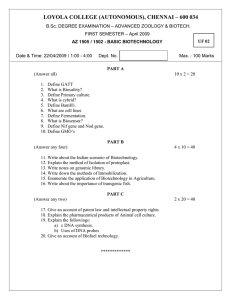

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/296514078 Risk assessment on the use of Genetically Modified Organisms (GMOs) for biofuel production Article · October 2015 CITATIONS READS 0 937 1 author: Alya Limayem University of South Florida 19 PUBLICATIONS 1,089 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Nanotherapeutics and invasive bacteria View project All content following this page was uploaded by Alya Limayem on 07 March 2016. The user has requested enhancement of the downloaded file. www.afabjournal.com Copyright © 2015 Agriculture, Food and Analytical Bacteriology Risk assessment on the use of Genetically Modified Organisms (GMOs) for biofuel production A. Limayem1 1 Department of Cell Biology, Microbiology and Molecular Biology, University of South Florida, 4202 East Fowler Avenue, Tampa, FL 33620, USA ABSTRACT In recent years concerns about energy security and climate change have sparked government interest in biofuels from crops. However, water and land availability for biofuel production could become major obstacles, if effective conservation practices are not implemented. In an effort to increase crop productivity with minimal use of natural resources, genetic manipulations of corn plants are conducted in the U.S. and worldwide to convey pest and herb resistance. Moreover, genetically engineered microorganisms have been developed to render biomass conversion to fuels cost competitive. This review summarizes the evolution of biotechnology in agricultural systems and its most current use in biofuel production. This includes the review of the recent genetically engineered microorganisms (GMOs) as well as the nanotechnology used to biofuel yield optimization. Potential bottlenecks pertaining to GMOs dispersal from biofuel production are thoroughly addressed. Novel point-of-care approaches exclusively adopted by the federal agencies and arising from systemic core modeling such as biotechnology risk assessment are discussed. Optimizing these tools by revealing a proficient model engineering practices toward achieving greater GMO traceability, biosafety and operational performance remains the option of choice to intervention. Keywords: Biotechnology, Biofuel, Biomass, Genetically modified organisms (GMOs), Risk assessment modeling Agric. Food Anal. Bacteriol. 5: xx-xx, 2015 INTRODUCTION With rising concerns about energy security, climate change, and sustainable development, agriculture-based biofuels have gained considerable atCorrespondence: Alya Limayem, alimayem@usf.edu Tel: +1 -813-974-7404 tention from governments, investors, and scientists in the U.S. and worldwide (Youngquist, 1999). The passage in the U.S. of the Energy Policy Act of 2005 and the Energy Independence and Security Act of 2007 (Bothast and Schlicher, 2005; Brookes 2009) has spurred growth in biofuel production from 1.6 billion gallons per year (6 billion liters) in 2000 to 13.3 billion gallons (50 billion liters) in 2014 (RFA, 2014). Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX The continuous expansion of the biofuels industry at such a fast pace has prompted substantial growth in modern biotechnology (James, 2011; Sanchez and Cardona, 2008). To date, agro-biotechnology involves mainly the use of genetically modified organisms (GMOs), including both transgenic crops and genetically transformed microorganisms (Holmes, 2010). GMO manipulations offer economic advantages to investors by maximizing product yield from limited land and water use (Ramasamy et al., 2007). In the last decade, the U.S. has become the world leader in the cultivation of genetically modified (Ladisch et al., 2010) crops, involving primarily corn and soybeans. In 2010, Brazil achieved the world’s sec- provide a qualitative and quantitative risk estimate to biotechnology investors and policy makers. These approaches assess the probability of occurrence and the severity of effects from exposure to GM living organisms. While a temperature of 500°F would be sufficient to inactivate the DNA from biofuel downstream operations (Gryson, 2010; Krohn et al., 2011), there is an imperative need to generate a comprehensive insight of all the operation steps that determine the risk. The biotechnology risk assessment is a comprehensive approach that should emerge as the method of choice to provide greater predictability of GMO dispersal during bioprocessing operations (Flory et al., 2012). ond largest increase in soybean cultivation, reaching a total area of approximately 23 million hectares (Cerdeira et al., 2010). In contrast, in Europe mandatory labeling and public concerns have so far substantially limited GM investments (Carter and Gruère, 2003). Currently, China is emerging in biotechnology, particularly in the cultivation of GM rice and cotton, followed by India in development of GM fiber, primarily cotton (Huang et al. 2002). Aside from transgenic plants, biofuel production from corn and lignocellulosic feedstocks also involves the use of GM fermentative microorganisms in various parts of the technologies (Phillips, 2008). However, as investment in agricultural biotechnology and in the biofuels industry expands, concerns about the risks of adverse health effects from GMOs have also increased. Within the last decade there have been a number of different groups calling for protection of the ecosystem and of biodiversity from GMO effects. Researchers indicate that adverse outcomes of GMOs could present a real risk to the environment from irreversible and unforeseen dissemination (Ho et al., 1999). Although clear evidence of adverse effects from GMO applications is currently lacking, the adoption of a scientifically sound method, such as risk assessment, would help develop This review encompasses the advancement of agricultural biotechnology in the U.S. and worldwide. It provides a summary on the most current GMOs used in biofuel production in the U.S. This review also examines potential obstacles related to GMOs dissemination. Future directions describing systemic core modeling such as Biotechnology Risk Assessment approach are suggested to maintain biosafety and bioprocessing operational performance. biosafety measures through a comprehensive model that could subside public concern and ensure environmental safety (Brookes, 2009). Systemic methods, including Biotechnology Risk Assessment, are gaining attention as potential statistical approaches that isms. From this perspective, the molecular explanation of life arose at the Rockefeller Institute of New York in the late 1930s as a novel discipline named “molecular biology” by Warren Weaver (Sarkar, 1991). Between 1926 and 1960 there were consid- XX HISTORICAL AND EMERGING TRENDS Background Although the public has become aware of genetic alterations rather recently, modifying