DISINFECTION OF FOODS BY LOW ENERGY X-RAY IRRADIATION

advertisement

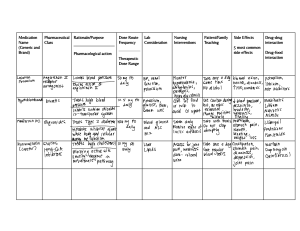

DALAT UNIVERSITY FACULTY OF NUCLEAR ENGINEERING NGUYEN DANG TRONG PHUC – 1510402 DISINFECTION OF FOODS BY LOW ENERGY X-RAY IRRADIATION ENGINEERING THESIS SUPERVISOR PROFESSOR TAMIKAZU KUME TUTOR PHAM THI NGOC HA 2015 - 2020 REMARKS OF SUPERVISOR ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ i REMARKS OF LECTURER ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ........................................................................................................................ ii ABSTRACT The reliable supply of safe food that is free from harmful contaminants is important for people‘s health and daily life. The contamination microorganism on food is unavoidable because food are contaminated in production, transportation or preservation process. Food irradiation is an effective method to eliminate the harmful microorganisms and extend their shelf-life. Disinfection of foods by radiation is widely used because of its safety and cost-efficiency. The low energy X-ray irradiator was installed at the Nuclear Engineering Department, Da Lat University in 2017. The low energy X-ray irradiator is compact and cheap compared to the 60Co-gamma-ray irradiator or high energy electron beam irradiator. However, the effective irradiation condition is required to study because the penetration and dose rate is low. The disinfection of foods by low energy X-ray irradiator depends on many factors such as voltage, current, distance from the irradiation port and thickness of foods. Experimental data of this research show that the voltage of the X-ray tube and the filters to cut off the low energy X-rays are two important factors affect the disinfection of E. coli. The low energy X-ray radiation without filter was effective for the surface (5 mm thickness) irradiation. For the irradiation of thick materials, the filter such as 1.0 mm Al or 2.0 mm Al is necessary to obtain a better dose uniformity ratio (Dmax / Dmin). Keyword: Food irradiation, disinfection, microbiological contamination, X-ray, E. coli, survival rate. iii ACKNOWLEDGMENT First of all, this thesis would not have been possible without the advice and guidance of my supervisor, Professor Tamikazu Kume. Although I am an unpredictable person and I had broken promises with him many times, he still was patient and understanding for me. Thank for his generous and kindness even I had made many mistakes. I also express my sincere thanks to Ms. Pham Thi Ngoc Ha who supported me with her knowledge to complete my thesis. To all the Nuclear Engineering Department professors, lecturers and staff who cheer me up and give me a lot of invaluable advice in difficult situations, I really appreciate their supports. I would like to thank Dr. Nguyen An Son, the dean of our department. I could not finish this thesis without his permission and mentorship. I am especially grateful for Dr. Ha, Ms. Sang who help and encourage me whenever I need and had bought me food many times since the thesis begun. Moreover, I could not finish my thesis without the support of the Biology Department and Chemistry Department. Especially, Miss Lien, Dr. Truong, Mr. Giang, Mr. Trieu and Faculty of Biology staff who taught me more about microbiology and allowed me to use their equipment. I am thankful to my family and my classmate for their encouragement and support. Last but not least, I want to thank University Security officers who guard my motorbike only left at 8 pm weekdays or weekends. Finally, I do apologize for any inconvenient which I had caused throughout my thesis and thank to all for supporting me. iv COMMITMENT I assure that the work embodied in this thesis was my own work carried out by me under the supervision of Prof. Tamikazu Kume. The content and research results in this thesis are honest and unpublished in any form before. In addition, the thesis also uses figures, the number of comments, reviews as well as data from other authors, agencies, and organizations as cited and annotated. If any fraud is detected, I bear full responsibility for the contents of my graduation thesis. Da lat, December 2th, 2019. Author, Nguyen Dang Trong Phuc v Contents ABSTRACT .................................................................................................................................... iii ACKNOWLEDGEMENT ............................................................................................................. iv COMMITMENT ............................................................................................................................. v INTRODUCTION ........................................................................................................................... 1 Chapter 1: Overview.......................................................................................................................... 2 1.1 Ionization radiation:................................................................................................................. 2 1.2 X-ray ........................................................................................................................................ 3 1.3 Biological effect of radiation ................................................................................................... 5 1.4 Food contamination ................................................................................................................. 9 1.5 Dose measurement.................................................................................................................. 9 1.5.1 Fricke dosimeter ............................................................................................................... 9 1.5.2 Gafchromic film dosimeter ............................................................................................. 10 Chapter 2: Materials and Methods .............................................................................................. 13 2.1 X-ray irradiation system ........................................................................................................ 13 2.2 Dosimetry .............................................................................................................................. 15 2.2.1 Fricke dosimetry ............................................................................................................. 15 2.2.2 Gafchromic film dosimetry ............................................................................................ 17 2.3 Microorganisms experiment .................................................................................................. 18 2.3.1 Microorganism sample preparation ................................................................................ 18 Chapter 3: Results and discussion ............................................................................................... 20 3.1 Dosimetry .............................................................................................................................. 20 3.1.1. Fricke dosimetry ............................................................................................................ 20 3.1.3 Gafchromic film dosimetry ............................................................................................ 