Cylinder switch guide

CONTENTS

Model No. of discrete switch

unit is as below.

SW

Switch model No.

Axial lead wire (H) direction and

L-shaped lead wire (V) direction

are available.

Ending2

Cylinder with switch variation table

Ending4

Safety precautions

Intro71

Proximity cylinder switch with 2-color LED

Strong magnetic field proof cylinder switch

M Series

R Series

T Series

K Series

F Series

H Series

V Series

E Series

Contact protecting circuit box

Cylinder switch with connector

Ending8

Ending9

Ending12

Ending14

Ending16

Ending20

Ending22

Ending24

Ending25

Ending26

Ending27

Ending28

Series option

Ending30

Operational principle, switch installation position

Ending31

Operating range and hysteresis of each cylinder with switch

Ending32

Relocation of switch

Ending42

How to install the product to terminal box

Ending44

Selection chart

Ending45

Troubleshooting

Ending46

The cylinder switches T2YH, T2YV, T3YH, and T3YV are

scheduled for end of production at the end of December 2023.

Cylinder switch

Discrete switch model No.

Cylinder switch variation table

Ending

Ending 1

Cylinder switch variation

CKD cylinders with switches cover wide applications with miniature to large cylinders

and rotary actuators. Refer to the variation table below to select the ideal product.

Proximity switch

R Series

T Series

K Series

F Series

Descriptions

M2

M2WV

M3

M3WV

R1

R2

R2Y

R3

R3Y

T1

T2

T2J

T2Y

T2W

T2YL

T3

T3P

T3Y

T3W

T3YL

T2YD

K2

K2Y

K3

K3P

K3Y

F2

F2Y

F2S

F3

F3Y

F3P

F3S

M Series

Grommet

Terminal box

2-wire

3-wire

*1

*1

*1

*1

*1 *1 *1

*2 *1 *1 *1 *1

*1

*2 *1 *2 *1

*2 *1 *1

LED

(Lit when ON)

Neon light

(Lit when OFF)

No indicator

lamp

2-color LED

5 VDC

10 VDC to

30 VDC

30 VDC or less

100 VAC

200 VAC

Programmable

controller

IC circuit

Compact relay,

valve

Large relay,

valve

Ending

*1: LEDs are red/green.

*2: LEDs are yellow.

*3: LEDs are green.

*4: LEDs other than those in *1 to *3 are red.

Ending 2

Cylinder switch

Series variation

*1

V Series

V0

*3

ET0

H0Y

*2

E0

H0

H

E

Series Series

F0

K5

K0

T8

T5

K

T

Series Series

T0

R6

R5

R4

R Series

R0

M0

M5

M

Series

Descriptions

F Series

Reed switch

Grommet

Connection

Terminal box

2-wire

Number of connections

3-wire

LED

(Lit when ON)

*2

Neon light

(Lit when OFF)

With indicator lamp

No indicator lamp

2-color LED

5 VDC

10 VDC to

30 VDC

Working voltage

30 VDC or less

200 VAC

Programmable

controller

IC circuit

Cylinder switch

100 VAC

Applications

Compact relay,

valve

Large relay,

valve

Ending

Ending 3

Cylinder with switch variations

CKD cylinders with switches cover wide applications with miniature to large cylinders

and rotary actuators. Refer to the variation table below to select the ideal product.

Proximity switch

*6

*8

*8

*8

*8

*8

*8

*8

*8

*8

*1: Including made-to-order products

*2: is mountable depending on variation. H type (L2), Coolant proof (G2/G3), etc.

*3: Excluding ø16 or less

Ending

Ending 4

*6

*6

*6

K3Y

K3P

K3

K2Y

K2

T2YD

*3

T3YL

*7

T3Y

*7

K Series

T3W

*7

T3P

*7

T3

*7

T2YL

*7

T2Y

*7

T2W

*3

T2J

*7

T1

*7

R3

*7

T2

R3Y

R2Y

*7

R2

F3S

*7

R1

F3P

*7

M3

F3Y

*7

M2

F3

M3WV

T Series

F2S

M3P

R Series

F2Y

M2WV

M Series

F2

F Series

*3

*4: Excluding ø12, ø16, position locking all bore sizes

*5: Excluding ø40 or less

*6: ø12 and ø16 of standard, X, Y, O, F, B, W and M are L1

Cylinder switch

Cylinder with switch variation table

Mounting

method

Pencil shaped cylinder SCP*3

ø6 to ø16

Medium bore size

cylinder

Medium bore size

cylinder

Round shaped

cylinder

Global cylinder

Tie rod cylinder

Medium bore size

cylinder

Large bore size

cylinder with valve

Large bore size

cylinder

Small cylinder with

valve

CMK2

ø20 to ø40

CMA2

ø20 to ø40

SCM

ø20 to ø100

SCG

ø40 to ø100

SCA2

ø40 to ø100

SCA2-V

ø40 to ø100

SCS2

ø125 to ø250

CKV2

ø20 to ø40

Cylinder with valve

CAV2

COV2

ø50 to ø100

Compact

cylinder

Guided super

compact cylinder

Compact

cylinder

Small

direct mounting cylinder

Small cylinder

with suction pad

Compact

cylinder

Small

compact cylinder

Small guided

compact cylinder

Flat compact

cylinder

SSD2

ø12 to ø200

*9

SSG

ø12 to ø100

*10

SSD

ø12 to ø160

*9

ø6, ø10

SMG

ø6 to ø32

MSD

ø6 to ø16

MSDG

ø6 to ø16

FC*

ø25 to ø63

STK

Brake cylinder

ULKP

ø20 to ø50

*5

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

ULK

ø20 to ø40

Brake cylinder

JSK2

ø20 to ø40

Brake cylinder

JSM2

ø20 to ø40

Tie rod

cylinder with brake

Brake cylinder

medium bore size

Brake cylinder

large bore size

Position locking

compact cylinder

Free position locking

flat cylinder

Free position locking

Medium bore size cylinder

JSG

ø40 to ø100

JSC3

ø40 to ø100

JSC4

ø125 to ø180

USSD

ø40 to ø63

UFCD

ø25 to ø63

ø40 to ø100

*8

*8

*8

*8

*8

*8

Magnet provided

as standard

ø16

Brake cylinder

USC

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

ø4 to ø10

MVC

Stopper cylinder

H

E

Series Series

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Cylinder switch

MDC2

F Series

Compatibility M

K

T

R Series

with body Series

Series Series

M0

M5

R0

R4

R5

R6

T0

T5

T8

K0

K5

F0

H0

H0Y

E0

ET0

Bore size

Band

Tie rod

Rail

Cylinder model

Reed switch

Magnet provided

as standard

*7: Mountable for ø20 and ø25 of SSD2. Mountable for ø25 of SSG

*8: Only V type (L-shaped lead wire) mountable

*9: Excluding ø12 to ø32 of L, XL, YL, OL, LF, BL, WL, ML, ø12 and ø16 of KL, DL, and ø16 of QL

*10: Excluding ø32 or less

Ending

Ending 5

Cylinder switch

Proximity switch

*10 *10 *10 *10 *10

*10

*11

*11

*11

*11

*10 *10 *10 *10 *10 *10 *10

*11

*11

*11 *11

*11

*10 *10 *10 *10 *10 *10 *10

*11

*11

*11 *11

*11

*7

*7

*7

*7

*7

*7

*7

*3

*8

*8

Ending 6

*3

*3

*2

*3

*3

*3

*3

K3Y

K3P

K3

K2Y

K2

T2YD

*3

*8

*1: Including made-to-order products

*2: is mountable depending on variation. H type (L2), Coolant proof (G2/G3), etc.