genomes of plants via breeding methods has been carried out over a long period of time (Phillips, 2008). At the end of the nineteenth century physiological genetics started to emerge over the classical theory of chromosome heredity, along with the segregation and inheritance law of Mendel (Burian and Gayon, 1999). At that time, several disciplines, such as physics, biology and virology, started to interact in an effort to achieve a scientific understanding of living organ- Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 erable advances in physiological genetics that were devoted to explaining the gene and protein relationship from the Drosophila fly and Neurospora fungus (Beadle and Tatum, 1941) up to the new model organism, a bacteriophage (T1 through T7), described by Delbrück and his group at the beginning of 1940 (Delbrück, 1949; Machine, 1984). More modern genetic engineering approaches that involve precise manipulation of genomic vectors (plasmid constructs and recombinant DNA) in bacteria and mice began in 1972 and 1974, respectively ( Arnold, 2009; Cohen et al., 1972; Jaenisch and Mintz, 1974). In the early 1980s the development of insulin-producing microorganisms (Crea et al., 1978; Whitman along with the employed major GMO techniques and gene sources used, are summarized in Table 1. Currently, both herbicide tolerance and insect resistance are among the most prevalent GMO traits that are used in agronomical biotechnology (Cerdeira et al. 2010; Edmeades, 2013; James, 2011). In 2006 insect- and herbicide-resistant GM plant cultivations, mainly soybean and corn, reached 101 million hectares across 22 countries (James, 2011). The most common herbicide tolerance is achieved by the insertion of glyphosate and glufosinate resistance genes, such as the 5-enolpyruvylshikimate-3-phosphate synthetase (EPSPS) gene, into the target plant (Powles and Yu, 2010). On the other hand, insect re- et al., 1996) was commercialized in the medical field. Then, the rapid evolution of agricultural biotechnology by the end of the twentieth century gave rise to genetically modified crops first for food and later for biofuel production (James, 2011). Agricultural biotechnology approaches have been widely used to ensure biological and economic benefits from the extensive cultivation of GM crops (Brookes, 2007). Increasing yields associated with less land erosion and water use are among the most desirable benefits of transgenic plants (Dunn et al., 2013; Mumm et al., 2014; Ramasamy et al., 2007). Genetically engineered corn has been grown in the U.S. since 1997 (James, 2011). It has been reported that 36% of corn planted around the world is genetically modified with 86% of it been planted in the U.S. (Boryan et al., 2011; Edmeades, 2013). sistance is conferred by genes that originate from the well-known Bacillus thuringiensis strain, whose toxic crystal protein causes host cell death (Shen et al., 2013). As a result, plants transformed by B. thuringiensis genes for insect resistance are called Bt crops (Entwistle et al., 1993). The Bt gene can be incorporated into the plant cell via various transformation techniques. ADVANCEMENTS IN AGRO-BIOTECHNOLOGY Currently, there are almost 150 million hectares of GM crops planted in 25 countries around the world. The U.S. alone grows almost 50% of the world’s transgenic plants (soybean and corn) with approximately 67 million hectares, followed by Brazil and Argentina that account for approximately 25.5 and 23 Although research and development in gene transfer technology has led to enhancements in cell transformation, genetic trait isolation (Feltus and Vandenbrink, 2012) has also achieved considerable progress, leading to greater insect resistance and herbicide-tolerance in biofuel and food crop. The Bt protein is variably pathogenic, meaning that it impacts specific species via a specific toxin receptor interaction, but not others lacking the receptor (Shen et al., 2013). During the last decade, B. thuringiensis strains including the Cry1A and Cry1B delta toxins were known for their effects on specific type of strains such as, Lepidoptera and Diptera insects million hectares, respectively (Cerdeira et al., 2010). Transgenic crops have reportedly helped U.S. farmers increase their product yield by 30% over the last decade (Erickson and Winters, 2012). The most prevalent transgenic plants in the world, (Carpenter et al., 2002). Currently, the pilot studies have demonstrated that genetically modified E. coli vectors are engineered so as to contain a wide range of Bt toxins in the same strain, thus optimizing Bt utility to convey greater stability, delivery, and ver- Current trends Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX Table 1. Most prevalent transgenic plants and GMO techniques used for biofuel production. (Brookes, 2007; Phillips 2008; Piekarowicz, 1978; Schell et al., 2007; Uchtmann and Nelson, 2000) Plants Corn Major components of the delivery system Desired traits and sources Transciption/translation genes and sources • Pest resistance: Cry genes • Promoter from rice from Bacillus thuringiensis (i.e., Cry 1A.105, Cry 2Ab2, Cry 1F for aerial pests and Cry 3Bb1, Cry 34Ab1 and Cry 35 Ab1 for subsoil pest resistance) • Terminator from Agrobacterium tumefaciens • CTP peptide (EPSPS transporter) from Selective markers • Antibiotic resistance marker (ARM), beta-lactamase (bla) corn itself and sunflower • Resistance to herbicides: EPSPS genes isolated from A. tumefaciens CP4 (resistance to glyphosate) • Promoter from cauliflower mosaic virus, Soy CamV 35S beans • Terminator from Arabidopsis plant ARM, neomycin phosphotranspherase II • CTP peptide (EPSPS transporter) from • Resistance to herbicides: Sugar beet EPSPS genes isolated from A. tumefaciens CP4 for herbicide resistance Canola • Herbicide resistance: EPSPS from A. tumefaciens CP4 • Increased content of laurate: petunia plant • Promoter from cauliflower mosaic virus, Marker genes NPTII (neomycin/kanamycin • 3’nos terminator from A. tumefaciens phosphotrans• Tn 5 terminator from bar from Streptomy- ferase) from ces hygroscopicus along with 3’ocs and microbial trans3’g7 controlled by bidirectional TR1/2 poson promoter from A. tumefaciens CamV 35S • Promoter from figwort mosaic virus • Terminator from pea ARM, streptomyin GOX from Ochrobactrum anthorpi strain LBAA; ACP thiosterase genes from California tree Sugar cane • Resistance to some insecticides: Cry genes from B. thuringiensis • Increased sugar content in the • Promoter from cauliflower mosaic virus, CamV 35S • Terminator, nopaline synthase (nos) from A. tumafaciens Selective markers, kanamycin (Kan) or hygromycin (Hyg) plant: Gene BetA from Escherichia coli (EcBetA) or Rhizobium meliloti (RmBetaA) Rice • Drought tolerant • Resistance to insects: CryIA (b) and CryIA (c) from