Stupple 2018 Modelling heat transfer aluminium X-ray anode CVD diamond heat spreader

advertisement

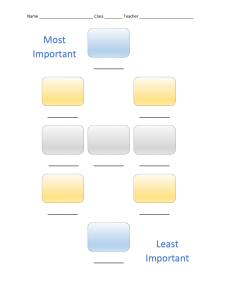

Modeling of Heat Transfer in an Aluminum X-Ray Anode Employing a Chemical Vapor Deposited Diamond Heat Spreader David J. Stupple1 Torr Scientific Ltd., Unit 11, Pebsham Rural Business Center, Pebsham Lane, Bexhill-on-Sea, East Sussex TN40 2RZ, UK e-mail: d.stupple@torrscientific.co.uk Victor Kemp Mecway Ltd., 1 Goring Street, Thorndon, Wellington 6011, New Zealand e-mail: victor@mecway.com Matthew J. Oldfield Department of Mechanical Engineering Sciences, University of Surrey, Guildford GU2 7XH, UK e-mail: m.oldfield@surrey.ac.uk John F. Watts Professor Department of Mechanical Engineering Sciences, University of Surrey, Guildford GU2 7XH, UK e-mail: j.watts@surrey.ac.uk Mark A. Baker Department of Mechanical Engineering Sciences, University of Surrey, Guildford GU2 7XH, UK e-mail: m.baker@surrey.ac.uk X-ray sources are used for both scientific instrumentation and inspection applications. In X-ray photoelectron spectroscopy (XPS), aluminum Ka X-rays are generated through electron beam irradiation of a copper-based X-ray anode incorporating a thin surface layer of aluminum. The maximum power operation of the X-ray anode is limited by the relatively low melting point of the aluminum. Hence, optimization of the materials and design of the X-ray anode to transfer heat away from the aluminum thin film is key to maximizing performance. Finite element analysis (FEA) has been employed to model the heat transfer of a water-cooled copper-based X-ray anode with and without the use of a chemical vapor deposited (CVD) diamond heat spreader. The modeling approach was to construct a representative baseline model, and then to vary different parameters systematically, solving for a steady-state thermal condition, and observing the effect on the maximum temperature attained. The model indicates that a CVD diamond heat spreader (with isotropic thermal properties) brazed 1 Corresponding author. Contributed by the Heat Transfer Division of ASME for publication in the JOURNAL OF HEAT TRANSFER. Manuscript received June 7, 2018; final manuscript received June 26, 2018; published online August 28, 2018. Assoc. Editor: Milind A. Jog. Journal of Heat Transfer into the copper body reduces the maximum temperature in the 4 lm aluminum layer from 613 C to 301 C. Introducing realistic anisotropy and inhomogeneity in the thermal conductivity (TC) of the CVD diamond has no significant effect on heat transfer if the aluminum film is on the CVD diamond growth face (with the highest TC). However, if the aluminum layer is on the CVD diamond nucleation face (with the lowest TC), the maximum temperature is 575 C. Implications for anode design are discussed. [DOI: 10.1115/1.4040953] Introduction X-rays are used as an excitation source in analytical techniques such as X-ray photoelectron spectroscopy (XPS) and X-ray diffraction, and in X-ray inspection and imaging. X-rays are produced by accelerating high-energy electrons to strike a metallic anode where the electrons cause the emission of X-ray photons through anode atomic core-level excitation. This conversion is inefficient, with 99% of the electron energy converted into heat within the anode assembly. It is advantageous to maximize X-ray flux to increase signal-to-noise ratio and minimize analysis time, but preventing damage to the anode from excessive heating is usually the limiting factor. In XPS, a common anode material is aluminum, producing characteristic aluminum Ka X-rays. A thin coating of aluminum is applied to the tip of a hollow copper anode body with the internal surfaces cooled by pumped water. Often, a smaller beam spot on the anode is desirable, providing a smaller focused X-ray spot on the sample and hence finer spatial resolution of the analysis. If high X-ray flux is demanded from a small spot, the power density at the anode can be very high. Some anodes employ a chemical vapor deposited (CVD) diamond heat spreader, brazed flush into the copper body beneath the aluminum film (Fig. 1). This technical brief reports the findings of finite element analysis (FEA) of the thermal performance of a watercooled anode both with and without a diamond heat spreader, and the effects of material and geometry variations. Generating a high X-ray flux may be desirable, so efficient removal of heat from the anode film to the cooling system is important. CVD diamond has excellent thermal conductivity (TC), a typical quoted value being 1800 W m 1 K 1 at room temperature.2 Single crystal gemstone diamonds have a TC of approximately 2200 W m 1 K 1 at room temperature [1]. In reality, polycrystalline CVD diamond can have substantially anisotropic and inhomogeneous TC, varying from one face to another by a factor of 4 [1,2]. Numerical methods have previously been used to model the spread of surface heat through a cylindrical diamond heat Fig. 1 (a) The beveled tip of a typical X-ray anode as used in a commercial XPS system, with (b) a