*3: Excluding ø16 or less

Ending

T3YL

T3W

K Series

T3Y

T3P

T3

T2YL

T2W

T2Y

T2J

T2

T1

T Series

R3Y

R3

R2Y

R2

R1

R Series

M3WV

M3P

M3

M2WV

M2

F3S

M Series

F3P

F3Y

F3

F2S

F2Y

F2

F Series

*4: Excluding ø12, ø16, position locking all bore sizes

*5: Excluding ø40 or less

*6: ø12 and ø16 of standard, X, Y, O, F, B, W and M are L1

Cylinder switch

Cylinder with switch variation table

Mounting

method

LCW

ø12 to ø20

Linear slide cylinder

LCR

ø6 to ø25

Linear slide cylinder

LCG

ø6 to ø25

Thin linear slide

cylinder

LCX

ø25,ø32

Linear slide cylinder

LCM

ø4.5 to ø8

Guided cylinder

STM

ø6 to ø10

Global cylinder

Guided cylinder

STG

ø12 to ø80

Guided cylinder

STS/L

ø8 to ø100

Twin rod cylinder

STR2

ø6 to ø32

Unit cylinder

UCA2

ø10 to ø32

High energy absorption

cylinder

High speed

cylinder

Rodless

cylinder

High precision guided

rodless cylinder

High precision guided

rodless cylinder

Rodless cylinder with

brake

Magnet rodless

cylinder

Magnet rodless cylinder

with high precision guide

HCM

ø20 to ø63

HCA

ø20 to ø100

SRL3

ø10 to ø100

SRG3

ø12 to ø25

SRM3

ø25 to ø40, 63

SRT3

ø32 to ø63

MRL2

ø6 to ø20

MRG2

ø10 to ø25

Clamp cylinder

CAC4

ø40 to ø80

Position locking

clamp cylinder

Lightweight clamp

cylinder

Position locking

clamp cylinder

UCAC2

ø50, ø63

CAC-N

ø32,ø40

UCAC-N

ø50,ø63

Rotary clamp cylinder RCS2

ø12 to ø63

Rotary clamp cylinder RCC2

ø16 to ø63

Robot cylinder

MFC

ø30 to ø80

High power cylinder

SHC

ø40 to ø100

Mechanical power

cylinder

MCP

For actual thrust

2 t, 5 t

Guideless cylinder

GLC

ø40 to ø100

Rotary actuator

RRC

Size: 8, 32, 63

Table

rotary actuator

GRC

Size: 5 to 80

Rotary actuator

RV3*

Size: 50 to 300

Hand-chuck

Hand : Cylinders II P786-P789

Chuck : Cylinders II P956-P957

F Series

H

E

Series Series

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

*11 *11

*11 *11

*11 *11

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

*4

*3

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

*12

Cylinder switch

Linear slide cylinder

Compatibility M

K

T

R Series

with body Series

Series Series

M0

M5

R0

R4

R5

R6

T0

T5

T8

K0

K5

F0

H0

H0Y

E0

ET0

Bore size

Band

Tie rod

Rail

Cylinder model

Reed switch

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

Magnet provided

as standard

*8

*8

Reference

*7: Mountable for ø20 and ø25.

*8: Only V type (L-shaped lead wire) mountable

*9: Excluding ø12 to ø32 of L, XL, YL, OL, LF, BL, WL, ML, ø12 and ø16 of KL, DL, and ø16 of QL

*10: Excluding ø16 and over

*11: Excluding ø12 or less

*12: Excluding ø12 and ø16

Ending

Ending 7

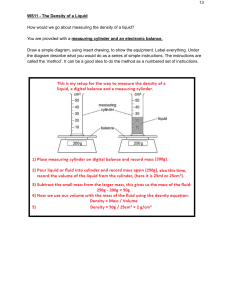

2-color LED proximity cylinder switch

Overview

Conventionally, the pneumatic cylinder position

detection switch required installation and adjustment

because of the operating range and hysteresis.

With the 2-color LED proximity cylinder switch, the

optimum installation position is instantly indicated by the

green LED lighting at the optimum installation position,

and the red LED lighting at the normal operating range.

This eliminates the time and hassle required to adjust

the switch and prevents setting errors, allowing highreliability equipment to be configured.

Light display

Features

Switch ON

Switch OFF

Operating range

Easy installation and adjustment

Since the green LED lights at the optimal

Red LED

lighting range

installation position, the switch can be installed

and adjusted very easily.

High reliability

Green LED

lighting range

The switch uses our original hybrid IC

Optimum installation range

integrated magnetic resistance element,

making it even more reliable.

Green lit

Green

(Optimum installation position)

Operating range

Red

Comparison of cylinder and switch setting

[Conventional]

[2-color LED switch]

Lighting start position

(1) The switch is moved in one direction and

the lighting start position is marked.

(1) The switch is moved in only one direction,

and is fixed at the position where the

green LED lights.

Mark (1)

Green lit

Installation position

(2) In the same manner, the switch is moved

from the other direction, and the lighting

start position is marked.

Mark (1)

Mark (2)

2-color LED switch is

(1) Quick to install

(2) Easy to install

(3) Free of setting errors

(3) The end of the switch is set and fixed at

the center of the two marks.

Ending

Ending 8

Center of mark

Strong magnetic field proof cylinder switch

Overview

This cylinder switch is used in environments having strong magnetic fields, such

as near spot welding machines and magnetizing units in automotive plants, etc.

Features

Easy installation/position adjustment (V0, T2YD)

Uses the rail mounting method. Mountable with a single set screw, and with

easy position adjustment.

Heat resistant material

Metal (H0, H0Y) and self-extinguishing resin UL94-V0 (V0, T2YD) body, and

flame-resistant lead wires (optional for T2YD) have been adopted. Prevents

body and lead wire burning or welding due to spatter.

No polarity (H0, T2YD, H0Y)

Integrated diode bridge eliminates polarity. Eliminates the time required for

checking positive and negative polarity, preventing connection errors.

2-color LED for easy installation adjustment (T2YD, H0Y)

Since the green LED lights at the optimal installation position, the switch can be

installed and adjusted very easily.

CAUTION

(1) Spot welding current - malfunction distance characteristics

(For detection stroke 30 mm and over for V0 switch)

(2) SSD detection stroke - malfunction distance characteristics

(V0 switch)

[mm]

Switch

Cable

Cylinder

[mm]

V0 type malfunction range

Safe range

60

H0Y type malfunction range (*2)

40

H0 type malfunction range

20

T2YD malfunction range (*1)

200

Safe range

150

20000 A

100

Cylinder switch

80

Distance between welding cable and switch ℓ

Distance between switch and welding cable surface ℓ

100

15000 A

10000 A

50

5000 A

Malfunction range

0

0

5000

10000

15000

20000

[A]

Welding current

The above external magnetic field resistance properties apply when H0 is installed within

the “max. sensitivity position ±1 mm,” within the “max. sensitivity position ±1.5 mm” for V0,

and within the “optimum installation range” for H0Y. Install switches within this range. Do

not apply welding current to flow during movement of the cylinder piston.

If 2 or more welding cables are energized simultaneously, the magnetic flux will increase

due to the synergistic effect of the cables. Contact CKD before use. Note that the switch

cannot be set within the cable loop.

*1: I ndicates malfunction occurring when the cylinder piston magnet is degaussed by a

welding field.

*2: Malfunction of H0Y indicates output malfunction.

*3: T2YD is a switch dedicated for AC magnetic field.

20

30

40 [mm]

Detection stroke

Detection stroke - malfunction distance characteristics

10

When using with the detection stroke set to 30 mm or

less, provide the distance in the figure above between the

welding cable and switch.

Ending

Ending 9

Distance between cylinder tube and welding cable surface

(3) H type cylinder switch

Magnetic performance near spot welding

[mm]

Spot welding current - piston magnet degaussing characteristics

50

40

30

Safe range

20

10

Degauss range

0

10000

15000

20000

[A]

Welding current

Degaussing occurs when an alternating current magnetic

field is applied to the magnet. Measures have been

taken for the cylinder with H type switch magnet. While

degaussing does not occur up to 15,000 A, at over 15,000

A, provide the above distance between the cylinder tube

and welding cable surfaces.

