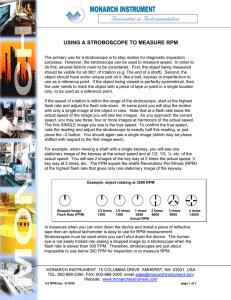

KIG3001 INSTRUMENTATION AND MEASUREMENT TECHNIQUES LECTURE 5: Measurement of Count, EPUT, & Frequency By: Assoc. Prof. Ir. Dr. Rahizar Ramli rahizar@um.edu.my Department of Mechanical Engineering rahizar@um.edu.my Contents 1. Introduction 2. Counters 3. Stroboscopy and High-Speed Imaging 4. Frequency Standards 5. Measurement of Rotary Motion rahizar@um.edu.my Introduction Learning Objectives 1. Understand the measurement of count, event per unit time (EPUT), time interval, and frequency. 2. Recognize the applications associated with these measurements rahizar@um.edu.my Introduction (cont.) Definition: • Counting of events or items per unit time (EPUT). • Frequency is measured at steady-state condition (e.g. acoustics, AC voltage or current, or mechanical vibration, in cycles/min (rpm), cycles/s (Hz)). • EPUT is measured at no specific time interval, sporadic or intermittent (e.g. particle count). • Time interval (period) for periodic event. Limitation to timing is when the event occurs at a very rapid succession. rahizar@um.edu.my Introduction (cont.) Counting and timing measurement category: a. Basic counting b. EPUT c. Frequency d. Time interval e. Phase relation Common laboratory equipment (oscilloscope, digital multi-meter) can be used for counting and timing primarily involving frequency, time interval and phase. rahizar@um.edu.my Counters a. Electronic counters It is one of the simplest form of counting technique comprises of front-end sensor (photodetector, variable resistance or inductance) that is capable of emitting voltage pulses. These low-voltage pulses require a simple amplifier to raise the voltage level suitable for counter. The signal input depends on the type of transducer used, measures mechanical quantities such as displacement, velocity, acceleration, pressure, etc., as long as it is in the form of voltage pulses. Typical application is in manufacturing assembly line (packaging, sorting). rahizar@um.edu.my Counters b. EPUT meters It combines an electronic counter with an internal time base module. It is used to limit the counting process at a specific time interval. It can be utilized for counting at a regular time interval or at intermittent interval. Beckman Model 7160 EPUT Meter https://digital.sciencehistory.org/works/ks65hc302 rahizar@um.edu.my Stroboscopy and High-speed Imaging Stroboscope § § § Stroboscope is used to measure revolutions, velocity and frequency of rotating components or moving parts. Invented in 1832. The term "stroboscope" comes from Greek for "whirling watcher“. How to measure rotational speed using a stroboscope? • An oscillator is made to produce a pulse wave of a known frequency. • It drives a bright LED, which can cope with the fast rate of flashing (typical flash frequency range: 0.5 Hz – 500 Hz (30 RPM – 30 000 RPM). • A mark is placed on the object that is rotating. • The oscillator is set to a low value and slowly increase. • The LED is shone at the object focussing on the “mark”. • Keep increasing the oscillator until the “mark” changes from random to stationary (flashing frequency = rotational speed. rahizar@um.edu.my Stroboscopy and High-speed Imaging (cont.) Stroboscope (cont.) § The frequency of the oscillator is then gradually increased until the mark appears to remain stationary. § If the strobe frequency is slightly slower than the speed of the object, the mark will creep forward. § If the strobe frequency is slightly faster than the speed of the object, the mark will creep backwards. 1 2 rahizar@um.edu.my http://web.mit.edu/6.933/www/Fall2000/edgerton/www/stroboscope.html http://homepages.which.net/~paul.hills/Circuits/Stroboscope/Stroboscope.html Stroboscopy and High-speed Imaging (cont.) Stroboscope (cont.) § The object can appear to be stationary even when it is integer multiple of the strobe frequency. § Problems might also arise when the strobe frequency is one half (½) of the object frequency, f1 (aliasing effect), where it would still appear as one mark on the object. § To determine the actual frequency of the object, one needs to slowly decrease the frequency until the next stationary mark is attained, f2. § The actual frequency, fo can be calculated as: fo = f1. f 2 f1 - f 2 Incandescent bulb cannot be used to replace the bright LED bulb because it could not cope with the rate of flashing (on-off state). The bulb needs longer time to