cutaway view showing the recessed diamond heat spreader, one of several cooling fins and internal water cooling 2 http://www.hediamond.cn/en/product/24.html DECEMBER 2018, Vol. 140 / 124501-1 C 2018 by ASME; use license CC-BY 4.0 Copyright V Downloaded From: https://asmedigitalcollection.asme.org/ on 09/10/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use Table 1 Thermal conductivity values for the baseline model materials Material Aluminum Chromium CVD diamond Braze Copper Thermal conductivity/W m 1 K 189.6 93.7 2082.4 at 20.9 C 100.0 404.0 1 Temperature dependence None None Yes None None Fig. 2 An overview of the mesh used as the basis of the analysis. (Color variations within components (e.g., within aluminum) are visual aids to facilitate the modeling process. spreader, with isotropic and temperature-independent TC, on a copper substrate, demonstrating that performance was sensitive to the radius of the heat spreader [3]. Finite element analysis has been used to analyze stress in a revolving X-ray anode during heating and cooling, again with heat applied at the surface [4]. Monte Carlo analysis was used to simulate subsurface heat delivery by electron emission in field effect devices, informing subsequent numerical analysis of the heat flow [5]. FEA of heat sinks on laser diodes has shown the superior performance of CVD diamond over aluminum nitride heat spreaders [6], again with the TC of the diamond assumed isotropic and temperatureindependent. Here, we use FEA in conjunction with Monte Carlo analysis to model the use of a CVD diamond heat spreader in a generic XPS X-ray anode. The effects of different thermal conductivities and of anode design variations are examined. Identification of those parameters which have the greatest effect on the thermal performance will allow design choices to be made that cost-effectively optimize anode cooling. No previous analysis includes subsurface heat delivery and temperature-dependent, anisotropic, and inhomogeneous TC of diamond. Fig. 3 A previously published temperature-dependent TC profile of CVD diamond used in the baseline FEA model [11,12]. The curve has been extrapolated to higher temperatures (above 270 C). Finite Element Analysis Modeling Approach The commercial FEA package Mecway3 was used for pre and postprocessing. Mecway’s internal solver was used for the sensitivity analysis of thermal properties and dimension changes. Calculix Crunchix (CCX) is a free structural FEA solver [7]. CCX was used where both temperature dependence and anisotropy of TC was needed. A baseline model was created, and then parameters were varied systematically, solving for a steady-state thermal condition, and comparing the maximum temperature attained. Rather than a circular body with a beveled tip (Fig. 1), the anode was modeled as a square tube with a flat tip, with the mesh representing one quarter of the whole. The model comprises a copper tube, an inset CVD diamond, a braze layer between diamond and copper, an aluminum anode layer, and a chromium adhesion layer between aluminum and diamond (Fig. 2). The 20 W electron beam was modeled with a Gaussian profile [8]. Most previous studies have assumed surface heating, while here a software package for Monte Carlo simulation, CASINO V2.42 [9], was used to model the vertical delivery of heat by 10 keV electrons into the aluminum film. The thermal conductivities of the materials in the baseline model are listed in Table 1. 3 https://mecway.com/ 124501-2 / Vol. 140, DECEMBER 2018 Fig. 4 Baseline model modified to have direct cooling of the diamond underside The density of the sputtered aluminum film was assumed to be 80% of bulk aluminum and the TC adjusted accordingly. This is a reasonable assumption for a sputtered film [10]. The temperaturedependent TC values of the CVD diamond material were extracted from published measurements [11,12], with extrapolation to higher temperatures (Fig. 3). To model the effect of direct cooling on the underside of the diamond, the cooling fins and a region of the copper and braze were removed to expose the diamond. The convection condition was applied to all newly exposed surfaces (Fig. 4). Results and Discussion Heat Spreader. The model without the heat spreader reported a maximum aluminum temperature of 613 C, greater by 312 C than the model with a diamond heat spreader (Fig. 5). Thermal Properties. The TC of both the diamond heat spreader and the aluminum anode material has a large effect on the aluminum temperature (Fig. 6). The aluminum temperature is Transactions of the ASME Downloaded From: https://asmedigitalcollection.asme.org/ on 09/10/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use Fig. 5 The copper-bodied model (right) has a maximum steady-state temperature 613 C, whereas the baseline model with the diamond heat spreader (left, same temperature scale) has maximum 301 C Fig. 6 Effect of varying TCs of components, and the convection coefficient of the cooling water. The steep curves indicate those thermal properties that have the greatest effect on