Ending

Ending 10

Cylinder switch

MEMO

Ending

Ending 11

M Series

M Series

Application

Cylinder

FC* RV3 * SRL3 SRG3 SRT3 UFCD

M*V

M*H

Specifications

Item

Applications

2-wire proximity

M2V/M2H

M2WV(2-color LED)

M3H/V (NPN output))

Dedicated for programmable controller

Output method

-

Power supply voltage

-

M3WV (2-color LED)

For programmable controller, relay, IC circuit, compact solenoid valve

NPN output

PNP output

4.5 to 28 VDC

NPN output

10 to 28 VDC

Load voltage

10 to 30 VDC

30 VDC or less

Load current

5 to 30mA

100 mA or less

Current consumption

-

10 mA or less with 24 VDC 10 mA or less with 24 VDC 15 mA or less with 24 VDC

Internal voltage drop

4 V or less

0.5 V or less

Indicator

Red LED (Lit when ON) Red/green LED (Lit when ON) Red LED(Lit when ON) Yellow LED (Lit when ON) Red/green LED (Lit when ON)

10 μA or less

Leakage current

1 mA or less

Lead wire length

1m (Oil resistant vinyl cabtyre cable 2-conductor 0.2mm2)

0.05 mA or less

980m/s2

100 MΩ and over with 500 VDC megger

Insulation resistance

Withstand voltage

No failure after 1 minute of 1,000 VAC application.

Ambient temperature

-10 to +60°C

Degree of protection

IEC standards IP67, JIS C0920 (water tight)

Weight

1 m: 22 g 3 m: 57 g 5 m: 93 g

Applications

1 m: 22 g 3 m: 57 g 5 m: 93 g

2-wire reed

Item

M0V/M0H

M5V/M5H

For programmable controller, relay

For programmable controller, relay, IC circuit (no indicator lamp), serial connection

Power supply voltage

-

Load voltage

12/24 VDC

110 VAC

5/12/24 VDC

110 VAC

Load current

5 to 50mA

7 to 20mA

50 mA or less

20 mA or less

Current consumption

Internal voltage drop

Indicator

3 V or less (with 30 mA load current for DC)

0.1V or less (*4)

Red LED (Lit when ON)

No indicator lamp

Leakage current

0 mA

Lead wire length

1 m (oil resistant vinyl cabtyre cable 2-conductor 0.2mm2)

Shock resistance

294 m/s2

Insulation resistance

Withstand voltage

100 MΩ and over with 500 VDC megger

No failure after 1 minute of 1,000 VAC application.

Ambient temperature

-10 to +60°C

Degree of protection

IEC standards IP67, JIS C0920 (water tight)

Contact protection circuit*5

Weight

None

1 m: 22 g 3 m: 57 g 5 m: 93 g

*1: M*H is available for SRL3, SRG3, and SRT3.

*2: Refer to the pages of each cylinder model for switch model No. capable of installing on a cylinder.

*3: Contact CKD separately for cylinder switch with connector.

*4: Internal resistance 0.5 Ω or less.

*5: Refer to Intro Page 80 for contact protective measures.

Ending 12

10 μA or less

1m (Oil resistant vinyl cabtyre cable 3-conductor 0.15mm2)

Shock resistance

Ending

3-wire proximity

M3PH/V (PNP output)

M Series

Dimensions

Dimensions

8.5

6.2

9

23.5

23.5

10.5

5.5

ø3.4

5.5

10

11.5

5.8

Sensor center

5.8

ø3.7

5.5

12.5

10.5

Sensor center

11

ø3.4

M*H Series (straight lead wire)

6.2

8.5

10.5

5.8

Sensor center

11

M*W Series (2-color LED, L-shaped lead

6.2

8.5

M*V Series (L-shaped lead wire)

26.5

Switch internal circuit diagram

M3V/M3H/M3WV

Blue wire (-)

Black wire (output)

Blue wire (power supply -)

M0V/M0H

Brown wire (power supply +)

Brown wire (power supply +)

Switch

main circuit

Switch

main circuit

Brown wire (+)

M3PV/M3PH

Switch

main circuit

M2V/M2H/M2WV

Black wire (output)

Blue wire (-)

Brown wire (+)

Blue wire (power supply -)

M5V/M5H

Blue wire

Cylinder switch

Brown wire

Ending

Ending 13

R Series

R Series

Application

cylinder

GLC HCA MFC SHC

(R1,Excluding R4)

Item

Applications

R*B

R*/R*Y

Specifications

2-wire proximity

R2/R2K

R1/R1K

Programmable controller,

relay, compact solenoid valve

Programmable controller,

Dedicated for programmable controller

Output method

relay, IC circuit, solenoid valve

-

Power supply voltage

NPN output

-

-

Load voltage

85 to 265 VAC

10 to 30 VDC

30 VDC or less

30 VDC or less

Load current

5 to 100mA

5 to 30mA

200 mA or less

100 mA or less

4.5 to 28 VDC

With 24 VDC (when ON)

Current consumption

-

-

Internal voltage drop

10% or less of load voltage

4 V or less

Indicator

Leakage current

Lead wire length

1 mA or less with 100 VAC,

16 mA or less

0.5 V or less

10 μA or less

1 mA or less

2 mA or less with 200 VAC

1 m (oil resistant vinyl cabtyre cable 2-conductor 0.3mm2)

1 m (oil resistant vinyl cabtyre cable 3-conductor 0.2mm2)

2

980 m/s

20 MΩ and over with 500 VDC megger

Insulation resistance

Withstand voltage

10 mA or less

0.5 V or less with 150 mA

Red/green LED (Lit when ON) Red LED (Lit when ON) Red/green LED (Lit when ON)

Red LED (Lit when ON)

Shock resistance

1500 VAC, per minute

No failure after 1 minute of 1,000 VAC application.

No failure after application

Ambient temperature

-10 to +60°C

Degree of protection

Grommet: IEC standards IP67, JIS C0920 (water-tight)

Option

Weight

With terminal box R*B (no waterproof)

Applications

1 m: 56 g 3 m: 114 g 5 m: 172 g

1 m: 42 g 3 m: 100 g 5 m: 158 g

1 m: 42 g 3 m: 100 g 5 m: 158 g

1 m: 56 g 3 m: 114 g 5 m: 172 g

2-wire reed

Item

R0

R4

R5

R6

Relay, programmable

For high capacity relay,

For programmable controller, relay, IC circuit

Dedicated for programmable

For controllers

solenoid valve

(no indicator lamp), serial connection

controller (with DC self-hold)

Power supply voltage

110 VAC

-

Load voltage

12/24 VDC

Load current

220 VAC

5 to 50mA 7 to 20mA 7 to 10mA 20 to 200mA

-

110 VAC

220 VAC

5/12/24 VDC

110 VAC

220 VAC

10 to 200mA 50 mA or less 20 mA or less 10 mA or less

24 VDC ±10%

5 to 50mA

Current consumption

-

-

-

-

Internal voltage drop

3.0 V or less

2 V or less

0.5V or less (*1)

5 V or less

Red LED(Lit when ON)

Neon light OFF (Lit when OFF)

No

Red LED (Lit when ON)

0 mA

1 mA or less

0 mA

0.1 mA or less

Indicator

Leakage current

Lead wire length

1 m (oil resistant vinyl cabtyre cable 2-conductor 0.3mm2)

Shock resistance

294 m/s2

Insulation resistance

Withstand voltage

20 MΩ and over with 500 VDC megger

No failure after 1 minute of 1,500 VAC application.

Ambient temperature

-10 to +60°C

Degree of protection

Grommet: IEC standards IP67, JIS C0920 (water-tight)

Contact protection circuit*2

Ending

3-wire proximity

R3/R3K

R 3Y/R3YK (2-color LED)

R2Y/ R2YK (2-color LED)

Yes

Option

With terminal box R*B (no waterproof)

Weight

1 m: 42 g 3 m: 100 g 5 m: 158 g

*1: Internal resistance 10 Ω or less.

*2: Refer to Intro Page 80 for contact protective measures.