25 3.2 Disinfection of E. coli by radiation ....................................................................................... 29 3.2.1 Filter effect on E. coli radiosensitivity ........................................................................... 29 3.2.2 Energy effect .................................................................................................................. 32 3.2.3 Effect of thickness of the sample ................................................................................... 35 3.3 Discussion.............................................................................................................................. 37 CONCLUSION .............................................................................................................................. 38 REFERENCES .............................................................................................................................. 39 vi List of Tables Table 2..1: Specifications of MBR-1618R-BE X-ray irradiator...................................................... 14 Table 3. 1 Dose and dose rate measured with different filter .......................................................... 21 Table 3. 2 Dose and dose rate in Eppendorf tube at 150 and 250 mm H ........................................ 24 Table 3. 3 Parameters of fitting equation with different measured dose rate .................................. 25 Table 3. 4 Dose rate measured by Gafchromic film at 150 mm H at different condition ............... 27 Table 3. 5 Dose rate distribution in PMMA with different filters ................................................... 27 Table 3. 6 Survival ratio inside the PMMA phantom ...................................................................... 35 vii List of Figures Figure 1. 1 Typical Bremssrahlung spectrum .................................................................................... 4 Figure 1. 2 Attenuation and energy-absorption coefficient ............................................................... 5 Figure 1. 3 Biological effect of radiation .......................................................................................... 6 Figure 1. 4 Typical dose response curves .......................................................................................... 8 Figure 1. 5 Configuration of Gafchromic HD-V2 dosimetry film .................................................. 11 Figure 2. 1 Irradiation system from external view .......................................................................... 13 Figure 2. 2 Irradiator‘s spectrum at 160kV, 18.7mA with different filter ....................................... 15 Figure 2. 3 Pyrex tube (left) and Eppendorf tube (right) ................................................................. 16 Figure 2. 4 Dosimetry diagram ........................................................................................................ 17 Figure 2. 5 Plastic bag microorganism container ............................................................................ 18 Figure 3. 1 Dose at 250 mm H (height) of irradiation table ............................................................ 20 Figure 3. 2 X-ray irradiator spectrum at 50kV, 100kV, 160kVat same current .............................. 22 Figure 3. 3 Change in doses by energy with 50, 100 and 160 keV ................................................. 22 Figure 3. 4 Dose and dose rate in Eppendorf tube at 150 and 250 mm H ....................................... 23 Figure 3. 5Dose in Eppendorf tube at different voltage .................................................................. 24 Figure 3. 6 Optical density of each color channel ........................................................................... 26 Figure 3. 7 Dose rate distribution in PMMA ................................................................................... 28 Figure 3. 8 F0 Survival curve .......................................................................................................... 29 Figure 3. 9 F1 Survival curve .......................................................................................................... 30 Figure 3. 10 F2 Survival curve ........................................................................................................ 30 Figure 3. 11 F3 Survival curve ........................................................................................................ 31 Figure 3. 12 F4 Survival curve ........................................................................................................ 31 Figure 3. 13 F5 Survival curve ........................................................................................................ 32 Figure 3. 14 Survival curve at 50 keV ............................................................................................. 33 Figure 3. 15 Survival curve at 100 keV ........................................................................................... 33 Figure 3. 16 Survival rate at different voltage at 150mm from the source ...................................... 34 Figure 3. 17 Survival curve at 150mm and 250mm height ............................................................. 35 viii INTRODUCTION Food crisis is a concerned issue around the globe because of overpopulation, climate change, sea level rising which are causing landfills shortage, natural disaster. Therefore, sustaining food for the increasing population is a critical problem for human civilization, there are many solutions for this problem such as genetic mutation, alternative food resource, lab-grown food production, food irradiation. Food irradiation is the most practical solution since it reduces food wasted, chemical pesticide, food poisoning, etc. Food may contain a great deal of microorganism species, some of them are harmless, or the other may cause many diseases such as Salmonella, Campylobacter, Escherichia coli, etc. The contamination depends on a lot of factors such as type of food, manufacture process, transportation, and so on. To disinfect food, there are many ways such as heated, refrigerated, frozen, treated chemical, etc. However, these processes change the taste, color, and decrease nutrition, even produce toxic chemicals. Ultraviolet light can kill the bacteria or fungus without side effect but its penetration is the only surface of a material. Higher energy radiation can solve this drawback, food has been irradiated food for around four decades, the source can be radioactive isotope which will become radioactive wastes after several decades using and require complex shielding structure or electron beam irradiator has low penetration but it is very effective to sterilize bacteria. Besides these irradiation systems, the 500 kilovolts X-ray irradiators also are used since they have high penetration like gamma-source and effective to disinfect bacteria like electron beam and its operation cost is much more economical when compared with the other two. The food crisis has also drawn a very hot issue in Vietnam, so food irradiation is important for the future of our country. Nuclear Engineering Department, Dalat University installed a low energy X-rays MBR-1618R-BE Hitachi irradiator in 2017. This machine can be used for many applications and food irradiation is one of them. The major purpose of this research is estimating the disinfection ability of low energy X-ray by using irradiation system. The effect of X-ray on microorganism can be different between distinct conditions. Escherichia coli bacteria were used to study these effects. 