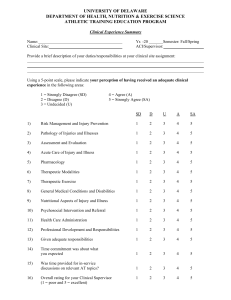

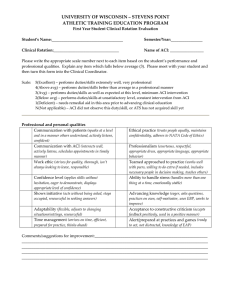

Lecturer: Habte Y.Damir Student: Ghaith Fatmi 1. INTRODUCTION Comparative studies of building codes, standards and codes are not uncommon in the available literature. These studies usually involve the comparison of nominal loads, Load combinations, load factors, resistance coefficients and resistance expressions for various limits state and structure types. Introduction of new structural codes, design concepts and materials Research into comparative studies between structural design codes has also been facilitated. These studies provide Gain insight and point out different approaches to regulatory structure design in different countries the extent to which a code differs from or matches another code in terms of accuracy, Security, complexity and detail. They are also useful in countries with multiple codes Can be used in structural design as they help determine which code has a higher coefficient Safer than any other. Objectives The main goal of this study is to compare the design requirements of the American ACI code with the British BS code. Specifically, the design of beams is considered. Also, the load factors and load combinations in the two codes are compared. 2. Structural design In this section American Concrete Institute ACI 318 and British Standard BS 8110 A brief overview of code requirements for bending, shear, and axial loading. Only rectangular cross-sections with straight stirrups and anchors are covered. There are also double reinforced beams, slender Columns and columns subject to eccentric loads are not included. It should be noted that ACI 318 specifications is based on concrete cylinder strength𝑓′𝑐 , while BS 8110 the code equation depends on the concrete cube strength𝑓𝑐𝑢 . Additionally, the ACI 318 code uses Resistivity for rated capacitance as opposed to BS 8110 which uses fractional coefficients Applies to material strength properties. ACI 318 The bending design of beams in the ACI 318 code assumes an ultimate compressive load specifically equal to 0.003. For under-reinforced concrete sections, the stresses in the reinforcement Rebar is equal to the yield stress 𝑓𝛾 (MPa), which is the compressive stress in concrete Reduced to a constant strength block equal to 0.85𝑓′𝑐 , where 𝑓′𝑐 is 28 days of compression The strength of the cylinder. Nominal flexural strength 𝑀𝑛 (N-mm) can be obtained from (Wight and McGregor 2011) 𝐴𝑠 𝑓𝑦 𝑀𝑛 = 𝐴𝑠 𝑓𝑦 (𝑑 − 0.59 𝑓′ 𝑏 ) (1) 𝑐 Where 𝐴𝑠 = area of tensile reinforcement (mm2 ) d = effective depth of reinforcement from extreme compressive fibers (mm), and b = width of the beam (mm). In the ACI 318 code, the strength reduction factor for flexure,, depends on the strain in the steel layer closest to the tension side, t . For tension-controlled regions (t ≥ 0.005) = 0.90, for compression-controlled regions (t ≤ y) = 0.65, and for transition-regions (y < t < 0.005) linearly varies between 0.65 and 0.90. To ensure adequate ductility in the design of new structures, the code requires t ≥ 0.004; in this case, ranges between 0.81 and 0.90. In the ACI 318 code, the nominal shear strength of a section transversely reinforced with stirrups, 𝑣𝑛 (N) is (ACI318M-11, Eq. (11)-(2)) 𝑣𝑛 = 𝑣𝑐 + 𝑣𝑠 (2) Where 𝑣𝑐 (N) is the shear strength provided by the concrete (ACI318M-11, Eq. (11)-(5)) 𝑣 𝑑 𝑣𝑐 = (0.16 𝜆 √𝑓′𝑐 + 17𝜌𝑤 ( 𝑀𝑢 )) 𝑏𝑤 𝑑 ≤ 0.29√𝑓′𝑐 𝑏𝑤 (3) 𝑢 And 𝑣𝑠 (N) is the shear strength contributed by the stirrups (ACI318M-11, Eq. (11)-(15)) 𝑣𝑠 = 𝐴𝑣 𝑓𝑦𝑡 𝑑 𝑠 (4) Where = factor that accounts for the density of concrete, w= is the flexural reinforcement ratio given by 𝐴𝑠 / (𝑏𝑤 𝑑), 𝑏𝑤 = narrowest width of the cross-section (mm) 𝑣𝑢 = critical factored shear (N), 𝑀𝑢 = factored moment concurrent with Vu (N-mm) 𝐴𝑣 = total area of vertical stirrups per spacing (mm2), 𝑓𝑦𝑡 = yield strength of the steel stirrups (MPa), and s = spacing of stirrups along the beam length (mm). BS Design for bending in BS 8110 code assumes an elongation at break of 0.0035 for concrete. Unlike the ACI Code, the British Code uses partial material safety factors (equal to 1.5 for concrete and 1.15 for steel) is used as a separator for the concrete cube strength𝑓𝑐𝑢 , and the yield strength of the steel, f. The compressive stress at failure of concrete is simplified as a constant strength block equals 0.67𝑓′𝑐𝑢 /1.5. According to the specification, the required face is steel Reinforcement For rectangular cross-sections subjected to a factored moment 𝑀𝑢 (BS 8110, Section 3.4.4.4) 𝑀 𝐴𝑠 = 0.95 𝑢𝑓 𝑧 (5) 𝑦 Where z is the moment arm (mm) within the cross-section, calculated from (BS 8110, section 3.4.4.4) 𝑀 𝑧 = 𝑑 (0.5 + √0.25 − 0.95 𝑓 𝑢 𝑏𝑑2 ) ≤ 0.95 𝑑 (6) 𝑐𝑢 Similar to ACI 318, the BS 8110 code bases the design shear strength, V, inclusive of the resistance factors, of a reinforced concrete section on the contributions of both the concrete and stirrups (BS 8110 sections 3.4.5.3 and 3.4.5.4) 𝑉= 0.79 100𝐴𝑠 1 400 1 𝑓𝑐𝑢 1 𝛾𝑚 ( 𝑏𝑑 )3 ( 𝑑 )4 ( 25 )4 + 0.95𝑓𝑦𝑣 𝐴𝑠𝑣 𝑠𝑣𝑏𝑣 (7) Where 𝑏𝑤 =𝑏𝑣 , 𝐴𝑠𝑣 =𝐴𝑣 , 𝑓𝑦𝑣 = 𝑓𝑦𝑡 (as defined earlier) and m is a material factor = 1.25 3. Load combinations The loads used in the design for ultimate strength are nominal values multiplied by load factors that are included in the various codes of practice. With this approach, the specified loads will rarely be exceeded during the useful life of the structure. The load factors, together with the strength resistance factors, provide the overall factor of safety against strength failure. The load combinations in the ACI 318 code are based on the ASCE7 standard (ASCE7 2010). The factored load combinations involving service dead load (D), floor live load (L), roof live load (Lr) and wind (W) in the ACI 318 code are presented below 1.4𝐷 1.2𝐷 + 1.6𝐿 + 0.5𝐿𝑟 1.2𝐷 + 1.6𝐿𝑟 + (𝐿 𝑜𝑟 0.8𝑊) 1.2𝐷 + 1.6𝑊 + 1.0𝐿 + 0.5𝐿𝑟 0.9𝐷 + 1.6𝑊 (10) The corresponding load combinations in the BS 8110 code for the considered loads are shown below 1.4𝐷 + 1.6𝐿 1.4𝐷 + 1.4𝑊 1.0𝐷 + 1.4𝑊 1.2𝐷 + 1.2𝐿 + 1.2𝑊 (11) Note that the ACI code differentiates between floor live load (L) and roof live load (Lr), whereas the BS code does not distinguish between the two live loads components and applies the same load factor to both. 4. design equations o Bending The design procedures in ACI 318:08 and BS 8110:97 are based on the simplified rectangular stress block as given in ACI 318:08–10.2 and BS 8110:97–3.4.4, respectively. The area of required flexural reinforcement in ACI 