B. thuringiens • Promoter from cauliflower mosaic virus, CamV 35S • Nopaline synthase promoter (Pnos) • NT, 3’ terminator XX Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 ARM, neomycin phosphotranspherase II (NPTII, hygromycin (Hyg) Figure 1. Generalized method for creating transgenic plants using the A. tumefaciens delivery system: (1) Sources of genes; (2) Delivery system (e.g. E. coli plasmid); (3) Mediated transformation of plant with A. tumefaciens. (1) Trait, promoter, and terminator genes from soil or other microorganisms and plants (2) Desired traits 1 Promoter 5 Sel. Marker 6 TT 7 (3) Agrobacterium tumefaciens plasmid OriT 3 Oriv 4 Transgenic plants Amp 2 1 Desired “traits”: (e.g. EPSPS gene isolated from A. tumefaciens; Cry1Ab gene from Bacillus thuringiensis) 2 Amp: Ampicillin marker gene for selecting transformation in A. tumefaciens 3 OriT: Transfer origin for conjugal transfer of the plasmid to recipient cell 4 OriV: Origin of replication 5 Promoter: Promoter gene (e.g. gene from cauliflower mosaic virus, such as CamV 35S, used for soybean vectors) 6 Sel. Marker: Selection marker (e.g kanamycin resistance or bla for beta lactamase or NPTII for neomycin/ kanamycin phosphotransferase) for selecting transformation in plants 7 TT: Termination of transcription (e.g. nopaline synthase, nos, from Arabidopsis plant) Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX satility to cope with different hosts and to control a wide range of insects (Feltus and Vandenbrink, 2012; Shen et al., 2013). Biolistic injection of constructs containing Bt, as well as the EPSPS gene, is now the most common technique to protect plants from insects and herbicides (FAO, 2009). In addition to its herbicide tolerance ability, the EPSPS gene is also used as a selection marker in the plant, thus conferring both resistance and selection to the target plant. It should be noted that along with insect- and herbicide-resistance traits that are used to increase plant yield performance, there is an increasing interest in enhancing the nutritional value of GM plants, as well as in developing cold- and drought-tolerance sect resistance Bt genes (e.g. Cry1A), are most commonly isolated from soil microorganisms (Agrobacterium tumefaciens and B. thuringiensis) or plants. E. coli plasmids constitute an ideal platform and cloning vector for gene transcription and translation to proteins, with most such genes originating from plants and microorganisms (Abbott, et al., 1998). They include promoters that enable target gene transcription (e.g. cauliflower mosaic virus (CamV 35S) and nopaline synthase (nos) from Arabidopsis plant) and provide termination signals (James, 2011; Nida et al., 1996). In addition, a selective gene marker is often incorporated to aid in the detection or tracking of the DNA delivery package within the crop variants via genetic modification. Perhaps the best-known example thus far is the drought-resistant gene BetA from E. coli (EcBetA) and Rhizobium meliloti (RmBetA), which have been demonstrated to be beneficial to plants without adverse effects (Kempken and Jung, 2009). There are a substantial number of transformation techniques that have been used till date, ranging from the indirect delivery-system-based Agrobacterium method to the direct transfer Agrobacterium microprojectile bombardment (biolistic) method ( FAO, 2009; Klein et al., 1987; Koziel et al., 1993). Typically, the delivery-system-based Agrobacterium method has been widely used to form a transgenic plant. This technique, also called binary-vector Agrobacterium, is summarized in Figure 1. It requires first the isolation of the gene of interest for its “desired traits” before its insertion into a delivery vector (plasmid) to form recombinant DNA (rDNA) (Berg and Mertz, 2010; Kiermer, 2007). The most common transfer and cloning vectors used in medical and agricultural biotechnology are bacterial plasmids transformed cells. This way only the transformed cells carrying the selective marker will be regenerated and transferred to the mediated transformation strain. The causative agent of crown gall disease A. tumefaciens has been used for its ability to infect plants and transfer genes into a callus (embryonic plant tissue) via insertion of its tumor-inducing Ti plasmid (Gelvin, 2003; Nester, 2014). Initially, the desired gene is transferred into the Ti plasmid through DNA recombination. This mechanism is enabled by the cleavage of the plasmid at specific sites for gene insertion, which is carried out with the use of endonuclease restriction enzymes (Piekarowicz et al., 1978). The same enzymes are also used to cleave the host cell DNA before ligation via a DNA-joining enzyme, ligase (Zimmerman et al., 1967). Finally, the transformed Ti plasmid (with its tumor-inducing mechanism deactivated) is injected into plant embryos (callus). Successful transfer of the desired trait gene to the plant chromosome is detected via the selective marker that was originally incorporated in the plasmid vector. Thus, transgenic plant regeneration is ensured by successfully injecting trait genes into the plant chromosome, which subsequently propagates as the plant grows. Molecular techniques including Polymerase Chain Reaction from Escherichia coli, selected primarily for their ability to generate numerous copies of the desired gene (James, 2011). The desired trait genes, such as the herbicide tolerance gene EPSPS (Marketed as Roundup Ready®) (Powles and Yu, 2010) or the in- (PCR), Southern hybridization, and DNA sequencing confirm gene transfer and its inheritance by the target plant (Lupien, 2000). The PCR technique traces the inserted gene in the plant through DNA amplification, confirming gene inheritance by the plant. Gene transfer methods and mechanisms in crops XX Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 Figure 2. Ethanol and major co-product manufacturing from GM corn using the wet-milling and dry-milling processes. Existing and potential GMO flows are depicted with black arrows. Potential gene dissemination through co-products is marked with an asterisk (*). Desired trait genes E. coli plasmids Agrobacterium GM corn Wet-milling Process Dry-milling Process Cleaning Steeping (Degermination) * * * Enzymes Milling Cyclone Separation Corn Oil * Cleaning Grinding Cooking Liquefaction/Saccharification Yeast Corn Gluten Feed Grinding Starch/Gluten Separation Corn Gluten Meal Centrifugation Dextrin Washing/Filtering Acid/Cooking of Starch Fermentation CO2 Distillation/Dehydration Ethanol Enzymes Centrifugation Liquefaction/Saccharification Yeast Fermentation CO2 Distillation/Dehydration Ethanol Residue * Drying Evaporation Distillers Dry Grains Distillers Solubles Distillers Dry Grains with Solubles (DDGS) (animal feed) * Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX While the