Ending 14

None

R Series

Dimensions

Dimensions

R Series (grommet)

R Series (terminal box R*B)

30

32.5

30

ø4.8

44.5

29

23

14.5

15

Sensor center

19

14.5

40.5

38.5

18

G(PF)1/4

18

14.5

Sensor center

Switch internal circuit diagram

R2/R2Y

R3/R3Y

Blue wire (~)

Brown wire (power supply +)

Switch

main circuit

Brown wire (~)

Switch

main circuit

Switch

main circuit

Brown wire (+)

Blue wire (-)

R0

R4

Brown wire ( to )

Brown wire (+)

Blue wire (-)

Black wire (output)

Blue wire (power supply -)

R5

R6

Blue wire (to)

Brown wire

Blue wire

Brown wire (+)

Blue wire (-)

Cylinder switch

R1

Ending

Ending 15

T Series

T Series

Application

cylinder

CAC4 CKV2 CMA2 CMK2

LCX MRG2 MRL2 RCS2

SSD2 SSG STG STS/STL

HCM JSC3 JSC4

RCC2 RRC SCA2

STK UCA2 UCAC2

JSG JSK2

SCG SCM

ULK Hand

JSM2

SCP*3

Chuck

LCG

SCS2

LCR LCW

SRM3 SSD

(T1,excluding T8)

T*H/T*WH

T*V/T*WV

T1H

Specifications

Item

Applications

2-wire proximity

T2HR3/T2VR3 T2JH/T2JV

T2H/T2V (Bending resistant

(Off-delay)

lead wire)

T1H/T1V

For programmable controller, relay, compact solenoid valve

T2YH/T2YV

(2-color LED)

T2WH/T2WV

(2-color LED)

Dedicated for programmable controller

3-wire proximity

T3PH/T3PV T3YH/T3YV T3WH/T3WV(2(PNP output) (2-color LED) color LED)

T3H/T3V

For programmable controller, relay

Output method

-

NPN output PNP output NPN output NPN output

Power supply voltage

-

10 to 28 VDC

24 VDC ±10%

Load voltage

85 to 265 VAC

Load current

5 to 100 mA

5 to 20 mA (*1)

-

-

Current consumption

10 to 30 VDC

Internal voltage drop 10% or less of load voltage

Off-delay time

*6

Shock resistance

With 24 VDC

10 mA or less

Red LED(Lit when ON)

-

Red/greenLED Red/greenLED

(Lit when ON) (Lit when ON)

Red LED (Lit when ON) Yellow LED (Lit when ON) Red/green LED (Lit when ON)

Applications

10 μA or less

1 m (oil resistant vinyl cab

Tire cable 3-conductor 0.2mm2)

1 m (oil resistant vinyl 1 m (oil resistant vinyl

Cabtyre cable

Cabtyre cable

3-conductor 0.3mm2) 3-conductor 0.2mm2)

20 MΩ and over with 500 VDC megger

100 MΩ and over with 20 MΩ and over with

500 VDC megger

500 VDC megger

980m/s2

No failure after 1 minute of 1,500 VAC application.

20 MΩ and over with

500 VDC megger

No failure after 1 minute of 1,000 VAC application.

-10 to +60°C

Degree of protection

Descriptions

10 mA or less with 24 VDC

-

1 mA or less with 100 VAC,

1 mA or less

2 mA or less with 200 VAC

1 m (oil resistant vinyl

1 m (oil resistant vinyl

3 m (elasticity, oil

(oil resistant vinyl

1 m (oil resistant vinyl cab 1 m cabtyre

Cabtyre cable

cabtyre cable

resistance Vinyl cabtyre

cable

2

2

2

2 Tire cable 2-conductor 0.3mm )

2-conductor 0.3mm )

2-conductor 0.2mm ) cable 2-conductor 0.2mm )

2-conductor 0.2mm2)

Ambient temperature

Weight

50 mA or less

With 24 VDC

10 mA or less

0.5 V or less

200±50 ms

Insulation resistance 100 MΩ and over with 500 VDC megger 20 MΩ and over with 500 VDC megger 100 MΩ and over with 500 VDC megger

Withstand voltage

30 VDC or less

100 mA or less

4 V or less

-

Indicator

Leakage current

Lead wire length

IEC standards IP67, JIS C0920 (water tight)

1 m: 33g 3 m: 87g 5 m: 142g

1 m: 18 g 3 m: 49 g 5 m: 80 g

1 m: 18 g 3 m: 49 g

5 m: 80 g

1 m: 33 g 3 m: 87 g 5 m: 142 g

1 m: 18 g 3 m: 49 g 5 m: 80 g

2-wire reed

T5H/T5V

T0H/T0V

For programmable controller, relay

For programmable controller, relay, IC circuit (no indicator lamp), serial connection

Power supply voltage

1 m: 33 g 3 m: 87 g

5 m: 142 g

1 m: 18 g 3 m: 49 g

5 m: 80 g

T8H/T8V

For programmable controller, relay

-

Load voltage

DC12/24V

110 VAC

DC5/12/24V

110 VAC

DC12/24V

110 VAC

220 VAC

Load current

5 to 50 mA

7 to 20 mA

50 mA or less

20 mA or less

5 to 50 mA

7 to 20 mA

7 to 10 mA

Current consumption

-

3 V or less

Internal voltage drop

(For DC, at load current 30mA)

Indicator

Red LED (Lit when ON)

0.1V or less (*5)

4 V or less

No indicator lamp

Red LED (Lit when ON)

Leakage current

Lead wire length

0 mA

1 m (oil resistant vinyl cabtyre cable 2-conductor 0.2mm2)

Insulation resistance

Withstand voltage

294 m/s

20 MΩ and over with 500 VDC megger

100 MΩ and over with 500 VDC megger

No failure after 1 minute of 1,000 VAC application.

No failure after 1 minute of 1,500 VAC application

Ambient temperature

Degree of protection

Contact protection circuit *6

Weight

1 m (oil resistant vinyl cabtyre cable 2-conductor 0.3mm2)

2

Shock resistance

Ending

T8V/T*YV

T2JV

T8H/T*YH

T2JH

T1V

-10 to +60°C

IEC standards IP67, JIS C0920 (water tight)

None

Yes

1 m: 18 g 3 m: 49 g 5 m: 80 g

1 m: 33g 3 m: 87g 5 m: 142g

*1:The above max. load current is 20 mA at 25°C. The current is lower than 20 mA if the operating ambient temperature around the switch is higher than 25˚C. (5 to 10 mA at 60°C)

*2: T2HR3, T2VR3, T3PH and T3PV switches are available as made to order when installed onto compatible cylinders.

*3: T2JH and T2JV switches are available as made to order when installed onto SRL3 (ø32 to ø100), MRL2, LCR, UCAC2 or Hand-chuck.

*4: Switch types are limited depending on cylinder. Refer to each cylinder page for the details.

*5: Internal resistance 0.5 Ω or less. *6:Refer to Intro Page 80 for contact protective measures.

Ending 16

T Series

Specifications

T Series

Application

AC magnetic field cylinder

CAC4

SCM

SSG

JSC3

SCS2

STG

JSC4

SRG3

STS/STL

JSG

SRL3

UCAC2

SCG

SSD2

T2YD

Specifications

Item

2-wire proximity

T2YDT

T2YD

Applications

T2YDU(Made to order)

Dedicated for programmable controller

Indicator

Red/green LED (Lit when ON)

Load voltage

24 VDC ±10%

Load current

5 to 20mA

Internal voltage drop

6 V or less

Leakage current

1.0 mA or less

Output delay time *1

(ON delay, OFF delay)

60 ms or less

Lead wire length

RCC2 RCS2 SCA2

SRM3 SRT3 SSD

USC

USSD

1 m (oil resistant vinyl cabtyre cable

ø6, 0.5 mm2× 2-conductor) *2

1 m (flame-resistant vinyl cabtyre cable 0.3 m (flame-resistant vinyl cabtyre cable with M12

ø6, 0.5 mm2× 2-conductor) *2

cable connector, AWG20, 2-conductor)

100 MΩ and over with 500 VDC megger

Insulation resistance

Withstand voltage

No failure after 1 minute of 1,000 VAC application.

Shock resistance

980 m/s2

Ambient temperature

-10 to +60°C

Degree of protection

JIS C0920 (water-tight), IEC standards IP67

Weight

1 m: 61 g 3 m: 166 g 5 m: 272 g

35

*1: Indicates the time from magnetic sensor detection of the piston magnet until switch output.

*2: 3 m and 5 m lead wires are available as options.

*3: The AC magnetic field proof switch (T2YD*) is for AC welding machines, so the effect of strong magnetic field proof performance cannot be obtained with DC

welding machines.

