational health • and safety • Socio-economic aspects and impacts See water quality and hydrology Proj. nº: WT2201 Doc nº: WT2201-FIT-HS-PLN-000-0001 Rev 1 Page 4 of 4 Environmental Impacts of the Project and Mitigation Measures Mitigation Measure • Collection and disposal of hazardous wastes to a proper landfill or facility will be accomplished by a certified company. • Oil spill response kits will be installed in maintenance areas. • Hazardous waste will be separated from the non-hazardous waste. • A site specific Waste Management Plan will be prepared and implemented. • The construction sites will be signed with warning panels for information of drivers. • More attention will be paid to the traffic to avoid any accidents. • A petroleum product recovery kit will be present in construction sites for small accidental spills. • Refueling, oil changes and mechanical checks will be carried out far from watercourses (when present), and cleaning activities will not be carried out near watercourses. • Any waste, oil or a chemical product or other contaminants will not be discharged in the water resources. Wastes of oil will be disposed of according to the standards in place at the sites authorized to handle them. • Accidentally introduced debris to the water resources will be removed as quickly as possible. • Surface water washed from the surface of construction camps and any other ancillary camps and waste waters generated by production processes and the domestic waste waters will be collected within the sewerage networks arranged on the locations of the sites. • The waters will be filtered and discharged into the nearest local utility system or collected into a septic tank from where they will be emptied and transported into an urban filtering station. • All service areas will be constructed with adequate drainage and filtration systems including sedimentary basins and grease/oil separators. The sludge collected by these systems will be collected periodically by a licensed contractor. • All waste water from the camp site activities will be appropriately collected within septic tanks built in accordance with regulatory standards and of sufficient capacity in relation to the number of workers expected. • The use of fuel, electricity, and water will be minimized in the constructional area, office, and camp site activities. • The construction site traffic and site visits will be optimized to decrease the fuel consumption. • The consumption of electricity in the main office area will be minimized by exploiting the use of sunlight, by turning the office equipments off when they are not in use, by using energy efficient lightning, etc. • The water consumption will be minimized by regular maintenance of the water taps. • Training sessions will be organized to raise awareness in the ways of reduction the natural resource usage and the benefits of adopting the preventive actions. • Drivers of the vehicles carrying materials to the construction sites have to drive maximum at the speed limit of 20 km/hour. • Barriers will be immediately built in excavation areas close to prevent accidents. • Excavated areas will be covered and/or filled back and notified using warning signs to inform the residents. Barriers will be employed to prevent fell down in deep excavation areas. The use of personal protective equipment will be forced and controlled regularly. An emergency plan will be prepared and implemented in the cases of fire and spillage. • Good relationship will be established and maintained with the local residents by prevention and minimization of the environmental impacts of the project. • The affected residential and industrial areas will be regularly informed about the progress of the project by organized meetings. • The complaints and requests from the local residents will be resolved and taken into consideration. • The benefits of the project from economic, social, and environmental point of view will be explained in the organized meetings with the local people. • The opinions of the local people about the project will be surveyed. • Turbidity and water quality control. • Emergency procedure defining and application Accidental Spill Measures