1 Chapter 1: Overview 1.1 Ionization radiation: Radiation can be described as the emission of energy as electromagnetic waves or subatomic particles. As a result, it covers a wide range of categories such as charged particle radiation, non charged particle radiation, or electromagnetic waves which include radio waves, visible light, infrared light, ultraviolet lights, and so on. It can be divided into two simple categories non-ionization radiation and ionization radiation which have more energy than the counterpart and this type of radiation have sufficient energy to detach an electron from the atom, molecule, thereby ionizing them. In nuclear physic field and high energy physic, the radiation is preferred to ionizing radiation which includes high energy electromagnetic wave, electron beam( beta ray), alpha ray (helium nucleus), etc. Although the effect of radiation on matter was recognized a few decades ago, the first discovery of radiation is 1895. In 1895, the physicist named Wilhelm Röntgen had found out that something has come out of cathode tube while testing the penetration of cathoderay through glass. Even covering the Crookes tube in heavy black paper, he noticed a barium platinocyanide screen nearby fluorescing. Through experimentation, he found that the mysterious lights would pass through most substances but leave shadows of solid objects. Because he did not know what the rays were, he called them ‘X’ meaning ‘unknown’ rays. This discovery was followed in 1896 by Henri Becquerel’s discovery that uranium salts gave off similar rays naturally. Though originally thinking that the rays were emitted by phosphorescent uranium salts after prolonged exposure to the sun, he eventually threw away this hypothesis. Through further experimentation including non-phosphorescent uranium, he instead came to recognize that it was the material itself that radiated the rays. Marie Curie, who was his doctoral student at that time named this phenomenon radioactivity. She continued her Professor‘s work, she did lots of experiments with radioactive material, including the discovery of additional radioactive elements: thorium, polonium, and radium. In 1899, Ernest Rutherford discovered that there were two kinds of radiation emitted by radium; one is a heavy particle that has a positive charge, which he 2 called an “alpha ray”, and the other is much lighter, with a negative charge, and he named it a “beta ray”. One year later, by eliminating alpha ray with lead screen, and sweeping beta ray away with magnetic field, Paul Villard found that radium still gave off another radiation which have no charge, and mass go into the detector. Villard did not name his rays, but Rutherford, who confirmed their existence, appropriately labeled them “gamma rays”, and gamma rays they have been ever since. Until 1932, the neutron had been discovered by James Chadwick when he repeated the Joliot-Curies beryllium emission experiment. By bombarding hydrogen, helium, nitrogen, and other elements as a target, and comparing the energies of recoil particles, he proved that the beryllium emissions contained a neutral component with a mass approximately equal to that of the proton, he called it the neutron. After these explorations, many research, and applications of ionizing radiation have been innovated. Ionizing radiations have been applied in a lot of fields like energy production, industry, material science, agriculture, etc. 1.2 X-ray X-rays are known as Röntgen rays which are electromagnetic waves with the frequency higher than visible light. X-rays are produced by the de-excitation of orbital electron of the atom, or the Coulomb interaction between high energy electron and high atomic number target. The de-excitation X-ray is emitted when the electron from higher-level shell fill the inside orbital vacancy caused by radiation, or nucleus transformation, this ray is called characteristic X-ray. The other mechanism is bremsstrahlung X rays emission where the high energy electron travel close to the nucleus due to the attraction of its positive charge and are subsequently influenced by its electric field. The course of these electrons would be deflected, and a portion or all of their kinetic energy would be lost. These kinetic energy differential is emitted as X-ray photons, specifically bremsstrahlung radiation or braking radiation. These processes are how the X-ray tube and some accelerators give off electromagnetic waves. Low energy irradiator contains the X-ray tube works as a specific energy converter, receiving the electrical energy and converting it into two other forms of energy: X-radiation and heat. This process is inefficient with 1% of the resulting 3 energy is emitted as X-rays, and the remaining 99% converted to heat. Due to the Bremsstrahlung effect, the energy of X-ray emitted is from zero to the kinetic energy of the incident electron, resulting in a continuous Bremsstrahlung spectrum. Figure 1. 1 Typical Bremssrahlung spectrum Ionizing electromagnetic waves interact with matter in four different ways from photoelectric, Thomson scattering, Compton scattering, pair production. The probability of each interaction depends on the energy of incident proton, it is called interaction cross-section in radiation physic. For the low energy X-ray, photoelectric absorption and Compton scattering is the dominant interaction. As a result, the X-ray photon transfer more energy to material than the higher than the high energy photon (gamma-ray or high-frequency X-ray). The energy transfer can be described as mass energy-absorption coefficient of the photon which is shown in Figure 1.2. 4 Figure 1. 2 Attenuation and energy-absorption coefficient (Measured by United States National Institute of Standard and Technology) In the figure above, the energy-absorption coefficient decreases exponentially in the low energy photon reason (<50keV), falls gradually at the higher energy, and nearly constant around 1MeV. 1.3 Biological effect of radiation All living entities are made up of protoplasm, which consists of inorganic and organic compounds dissolved or suspended in water. The smallest unit of protoplasm capable of independent existence is the cell, the basic microscopic unit of all living organisms. Although we tend to think of biological effects in terms of the effect of radiation on living cells, in actuality, ionizing radiation, by definition, interacts only with atoms by the ionization process. Thus, all biological damage effects begin with the consequence of radiation interactions with the atoms forming the cells. Even though all subsequent biological effects can be traced back to the interaction of radiation with atoms, there are two mechanisms by which radiation ultimately affects cells. These two mechanisms are commonly called direct and indirect effects. 