Cutting oil

Application

cylinder

CMK2-G2/3 HRL-G2/3

SCA2-G2/3 SCG-G2/3

SSD-G2/3

SSD2-G2/3 STG-G2/3

STS/STL-G2/3

T*YLH

Specifications

Item

Applications

2-wire proximity

T2YLH, T2YLV

3-wire proximity

T3YLH, T3YLV

Dedicated for programmable controller

Programmable controller, relay

Output method

-

NPN output

Power supply voltage

-

10 to 28 VDC

Load voltage

10 to 30 VDC

30 VDC or less

Load current

5 to 20mA

50 mA or less

-

10 mA or less at 24 VDC (when ON)

Current consumption

Internal voltage drop

Leakage current

4 V or less

0.5 V or less

1 mA or less

10 μA or less

Cylinder switch

T Series

Indicator

Red/green LED (Lit when ON)

Lead wire

Oil resistant vinyl cabtyre cable 0.3mm2, 2 conductor 1 m Oil resistant vinyl cabtyre cable 0.2mm2, 3 conductor 1 m

Insulation resistance

100 MΩ and over with 500 VDC megger

Withstand voltage

No failure after 1 minute of 1,000 VAC application.

Shock resistance

980m/s2

Hysteresis

1.5 mm or less

Ambient temperature

-10 to +60°C

Degree of protection

IEC Standards IP67, JIS C0920 (water-tight), oil resistance (substrate coating)

Weight

1 m: 33g 3 m: 87g 5 m: 142g

Ending

Ending 17

T Series

Dimensions

T*YH/T2JH/T8H Series

(straight lead wire)

T1H Series

(straight lead wire)

Set screw (M3)

Set screw (M3)

10.5

Sensor center

Sensor center

30.5

3

T

*V/T*WV Series

(L-shaped lead wire)

29.5

6

3

T*YV/T2JV/T8V Series

(L-shaped lead wire)

6

T

1V Series

(L-shaped lead wire)

Set screw (M3)

Set screw (M3)

4.5

Set screw (M2.5)

16

T0H, T5H, T*WH=22.5

T2H, T3H=18.5

11

5.2

6

8

16

8

6.1

Mounting bracket

ø4.8

ø3.4

Mounting bracket

4.5

11.1

T*YH,

T2JH=10.5

T8H=15.5

T0H, T5H=9.5

T2H, T3H=9

T*WH=7.5

Sensor center

11.1

Set screw (M2.5)

ø4.8

T

*H/T*WH Series

(straight lead wire)

T*YH,

T2JH=10.5

T8H=15.5 Sensor center

10.5

Sensor center

8

Mounting bracket

ø4.8

ø4.8

6.1

6

T0V, T5V, T*WV=22.5

T2V, T3V=18.5

30.5

11

5.2

8.7

ø3.4

6

29.5

T2YD (switch for AC magnetic field)

10.5

0.4

ø6

Sensor center

8

8

Ending 18

16

11

16

11

Ending

6

Sensor center

Mounting bracket

Mounting bracket

6

M12

Switch indicator lamp

ø6

M3

29.5

6

T2YDU (switch for AC magnetic field with M12 cable connector)

Set screw (M3)

10.5

8

3

Mounting bracket

3

T0H, T5H=9.5

T2H, T3H=9

T*WH=7.5

Sensor center

6

29.5

300

T Series

Dimensions, switch internal circuit diagram

Dimensions

T*YLH Series

(straight lead wire)

T*YLV Series

(L-shaped lead wire)

Set screw (M3)

Set screw (M3)

10.5

Sensor center

Sensor center

3

3

6.1

ø4.8

6.1

30.5

8

11

Mounting bracket

ø4.8

Mounting bracket

8

6

30.5

11

10.5

6

Switch internal circuit diagram

Blue wire (-)

T0H/T0V

Brown wire (+)

T5H/T5V

Black wire

(output)

Blue wire

(power supply -)

T8H/T8V

Blue wire (-)

Brown wire(+)

Brown wire

Brown wire

(power supply +)

Blue wire

Brown wire (power supply +)

Black wire (output)

Blue wire (power supply -)

T2YD/T2YDT/T2YDU

Blue wire(-)

Brown wire

(4Pin)

Blue wire

(3Pin)

This switch is not polarized.

Values in ( ) are the pin layout for T2YDU.

However, 1-pin and 2-pin are NC

Cylinder switch

Blue wire (~)

Switch

main circuit

Brown wire (~)

Switch

main circuit

Switch

main circuit

Brown wire (+)

T3PH/T3PV

Switch

main circuit

T3H/T3V/T3YH/T3YV/T3WH/

T3WV/T3YLH/T3YLV

Main circuit

Switch

T

2H/T2V/T2YH/T2YV/T2WH/

T2WV/T2JH/T2JV/T2YLH/T2YLV

T1H/T1V

Ending

Ending 19

K Series

K Series

Application

cylinder

SMG STR2

K*H

K3PH

K*V

K3PV

K*YH

K*YV

Specifications

Item

Applications

2-wire proximity

K2H/K2V

K2YH/K2YV

K3H/V (NPN output)

Dedicated for programmable controller

3-wire proximity

K3PH/V (PNP output)

K3YH/V (2-color LED)

For programmable controller, relay

Output method

-

Power supply voltage

-

10 to 28 VDC

Load voltage

10 to 30 VDC

30 VDC or less

Load current

5 to 20 mA (*1)

50 mA or less

-

10 mA or less with 24 VDC 10 mA or less with 24 VDC 10 mA or less with 24 VDC

4 V or less

0.5 V or less

Current consumption

Internal voltage drop

Indicator

PNP output

10 μA or less

1 mA or less

1 m (oil resistant vinyl cabtyre 1 m (oil resistant vinyl cabtyre 1 m (oil resistant vinyl cabtyre cable 3-conduc- 1 m (oil resistant vinyl cabtyre

cable 2-conductor 0.2mm2)

cable 2-conductor 0.3mm2)

tor 0.2mm2)

cable 3-conductor 0.2mm2)

980m/s2

Shock resistance

Insulation resistance 20 MΩ and over with 500 VDC megger 100 MΩ and over with 500 VDC megger

Withstand voltage

20 MΩ and over with 500 VDC megger

-10 to +60°C

Degree of protection

IEC standards IP67, JIS C0920 (water tight)

1 m: 18 g 3 m: 49 g 5 m: 80 g 1 m: 31 g 3 m: 85 g 5 m: 139 g

1 m: 18 g 3 m: 49 g 5 m: 80 g

2-wire reed

Item

Applications

K0H/K0V

K5H/K5V

For programmable controller, relay

For programmable controller, relay, IC circuit (no indicator lamp), serial connection

Power supply voltage

-

Load voltage

12/24 VDC

110 VAC

5/12/24 VDC

110 VAC

Load current

5 to 50mA

7 to 20mA

50 mA or less

20 mA or less

Current consumption

Internal voltage drop

Indicator

3 V or less (with 30mA load current for DC)

0.1V or less (*3)

Red LED(Lit when ON)

-

Leakage current

0 mA

Lead wire length

1 m (oil resistant vinyl cabtyre cable 2-conductor 0.2mm2)

Shock resistance

294 m/s2

Insulation resistance

Withstand voltage

20 MΩ and over with 500 VDC megger

No failure after 1 minute of 1,000 VAC application.

Ambient temperature

-10 to +60°C

Degree of protection

IEC standards IP67, JIS C0920 (water tight)

Contact protection circuit*4

Weight

None

1 m: 18 g 3 m: 49 g 5 m: 80 g

*1: The above max. load current is the value at 25°C. The current is lower than 20 mA if the operating ambient temperature around the

switch is higher than 25˚C. (5 to 10 mA at 60°C)

*2: Installation of K3PH, K3PV onto compatible cylinders is made to order.

*3: Internal resistance 0.5 Ω or less.

*4: Refer to Intro Page 80 for contact protective measures.

Ending

Ending 20

100 MΩ and over with 500 VDC megger

No failure after 1 minute of 1,000 VAC application.

