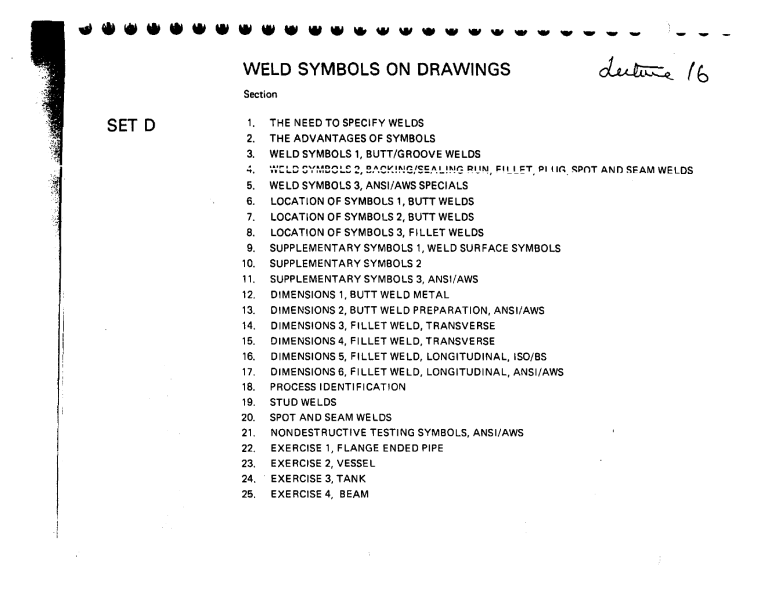

...... - - - - WELD SYMBOLS ON DRAWINGS

Section

SET D

1.

THE NEED TO SPECIFY WELDS

2.

THE ADVANTAGES OF SYMBOLS

3.

WELD SYMBOLS 1, BUTT/GROOVE WELDS

5.

WELD SYMBOLS 3, ANSI/AWS SPECIALS

6.

LOCATION OF SYMBOLS 1, BUTT WELDS

7.

LOCATION OF SYMBOLS 2, BUTT WELDS

8.

LOCATION OF SYMBOLS 3, FILLET WELDS

9.

SUPPLEMENTARY SYMBOLS 1, WELD SURFACE SYMBOLS

10.

SUPPLEMENTARY SYMBOLS 2

11.

SUPPLEMENTARY SYMBOLS 3, ANSI/AWS

12.

DIMENSIONS 1, BUTT WELD METAL

13.

DIMENSIONS 2, BUTT WELD PREPARATION, ANSI/AWS

14.

DIMENSIONS 3, FILLET WELD, TRANSVERSE

15.

DIMENSIONS 4, FI LLET WELD, TRANSVERSE

16.

DIMENSIONS 5, FILLET WELD, LONGITUDINAL, ISO/BS

17.

18.

DIMENSIONS 6, FILLET WELD, LONGITUDINAL, ANSI/AWS

PROCESS IDENTIFICATION

19.

STUD WELDS

20.

SPOT AND SEAM WELDS

21.

NONDESTRUCTIVE TESTING SYMBOLS, ANSI/AWS

22.

EXERCISE 1, FLANGE ENDED PIPE

23.

EXERCISE 2, VESSEL

24.. EXERCISE 3, TANK

25.

EXERCISE 4, BEAM

BOLT

jHERE

I

U

rt/i1

o THE WELDING INSTITUTE 1982

WELD

/HERE

-.-.,,:

:-_-.:--=..\

--- _"

1 ---- ...----;.I

)'

U

I

U

J

U

1-6

PREPARATION

FULL

PENETRATION

WELD

T

I

t..l-:/,.:.....---_

I

1-------

,

1----- _

M15X25 BOLT

6[7

--f - ---t

(9

~

W/i2

OTHE WELDING INSTITUTE 1982

...'_t.JLfIW!

'LH>_~_?~"_t_t_Lt-r

. ut.Jt.Jt.~.,

I

,.....,.

I;~

.