5 In the direct effect, the radiation interacts with the atoms of the DNA molecule, or some other cellular component critical to the survival of the cell. The damage leads to the chain of physical and chemical events that eventually produce the biological damage. Particularly, an interaction may affect the ability of the cell to reproduce and, thus, survive. If enough atoms are affected such that the chromosomes do not replicate properly, or if there is significant alteration in the information carried by the DNA molecule, then the cell may be destroyed by “direct” interference with its life-sustaining system. Direct action is the dominant process in the interaction of high linear energy transfer (LET) particles with biological material. In indirect action, the radiation interacts with other molecules and atoms (mainly water, since about 80% of a cell is composed of water) within the cell to produce free radicals, which can, through diffusion in the cell, damage the critical target within the cell. In interactions of radiation with water, short-lived yet extremely reactive free radicals such as H2O+(water ion) and OH* (hydroxyl radical) are produced. The free radicals in turn can cause damage to the target within the cell. The free radicals that break the chemical bonds and produce chemical changes that lead to biological damage are highly reactive molecules because they have an unpaired valence electron. However, they could combine to form toxic substances, such as hydrogen peroxide (H2O2), which can contribute to the destruction of the cell. Figure 1. 3 Biological effects of radiation Figure 1.3 shows that ionizing radiation can (a) directly damage a biomolecule by ionizing it or breaking its bonds, or (b) create an H2O+ ion, which reacts with H2O to form a hydroxyl radical, which in turn reacts with the biomolecule, causing damage indirectly. 6 About two-thirds of the biological damage by low LET radiations (sparsely ionizing radiations) such as X rays or electrons is due to indirect action. The consequences of radiation exposure occur immediately, timescale involved between the breakage of chemical bonds and the biological effect maybe hours to years, depending on the type of damage. If cell kill is the result, it may happen in hours to days, when the damaged cell attempts to divide (early effects of radiation). A microorganism survival curve describes the relationship between the surviving fraction of bacteria or fungi cells (i.e. the fraction of irradiated cells that maintain their reproductive integrity) and the absorbed dose. Microorganism survival as a function of radiation dose is graphically represented by plotting the surviving fraction on a logarithmic scale on the ordinate against dose on a linear scale on the abscissa. The survival curve equation: S ( D) e D Where: (1.1) S(D) is the fraction of cells surviving a dose D; is a constant describing the initial slope of the cell survival curve; The type of radiation influences the shape of the cell survival curve. Densely ionizing radiations exhibit a cell survival curve that is almost an exponential function of dose, shown by an almost straight line on the log-linear plot. For sparsely ionizing radiation, however, the curves show an initial slope followed by a shoulder region and then become nearly straight at higher doses. A plot of a biological effect observed (e.g. microorganism mutation, cell death ) against the dose given is called a dose response curve. Generally, as dose increases so does the effect. Three types of dose response relationship are known: Linear; Linear quadratic; Sigmoid. 7 Dose response curves may or may not have a threshold. A threshold dose is the largest dose for a particular effect studied below which no effect will be observed. Various dose response curves are shown in Fig. 1.4, with: A linear relationship with no threshold; A linear relationship with a threshold; A linear-quadratic relationship with no threshold; A linear relationship (the area below the dashed line indicates the natural incidence of the effect); A sigmoid relationship with a threshold. Figure 1. 4 Typical dose response curves Curve A represents a linear relationship with no threshold; curve B represents a linear relationship with threshold DT ; curve C represents a linearquadratic relationship with no threshold (assumed for stochastic effects); curve D represents a linear relationship with no threshold (the area below the dashed line represents the natural incidence of the effect, for example, carcinogenesis); and curve E represents a sigmoid relationship with threshold D1, as is common for 8 deterministic effects in organism tissues. The curves are diagrammatic only and are separated for clarity (in practice the dashed line would be lower). The response of different species or strains to radiation varies markedly, depending primarily on the inherent sensitivity of the microorganism. Microorganism survival does not only depend on the microorganism itself but the environment and radiation also affect the response. For example, oxygen concentration in the environment, effect of nearby cell, or dose rate effect. The higher energy transfer the more damage is caused to the microorganism, and the response to radiation also depends on the cells. The relative biological effectiveness (RBE) compares the dose of test radiation to the dose of standard radiation to produce the same biological effect. 1.4 Food contamination Food is contaminated by toxic metals, pesticides, and veterinary drug residues, as well as organic pollutants and mycotoxins. Ensuring food safety and quality is a central public health concern. The major food contamination is related to bacteria, fungus, or parasite. Microbiological contamination of food by pathogens such as Salmonella, Staphylococcus or E. coli has significantly increased over the past decades. There are many processes to disinfect microbiological contamination, food radiation is a practical method to sterilize microorganisms. Sterilization is the complete elimination or removal of all forms of contaminating microorganisms from the foodstuff, container and food package. A sterility assurance level (SAL) of 10–6 is currently required for sterilization procedures, i.e., a probability of not more than one viable microorganism in one million sterilized items of the final product. The inherent problem with these requirements is that evaluating the success of such sterilization by means of a final inspection is all but impossible, since contamination rates on the order of an SAL of 10–6 cannot be recorded in experiments 1.5 Dose measurement 1.5.1 Fricke dosimeter To measure absorbed dose in water, Fricke dosimeter is commonly used as a standard. Fricke solution which has the following composition: 1mM FeSO4 or Fe(NH4)2(SO4)2 (Morh’s salt) 9 0.8N H2SO4 1mM NaCl As the solution expose to ionizing radiation, ferrous (Fe2+) ion was converted to ferric (Fe3+) ion. The reaction scheme for this process is assumed as follows: H 2O OH , H , eaq , H 2O2 , H 2 eaq H H in acidic medium (1.2) Fe2 OH Fe3 OH Fe2 H 2O2 Fe3 OH OH In oxygen presence medium H O2 HO2 Fe2 HO2 H Fe3 H 2O2 (1.3) In the absence of oxygen Fe2 H H Fe3 H 2 (1.4) Ferric (Fe3+) ion exhibits a strong absorption peak at 304 nm, whereas ferrous ions do not show any absorption at this wavelength. Radiation-induced ferric ion concentration can be determined using spectrophotometry, which measures the absorbance (in OD units) of the solution. Fricke dosimeter is affected by organic impurities present in the system these solutes react with the ferrous ions faster than the radicals. To prevent organic impurities effect, a small amount of sodium chloride is added in solution. 