Ambient temperature

Weight

NPN output

Red LED(Lit when ON) Red/green LED (Lit when ON) Red LED(Lit when ON) Yellow LED (Lit when ON) Red/green LED (Lit when ON)

Leakage current

Lead wire length

NPN output

1 m: 31 g 3 m: 85 g 5 m: 142 g

K Series

Dimensions

Dimensions

K*H Series (axial lead wire)

K*YH Series

(2-color LED, axial lead wire)

Set screw (M3)

ø3.4

Set screw (M2.5)

10.5

8

5

11

Mounting bracket

6.2

Sensor center

Sensor center

ø4.8

9.5

24

7

27

31

K*V Series (L-shaped lead wire)

3

7

K*YV Series

(2-color LED, L-shaped lead wire)

Set screw (M3)

Set screw (M2.5)

9.5

10.5

Sensor center

Sensor center

8

ø4.8

11

6.2

5

7.8

Mounting bracket

3

ø3.4

27

7

31

7

Switch internal circuit diagram

Switch

main circuit

Switch

main circuit

Brown wire (+)

Blue wire (-)

K0H/K0V

Brown wire (+)

K3PH/K3PV

Brown wire

(power supply +)

Black wire

(output)

Blue wire

(power supply -)

Brown wire

(power supply +)

Black wire

(output)

Blue wire

(power supply -)

Cylinder switch

K3H/K3V/K3YH/K3YV

Switch

main circuit

K2H/K2V/K2YH/K2YV

K5H/K5V

Blue wire (-)

Brown wire

Blue wire

Ending

Ending 21

F Series

F Series

Application

cylinder

CKL2 LCG LCM LCR MDC2 MSD MSDG-L MVC RCS2 SSD2 STM hand (LSH BSA2 LHA)

Uses a bend-resistant lead wire as standard.

* There are bore sizes which cannot be combined.

F*V

F*S

F*H

F*YV

F3PV

F*YH

F3PH

Specifications

Item

Applications

2-wire reed

F0H/V

2-wire proximity

F2H/V / F2S

F2YH/F2YV

3-wire proximity

F3PH/V

F3H/V / F3S

Dedicated for programmable controller

F3YH/F3YV

For programmable controller, relay

Output method

-

NPN output

PNP output

NPN output

Power supply voltage

-

10 to 28 VDC

4.5 to 28 VDC

10 to 28 VDC

Load voltage

24 VDC ±10%

Load current

Current consumption

Internal voltage drop

Indicator

10 to 30 VDC

24 VDC ±10%

30 VDC or less

5 to 20 mA (*1)

50 mA or less

-

10 mA or less with 24 VDC

4 V or less

0.5 V or less

Leakage current

0.5 V or less at 30 mA

0.5 V or less

*3 Red/green LED (Lit when ON) Yellow LED *3 (Lit when ON) Yellow LED (Lit when ON) Red/green LED (Lit when ON)

Yellow LED (Lit when ON)

10 μA or less

1 mA or less

2

Lead wire length 1 m (elasticity, oil resistant vinyl cabtyre cable 2-conductor 0.15mm ) 1 m (elasticity, oil resistant vinyl cabtyre cable 3-conductor 0.15mm2)

Shock resistance

294m/s2

980 m/s2

Insulation resistance

20 MΩ and over with 500 VDC megger

Withstand voltage

No failure after 1 minute of 1,000 VAC application.

Ambient temperature

-10 to +60°C

Degree of protection

Contact protection circuit*4

Weight

IEC standards IP67, JIS C0920 (water-tight)

None

1 m: 10 g 3 m: 29 g

1 m: 10 g 3 m: 29 g

*1:The max. load current is 20mA at 25°C. The current is lower than 20 mA if the operating ambient temperature around the switch is higher than 25˚C. (5 to 10 mA at 60°C)

*2: With F2S and F3S, if mounting two switches in one groove to enable detection at both ends, mount them so that their set screws face outward.

*3: Indicators for F2S and F3S are red.

*4: Refer to Intro Page 80 for contact protective measures.

*5: Uses a bend-resistant lead wire.

Ending

Ending 22

F Series

Dimensions, switch internal circuit diagram

Dimensions

F*S Series (Lead wire vertical lead-out, for short stroke detection)

Set screw (M2)

Sensor center

6

15.5

2.5

ø2.7

8.5

F*H Series (straight lead wire)

F*V Series (L-shaped lead wire)

Set screw (M2)

Set screw (M2)

F0H:9.5

F2H, F3H:5

3

F0H:9.5

F2H, F3H:5

Sensor center

ø2.7

ø2.7

9.5

4.5

3

Sensor center

ø2.7

4.5

4

4

3

16.7

4

F*YH/F3PH Series (straight lead wire)

16.7

F*YV/F3PV Series (L-shaped lead wire)

Set screw (M2)

3

Set screw (M2)

5

Sensor center

4

3

21.2

Cylinder switch

9.5

4.5

4

ø2.7

4.5

3

Sensor center

ø2.7

ø2.7

5

21.2

Switch internal circuit diagram

F0H/F0V

F2S/F2H/F2V/F2YH/F2YV

F3S/F3H/F3V/F3YH/F3YV

F3PH/F3PV

Switch

main circuit

Switch

main circuit

Switch

main circuit

Brown wire (+)

Blue wire (-)

Blue wire (-)

Brown wire

(power supply +)

Black wire

(output)

Blue wire

(power supply -)

Switch

main circuit

Brown wire (+)

Brown wire (power supply +)

Black wire (output)

Blue wire (power supply -)

Ending

Ending 23

H Series

H Series

Strong magnetic field proof

Applicable

cylinder

CAC4-L2 GLC-L2 JSC3-L2 SCA2-L2 SHC-L2 UCAC2-L2 USC-L2

H0

H0Y

Specifications

2-wire reed

Item

H0

H0Y (2-color LED)

Applications

For programmable controller, relay

Dedicated for programmable controller

Load voltage

12/24 VDC

110 VAC

24 VDC ±10%

Load current

5 to 50 mA

7 to 20 mA

5 to 20 mA

Internal voltage drop

Indicator

5 V or less

6 V or less

Green LED (Lit when ON)

Red/green LED (Lit when ON)

0 mA

10 μA or less

Leakage current

1 m (flame-resistant cabtyre cable 2-conductor 0.5 mm2)

Lead wire length

100 MΩ and over with 500 VDC megger

Insulation resistance

Withstand voltage

No failure after 1 minute of 1,000 VAC application.

Shock resistance

294 m/s2

Ambient temperature

-10 (14°F) to +60°C (140°F)

Degree of protection

IEC Standard IP67, JIS C0920 (water-tight), oil resistance

Contact protection circuit *1

None

Weight

1 m:76 g 3 m:181 g 5 m:289 g

*1: Refer to Intro Page 80 for contact protective measures.

Dimensions

H Series (strong magnetic field proof)

13

11.4

ø6

34

30

18

15

Switch internal circuit diagram

H0

H0Y

Brown

wire

Ending

Ending 24

Switch

main circuit

Blue

wire

This switch is not polarized.

Brown

wire

Blue

wire

This switch is not polarized.

Sensor center

V Series

Specifications

V Series

Applicable

cylinder

Small strong magnetic field proof

SSD-L4 SSD2-L4 USSD-L4

V0

Specifications

2-wire reed

V0

Item

Applications

For relay, programmable controller

Load voltage

24 VDC

110 VAC

Load current

5 to 50 mA

7 to 20 mA

Internal voltage drop

3.0 V or less (with 40 mA load current)

Indicator

LED (Lit when ON)

Leakage current

0 mA

Lead wire length

1 m (flame-resistant cabtyre cable 2-conductor 0.5 mm2)

100 MΩ and over with 500 VDC megger

Insulation resistance

Withstand voltage

No failure after 1 minute of 1,000 VAC application.

Shock resistance

294 m/s2

Ambient temperature

-10 (14°F) to +60°C (140°F)

Degree of protection

IEC Standards IP67, JIS C0920 (water-tight), oil resistance

Contact protection circuit *1

None

Weight

1 m:63 g 3 m:170 g 5 m:277 g

*1: Refer to Intro Page 80 for contact protective measures.