binary-vector Agrobacterium technique requires a vector (plasmid) to transfer the desired trait, direct gene transfer methods do not require a delivery system to enable gene transfer to the recipient organism. Currently, there are several direct gene transfer methods that include primarily Agrobacterium microprojectile bombardment in addition to chemical mediation and electroporation, as well as microinjection (Kempken and Jung, 2009; Klein et al., 1987). However, Agrobacterium-mediated recombination is often preferred over direct methods because it causes less damage to the plant tissue (Koziel et al., 1993). Direct techniques have been extensively described by the Food and Agriculture cesses and the generated co-products are illustrated in Figure 2. Wet milling separates corn into several components, such as oil, gluten meal, starch, and fiber, producing livestock co-products and corn oil in addition to ethanol from starch, but also increasing the chances of GMO release into the environment. The more popular dry milling process requires less capital per gallon of ethanol produced and involves fewer steps (Bothast and Schlicher, 2005). The solid residue from the ethanol distillation column is centrifuged and dried to form distiller’s dry grain with solubles (DDGS), a major source of animal feed that is vulnerable to GMO concerns. Although the corn ethanol industry has expe- Organization (FAO, 2009). Aside from modification of crops for higher plant productivity and resilience, considerable research has also been directed towards engineering enzymeproducing and fermentative microorganisms for wider sugar utilization and increased biofuel yield. rienced significant growth in the last 15 years, increasing societal and economic concerns regarding food-based biofuels have shifted researchers’ focus towards non-food biomass sources, such as cellulosic materials. Such biofuels, termed advanced or second-generation, could help significantly the U.S. reach its Renewable Fuel Standard (RFS) annual target of 36 billion gallons of biofuels by 2022 (Corredor et al., 2007). CROP-BASED BIOFUEL PRODUCTION IN THE U.S. Biomass-derived biofuels Corn-based biofuels Biofuels have gained significant attention in the last decade thanks to benefits they bring to energy security, lower carbon emissions, and cleaner air (Sticklen, 2008). Among several countries around the world that have invested in the biofuel sector, the U.S. is the leader in ethanol production with approximately 70% of the total world production, followed by Brazil (RFA, 2015). In the U.S. corn is the primary feedstock for ethanol production, which reached 13.3 billion gallons (50 billion liters) in 2014 (RFA, 2015). Among the 29 ethanol-producing States, the top ones are located in the U.S. Midwest “corn belt” (James, 2011). Lignocellulosic feedstocks are the most prevalent biofuel resources worldwide in the form of agricultural residues, forestry residues, energy crops (e.g. Miscanthus and switchgrass), and municipal solid waste (MSW) (Pettersen, 1984). The U.S. is believed to generate over one billion tons of cellulosic biomass annually that, if converted to ethanol, could replace 30% of petroleum-derived gasoline by 2030 (Perlack et al., 2005). Another study estimated that the same ethanol target could be reached if energy crops were cultivated on available federal land, in addition to agricultural and forestry residues, to reduce feedstock cost and make ethanol cost competitive (Khanna et al., 2011). Feedstocks for biofuel According to the Renewable Fuels Association (RFA) there are 204 operational corn-ethanol plants in the U.S. using the wet milling (33%) or the dry milling (67%) technology (RFA, 2014). The major steps involved in these two corn ethanol manufacturing pro- production have already been extensively reviewed (Sticklen, 2008). The major steps involved in cellulosic ethanol production are illustrated in Figure 3. Pretreatment, which intended to render recalcitrant biomass more XX Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 Figure 3. Ethanol and major co-product manufacturing from lignocellulosic biomass. Potential GMO inputs and outputs are depicted with black arrows, whereas potential gene dissemination through co-products is marked with an asterisk (*). Lignocellulosic biomass Pretreatment - Mechanical and/or - Thermo-chemical and/or - Biological Potential GMO inputs Cellulolytic enzymes Liquefaction/Saccharification CBP microorganisms CO2 Fermentation SSCF microorganisms Ethanol Lignin combustion Distillation/Dehydration Residue * White-rot fungi (lignin degradation) Power Generation Biological Decomposition Fungal proteins (animal feed) * Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX Figure 4. Hypothetical modeling of GMOs risk exposure in lignocellulosic-based biofuel (CBP: Consolidated Bioprocessing, SSCombF: Simultaneous Enzymatic Saccharification and Combined Fermentation). GMOs use for CBP or SSCombF Cellulosic feedstocks Bioprocessing: Distillation/ Dehydration (500°F) GMOs Concentrations GMOs Prevalence -Pretreatment -Hydrolysis -Fermentation Potential GMOs spread Biofuel and Co-products Risk Characterization amenable to further processing, accounts for almost one third of the total operating cost (Mosier et al., 2005). The high level of non-conventional pentose sugars in cellulosic materials constitutes another challenge for ethanol productivity (Wyman et al., 2005). Furthermore, the use of high-cost enzymes in the hydrolysis step is of particular financial concern (Wyman et al., 2005; 2009). Residual lignin can serve would be potential sources of GMOs that could affect the environment. as a fuel for power generation (Ladisch et al., 2010) or can be converted by fungal microorganisms, such as the white rot fungus Basidiomycete, to fungal proteins for animal consumption (Zadrazel, 1976). The distillation residue and any animal feed byproducts Fermentative microorganisms can be engineered with several important characteristics: wider sugar substrate range, elimination of toxicity by cellulose hydrolysates and fermentation products, and improvement of regulatory functions (Lee et al., 2008). XX CURRENT GENETICALLY ENGINEERED MICROORGANISMS AND NANOTECHNOLOGY FOR BIOFUEL Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 Overexpression of Inulinase Gene (INU) Insertion of pdc and adhB genes from Z. mobilis Deletion of lactate dehydrogenase gene (ldh) Functional heterologous expression of an engineered full length CipA from Clostridium thermocellum Isolation of endogenous GAP promoter and GAP terminator • • • • • Kluyveromyces marxianus Escherichia coli Clostridium thermocellum Thermoanaerobacterium saccharolyticum Candida lignohabitans • • • • • (Yuan et al., 2013) (Currie et al., 2013) (Biswas et al., 2014) Expression of lactate dehydrogenase