warm-up the filament when it is switch on, for the bulb to glow. The bulb will remain glowing despite the change in the rate of flashing, thus could not be tuned to synchronise with the machine’s rotating frequency to “freeze” the motion. rahizar@um.edu.my Stroboscopy and High-speed Imaging (cont.) • • In machinery diagnostics, stroboscope is used as a device to look for defects in rotating machinery such as misalignment, belt flap, or for loose parts in the structure supporting the machine. In machining to observe interaction between cutting tool & workpiece. https://www.youtube.com/watch?v=oCvP3LhRFRc Machining => https://www.youtube.com/watch?v=kH3v8Fg-5zc Dynamic stress analysis => https://www.youtube.com/watch?v=ailowlpjfxA rahizar@um.edu.my Stroboscopy and High-speed Imaging (cont.) b. High-speed imaging Similar concept to digital or light emitting stroboscope but it has the capability to record the motion. Basic element in high speed camera is the very short exposure captured in quick succession. The images are recorded at the rate between 1000 frame per seconds (fps) using analogue recording i.e. magnetic tapes and 2 millions fps using high-speed digital camera. Note human eye can visualize motions at about 100 fps. Typical application for high-speed imaging is when studying vehicle impact (crashworthiness), the combustion process in the internal combustion engine, formation of crystallization in materials, etc. https://www.youtube.com/watch?v=jdW1t8r8qYc&t=207s rahizar@um.edu.my Frequency Standards Frequency is the number of events during a specific time interval. The reciprocal of frequency is the period. Frequency can be utilized as timing devices (i.e. to measure a quantity at a regular interval) or as driving instrument (function generator). Typical frequency range classification; a. Audible frequency (20 Hz to 20 kHz) b. Supersonic (20 kHz to 50 kHz) c. Radio frequency (50 kHz to10 GHz) rahizar@um.edu.my Frequency Standards (cont.) Typical applications of frequency are as in; • Global Positioning System (GPS) Signals • Radio Time and Frequency Transmission • Quartz-Crystal Oscillators • Waveform and Function Generators Function Generator (Source: Agilent Technologies) rahizar@um.edu.my Measurement of Rotary Motion Non-contact optical tachometer Contact digital tachometer Measurement of rotational motion in pulse per revolution i.e. tachometer that measures angular velocity in rpm. a. Electrical type i. Variable reluctance sensors ii. Hall-effect sensors iii. Generators b. Optical type i. Optical shaft encoders ii. Non-contact optical tachometers iii. Stroboscopes c. Mechanical i. Discrete counters ii. Centrifugal speed indicators rahizar@um.edu.my Variable reluctance sensors Hall-effect sensor Measurement of Rotary Motion (cont.) Tachometer • Tachometer provides vital information about a rotational reference. • The most common tachometers are proximity probes and optical transducers. These transducers generate pulses at a rate proportional to the rotational speed. • In rotating equipment diagnostics, tachometer generates phase information which is useful for balancing, run-up/run-down, rpm tracking, and operating deflection shape analysis. rahizar@um.edu.my Measurement of Rotary Motion (cont.) Tachometer • A proximity probe can detect the presence of a keyway slot. The probe then generates a pulse at a certain fixed amplitude as the keyway slot passes. • Optical transducers observe a piece of reflective marker attached to the shaft / rotor. The coincidence of the reflective marker and the optical transducer produces a pulse signal. Proximity Probe (analog) Tachometer rahizar@um.edu.my Optical (digital) Tachometer References [1] Richard S. Figliola and Donald E. Beasley, Theory and Design for Mechanical Measurements, 5th Ed., International Student Version, John Wiley & Sons, Inc. 2011. [2] Thomas G. Beckwith, Roy D. Marangoni, John H. Lienhard, V., Mechanical Measurements, 6th Ed., Prentice Hall, 2007. [3] James W. Dally, William F. Riley, Kenneth G. McConnell, Instrumentation for Engineering Measurements, 2nd Ed., John-Wiley & Sons, 1993. [4] F. Alton Everest, The Master Handbook of Acoustics, 3rd ed., McGraw Hill, Inc., New York, 1994. [5] Charles E. Wilson, Noise Control, Harper & Row, New York, 1989. [6] Hewlett Packard Co., The Fundamentals of Signal Analysis, Application Note 243, 1985. rahizar@um.edu.my Q&A rahizar@um.edu.my