Dimensions

V Series (strong magnetic field proof)

M3 × 6 hexagon socket head cap screw

17

6

27

5

Cylinder switch

ø6

Mounting bracket

10

15

8

Sensor center

Switch internal circuit diagram

V0

Brown (+)

(-) Blue wire

Ending

Ending 25

E Series

E Series

Applicable

Heat resistance cylinder

SCA2-L2T(E0) SSD-T1L(ET0) SSD2-T1L(ET0)

(Excluding E0)

E0

Specifications

ET0

2-wire reed

Item

E0

ET0

Applications

For relay, programmable controller

Load voltage

12/24 VDC

110 VAC

220 VAC

12/24 VDC

110 VAC

Load current

5 to 50 mA

7 to 20 mA

7 to 10 mA

5 to 50 mA

7 to 20 mA

Internal voltage drop

4 V or less

3.0 V or less

Leakage current

0 mA

Indicator

Red LED (Lit when ON)

Conduit screw

Lead wire length

Yellow LED (Lit when ON)

G1/2

-

-

1 m (heat-resistant fluorine insulation cabtyre cable 2-conductor 0.5 mm2)

100 MΩ and over with 500 VDC megger

Insulation resistance

Withstand voltage

No failure after 1 minute of 1,500 VAC application. No failure after 1 minute of 1,000 VAC application.

Shock resistance

294 m/s2

Ambient temperature

-10 (14°F) to +120°C (248°F)

Degree of protection

-10 (14°F) to +150°C (302°F)

IEC Standards IP67, JIS C0920 (water-tight), oil resistance

Contact protection circuit *1

None

Weight

164 g

44 g

*1: Refer to Intro Page 80 for contact protective measures.

Dimensions

E Series

ET0H Series (axial lead wire)

ET0V Series (L-shaped lead wire)

Set screw (M3)

Set screw (M3)

54

44

8

30.5

42

57

Switch internal circuit diagram

Brown wire (+)

ET0H

Blue wire (-) Brown wire

(+)

Ending

Ending 26

6

3

Mounting bracket ø4.8

6

8

11

Mounting bracket

45.5

25.5

G1/2

ø12

E0

Sensor center

Sensor center

ø4.8

21

16

Sensor center

16

Blue wire

(-)

3

6

30.5

6

11

34

Indicator

SKAC/SKDC Series

Specifications

Contact protecting circuit box

SKAC/SKDC

Specifications

How to order

For AC circuit

SKAC

Item

For DC circuit

SKDC

Load voltage

100/110 VAC

200/220 VAC

24 VDC

Load current

20 mA or less

10 mA or less

50 mA or less

2

Lead wire length

1 m (oil resistant vinyl cabtyre cable 2-conductor 0.2 mm )

Shock resistance

980 m/s2

Insulation resistance

Withstand voltage

SW

SKAC

Code

SKAC

SKDC

Description

Circuit AC

Circuit DC

100 MΩ or more at 500 VDC megger

No failure after 1 minute of 1,500 VAC application

Ambient temperature

-10 (14°F) to +60°C (140°F)

Degree of protection IEC Standards IP67, JIS C0920 (water-tight), oil resistance

Dimensions

16

SKAC/SKDC Series

ø3.4

10

Internal circuit diagram

SKAC/SKDC

Brown wire

Brown wire

Blue wire

Blue wire

Cylinder switch

30

*: Input side and output side do not have polarity, so either can be connected to the switch.

Note: SKAC is for AC circuit only and SKDC is for DC circuit only.

Ending

Ending 27

Series option

Cylinder switch with connector

Features

M8 and M12 connectors with high versatility are adopted

Conforms to standards No. NECA4202 and IEC947-5-2

Reduced work-hours for piping and ease of maintenance

IP67 is adopted as degree of protection

Protective cover for anti-spatter adherence is available

For T0H

For T2YD

How to order

* This is a made to order product.

2-wire cylinder switch

SW

A

Model

T0

H

F

K

A

B

C

D

B

T0

T2

T2W

T2YL

K2Y

F2Y

Lead wire leadout direction

H

V

C

Straight type

L-shaped type

Connector type, PIN configuration

F

M

U

Lead wire length

M8 connector 4PIN (+) 3-pin (-) *1

M12 connector 1PIN (+) 4PIN (-)

M12 connector 3, 4PIN not polarized

Blank

0.3m

D Option *3

K Protective cover for anti-spatter adherence

*3: Applies only to T0H

*2

*1: Supports only T0, T2, T2W

*2: Does not support T2YL.

Note that the "internal voltage drop" will be higher by 1 V than the specification value listed in the catalog.

3-wire cylinder switch

SW

A

Model

T3

H

F

A

B

C

B

T3

T3P

T3W

Lead wire leadout direction

H

V

Straight type

L-shaped type

C

Type of connector

F

Lead wire length

M8 1PIN(+) 3PIN(-) 4PIN:(OUT)

Blank

0.3m

Cylinder switch for strong magnetic field

SW

A

Model

H0

H0Y

V0

H0

M

A

B

B

Type of connector

M

U

M12 connector 1, 4PIN not polarized

M12 connector 3, 4PIN not polarized

Lead wire length

*4

Blank

0.3m

*5

*4: Supports only H0, H0Y

*5: V0 only 4PIN (+) 3 PIN (-)

Cylinder switch dedicated for AC magnetic field

SW

A

Model

T2YD

Ending

T2YD

G

K

A

B

C

B

Type of connector

G

B

U

W

Lead wire length

Spatter-proof lead wire M12 connector 1, 4-pin no polarity

Blank

Spatter-proof lead wire M12 connector 3, 4-pin no polarity

Flame-resistant lead wire UL electric wire M12 connector 3, 4PIN not polarized

Flame-resistant lead wire UL electric wire M12 connector 1, 4PIN not polarized

0.3m

*6 : Cylinder switch specifications are the same as those of lead wire. Refer to Ending Pages 16 to 26 for details.

Ending 28

C

Option

K

Protective cover for anti-spatter adherence

Series option

Pin array of connector

Series

2-wire

Strong magnetic field proof

Dedicated for AC magnetic field

3-wire

Code

Type of connector

F

M

U

M, G, W

U, B*

F

M8

Connector pin array

1PIN

2PIN

(+)

(±)

(+)

M12

M8

-

3PIN

4PIN

(-)

(±)

(±)

(-)

(+)

(-)

(±)

(±)

(±)

(OUT)

* Only SW-V0U is polarized (4-pin (+), 3PIN (-)).

Connector specifications

Item

M8

M12

2

3

3

2

Pin array

Shock resistance

Degree of protection

Insulation resistance

Withstand voltage

3

1

3

4

2

4

4

1

4

1

2

1

294 m/s²

IP67

100 MΩ with 500 VDC megger

1000 VAC for 1 minute (between contacts and between contact housings)

leakage current 1 mA or less

dimensions

M12 connector (connector for 2-wire cylinder switch, only pin array code of "U" )

Standard for outer shape of connector section: IEC64076-2-101

0.3 m

φ14

0.3 m

Cylinder switch

63

M12 connector (M12 connector other than

)

Cylinder switch

63

0.3 m

63

φ14

Standard for outer shape of connector section: IEC64076-2-101

0.3 m

φ14φ14

0.3 m

44.5

44.5

φ10

φ10φ10

Cylinder switch

0.3 m

0.3 m

Standard for outer shape of connector section: IEC64076-2-104

31.4

Cylinder switch

Cylinder switch

44.5

M8 connector (supporting all models)

Cylinder switch

0.3 m

Cylinder switch

Cylinder switch

Cylinder switch

31.4

31.4

Cylinder switch

φ14φ14

0.3 m

* For the external dimensions of the cylinder switch, refer to Ending Pages 18 to 26.

Ending

Ending 29

Series option

T type cylinder switch with off delay timer

T2JH/T2JV

Overview

Optimum for intermediate detection of high speed cylinder.

Off delay timer realizes secure PC input.

Features

· PC input malfunctions at cylinder intermediate detection

are prevented.

· Off delay timer 200±50 ms

· Installation to rodless cylinder SRL3 is possible.

· A great variety of cylinders.

* Made-to-order product when a switch is installed on the cylinder.

* Switchs are limited depending on cylinder. Refer to each

cylinder page for the details.

T type cylinder switch coolant proof

T2YLH/V, T3YLH/V

Overview

This is a cylinder switch that prevents coolant for machine

tools used at machining site, etc., from entering the

cylinder switch.

Features

· Oil resistance increased by applying coating to the circuit

board.

Usable even in an environment exposed to coolant.

· A great variety of cylinders

* Made-to-order product when a switch is installed on the cylinder.