the aluminum temperature. relatively insensitive to the thermal conductivities of most other components. This suggests that while the quality of diamond is of great importance, the material choice for the anode body is more flexible. A material with more suitable engineering properties than copper might be feasible with minimal effect on the aluminum temperature. diamond heat spreader allows it to maintain a comparable temperature gradient to that of the copper model despite the considerably lower maximum temperature (Fig. 8). This gradient drives the heat flux. With the anode film on the nucleation face, where TC Dimensions. The aluminum temperature of the model is highly sensitive to the thickness of the aluminum (Fig. 7). The temperature is moderately increased by reduction of the diamond thickness, but with little improvement from a thicker diamond. Unlike earlier numerical modeling [3], the width of the diamond here had little effect. Changes to other dimensions also had little effect, though making the copper tip thinner caused a slightly increased temperature. Anisotropy and Inhomogeneity. Introducing anisotropic and inhomogeneous thermal properties of CVD diamond [1,2] shows that the orientation of the diamond is important. In the CVD process, the nucleation face of the diamond is next to the substrate, and the growth face is furthest from the substrate. With the aluminum anode on the growth face, temperatures are similar to the isotropic model; with the anode on the nucleation face— where the TC is lower [2]—the maximum temperature is 273 C higher at 575 C. The primary role of the diamond is to facilitate the vertical flow of heat away from the hot spot at the center. The high TC of the Journal of Heat Transfer Fig. 7 The peak temperature of the aluminum for different dimensions in the model. The aluminum temperature of the baseline model is highly sensitive to the thickness of the aluminum layer (steep curve). DECEMBER 2018, Vol. 140 / 124501-3 Downloaded From: https://asmedigitalcollection.asme.org/ on 09/10/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use There is no benefit to be gained from having a hole in the metal body such that the diamond is directly cooled by water. The lateral flow of heat should not be impaired by having the metal body too thin or in poor thermal contact with the side walls. The contribution of the side walls to heat removal is important. The return route of the cooling water should be fully exploited by passing the water over as much internal surface as possible. The TC of the anode body does not seem to be a critical factor. It might be beneficial to choose a metal with more suitable mechanical properties than copper, without necessarily affecting the anode cooling, especially if the material is one that resists fouling by the cooling fluid. Conclusions Fig. 8 A comparison of vertical and horizontal temperature profiles in models with and without a diamond heat spreader. The profiles are taken from the top/center of each model. While the temperatures are higher without a heat spreader, the temperature gradients are quite similar. may be lower by a factor of 4 [2], the removal of heat from the hot spot is impaired. Away from the center, both the diamond and the copper body serve to channel the heat mainly horizontally to the side walls (Fig. 9). In both models, approximately 65% of the heat is removed via the side walls, so that most of the heat flux in the tip is horizontal, rather than vertically toward the nearest cooled surface, as might be expected. Any restriction of the heat flow to the walls will raise the maximum temperature reached in the aluminum. This is why making the copper wall of the anode tip thinner caused a slight increase in temperature. Likewise, removing a part of the metal body so that the diamond is directly cooled by the water (Fig. 4) had no beneficial effect. With the diamond cooled directly, the aluminum reached 310 C. A model with no through-hole in the copper reached 307 C. Removing copper material restricts the heat flow to the side walls. Design Implications This model suggests that the TC of the diamond heat spreader should be as high as possible and that the aluminum coating should be applied to the growth surface of the diamond to minimize the effect of anisotropic microstructure in the CVD diamond material. The diamond should not be made too thin, in this model no thinner than 100 lm. The TC of the aluminum thin film should be enhanced by ensuring that the film is as dense and pure as possible. The film should be as thin as the application will allow. The analysis confirms that a high-quality CVD diamond heat spreader can drastically reduce the steady-state temperature of the anode, here by 312 C, but the diamond must have its growth face outermost because of the effects of anisotropic microstructure. Fitting the diamond with the nucleation face outermost increases the model temperature by 273 C. Even with a greatly reduced maximum temperature, heat flow both within the aluminum film and in adjacent