and cis(Bellasio et aconitate decarboxylase resulted in stable and re- al., 2015) producible production of lactic acid and itaconic acid, respectively The expression of a critical C. thermocellum cellulosomal component in T. saccharolyticum as a step toward creating a thermophilic bacterium capable of consolidated bioprocessing -ncreasing in ethanol yield The enzymes pyruvate decarboxylase and alcohol (Yang et al., dehydrogenase are overexpressed, resulting in 2014) high ethanol production Increasing ethanol production from Jerusalem artichoke tubers by CBP Reduction of cell growth and ethanol production under osmotic, heat and ethanol stresses • Inactivation of gfo (ZMO0689) gene by homologous recombination (fusion-PCRbased construction technique) • (Sootsuwan et al., 2013, Wang et al., 2013) Inactivation of gfo (ZMO0689) gene by site-specific FLP recombinase • Zymomonas mobilis Improves growth and ethanol production without formation of sorbitol as a by-product in sucrose medium Increasing tolerance to inhibitors such as ethanol • • Use glucose and D-xylose with high consumption Demeke et rates and partial cofermentation in various ligno- al., 2013 cellulose hydrolysates with very high ethanol yield • The gene Clostridium phytofermentans XylA, encoding D-xylose isomerase (XI), and enzymes of the pentose phosphate pathway was inserted • Saccharomyces cerevisiae References Expected Outcomes Genetic Modification Species Table 2. The most promising GMOs for biofuel production in the U.S Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX Genetically engineered fermentative microorganisms, such as Saccharomyces cerevisiae (Almaida et al., 2008; Toon et al., 1997) and Zymomonas mobilis (He et al., 2014), along with Phanerochaete chrysosporium, Kluyveromyces marxianus and Clostridium cellulolyticum, have been developed over the last 20 years with a potential to advance the commercialization of advanced biofuels. The promising microorganisms for genetic manipulation in lignocellulosebased biofuel systems are extensively reviewed by Limayem and Ricke (Limayem and Ricke, 2012) and the expected outcomes are summarized in Table 2. Recent development in nanotechnology has been also made to advance the biofuel system productivity through gene transformation (Tzfira and Citovsky, 2006; Ziemienowicz, 2001; Ziemienowicz et al. 2012). A novel nano-complex method derived from Agrobacterium T-DNA has been developed by Pitzschke and Hirt (Pitzschke and Hirt, 2010) and optimized by Gelvin ( 2012) to add substantial value to agricultural biotechnology (Tzfira and Citovsky, 2006). The nanocomplex is composed of Agrobacterium T-DNA, single stranded DNA binding protein RecA and virulence protein VirD2. It is delivered to triticale microspores by the assistance of a Tat2 cell- penetrating peptide (CPP) (Chugh et al., 2009). This evidence will protect the integration of single transgene copy and inhibit the degradation of the target DNA (Ziemienowicz et al., 2012). tions have been associated with new allergens, toxins, and antibiotic resistance. Transgenic crops could develop tolerance to abiotic hurdles and conditions (Mei et al., 2005). The case of the Bt Cry9C protein used in corn that was alleged to have caused allergic reactions has raised concerns among epidemiologists and regulators (EPA, 2003). However, the Centers for Diseases Control (CDC) suggest otherwise by concluding that the risk of allergic reactions to Cry9C is very low (EPA, 2003). Concerns also exist about altered genes resisting abiotic stressors that could be transferred to microorganisms via animal digestion and hence could transform bacteria into altered-gene vectors. In a biofuels system altered genes could be transmitted to organisms like Lactobacillus strains, which are common contaminants in ethanol fermentations. The main issue would be the dispersal of these strains in the surrounding environment (Curragh and Collins, 1992). BIOTECHNOLOGY RISK ASSESSMENT MODELING According to an extensive study conducted by the Council for Agricultural Science and Energy (Carpenter et al., 2002), GMOs could impact considerably the environment by reducing biodiversity via cross- The Biotechnology Risk Assessment models have emerged as potential means for enhancing biosafety in agricultural systems (Wolt, 2009). This statistical approach is a leading scientific method that estimates the biological and physical risks of release to the environment of genetically engineered microorganisms, plants, and animals. It integrates the distribution of exposure to GMOs with data on probability of occurrence and the severity of the effect (dose response). Currently, the systemic approach is emerging as the most effective point-of-care method adopted by federal regulatory agencies attempting to create a set of practical management tools pertaining to GMO dispersal in the environment (Flory et al., 2012). It provides proper accounting of inputs and outputs and hence helps elucidate all potential pollination or by destroying beneficial organisms, in addition to other unforeseen outcomes. The study placed emphasis on the potential adverse effects of GMOs on human health through the risk assessment approach. Potential hazards from GMO manipula- process steps that carry the risk of exposure to irreversible potentially harmful gene mutations (Krimsky and Golding, 1992). It also provides a qualitative and quantitative risk estimation that can assist users in setting up preventive action to ensure ecosystem POTENTIAL BOTTLENECKS GMOs dispersal XX Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 biosafety. The risk analysis relies primarily on hazard identification, collection of data, and subsequent estimation of the likelihood of occurrence and severity of effects in all steps of the production process. This includes the exposure assessment modeling through the GMO dynamic flow (Flory et al. 2012; Krimsky and Golding, 1992; Schierow, 2008). GMO dynamic flows in biofuel system Unlike biomass-derived ethanol that usually requires genetic modifications to enable microorganisms to efficiently co-ferment pentose sugars, corn-based biofuel production includes transgenic (Ribeiro, 2004) Where the horizontal axe shows the interdependent variables and vertical axe conveys the probability of uncertain numbers. Thus, the algorithm analyzes uncertainty variables, such as size of GMO-containing stream (solid, liquid or gaseous) released to the environment and GMO concentration in the released stream. This holistic integration estimates the overall risk posed by feedstocks but not necessarily GM microorganisms (Tomás-Pejó et al., 2009; Yanase et al., 2010). From this perspective, aside from GM corn by-products, it is quite possible that inadvertent GMO dissemination could also occur during various processing steps, such