-

II

,~-_., ... ~- ..

_-----,-------------------------

-

(5)

Arrow line

y,..._--=-'---

"Reference

ARROW SIDE

line

OTHER SIDE

M6

'

ii

o THE WELDING INSTITUTE 1982

, ~ ••• " " " •• .,,, "4t" "..... " 4\ .... it .. "

" ".

E.

-

OTHER SIDE

SYMBOL

ARROW SIDE

SYMBOL

n

...-.-.../

TITLE

3rd ANGLE

"/i

7

C THE WELDING INSTITUTE 1982

..L'L"_L,,-,. .t_'_J"...t.'.. .,...

_~a....I'I .... ~_"-f

'.~-'-'

~~~~~WWW~W~~www~ili~W~~~~w~W

--

'

..............~'~._............---------------~--

W/i8

OTHE WELDING INSTITUTE 1982

v

~

-

[Iii 9

o THE WELDING INSTITUTE 1982

.' _"'_ ,~~f~LLLL~"'~'"

'.

! !

'

,

~~~~~~~~~~~~W~~~~~~

") \r,

'.

oJ

-

IJ~,V ,

I

~/i10

o THE WELDING INSTITUTE 1982

I '-J

-

.--

M

MR

M

,

~1i11

OTHE WELDING INSTITUTE 1982

.-oIIl"""lII_~~tt.~a-L!Jl.tJL'_'_Lf...'--'-'..AUI!-'-'-'-1t~

,

;

~ ~ ~ \l) \l) ~ ~ ~ I&) ~ ~

W~

II) tJj

\II W IV tli tli lJ) 111 ij; Iii IlJ

v

--~~P

12

8

8

W/i12

""

o THE WELDING INSTITUTE 1982

, ;,

~ ~~_.~.,~._~_!_~_?J_~_,_,_,_,_,_,.Jt_""'_'.Jt.Jt~~-L'"

c=

G

I

f

{

I

''''''

:1

I

:1

1

0

II

\(

"-

i

i

i

60°

\

18(25)

,

W

H

i

I

./i13

o THE WELDING INSTITUTE 1982

.

11'_"_!_~ __~_.!_.~__!__!~~-~_~_~_T_'l-T_1'_'Jt_,-,-,-,-,-,-,-,,,,,,-+

~ ~ ~ ~ ~

\ll

~

\ll

~ ~ ~ ~

iii

w IV

W W W W W W W ti;

11) IV tjj Ii) Ii) 11$

'..

~,

t

--....,----------------,.------

"-'-"'-~~'

14

~/i14

o THE WELDING INSTITUTE 1882

20t\.

2019f'\.

19

20

20

3,4,5,6,8,10,12,16,18,20,22,25

6)

(10x20)

,

\

~/i15

C THE WELDING INSTITUTE 1982

.~~fA_'-'~'~L~,-,

...

'.JL'-'-''''''-I-f-'-If1~~ ,

\il

w

~

\il ~ \II \il Ii; ~ ~ \l;. Ii;

U;

\iJ \i} Ii; Ii>

\i,l ~ I;; Ii) til i~ I;) I~

iZi

I

25-75

~

.. ~l.

,

V

25-75

25-75

25-75

25-75

"

ARCWELOJNG

SHIELOEOMETAL ARC WELDING

AW

SMAW

FLUX CORED ARC WELDING

SUBMERGED ARC WELDING

FCAW

SAW

GAS METAL ARC WE LOING

GMAW

GAS TUNGSTEN ARC WELDING

PLASMAARCWF=LD!I\!G

GTAW

,RESISTANCE WELDING'

;iJ;';·F{I~SISTANCESF'.OTWE LDI NG

RES.iSTANCESEAMWE LDI NG

'PROJECTIONWELDING

FLASHWELDING

OXYFUEL GAS WELDING

OXYACETYLENE WELDING

FRICTION WELDING

FORGE WE1.DING

. THERMITWELDING

ELECTROSLAG WELDING

"'STUDARC WELDING

BRAZING

SOLDERING

~.