1.5.2 Gafchromic film dosimeter Radiochromic film are coated with a special chemical that change properties under radiation exposure. For example, radiographic X-ray film consists of a base of thin plastic with a radiation sensitive emulsion (silver bromide (AgBr) grains suspended in gelatin) coated uniformly on one or both sides of the base. A new type of film is developed and the films have a wider dose range limit, dose and energy independence, uniformity. The most commonly used is a Gafchromic film which is a colorless film with a nearly tissue equivalent composition (9.0% hydrogen, 60.6% 10 carbon, 11.2% nitrogen and 19.2% oxygen) that develops a blue color upon radiation exposure. Radiochromic film contains a special dye that is polymerized upon exposure to radiation. The polymer absorbs light, and the transmission of light through the film can be measured with a suitable densitometer. Radiochromic film is selfdeveloping, requiring neither developer nor fixer. Since radiochromic film is grainless, it has a very high resolution and can be used in high dose gradient regions for dosimetry. Dosimetry with radiochromic films has a few advantages over radiographic films, such as ease of use; elimination of the need for darkroom facilities, film cassettes or film processing; dose rate independence; better energy characteristics and insensitivity to ambient conditions (although excessive humidity should be avoided). Ashland Gafchromic HD-V2 films had been used to measure the absorbed dose due to its wide dose range from 10 to 1000Gy, low dose and dose rate dependence. The film is comprised of an active layer, nominally 12μm thick, containing the active component, marker dye, stabilizers and other components giving the film its energy-independent response. The thickness of the active layer may vary slightly from batch-to-batch. The active layer is coated on a clear, 97 μm polyester substrate. Figure 1. 5 Configuration of Gafchromic HD-V2 dosimetry film Ashland company recommend to use 48-bit (16bit per color channel) to measure optical density. The typical dose response of HD-V2 film on an Epson color scanner is shown in Figure 2.4. We recommend to fit the calibration data to a function having the form d x ( D) a b / ( D c ) 11 (1.5) where dx(D) is the optical density of film in scanner channel x at dose D, and a, b, c are the equation parameters to be fitted. Figure 1.6: Response of Gafchromic HD-V2 in all Color Channels 12 Chapter 2: Materials and Methods 2.1 X-ray irradiation system The irradiator of Nuclear Engineering faculty is an X-ray irradiation system model MBR-1618R-BE made by Hitachi Corporation. This X-ray irradiator is mainly designed to emit X-rays for experiments involving cultured cells, microorganisms, mice, rats, and other specimens. The tube voltage (35 to 160kV), tube current (1 to 30mA) and irradiation time or irradiation dose are set to emit Xrays. Figure 2. 1 Irradiation system from external view (1) Irradiation chamber door (5) Filter cabinet (2) Opening/closing handle (6) LAN connector port (3) Three-color status indicator lamp (7) Receptacles (4) Filter mounting base (8) Wireless LAN router pocket Some specifications of MBR-1618R-BE X-ray irradiation system are shown in Table 2.1. 13 Table 2..1: Specifications of MBR-1618R-BE X-ray irradiator No. Item 1 Tube voltage Specifications Enables fine-adjustment from 35 to 160kV in 0.1kV steps. 2 Tube current Enables fine-adjustment from 1 to 30mA in 0.1mA steps 3 Maximum power 3kW 4 Turntable 5 Filters Enable fine-adjustment from 550 to 250 mm height in 1mm steps. ( 150mmH with 100mm pedestal) F1 Aℓ1mm F2 Aℓ2mm F3 Aℓ0.5mm+Cu0.1mm, F4 Aℓ0.5mm+Cu0.2mm F5 Aℓ0.5mm+Cu0.3mm 6 Air kerma Approx. 8.5Gy/min (at 160kV,18.7mA, filter F1, 250mmH) Irradiation system radiate X-ray by Bremsstrahlung effect which produces a continuous spectrum below: 14 Figure 2. 2 Irradiator‘s spectrum at 160kV, 18.7mA with different filter 2.2 Dosimetry 2.2.1 Fricke dosimetry Since Fricke ferrous solution is sensitivity to impurity, Pyrex tube is used as standard (Figure 2.3). 15 Figure 2. 3 Pyrex tube (left) and Eppendorf tube (right) Pyrex tube was made of Borosilicate with a length of about 10.9 cm and a diameter of 15.4 mm. Eppendorf tube was made of Polypropylene with length around 3.8cm and diameter of 9.1 mm (11.2 cap diameter). The dose uniform area of the irradiator is a circle with 8 cm diameter at 150mm from the window. Pyrex tube is slightly longer than this and it has a large volume which requires prepare a great deal of microorganism solution. Therefore, the Eppendorf tube is used for microorganisms test due to its small volume and availability. Eppendorf tube is made of plastic instead of glass which some low energy X-rays can penetrate. The height of turntable was adjusted to both of tubes center at the same distance from the source (Figure 2.4). 16 Figure 2. 4 Dosimetry diagram After irradiation, the Fe3+ concentration was measured by UV-VIS spectrometer by measuring Fe3+ absorbance at 304nm wavelength. The absorbed dose in solution was calculated by equation: D (Gy ) 2.77 10 2 A 1 0.007(T 25) Wher D is absorbed dose A is absorbance difference between irradiated solution and control solution T is the temperature of solution in Celsius degree when measure the absorbance 2.2.2 Gafchromic film dosimetry Ashland Gafchromic film HD-V2 has a dynamic dose range from 10 to 1000 Gy, high dose rate and energy independence. After irradiation at the center of the turntable, the film is kept for 24 hours and the color change was scanned by scanner KONICA MINOLTA Biz195 at 24-bit color resolution (8-bit per channel). Then the optical density was analyzed from the scan picture by ColorPic v4.1 software. The measured optical density is used to calculate dose by using the equation 1.5. To identify the dose distribution in material, the film was sandwiched between PMMA plates Due to living organic material and PMMA have the 17 component ratio of carbon, hydrogen and oxygen, the PMMA can be used as an organic material phantom. 2.3 Microorganisms experiment 2.3.1 Microorganism sample preparation E.coli K12 strain is obtained from Osaka Prefecture University and this strain is harmless to human. The growth medium for E. coli is the Lysogeny broth (LB) which contain 0.5g sodium chloride, 0.5g Yeast extract, 1g Peptone per 100 ml. For the preparation of irradiation sample, E. coli was incubated in LB broth at 30 oC for 15 hours. 2.3.1.1 Microorganism sample in Eppendorf tubes As the broth affects the radiation sensitivity of E. coli, the cell suspension was centrifuged at 5,000 rpm for 5 minutes and washed three times by sterilized distilled water. The pure final microorganism liquid was put into the sterilized Eppendorf tubes and sealed with parafilm. These prepared samples are used for irradiation. 2.3.1.2 Plastic bag sample To estimate the depth dose effect of radiation, a thin layer sample was prepared by using a heat-resistant plastic bag (Figure 2.5). Figure 2. 