as starch hydrolysis and sugar fermentation (Kádár et al., 2004). Moreover, a number of modified microorganisms in lignocellulosic biofuels have been identified to render the promising CBP and SSCF processes cost-effective (Limayem and Ricke, 2012; Yamada et al., 2010,). Although a high temperature of 500°F in downstream operations would suppress GMOs residues, such GMO applications need to be traced from the source to the final product. A hypothetical modeling to GMOs risk exposure from feedstocks to biofuel production and end-products is depicted in Figure 4. Computationally, the assessment uses a probability density function in conjunction with Monte Carlo simulations that select randomly a set of data from numerous probability distributions. The certified software (i.e., @ Risk tool) enables the random inputs selection from extensive number of probability distributions (Haas et al., 1999). As such, it determines the interdependent variables through a high selected number of repetitions (i.e., GMOs. Hence, a holistic view of the GMO dynamic flow constitutes a comprehensive first step for GMO users in the biofuel industry through Biotechnology Risk Assessment analysis and development of proper management practices (Haas et al., 1999). 104 trials). The Gaussian probability density function p(x) equation is described as follows: can serve as a decision-making tool to help institute comprehensive protective standards as the sector grows. The same risk assessment approach could also serve the industry well when GMOs are introduced on a large scale biofuel production annually CONCLUSIONS The development of agricultural biotechnology in the 1980s has given rise to a genetic revolution in crops. More recently, the biofuel industry has opted for GMO practices to increase product yields and minimize land and water use via transgenic plants and engineered microorganisms. Corn-derived biofuels have benefitted from government incentives and extensive cultivation of transgenic plants. Biomass-derived ethanol and other biofuels hold great promise for energy security owing to the development of novel GM microorganisms that allow process-step integration and higher efficiencies with minimal capital cost. Although to date there is no clear evidence or direct proof of GMO side effects on the environment, preventive measures should be undertaken by the industry to drastically ensure the environmental safety. The risk assessment approach Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX as dictated by the federal government’s renewable fuel standard. Elucidating a practical engineered core modeling to optimization of GMOs traceability and biosafety in biofuel production holds promises as the future method of interest to sustain biotechnology advancement. ABBREVIATIONS GMOs: Genetically Modified Organisms GM: genetically modified RA: Biotechnology Risk Assessment RFA: Renewable Fuels Association DDGS: distiller’s dry grain with solubles RFS: Renewable Fuel Standard MSW: municipal solid waste EPSPS: 5-enolpyruvylshikimate-3-phosphate synthetase Bt: Bacillus thuringiensis DNA: recombinant DNA CR: Polymerase Chain Reaction CBP: consolidated bioprocessing SSCF: simultaneous saccharification and co fermentation CDC: Centers for Disease Control and Prevention FIB: fecal indicator bacteria HGT: Horizontal Gene Transfer CTP: Cytoplasmic Transduction Peptide GOX: Glyphosate Oxidase ACP: Palmitoyl-Acyl Carrier Protein ACKNOWLEDGEMENTS This research was partially supported by grants from the South Central Sun Grant Program (U.S. Department of Transportation) and Novozyme North America, Inc. (Franklinton, NC). REFERENCES Abbott, C., P. Leeds-Harrison, and H. Wallingford. 1998. Research priorities for agricultural drainage in developing countries, HR Wallingford Firm. XX Almaida, J., T. Modig, A. Roder, G. Liden, and M. Gorwagrauslund. 2008). Pichia stiplis xylose reductase helps detoxifying lignocellulosic hydrolysate by reducing 5-hydroxymethyl-furfural (HMF). Biotechnol. Biofuels 11:1-12. Arnold, P. 2009. History of genetics: Genetic engineering timeline. from http://www.brighthub.com/ science/genetics/articles/21983.aspx Accessed 12 Nov 2009. Beadle, G. W., and E. L. Tatum. 1941. Genetic control of biochemical reactions in Neurospora. PNAS 27: 499-506. Bellasio, M., D. Mattanovich, M. Sauer, and H. Marx. 2015. Organic acids from lignocellulose: Candida lignohabitans as a new microbial cell factory. J. Indust. Microbiol. Biotechnol. 42:681-691. Berg, P., and J. E. Mertz. 2010. Personal reflections on the origins and emergence of recombinant DNA technology. Genet. 184:9-17. Biswas, R., S. Prabhu, L.R. Lynd, and A.M. Guss. 2014. Increase in ethanol yield via elimination of lactate production in an ethanol-tolerant mutant of Clostridium thermocellum. PloS one 9: e86389. Boryan, C., Z. Yang, R. Mueller, M. Craig. 2011. Monitoring US agriculture: the US department of agriculture, national agricultural statistics service, cropland data layer program. Geocarto Int. 26:341358. Bothast, R., and M. Schlicher. 2005. Biotechnological processes for conversion of corn into ethanol. Appl. Microbiol. Biotechnol. 67:19-25. Brookes, G. 2007. The benefits of adopting genetically modified, insect resistant (Bt) maize in the European Union (EU): first results from 1998-2006 plantings. PG Economics Ltd, UK. Brookes, G. 2009. Socio-economic impacts of GM crop technology: Primary first round impacts 19962007. Briefing note. PG Economics Ltd. Burian, R. M., and J. Gayon. 1999. The French school of genetics: From physiological and population genetics to regulatory molecular genetics. Genet. 33:313-349. Carpenter, J., A. Felsot, T. Goode, M. Hammig, D. Onstad, and S. Sankula. 2002. Comparative environmental impacts of biotechnology-derived and Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 traditional soybean, corn, and cotton crops. from http://heartland.org/sites/all/modules/custom/ heartland_migration/files/pdfs/9925.pdf Accessed June 2002. Carter, C. A., and G. P. Gruère. 2003. Mandatory labeling of genetically modified foods: does it really provide consumer choice? AgBioForum 6:68-70. Cerdeira, A. L., D.L. Gazziero, S.O. Duke, and M.B. Matallo. 2010. Agricultural impacts of glyphosateresistant soybean cultivation in South America. J. Agric. Food Chem. 59:5799-5807. Chugh, A., E. Amundsen, and F. Eudes. 2009. Translocation of cell-penetrating peptides and delivery of their cargoes in triticale microspores. Plant cell Biofuels 6:89. Dunn, J. B., S. Mueller, H.