~/i18

C THE WELDING INSTITUTE 1982

a111'lIa

~~

RW

RSW

RSEW

RPW

FW

OFW

OAW

FRW

FOW

TW

ESW

SW

B

S

Type of test

Symbol

ACOUSTIC EMISSION

AET

EDDY CURRENT

ET

LEAK

LT

MAGNETIC PARTICLE

MT

........

NEUTRON HAuiOuHAPHiC Nn I

PT

PENETRANT

PRT

PROOF

RT

RADIOGRAPHIC

UT

ULTRASONIC

VT

VISUAL

____ P

VT+UT

- -----+-1-...... - _ _I-

Be)

......-

- -----.""

-RT

~3

~--

PT

W/i 21

''''fIl ••• fJI.fJ\'''''II~tI\tI\~~~(t.ftfi\~~~~~~~ ~

c THe We~DING INSTITUTe 1982

I

,,"

- _. __ . i _ ...

..

~---

.. - .

-~ ~

i

:::

:';

",",',

- -

~-~8"---..-j

~::::t-----

-----4

..........~~~ ..........~Ll_i.

~~lt

Single 'J' welds 10 deep

All dimensions in millimetres

~/i

22

C TH E WE LD ING INSTITUTE 1982

FLANGE ENDED PIPE

-SECTION 23: EXERCISE 2, VESSEL

23 (Base transparency

+ 2 overlays)

BASE TRANSPARENCY

Symbols representing ",!elds to be made: letters in circles are for ease of reference below only.

Problem 1. Describe welds to be made, with sketches where necessary.

Comments

The standard used for welding symbols has not been identified: there are six

1

that it is to ANSI/AWS.

A: process abbreviation in fork is alphabetical.

B, C, 0: 3 x 'melt-thru' symbols.

Band 0: 2 x 'radiographic test' symbol.

<;i~d" ;"d;~~~:~~~

2

A: stud arc welding, confirmed by studs on drawing.

3

Band 0: single-V butt weld with melt-thru, ground flush inside and radiographed.

4

C: single-bevel butt weld, stub pipe only bevelled, (set-on branch), with melt-thru, ground flush

inside.

5

E: fillet weld, of 6mm leg length, both sides of joint. See sketches on overlay (a) for

interpretation.

a

OVERLAY: possible interpretations of flange to tube joint E.

F: this is consistent with the weld symbol, but the view does not show the expected projection

of the tube through the flange: also a form unlikely to be used, because of clearance problems.

G, H: consistent with weld symbol and drawing. To decide between these two, it would be

necessary to have details of the flange.

Problem 2. Modify symbols to conform to BS 499: Part 2: 1980, with joint as at H.

b

OVERLAY: symbols to BS, solution to problem 2.

I: symbol replacing A.

J: symbol replacing B: note that BS can only specify NOT, not specifically radiography. As

there is no 'melt·thru' symbol, only full penetration and a flat rear face can be specified: the

symbol requirements would be met by welding to produce a substantially flat surface, without

further treatment.

K: symbol replacing C }

L: symbol replacing 0

see comments on J above

M: Symbol replacing E

\.J....._--+-_ _L/

<9_

All dimensioN In millimetre.

VESSEL

~/i23

o THE WELDING INSTITUTE 1982

/

MATERIAL:

STAINLESS STEEL

BODY6mm

FLANGE 20mm

SECTION 25: EXERCISE 4, BEAM

25 (Base transparency and

overlay)

BASE TRANSPARENCY

Sketch of beam, not to scale, to be assembled by manual metal arc welding in the shop and on site.

Problem. Sketch in welding details and symbols to BS 499: Part 2: 1980 (or other standard as

instructed).

a

------

_ ••

-_."-'-.'

..

. "

.'

UVt:t1LAY: ~ULU IIUI~. \LtHl~l~ III

•

I

(,;1Il;1t:::J dlt:

,

"':11

.

1.