5 Plastic bag microorganism container The microorganism suspension was put into these sterilized bag without centrifuging. The bag with 200l microorganism was heat-sealed completely. PMMA plates were used as a phantom to study the depth dose effect. The plastic 18 bag samples were placed at the top, middle and bottom of the phantom. Then the phantom system was irradiated at 150mmH, 160kV, 18.7mA, F0. 19 Chapter 3: Results and discussion 3.1 Dosimetry 3.1.1. Fricke dosimetry As the Fricke dosimeter is a most common liquid dosimeter, it was used as a standard measurement because of its precision and wide measurable dose range. Additionally, food and agriculture products contain water, and microorganism samples are suspension in water. Fricke dosimeter is used to determine the absorbed doses in the samples. 3.1.1.1 Absorbed dose measurement The Fricke dosimetry solution is highly sensitive to impurities, particularly organic impurities. Pyrex tube is recommended to make Fricke dosimetry system since Pyrex tubes were made of high-quality glass. - Dose rate at different height of irradiation position Absorbed doses are measured at different height of irradiation table because the dose is decreased by the inverse square law. Figure 3.1 shows the relationship of irradiation time vs dose. F1 250mmH F1 150mmH 200 y=16.828x-2.409 R2=0.9991 Dose (Gy) 150 100 y=6.335x-0.662 R2=0.9998 50 0 0 5 10 15 20 25 30 Time (Mins) Figure 3. 1 Dose at 250 mm H (height) of the irradiation table (160kV, 18.7mA, filter F1) The data fit well in linear (R2 = 0.9998) and the dose rate at 250mm H obtained from the equation is 6.335 Gy/minute. The dose rate at 150mm H is 16.828 Gy/minute is about 2.66 times higher than that at 250mm H. It nearly fits 20 with the ratio 2.78 of inverse square law. The ratio measured is less than theory because the X-ray beam goes through air inside the irradiator chamber, so some energy is transferred to air molecules. - Effect of filter to cut the low energy X-rays The filters block low energy of X-rays emitted by the Röntgen tube and some proportion of higher-energy X-rays is also absorbed. The decrease of dose by various filters is shown in Table 3.2. Table 3. 1 Dose and dose rate measured with different filter (160keV, 18.7mA, 150mm H) Time (minute) 5 10 Dose rate (Gy/min) Dose (Gy) F0 109.10 F1 F3 F4 F5 58.57 43.57 33.95 40.53 208.65 170.047 111.48 95.63 65.93 86.04 9.3 6.64 8.82 21.01 84.83 F2 16.8 11.34 The dose rate decrease with the thickness and the density of the filter. The dose rate with F5 is higher than that of F4. This might be an experimental error by using the distinct spectrometer. - Energy and intensity effect Absorbed dose depend on the voltage and current of the irradiator due to X-ray spectrum will be shifted when they are changed. In other words, the voltage determines X-ray average energy emitted and the current determine number of photons are given off at certain energy or intensity of the beam for short. Therefore, adjust these specifications can affect the energy absorbed in the material, the dose maybe not the same even at the same power with different electron speed or intensity. 21 Number of photon 4000 50kV 100kV 160kV 3000 2000 1000 0 0 20 40 60 80 100 120 140 160 X-ray energy (keV) Figure 3. 2 X-ray irradiator spectrum at 50kV, 100kV, 160kVat same current As figure 3.2, adjust the voltage of the X-ray tube affect the number of photons emit at the same energy channel. 160kV 18.7mA 100kV 30mA 50kV 15mA Dose (Gy) 200 y=17.016x-0.156 R2=0.9999 y=9.773x-0083 R2=0.9971 100 y=2.982x-0.02 R2=0.9985 0 0 5 10 TIme (Minute) Figure 3. 3 Change in doses by energy with 50, 100 and 160 keV (150mm H, F1) 22 As shown in Figure 3.3, dose and dose rate are changed with the voltage and current of the X-ray tube. The dose rate at 160 kV, 18.7 mA is highest and around 17.02 Gy/minute. This value was dropped nearly a half to 9.77 Gy/min with the voltage changed to 100kV, 30mA. This means that at the same power 3kW the dose rates are different. Decreasing the power to half by 50 kV, 30 mA, the dose rate is one-third of the dose rate at 100kV because the low energy X-ray intensity at 50kV is much higher than at 100kV and this low energy X-ray is absorbed completely in 1 mm aluminum sheet. 3.1.2 Absorbed dose in Eppendorf tubes 250mmH 150mmH 300 y=18.628x-0.595 R2=-.9964 Dose(Gy) 200 y=7.758x-0.526 R2=0.9975 100 0 0 5 10 15 20 25 30 Time (Minute) Figure 3. 4 Dose and dose rate in Eppendorf tube at 150 and 250 mm H (160kV, 18.7mA, filter F1) The dose rate in the Eppendorf tube is higher than in Pyrex tube because the diameter of Eppendorf is smaller and the denser glass than plastic of Pyrex tube block more low energy X-ray than the Eppendorf. Doses in Eppendorf tube were measured using different filters and the result is shown in Table 3.5. 23 Table 3. 2 Dose and dose rate in Eppendorf tube at 150 and 250 mm H (160 keV, 18.7 mA, 150mm H) Dose (Gy) Time (minute) F0 F1 F2 78.00 56.51 41.00 38.50 48.33 10 528.03 184.92 124.10 84.49 79.22 96.67 5 251.74 F3 F4 F5 Dose rate (Gy/min) 60.33 18.67 11.83 8.33 7.83 9.67 Dose rate in Pyrex tube (Gy/min) 21.01 16.8 11.34 9.3 6.64 8.82 Dose rate difference (%) 65.19 9.82 4.23 -12.00 14.89 8.62 The dose rate in the Eppendorf tube is decreased when the filter is increased and the dose rate in Eppendorf tube is nearly 3 times higher than the dose rate in Pyrex tube because Pyrex tube have bigger diameter than the Eppendorf tube and Pyrex tube was made of glass which is denser than plastic. Doses in Eppendorf tube were measured using different energy and the result is shown in Figure 3.5. 160kV 100kV 50kV Linear Fit 160kV Linear Fit 100kV Linear Fit 50kV Dose (Gy) 200 y=18.628x-5.955 R2=0.9964 y=12.227x+1.709 R2=0.9987 100 y=4.138x+1.524 R2=0.9908 0 0 5 10 Time (Minute) Figure 3. 5Dose in Eppendorf tube at different voltage (150 mm H, F1) 24 The doses and dose rate are changed with the current and voltage. The results are similar in the Pyrex tube but the dose rates measured in the Eppendorf tube are higher than the Pyrex tube because the diameter and material are different. 3.1.3 Gafchromic film dosimetry 3.1.2.1 Gafchromic film calibration Gafchromic film dosimetry has good energy independence and Ashland Company provides a high-quality dependence equation between dose and optical density. It is necessary to make calibration because the X-ray irradiator gives off a wide range of energy electromagnetic wave. The film color changed over time that required to build a new equation for a 24-bit scanner with the X-ray irradiator. To get a good equation, Fricke dosimeter is used as a standard because it is a precise measurement in solution. The dose rate obtained by Fricke dosimetry was used to estimate the dose absorbed by film. The irradiated Gafchromic film was scanned after 24 hours. The optical density (OD) of each film was recorded by ColorPic software to make a calibration equation. Ashland Company recommends to fit the calibration data to a function having the form: d x ( D) a b / ( D c ) Table 3. 3 Parameters of fitting equation with different measured dose rate (160kV, 18.7mA, 150mm H) Optical density Filter Parameter Green a F1 F5 F1 Air kerma * b Red -13.826 Blue -24.401 -7.480 3339.650 12481.750 7708.734 c -28.099 -77.778 -210.958 a -9.538 0.759 10.863 b 3190.135 7995.522 2116.031 c -26.684 -56.956 -91.362 a -13.825 -24.401 -7.480 b c 4553.167 17017.200 10509.820 -38.310 -106.039 *Note: Air kerma is obtained from Hitachi. 