-Y. Kwon, and M.Q. Wang. 2013. Land-use change and greenhouse gas emissions from corn and cellulosic ethanol. Biotechnol. Biofuels 6:51. Edmeades, G. 2013. Progress in achieving and delivering drought tolerance in maize–An update. ISAAA, Ithaca, NY. Entwistle, P. F., J. Cory, M. Bailey, and S. Higg. 1993. Bacillus thuringiensis: an environmental biopesticide: theory and practice. Chichester, Wiley. EPA Guidelines establishing test procedures for the analysis of pollutants; Analytical methods for biological pollutants in ambient water; Final Rule, U.S. reports 28:801-810. Cohen, S. N., A.C. Chang, and L. Hsu. 1972. Nonchromosomal antibiotic resistance in bacteria: genetic transformation of Escherichia coli by R-factor DNA. PNAS 69:2110-2114. Corredor, E., A.J. Lukaszewski, P. Pachón, D.C. Allen, and T. Naranjo. 2007. Terminal regions of wheat chromosomes select their pairing partners in meiosis. Genet. 177:699-706. Crea, R., A. Kraszewski, T. Hirose, and K. Itakura. 1978. Chemical synthesis of genes for human insulin. PNAS 75:5765-5769. Curragh, H. J., and M. Collins. 1992. High levels of spontaneous drug resistance in Lactobacillus. J. Applied Bacteriol. 73: 31-36. Currie, D. H., C.D. Herring, A.M. Guss, D.G. Olson, D.A. Hogsett, and L.R. Lynd. 2013. Functional heterologous expression of an engineered full length CipA from Clostridium thermocellum in Thermoanaerobacterium saccharolyticum. Biotechnol. Biofuels 6:1-11. Delbrück, M. 1949. A physicist looks at biology. Connecticut Academy of Arts and Sciences. Demeke, M. M., H. Dietz, Y. Li, M.R. Foulquié-Moreno, S. Mutturi, S. Deprez, T. Den Abt, B. M. Bonini, G. Liden, F. Dumortier, A. Verplaetse, E. Boles, and Environmental Protection Agency. Erickson, B., and P. Winters. 2012. Perspective on opportunities in industrial biotechnology in renewable chemicals. Biotechnol. J. 7:176-185. FAO. 2009. Biosafety of genetically modified organisms: basic concepts, methods and issues. Proceedings of the Biotechnology and Biosafety Workshop. from http://www.fao.org/docrep/012/ i1252e/i1252e.pdf Accessed Nov 2008. Feltus, F. A., and J. P. Vandenbrink. 2012. Bioenergy grass feedstock: current options and prospects for trait improvement using emerging genetic, genomic, and systems biology toolkits. Biotechnol. Biofuels 5:80. Flory, S. L., K.A. Lorentz, D.R. Gordon, and L.E. Sollenberger. 2012. Experimental approaches for evaluating the invasion risk of biofuel crops. Environ. Res. Lett. 7:045904. Gelvin, S. B. 2003. Agrobacterium-mediated plant transformation: the biology behind the “genejockeying” tool. Microbiol. Mol. Biol. Rev. 67:16-37. Gelvin, S. B. 2012. Traversing the cell: Agrobacterium T-DNA’s journey to the host genome. Frontiers Plant Sci. 3:52. Gryson, N. 2010. Effect of food processing on plant DNA degradation and PCR-based GMO analysis: J. M Thevelein. 2013. Development of a D-xylose fermenting and inhibitor tolerant industrial Saccharomyces cerevisiae strain with high performance in lignocellulose hydrolysates using metabolic and evolutionary engineering. Biotechnol. a review. Anal. Bioanal. Chem. 396:2003-2022. Haas, C. N., J.B. Rose, and C.P. Gerba. 1999. Quantitative microbial risk assessment, John Wiley & Sons. He, M. X., B. Wu, H. Qin, Z.Y. Ruan, F.R. Tan, J. L. Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX Wang, Z. X. Shui , L. C. Dai , Q. L. Zhu , K. Pan, X. Y. Tang, W. G. Wang, and Q. C. Hu. 2014. Zymomonas mobilis: a novel platform for future biorefineries. Biotechnol. Biofuels 7:101. Ho, M.-W., A. Ryan, and J. Cummins. 1999. Cauliflower mosaic viral promoter-a recipe for disaster? Microb. Ecol. Health Dis. 11:194-197. Holmes, B. 2010. Altered animals: Creature with bonus features. from http://www.newscientists.com/ article/mg20727680.300-altered-animals-creatures-with-bonus-features.html Accessed 14 July 2010. Huang, J., S. Rozelle, C. Pray, and Q. Wang. 2002. Plant biotechnology in China. Sci. 295:674-676. cillus thuringiensis. Nat. Biotechnol. 11:194-200. Krimsky, S., and D. Golding. 1992. Social theories of risk. Westport, CT, Praeger. Krohn, B. J., C. V. McNeff, B. Yan, and D. Nowlan. 2011. Production of algae-based biodiesel using the continuous catalytic Mcgyan® process. Biores. Technol. 102:94-100. Ladisch, M. R., N. S. Mosier, Y. Kim, E. Ximenes, and D. Hogsett. 2010. Converting cellulose to biofuels. Chem. Eng. Prog. 106:56-63. Lee, S. K., H. Chou, T.S. Ham, T.S. Lee, and J.D. Keasling. 2008. Metabolic engineering of microorganisms for biofuels production: from bugs to synthetic biology to fuels. Curr. Opin. Biotechnol. Jaenisch, R., and B. Mintz. 1974. Simian virus 40 DNA sequences in DNA of healthy adult mice derived from preimplantation blastocysts injected with viral DNA. PNAS 71:1250-1254. James, C. 2011. Brief 43: Global Status of Commercialized Biotech/GM Crops: 2011. from http:// www.isaaa.org/resources/publications/briefs/43/ executivesummary/ Accessed 20 Feb 2015. Kádár, Z., Z. Szengyel, and K. Réczey. 2004. Simultaneous saccharification and fermentation (SSF) of industrial wastes for the production of ethanol. Ind. Crops Prod. 20:103-110. Kempken, F., and C. Jung. 2009. Genetic modification of plants: agriculture, horticulture and forestry, Springer Science & Business Media. Khanna, M., X. Chen, H. Huang, and H. Önal. 2011. Supply of cellulosic biofuel feedstocks and regional production pattern. Am. J. Agric. Econ. 93:473480. Kiermer, V. 2007. The dawn of recombinant DNA.Nature Milestones DNA Technologies. Klein, T. M., E. Wolf, R. Wu, and J. Sanford. 1987. High-velocity microprojectiles for delivering nucleic acids into living cells. Nat. 327:70-73. Koziel, M. G., G.L. Beland, C. Bowman, N.B. Carozzi, R. Crenshaw, L. Crossland., J. Dawson, N. Desai, 19:556-563. Limayem, A., and S. C. Ricke. 2010. Lignocellulosic biomass for bioethanol production: current perspectives, potential issues and future prospects. Prog. Energy Combust Sci. 38:449-467. Lupien, J. R. 2000. The Codex Alimentarius Commission: International science-based standards, guidelines and recommendations. AgBioForum 3:192-196. Machine, A. S. 1984. A Broken Test Tube: An Autobiography, New York: Harper and Row. Mei, F., M. Dudukovic, M. Evans, and N. Carpenter. 2005. Mass and energy balance for a corn-to-ethanol plant. Washington University, St Louis, MO. Mosier, N., C. Wyman, B. Dale, R. Elander, Y. Lee, M. Holtzapple, and M. Ladischa. 2005. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 96:673-686. Mumm, R. H., P.D. Goldsmith, K.D. Rausch, and H.H. Stein. 2014. Land usage attributed to corn ethanol production in the United States: sensitivity to technological advances in corn grain yield, ethanol conversion, and co-product utilization. Biotechnol. Biofuels 7:61. Nester, E. W. 2014. Agrobacterium: nature’s genetic engineer. Frontiers Plant Sci. 5:730. M. Hill, S. Kadwell, K. Launis, K. Lewis, D. Maddox, K. McPherson, M. R. Meghji, E. Merlin, R. Rhodes, G. W. Warren, M. Wright, and S. V. Evola. 1993. Field performance of elite transgenic maize plants expressing an insecticidal protein derived from Ba- Nida, D. L., K.H. Kolacz, R.E. Buehler, W.R. Deaton, W.R. Schuler, T.A. Armstrong, M. L. Taylor, C. C. Ebert, G. J. Rogan, S. R. Padgette, and R. L. Fuchs. 