_

L

I

__

Icn:::I-';IIl:'c UCIVV·Y

1\

viil"Y·'.

Comments

A

Cope· holes have been introduced to avoid the need to dress welds where they meet other welds,

and to avoid welding up into corners, often a site for defects.

B

We cannot use a 'weld all round' symbol for the end flange joints, as it cannot go over top and

bottom of the flanges, and it is interrupted by the cope·holes.

C

Similarly to B, the web-to·flange joints are in four sections, needing four arrows if they are to be

shown individually.

The spacing in BS is not the pitch (here 300mm) but the distance between the ends of weld

elements, here (300-100) = 200mm.

o

A suggestion to be taken seriously! Apart from simplifying the drawing, complete shop

fabrication can considerably reduce the costs of welding and of quality assurance.

I

...· --10·0m

.----5·1m

1+---

4·9m

·1

I

~-

Top flange wold

flnlshod flush

-

-

x

I

t

I

•

500mm

L_

!

I

I

-

SECTION X-X

x

FLANGES

WEB

END PLATES

End flanges: 12mm flll.t w.ld

II' round (lnsld.)

FI.nge.to....b: 12mm fllI.t w.lds

100mm long, 300mm pitch .och

sid., alternately aach sid•.

~/i25

C THE WELDING INSTITUTE 1982

15mm

10mm

20mm

Not to scale

SKETCH FOR BEAM

f.>.

i""",,:

,I.

'

\

"

.....

_._.

·.O'HI,\I"

_. nr< ~

...... lilt

''''11 ""

-

IOtll 11111

M

_..,

-

_.-

_... r-<

_.-

.'

wII'

ll .. ~~(,vGJlOOv( WUI)ING

~

/

A-.~

~._,

~

,~

.•.•., .

, .HI . '

""10\. 'NDIUIIIIIG !tOOl It(N(1I'u1Qtl

) •. l;X

.~.

,

......

;..... ";.,~; ..."o........... '" •. ,~ __ ,................

l _, "."0.'-

'-.,.- ._,

.I- Ill"/"

~""""OC' Y

...'tlM.......

.......

_1"

._.

w ..... '~

'

,"""""1...._.04

•••I t

'UII WlLDlIIIG ,,,. . . .

J·t

---~W1!C!P

~

,

./

---

_"".-c

.....,. C••ll.ftl.

......... _ ••, _ ,

._.........

..,--_._._11.

-

_..... _.J

11_11&0 1111[. .1"1111 PIU.a WlLDlIIIG

..... "

~

·_1

/

.-.......

•... - _

_-....

.......•--".111..1

~.-t'

"lIIOI.

.--<,...J;.,C~ ,

-/'i".f=;<.'

l£oo.. tSI

W·-·

'---"

-

.

,

...·,

Welding

Symbols

- .......

_.".,

.!-ti'

·,·._. ,,-, ,,..... '.,

..........

...,' ... ,

""'

.

.... '

.... " .... ,

- ( ; . . .._fO

/----1f(~_-<

~

,'.'

'

"'400"

...

,

,

._.--.

--.

.

_.

E

~

E-==

r-.

_..-.

==

~F

=.-=.

=:

::;-:::-::=..

.-c..-::z..

ru

-e:-=-.. . -..

---:'\.-.

-~::::::

....:.:::l..

"Ill

._

S"

_.

.

-....

fIIlLl,l"lN IVIlSOL

'l

·,··.. ·..·

"==<::-..... S""""·COOl'OI,.

'.:: ::::.::

It-S

••.. 1 , ~I'.

~':'.-..: :":..,;·t·

.J

.......

"~IO

..

__.......---........

-"' ,.,..,

..''''-

.

WOf ....-0 SYlllOI.

..........." .. - ' - 1 1 .

>~

_

_ _........

_fli

1Pf."

'"

_

Supplementary Symbols Used with

:.

4'·

I

,

_-

aoctI· AND COllttlI·FUIIGI wne ........ . . /

'I

.J-,.".........II

~

..n ........- ·

\

.. _

....