25 -287.612 All three Gafchromic film calibration equations are reliable with R2 value close to 1. The F1 equations are more precise because the doses calculated for the other condition from these equations are nearly the same. Optical density (8-bit color) 150 Channels Red Green Blue 100 y=-24.401+7708.734/(x+77.777) R2=0.9989 50 y=-13.825+3339.650/(x+29.099) R2=0.9992 y=-7.480+7708.734/(x+210.968) R2=0.9876 0 0 50 100 150 200 Dose (Gy) Figure 3. 6 Optical density of each color channel (160 kV, 18.7 mA, filter F1, 150 mm H) Figure 3.6 shows the red channel is quite sensitive to radiation, the original curve of Ashland is also the same. To measure a dose above 150 Gy, green and blue channels are a better option because the red channel is saturated. However, since the red channel have high dose responsibility at the dose lower than 150 Gy, it is an optimal equation to measure the dose rate due to 8-bit scanner disadvantage. Particularly, the limit of 8-bit scanner that the OD range is from 0 to 255 (28) and the 16-bit scanner OD range is 0 to 65535. The 16-bit scanner has a higher resolution. So the 8-bit scanner measure less precise than the 16- bit with the same film. Moreover, the 8-bit scanner cannot measure the small change in color when the channel has a low response to radiation. 26 3.1.2.2 Filter and energy effect Table 3. 4 Dose rate measured by Gafchromic film at 150 mm H at different condition Energy & Current 160kV, 18.7mA 100kV, 30mA Filter F0 F1 F2 F3 F4 F5 F1 Dose rate (Gy/min) 75.33 16.83 15.33 14.17 10.50 8.17 13.17 21.01 16.8 11.34 9.3 6.64 Dose rate in Pyrex tube (Gy/min) 8.82 9.77 Dose rates are decreased when filter thickness and density are increased (Table 3.4). The non-filter (F0) dose rate is about 4.5 times higher than F1 since the low energy X-rays have high linear energy transfer. The dose rate measured by Gafchromic film is higher than the dose rate measured by Fricke dosimeter in Pyrex tubes. The dose rate of F3, F4 and F5 is fluctuated and the further experiment is required. 3.1.2.3 Dose distribution in PMMA Polymethyl methacrylate (PMMA) has comparable density to water and organic materials. Therefore, PMMA is applied to measure the dose rate distribution in foods as phantom. Table 3. 5 Dose rate distribution in PMMA with different filters (160keV, 18.7mA) Dose rate (Gy/min) Sample Thickness (mm) 1 0 77.500 15.320 14.233 10.556 6.982 5.865 2 1 56.251 13.374 13.413 11.177 7.332 6.159 3 2 40.135 12.806 11.988 9.471 6.075 5.103 4 3 32.405 11.772 11.988 9.471 6.658 5.593 5 4 21.492 11.300 11.988 8.553 6.982 5.865 6 5 11.492 10.853 11.988 8.553 6.357 5.340 7 6 10.748 10.432 10.792 8.553 5.812 4.882 8 7 10.116 10.032 10.264 9.471 5.812 4.882 9 8 F0 9.573 F1 9.653 27 F2 9.322 F3 F4 F5 7.768 5.566 4.675 10 9 9.091 8.625 9.775 7.416 5.566 4.675 11 10 8.660 7.734 8.505 7.088 5.566 4.675 12 20 5.823 4.621 5.248 4.538 3.243 2.725 13 30 4.162 2.657 3.217 2.681 2.077 1.745 14 40 1.991 1.802 1.738 1.979 1.429 1.200 15 50 1.383 1.007 1.289 1.033 0.995 0.836 The dose rate decreases while the PMMA thickness is increasing. The dose rates with F1 to F5 are gradually decreased but the dose rate of F0 is rapidly decreased in the thin layer because the low energy X-rays lose a large amount of their energy while they penetrate into material. Dose rate distribution in PMMA irradiated with F0 and F1 is shown in Figure 3.7. F0 F1 100 Dose(Gy/min) y=77.907e-0.327x R2=0.9956 y=13.936e-0.0448x R2=0.9937 10 y=14.515e-0.0570x R2=0.9931 1 -5 0 5 10 15 20 25 30 35 40 45 50 55 Thickness (mm) Figure 3. 7 Dose rate distribution in PMMA The dose rate of F1 decreases exponentially with increase of PMMA thickness while the dose rate of F0 decreased markedly from 0 to 5mm thickness of PMMA. At 5mm PMMA thickness, the dose distribution is nearly the same with other filters because the higher energy X-rays can through the filters. They have high penetration and the dose rates distribution nearly the same among different filters. 28 3.2 Disinfection of E. coli by radiation 3.2.1 Filter effect on E. coli radiosensitivity Filters absorb the low energy of X-rays, and their intensity so the effect of radiation maybe not the same with different filters. The dose rate is used for calculating in this part is measured by the Fricke dosimeter in Eppendorf tube at each condition since the microorganism samples contained in Eppendorf. 1 y=e-0.0299x R2=0.9921 0.1 Survival rate Survival rate Low dose survival curve High dose survival curve y=0.1291e-0.0092 R2=0.9937 0.01 1E-3 1E-4 0 200 400 600 Dose (Gy) Figure 3. 8 F0 Survival curve (160kV, 18.7mA, 150mmH, filter F0) Figure 3.8 shows that the survival rate of E.coli decreases dramatically from 0 to 100 Gy, and it decreases gradually at the higher dose range. This can be explained by the penetrate of low energy X-ray is shorter than the high energy Xray. Therefore, dose distribution inside the Eppendorf tube is not even, the upper part of the tube exposed to more radiation than the bottom part. The survival rate when the tube is mixed is average of the survival rates at two parts of the tubes. This average survival rate will drop rapidly when the high dose region survival rate decrease more dramatically than the low energy region. At the higher dose range above 100 Gy, the survival rate of high dose part of the tube is much less than the low dose counterpart, so the average survival rate is mainly determined by the low dose region. 29 F1 Low dose curve High dose curve 1 y=e-0.0265x R2=0.9987 Survival rate 0.1 y=0.0492e-0.009x R2=0.9926 0.01 1E-3 1E-4 0 200 400 600 Dose (Gy) Figure 3. 9 F1 Survival curve (160kV, 18.7mA, 150mmH, filter F1) At this condition, the shape of the survival curve is the same as the F0 curve, but the decreasing rate is slightly lower in the low dose range, and the high dose range curve is nearly the same as F0 condition. The small difference between the two condition that the low dose range of F1 is wider than the F0 one due to great amount of X-ray below 15keV have been absorbed by the filter F1. F2 F2 Survival curve 1 Survival rate 0.1 y=e-0.02438x R2=0.9991 0.01 1E-3 1E-4 0 100 200 300 Dose (Gy) Figure 3. 10 F2 Survival curve (160kV, 18.7mA, 150mmH, filter F2) 30 400 The figure 3.10 show that the survival rate of microorganism decrease not fast as the low dose part of F0 and F1 survival curve due to the low energy X-rays are completely shielded. The same thing happened with the other filters, these curves are slightly differences. F3 F3 Survival curve 1 0.1 Survival rate 0.01 y=e-0.0247x R2=0.9998 1E-3 1E-4 1E-5 0 200 400 600 Dose (Gy) Figure 3. 11 F3 Survival curve (160kV, 18.7mA, 150mmH, filter F3) F4 F4 survival curve 1 0.1 Survival rate 0.01 y=e-0.0245x R2=0.9987 1E-3 1E-4 1E-5 0 100 200 300 400 Dose (Gy) Figure 3. 12 F4 Survival curve (160kV, 18.7mA, 150mmH, filter F4) 31 F5 F5 survival curve 1 0.1 Survival rate 0.01 1E-3 y=e-0.0225x R2=0.9969 1E-4 1E-5 0 200 400 600 Dose (Gy) Figure 3. 