1996. Glyphosate-tolerant cotton: genetic characterization and protein expression. J. Agric. Food XX Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 Chem. 44:1960-1966. Perlack, R. D., L.L. Wright, A.F. Turhollow, R.L. Graham, B.J. Stokes, and D.C. Erbach. 2005. Biomass as feedstock for a bioenergy and bioproducts industry: the technical feasibility of a billion-ton annual supply, DTIC Document. Pettersen, R. C. 1984. The chemical composition of wood, The chemistry of solid wood. Adv. Chem. 207:57-126. Phillips, T. 2008. Genetically modified organisms (GMOs): Transgenic crops and recombinant DNA technology. Nat. Edu. 1:213. Piekarowicz, A. 1978. Werner Arber, Daniel Nathans and Hamilton Smith. Nobel prizes for the studies sour. Technol. 98:2942-2948. Schierow, L.-J. 2008. The toxic substances control act (TSCA): Implementation and new challenges, Congressional Research Service, Library of Congress. Shen, H., C. R. Poovaiah, A. Ziebell, T. J. Tschaplinski, S. Pattathil, E. Gjersing, N. L. Engle, R. Katahira, Y. Pu, R. Sykes, F. Chen, A. J. Ragauskas, J. R. Mielenz, M. G. Hahn, M. Davis, C. N. Stewart Jr, and R. A. Dixon. 2013. Enhanced characteristics of genetically modified switchgrass (Panicum virgatum L.) for high biofuel production. Biotechnol. Biofuels 6:71. Sootsuwan, K., P. Thanonkeo, N. Keeratirakha, S. Thanonkeo, P. Jaisil, and M. Yamada. 2013. Sorbi- on DNA restriction enzymes. Postepy biochemii 25:251-253. Pitzschke, A., and H. Hirt. 2010. New insights into an old story: Agrobacterium-induced tumour formation in plants by plant transformation. The EMBO Journal 29:1021-1032. Powles, S. B., and Q. Yu. 2010. Evolution in action: plants resistant to herbicides. Ann. Rev. Plant Biol. 61:317-347. Ramasamy, C., K. Selvaraj, G.W. Norton, and V. Vijayragahavan. 2007. Economic and environmental benefits and costs of transgenic crops: ex-ante assessment, Tamil Nadu Agricultural University. RFA. 2014. Falling walls & rising tides: 2014 Ethanol industry outlook. RFA. 2015. US fuel ethanol industry biorefineries and capacity. Washington, DC, Renewable Fuels Association. Ribeiro, M. I. 2004. Gaussian probability density functions: Properties and error characterization. Institute for Systems and Robotics, Lisboa, Portugal. Sanchez, O. J., and C. A. Cardona. 2008. Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour. Technol. 99:52705295. Sarkar, S. 1991. What is life? Revisited. BioSci: 631- tol required for cell growth and ethanol production by Zymomonas mobilis under heat, ethanol, and osmotic stresses. Biotechnol. Biofuels 6:180. Sticklen, M. B. 2008. Plant genetic engineering for biofuel production: towards affordable cellulosic ethanol. Nat. Rev. Genet. 9:433-443. Tomás-Pejó, E., J. M. Oliva, A. González, I. Ballesteros, and M. Ballesteros. 2009. Bioethanol production from wheat straw by the thermotolerant yeast Kluyveromyces marxianus CECT 10875 in a simultaneous saccharification and fermentation fed-batch process. Fuel 88:2142-2147. Toon, S. T., G.P. Philippidis, N.W. Ho, Z. Chen, A. Brainard, R.E. Lumpkin, and C. J. Riley. 1997. Enhanced cofermentation of glucose and xylose by recombinant Saccharomyces yeast strains in batch and continuous operating modes. Appl. Biochem. Biotechnol. 63:243-255. Tzfira, T., and V. Citovsky. 2006. Agrobacterium-mediated genetic transformation of plants: biology and biotechnology. Curr. Opin. Biotechnol. 17:147-154. Uchtmann, D. L., and G. C. Nelson. 2000. US regulatory oversight of agricultural and food-related biotechnology. Am. Behav. Sci. 44:350-377. Wang, C., C. Liu, J. Hong, K. Zhang, Y. Ma, S. Zou, M. Zhang. 2013. Unmarked insertional inactiva- 634. Schell, D. J., N. Dowe, K.N. Ibsen, C.J. Riley, M.F. Ruth, and R.E. Lumpkin. 2007. Contaminant occurrence, identification and control in a pilot-scale corn fiber to ethanol conversion process. Biore- tion in the gfo gene improves growth and ethanol production by Zymomonas mobilis ZM4 in sucrose without formation of sorbitol as a by-product, but yields opposite effects in high glucose. Biochem. Eng. J. 72:61-69. Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 XX Whitman, M. S., P.G. Pitsakis, E. DeJesus, A.J. Osborne, M.E. Levison, C.C. Johnson. 1996. Gastrointestinal tract colonization with vancomycin-resistant Enterococcus faecium in an animal model. Antimicrob. Agents Chemother. 40:1526-1530. Wolt, J. D. 2009. Advancing environmental risk assessment for transgenic biofeedstock crops. Biotechnol. Biofuels 2:27. Wyman, C. E., B.E. Dale, R.T. Elander, M. Holtzapple, M.R. Ladisch, Y. Lee. 2005. Coordinated development of leading biomass pretreatment technologies. Bioresour. Technol. 96:1959-1966. Wyman, C. E., B.E. Dale, R.T. Elander, M. Holtzapple, M.R. Ladisch, Y. Lee, C. Mitchinson C, and rotus cornucopiae, and Pleurotus eryngii. Mush Sci 9:621-625. Ziemienowicz, A. 2001. Odyssey of agrobacterium TDNA. Acta Biochim. Pol. 48:623-635. Ziemienowicz, A., Y.-S. Shim, A. Matsuoka, F. Eudes, and I. Kovalchuk. 2012. A novel method of transgene delivery into triticale plants using the Agrobacterium transferred DNA-derived nano-complex. Plant Physiol. 158:1503-1513. Zimmerman, S., J. Little, C. Oshinsky, and M. Gellert. 1967. Enzymatic joining of DNA strands: a novel reaction of diphosphopyridine nucleotide. PNAS 57:1841. J.N. Saddler. 2009. Comparative sugar recovery and fermentation data following pretreatment of poplar wood by leading technologies. Biotechnol. Prog. 25:333-339. Yamada, R., N. Taniguchi, T. Tanaka, C. Ogino, H. Fukuda, and A. Kondo. 2010. Research Cocktail δ-integration: a novel method to construct cellulolytic enzyme expression ratio-optimized yeast strains. Appl. Microbiol. Biotechnol. 85:1491-1498. Yanase, S., T. Hasunuma, R. Yamada, T. Tanaka, C. Ogino, H. Fukuda, and A. Kondo. 2010. Direct ethanol production from cellulosic materials at high temperature using the thermotolerant yeast Kluyveromyces marxianus displaying cellulolytic enzymes. Appl. Microbiol. Biotechnol. 88:381-388. Yang, M., X. Li, C. Bu, H. Wan, G. Shi, X. Yang, Y. Hu and X. Wang. 2014. Pyruvate decarboxylase and alcohol dehydrogenase overexpression in Escherichia coli resulted in high ethanol production and rewired metabolic enzyme networks. World J. Microbiol. Biotechnol. 30:2871-2883. Youngquist, W. 1999. The post-petroleum paradigm—and population. Popul. Environ. 20:297315. Yuan, W., X. Zhao, L. Chen, and F. Bai. 2013. Improved ethanol production in Jerusalem artichoke tubers by overexpression of inulinase gene in Kluyveromyces marxianus. Biotechnol. Bioprocess Eng. 18:721-727. Zadrazel, F. 1976. The ecology and industrial production of Pleurotus ostreatus, Pleurotus florida, PleuXX Agric. Food Anal. Bacteriol. • AFABjournal.com • Vol. 5, Issue 3 - 2015 View publication stats