318:08–10.3.4 is given as 𝐴𝑠 = 𝑀𝑢 𝑎 𝜙𝑓𝛾(𝑑 − 2) Where 2𝑀𝑢 a =d-√𝑑 2 − 0.85𝑓′𝑐𝜙𝑏 In BS 8110:97–3.4.4.4, the area of required reinforcement is given by 𝐴𝑠 = 𝑀𝑢 0.95𝑓𝛾𝑧 o Shear The concrete shear strength, vc, in a beam can be calculated from ACI318:08– 11.2.2.1 as the resulting smaller value of (0.16√𝑓 ′ 𝑐 + 17𝜌 𝑣𝑐 = min of ( 0.29𝑓 ′ 𝑐 𝑉𝑢𝑑 𝑀𝑢 ) Where 𝑓 ′ 𝑐 ≤ 70 N/mm2 and 𝑣𝑢 d/𝑀𝑢 ≤ 1. According to Table 3.8 of BS 8110:97–3.4.5.4, the concrete shear strength 𝑣𝑐 , is calculated as 𝑣𝑐 = 0.79 100𝐴𝑠 1 400 1 𝑓𝑐𝑢 1 ( )3 ( )4 ( )4 𝛾𝑚 𝑏𝑑 𝑑 25 With the following limitation: 𝛾𝑚 =1.25, 0.15≤ 100𝐴𝑠 /bd ≤ 3, (400/d) ≥1 and 𝑓𝑐𝑢 ≤40 N/mm2 . o Torsion The design provision for torsional cracking strength of RC solid beam in ACI 318:08– 11.5.1 is specified as √𝑓′𝑐 𝐴2 𝑐𝑝 𝑇𝑐𝑟 = ( ) 3 𝑝𝑐𝑝 If 𝑇𝑢 ≤ 𝜙𝑇𝑐𝑟 ,/4 no torsional reinforcement is needed. The torsional strength of a member is given by ACI 318:08 – 11.5.3.5 as 𝑇𝑛 = 2𝐴𝑡 𝐴0 𝑓𝑦𝑣 𝑐𝑜𝑠 𝜃 𝑠 Where 𝐴0 = 0.85𝐴0ℎ and 𝜃 =45° for RC member. In BS 8110–2:85 (BSI 1985)–2.4.4.1, the torsional shear stress 𝑣𝑡 , for rectangular beam is computed as 𝑣𝑡 = 2𝑇𝑢 ℎ ℎ𝑚𝑖𝑛 2 (ℎ𝑚𝑎𝑥 − 𝑚𝑖𝑛 3 ) The minimum torsion stress, 𝑣𝑡𝑚𝑖𝑛 , below which torsion in the section can be ignored based on BS 8110–2:85–2.4.6, is given for different grades of concrete as 𝑣𝑡𝑚𝑖𝑛 = 0.067√𝑓𝑐𝑢 ≤ 0.4𝑁/𝑚𝑚2 If 𝑣𝑡 > 𝑣𝑡𝑚𝑖𝑛 , then torsional resistance is to be provided by closed stirrups and longitudinal bars. 5. Comparison for Minimum Area of Flexural Reinforcement The equations of minimum required flexural reinforcement based on the ACI and BS codes are shown in Figures were developed based on those equations for different values of f’c , which is taken as 0.8 f cu. The beam cross-sectional dimension is 3503700mm with effective depth of 625 mm. The yield strength of reinforcement was taken as 460N=mm2. It can be seen that the minimum area of flexural reinforcement required by ACI is much larger than that required by BS. The BS curve is constant with all grades of concrete, while the ACI curve changes from being constant for concrete grades of 30–40N=mm2 to nonlinear for concrete grades larger than 40N=mm 2. The difference is constant at the value of 106% for the concrete strengths of 30– 40N=mm2, then it increases with the increase in the concrete strength. The maximum difference for the given beam geometry and concrete strengths was 133.5%. 6. Comparison for Minimum Area of Shear Reinforcement 7. Conclusion The results of the study on the ACI 318 and BS 8110 codes lead to the following conclusions: • There are somewhat large discrepancies between the shear strengths obtained by the two codes. Except for very lightly transversely reinforced sections, the ACI code shear strength equations predict 10-30% lower capacity than the corresponding equations in the BS code. Since the ACI 318 code predicts a little lower structural strength while at the same time slightly overestimates the factored load effect, compared to the BS 8110 code, the net effect results in a larger overall factor of safety. This translates to somewhat larger cross-sections and/or more steel reinforcement, and consequently higher construction costs, for members designed following the ACI 318 code over corresponding members sized based on the BS 8110 code.