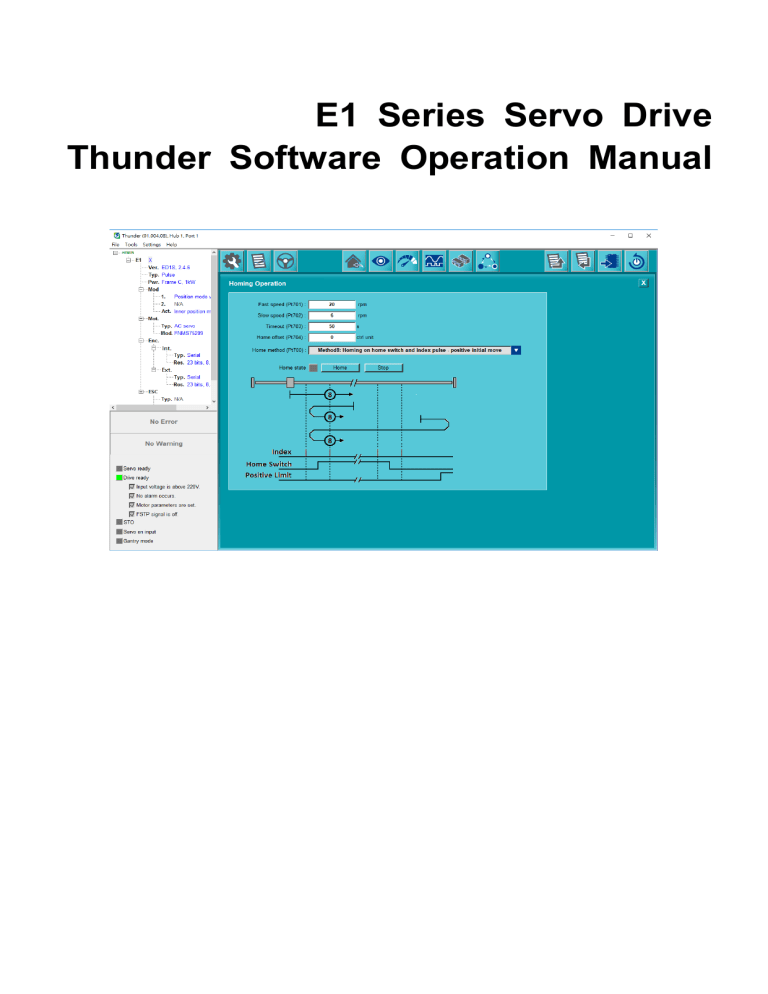

E1 Series Servo Drive Thunder Software Operation Manual

advertisement