13 F5 Survival curve (160kV, 18.7mA, 150mmH, filter F5) The filter effect is dominated with filter F0, F1, this effect becomes less important with the thicker and denser filters. For sterilizing E. coli, depend on the thickness different filters can be used to get optimal penetration and time. 3.2.2 Energy effect Voltage changing also can affect X-rays energy emitted by the tube, it is similar to filter but on the reverse way. Particularly, changing voltage will reduce or increase the highest energy and average energy, intensity of photon coming out at certain energy. This effect causes not only dose variation but also make the result different since different wavelength photons transfer not the same amount of energy to material. This effect was shown in Fig. 3.14, 3.15 32 F1 50kV 30mA Low dose curve High dose curve 1 Survival rate 0.1 0.01 1E-3 y=0.061e-0.0105x 2 =0.9958 -0.02314x y=e R2=0.99996 1E-4 0 200 400 600 Dose (Gy) Figure 3. 14 Survival curve at 50 keV ( 30mA, 150mmH, filter F1) F1 100kV 30mA High dose curve Low dose curve 1 Survival rate 0.1 0.01 1E-3 y=e-0.03x R2=0.99796 y=e-0.0083x R2=0.8627 1E-4 0 200 400 600 Dose (Gy) Figure 3. 15 Survival curve at 100 keV (30mA, 150mmH, filter F1) There is a similar survival curve of E. coli between 160kV, 18.7mA; 100kV, 30mA; and 50kV, 30mA curves at the same condition. In three lines, survival rate 33 decreases rapidly in low dose range and drop gradually in high dose range. 160kV 18.7mA 100kV 30mA 50kV 30mA 1 0.1 Survival rate 0.01 1E-3 1E-4 1E-5 0 200 400 600 Dose (Gy) Figure 3. 16 Survival rate at different voltage at 150mm from the source - Survival rate at the different distance from source\ y=e-0.0265x R2=0.9987 1 250mmH 150mmH 0.1 Survival rate 0.01 y=e-0.03931x R2=1 y=0.0492e-0.009x R2=0.9926 1E-3 1E-4 y=0.059e-0.0188x R2=0.9975 1E-5 0 200 400 Dose (Gy) 34 600 Figure 3. 17 Survival curve at 150mm and 250mm height (160kV, 18.7mA, filter F1) The 250mmH survival rate decrease sharply than the 150mmH survival rate due to distance adjustment change the dose rate which requires long time irradiation. Particularly,14 minute irradiating at 250mmH and 6 minute irradiating at 150mmH is necessary for the samples expose to 100Gy. 3.2.3 Effect of thickness of the sample Food is contaminated not only on the surface but also deep inside the food. To analyze the depth dose distribution, PMMA is used as a phantom. Table 3.4 shows the survival ratio of E. coli at 6 mm depth of PMMA phantom. The survival ratios increase when the thickness of PMMA layers increase because of dose attenuation. However, the data were varied and the further experiment is required to clarify the depth effect. Table 3. 6 Survival ratio inside the PMMA phantom ( 160kV, 18.7mA, 150mmH, filter F0, 2 minutes irradiating) Sample Position (mm) Dose (Gy) Control 0 0 0 2 mm 4 mm 6 mm Dilution Plate 1 Plate 2 Plate 3 CFU/ml Survival ratio 5 291 480 252(C) 6 35 20 37 3.49E+0 8 1.00E+0 0 155 4 32 42 34 3.60E+0 6 1.03E-02 1 112 4 C C 252 2.52E+0 7 7.23E-02 2 80 5 84 92 79 8.50E+0 7 2.44E-01 0 155 3 1402 1616(C) 1586 1.53E+0 7 4.40E-02 2 80 4 317 540 429 4.29E+0 7 1.23E-01 4 43 4 449 540 628(C) 5 55 52 33 5.37E+0 7 1.54E-01 0 155 2 133 139 219 1.64E+0 5 4.69E-04 35 3 64 4 1200 1002 1160 1.12E+0 8 3.21E-01 6 20 5 105 81 113 9.97E+0 7 2.86E-01 *Note: C: the plates are contaminated by another microorganism The dose is calculated from the Gafchromic film dose distribution in PMMA. 36 3.3 Discussion Fricke dosimeter, Gafchromic film are used to measure the dose, dose rate and dose distribution inside the organic material. It is necessary to measure again in the future experiment for more precise dose, dose rate. Measurement of low energy X-ray dose is a complicated and sophisticated process because low energy X-rays (<20keV) dosimetry can be contaminated with the secondary electron and higherenergy X-rays can have a big backscatter factor. The X-rays emitted by the MBR-1618R-BE Hitachi irradiation system can be applied to the disinfection of microorganisms in foods. The filter is an important factor because the filter cuts off the low energy parts of X-rays. The survival curves of E.coli are exponential with higher filters such as F3 – F5 but the survival curve of F0 and F1 composed with two parts of sharp decrease in low dose range and slow decrease in high dose range. The low energy part of X-rays is useful for the disinfection of thin foods or small granules such as peppers. X-ray tube irradiator is compact and inexpensive. For the industrial scale irradiation, high dose rate and good dose uniformity ration (Dmax/Dmin) are important. It is considered that the low energy X-ray radiation without filter was effective for the surface (5 mm thickness) irradiation. For the irradiation of thick materials, the filter such as 1.0 mm - 2.0 mm Al is necessary to obtain a better dose uniformity ratio. 37 CONCLUSION Although dose measurement for X-ray irradiator has many disadvantages and errors, the dosimetry results are still precise enough for the microorganism control experiment. The absorbed dose measured by Fricke dosimetry at 250mmH, 160kV, 18.7mA filter F1 is about 1,01 Gy/h. The Eppendorf dose is slightly higher than Pyrex dose because of its lighter material and smaller diameter. The distribution of dose inside material, the PMMA is used to measure the distribution, the dose and dose rate decrease exponentially when X-ray penetrates into PMMA. The thicker filter, the more uniform dose becomes, so it is necessary to use filter for high dose uniformity ratio. The X-ray is effective to disinfect microorganism, the D10 value is around 100Gy for E.coli K12. For comparison, this value with the gamma source is about 200Gy. Moreover, an X-ray irradiator is very effective to sterilize the surface of the food and the optimal thickness of the irradiated object is 5mm with filter F0. To disinfect the thicker food, different filters can be used to get a uniform dose, but the effectiveness will be decreased and the time irradiate will also increase. Moreover, the X-ray emitted has low penetration so the size of the food is limited, and the dose rate is lower than Co60 gamma source so it takes a longer time to irradiate food. All in all, MBR-1618R-BE Hitachi irradiator has good disinfection ability, especially disinfect thin or small grain food such as pepper, powder, milk, etc. However, this research just experimented on E.coli but there are many microorganisms that resist radiation and it is necessary to study more about the effect of X-ray on these microorganisms. 38 REFERENCES Ashland company, GAFCHROMIC HD-V2 Dosimetry Film A. E. Akanele, Microbiological Contamination of Food: The Mechanisms, Impacts And Prevention, 2016 Hitachi Company Operation manual X-ray Irradiation System MBR-1618RBE, 2018. International Atomic Energy Agency, Manual of good practice in Food irradiation, IAEA report No.481, 2015 International Atomic Energy Agency, Review of Radiation Oncology Physics: A Handbook for Teachers and Students, VIENNA, 2005 International Atomic Energy Agency, Absorbed dose determination in photon and electron beams. An international code of practice. IAEA report No. 277, 2000 S. C. Klevenhagen, D. D’Souza and I. Bonnefoux, Complications in low energy X-ray dosimetry caused by electron contamination, 1991 Kume T, Tachibana H, Takehisa M, Fricke dosimetry in low dose range for food irradiation, Food Irradiation Development Laboratory, Takasaki Radiation Chemistry Research Establishment, 1982, JAERI P. Kunstadt, Food Irradiation: Gamma Processing Facilities, 1997 T. H. V Phuong, Dosimetry for low energy X-ray irradiator MBR-1618RBE, 2018 United States National Institute of Standard and Technology, X-Ray Mass Attenuation Coefficients 39