components is maintained when the heat spreader is present. The high TC of diamond allows it to efficiently remove heat at the base of the anode film. This maintains a temperature gradient within the aluminum that is similar in magnitude to the copper-bodied anode and that drives the heat flow. Around 65% of the heat is removed by the coolant via the side walls. Measures that might be expected to assist cooling, such as thinning the wall at the tip, or having direct cooling of the diamond, actually throttle heat flow to the walls, giving higher temperatures. The main implications for anode design are as follows: (i) reduce the aluminum layer thickness as much as practically allowable; (ii) fabricate the aluminum layer to be dense and thermally conductive; (iii) fit the CVD diamond heat spreader with the growth face outermost; (iv) do not impede the flow of heat to the side walls by thinning the anode walls. More broadly, anode designs might incorporate a metal that is easier to braze to and less prone to fouling than copper. The route of the coolant must be optimized to fully exploit the cooling opportunities both at and away from the anode tip; anode designs where the return path from the tip is via a narrow channel may be far from optimum. Fig. 9 A schematic diagram of the heat flux through a central section of the anode tip, with the anode tip center at top left. For clarity, the heat flux magnitude range of 0–1.5 MW m22 is chosen, such that the highest fluxes near the center of the tip (top left) are not shown. The section shown is from the heat spreader model; the model with no heat spreader shows a similar pattern. The flux magnitude is proportional to arrow length. 124501-4 / Vol. 140, DECEMBER 2018 Transactions of the ASME Downloaded From: https://asmedigitalcollection.asme.org/ on 09/10/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use Appendix: Conversions of values in the text to U.S. customary units C 270 273 301 307 310 312 575 613 Wm 1 93.7 100 189.6 404 2082.4 K 1 F lm Millipoints mm Points 518 523 574 585 590 594 1067 1135 1 2 3 4 5 8 90 100 150 420 450 980 2.8 5.7 8.5 11.3 14.2 22.7 255 283 425 1191 1276 2778 1 1.8 2 5.6 2.8 5.0 5.7 15.7 nm millipoints 20 200 0.06 0.57 Btu/(h F ft) 54.1 57.8 109.5 233.4 1203.2 MW m 2 Btu/(h in2) 1.5 3302 W Btu/h 20 68 Funding Data Engineering and Physical Sciences Research Council (EPSRC Grant No. EP/G037388/1) via the MiNMaT Centre for Doctoral Training at the University of Surrey, in collaboration with Torr Scientific Ltd. Journal of Heat Transfer References [1] Graebner, J. E., Jin, S., and Kammlott, G. W., 1992, “Large Anisotropic Thermal Conductivity in Synthetic Diamond Films,” Nature, 359(6394), pp. 401–403. [2] Graebner, J. E., Altmann, H., and Balzaretti, N. M., 1998, “Report on a Second Round Robin Measurement of the Thermal Conductivity of CVD Diamond,” Diamond Relat. Mater., 7(11–12), pp. 1589–1604. [3] Hui, P., and Tan, H. S., 1994, “Temperature Distributions in a Heat Dissipation System Using a Cylindrical Diamond Heat Spreader on a Copper Heat Sink,” J. Appl. Phys., 75(2), pp. 748–757. [4] Plankensteiner, A., and R€ odhammer, P., 2001, “Finite Element Analysis of XRay Targets,” 15th International Plansee Seminar 2001: Powder Metallurgical High Performance Materials, Reutte, Austria, accessed Sept. 5, 2017, https:// www-plansee-com.azureedge.net/fileadmin/user_upload/Finite_Element_Analysis_ of_X-Ray_Targets.pdf [5] Fisher, T. S., Walker, D. G., and Weller, R. A., 2003, “Analysis and Simulation of Anode Heating Due to Electron Field Emission,” IEEE Trans. Compon. Packag. Technol., 26(2), pp. 317–323. [6] Labudovic, M., and Burka, M., 2003, “Heat Transfer and Residual Stress Modeling of a Diamond Film Heat Sink for High Power Laser Diodes,” IEEE Trans. Compon. Packag. Technol., 26(3), pp. 575–581. [7] Dhondt, G., and Wittig, K., 2016, “CALCULIX,” R€ ohrmoos, Germany, accessed Apr. 1, 2017, http://www.calculix.de/ [8] BSI, 2005, “Lasers and Laser-Related Equipment. Test Methods for Laser Beam Widths, Divergence Angles and Beam Propagation Ratios. Part 1: Stigmatic and Simple Astigmatic Beams,” BSI, London, Standard No. BS EN ISO 11146-1:2005. [9] Drouin, D., Couture, A. R., and Joly, D., 2007, “CASINO V2.42—a Fast and Easy-to-Use Modeling Tool for Scanning Electron Microscopy and Microanalysis Users,” Scanning, 29(3), pp. 92–101. [10] Mattox, D. M., and Kominiak, G. J., 1972, “Structure Modification by Ion Bombardment During Deposition,” J. Vac. Sci. Technol., 9(1), pp. 528–532. [11] Diamond Materials, 2004, “The CVD Diamond Booklet,” Diamond Materials GmbH, Freiburg, Germany, accessed Mar. 1, 2016, http://www.diamond-materials. com/downloads/cvd_diamond_booklet.pdf [12] W€ orner, E., Wild, C., and M€ uller-Sebert, W., 1996, “Thermal Conductivity of CVD Diamond Films: High-Precision, Temperature-Resolved Measurements,” Diamond Relat. Mater., 5(6–8), pp. 688–692. DECEMBER 2018, Vol. 140 / 124501-5 Downloaded From: https://asmedigitalcollection.asme.org/ on 09/10/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use