Ending

Ending 30

Cylinder switch

Operational principle

Proximity switch

Reed switch

Switch

Indicator

Indicator

Magnetic resistance

element

Reed switch

Power supply +

Output

Power supply -

Amplifier

Magnet

Magnet

Switch ON

Switch OFF

Detection level

Magnetic resistance element output

Switch ON

Amplifier output

Switch OFF

The magnetic field changes when the piston’s magnet approaches, and the

The magnetic field is generated when the piston’s magnet

magnetic resistance element’s output voltage changes as shown in the figure.

approaches, and the contact matching the reed switch direction is

Switching output as shown above is attained when this signal is amplified.

magnetized to generate an attraction force and close the contact.

Switch mounting position

RD

Max. sensitivity position

Lead wire

RD

HD

Head cover

HD

Rod cover

Stroke end installation

Intermediate stroke position installation

Circumference direction installation

To check that the switch functions at the

In detection at the middle of the stroke, fix

Differs depending on mounting bracket.

max. sensitivity position, mount 1 each at

the piston at the stop position, and move

When using a band, no limits are set on

the rod side RD dimension position and at

the switch back and forth over the piston.

circumference direction.When using a

the head side HD dimension position.

Find the position where the switch turns ON

tie rod, the position can be rotated in 90°

HD and RD dimensions differ based on a

first. The point between these 2 positions is

increments. Circumferential rotation is not

cylinder. Refer to each cylinder dimension.

the max. sensitivity position at that piston

possible for the rail method.

Mount the switch so the lead wire comes to

position, and is the installation position.

Hysteresis

ON

Hysteresis is the distance from the point

OFF

Hysteresis

Operating range

Cylinder

piston

movement direction

where the piston moves and the switch turns

ON to the point where the piston moves in the

reverse direction and the switch turns OFF.

Cylinder switch

the inside as shown above.

If the piston stops between these points,

switch operation becomes unstable and

is easily adversely affected by external

Operating range

sources. Please be careful.

The operating range is from the point where

the piston moves and the switch turns ON to

the point where the piston moves further in the

same direction and the switch turns OFF.

The center of the operating range is max. sensitivity

position. If this position is set as the piston stop position, it is

not affected by disturbance and switch operation is stable.

Ending

Ending 31

Cylinder switch

Operating range and hysteresis of each cylinder model with switch

Model No.

Bore

size

(mm)

Proximity switch

Operating range

Hysteresis

1-color type 2-color type 1-color type 2-color type

(Unit: mm)

Reed switch

Operating range

Hysteresis

Page

Pencil shaped cylinder

Applicable switch: Proximity switch (T2 , T3 , T2W , T3W ), reed switch (T0 , T5 )

SCP*3

ø6

ø10

ø16

Medium bore size cylinder

CMK2

Medium bore size cylinder

CMA2

1.5 to 4

1.5 to 5.5

2 to 6

2.5 to 5

2.5 to 6

2.5 to 6

1.5 or less

1.0 or less

4 to 6

3.5 to 7

3.5 to 7.5

3 or less I-3

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T1 ), reed switch (T0 , T5 , T8 )

ø20

ø25

ø32

ø40

2.5 to 5.5

2.5 to 5.5

2.5 to 6

3 to 7

3.5 to 7.5

3.5 to 7.5

3.5 to 8

4 to 9

1.5 or less

1.0 or less

6.5 to 11

7.5 to 12

6.5 to 11.5

7.5 to 13.5

3 or less I-79

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T1 ), reed switch (T0 , T5 , T8 )

ø20

ø30

ø40

3 to 6

3 to 5.5

2.5 to 5.5

5 to 6.5

6 to 7

5.5 to 7.5

1.5 or less

1.0 or less

8.5 to 12

8 to 13

8.5 to 12.5

3 or less I-191

Round shaped cylinder ● Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

SCM

Tie rod cylinder

SCG

Medium bore size cylinder

ø20

ø25

ø32

ø40

ø50

ø63

ø80

ø100

3 to 8

3 to 9

3 to 8

3 to 9

3 to 9

3 to 9

4 to 10

4 to 10

4.5 to 9

5 to 9

5 to 9

5.5 to 9.5

6 to 10

6 to 10.5

6.5 to 11

7 to 11.5

1.5 or less

1.0 or less

6 to 14

5 to 14

5 to 12

6 to 14

6 to 14

7 to 15

7 to 15

9 to 15

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

ø32

ø40

ø50

ø63

ø80

ø100

2 to 7

2 to 7

2 to 7

2 to 7.5

2.5 to 8

2.5 to 8

6 to 9

6.5 to 9

7 to 10

7 to 10

7.5 to 10.5

8 to 11

1.5 or less

1.0 or less

6 to 11

7 to 12

7.5 to 12

8.5 to 13

9 to 13.5

9 to 14

SCA2

Medium bore size cylinder

Applicable switch: Reed switch for strong magnetic fields (H0 )

SCA2-L2

ø40

ø50

ø63

ø80

ø100

SCS2

Ending

Ending 32

3 or less I-335

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

ø40

ø50

ø63

ø80

ø100

Large bore size cylinder

3 or less I-213

2 to 7

2 to 7.5

2.5 to 7.5

3 to 8

3 to 8.5

3 to 10

3 to 10

3.5 to 10.5

4 to 11.5

4 to 11.5

-

1.5 or less

-

1.0 or less

-

5 to 12.5

5.5 to 13.5

5.5 to 14

6.5 to 14.5

6.5 to 15.5

3 or less I-427

* The values in ( ) indicate H0Y.

4 to 7.5(10.5 to 13.5)

4 to 7.5(11 to 14)

5 to 8(11.5 to 14.5) 3 or less I-427

5 to 8(10.5 to 14.5)

5 to 8(10.5 to 14.5)

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

ø125

ø140

ø160

ø180

ø200

7.5 to 14

7.5 to 14

7.5 to 14

7.5 to 14

7.5 to 14

14 to 21

18 to 26

18 to 26

18 to 26

18 to 26

1.5 or less

1.0 or less

11 to 16

3 or less I-605

Cylinder switch

Operating range, hysteresis

Operating range and hysteresis of each cylinder model with switch

Model No.

Tie rod cylinder

CKV2

Tie rod cylinder

CAV2-L

COVP2-L

COVN2-L

Compact cylinder

SSD2

Compact cylinder

SSD2-T1L

Bore

size

(mm)

Proximity switch

Operating range

Hysteresis

1-color type 2-color type 1-color type 2-color type

(Unit: mm)

Reed switch

Operating range

Hysteresis

Page

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T1 ), reed switch (T0 , T5 , T8 )

ø20

ø25

ø32

ø40

2.5 to 5.5

2.5 to 5.5

2.5 to 6

3 to 7

3.5 to 7.5

3.5 to 7.5

3.5 to 8

4 to 9

1.5 or less

1.0 or less

6.5 to 11

7.5 to 12

6.5 to 11.5

7.5 to 13.5

3 or less I-659

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

ø50

ø75

ø100

3.8 to 6.7

3.8 to 6.7

3.8 to 6.7

4 to 6

4 to 6

4 to 6

0.8 or less

0.7 or less

7.7 to 8.3

7.7 to 8.3

7.7 to 8.3

1 or less I-687

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

ø12

ø16

ø20

ø25

ø32

ø40

ø50

ø63

ø80

ø100

ø125

ø140

ø160

1.5 to 5.5

1.5 to 4.5

3 to 8

3 to 9

3 to 8

3 to 9

3 to 9

3 to 9

4 to 10

4 to 10

4 to 10

4 to 10

4 to 10

3 to 6

3 to 7

4.5 to 8

4.5 to 8

4.5 to 8

5 to 8.5

5.5 to 9.5

5.5 to 9.5

6 to 10

6 to 10

8 to 10

8 to 10

8 to 10

1.5 or less

1.0 or less

5 to 8

4 to 9

6 to 14

5 to 14

5 to 12

6 to 14

6 to 14

7 to 15

7 to 15

9 to 15

9 to 15

9 to 15

9 to 15

3 or less I-729

-

8 to 11.5

9 to 13.5

9.5 to 14

9 to 13

9 to 14

11 to 16

13 to 18

3 or less I-729

Applicable switch: Reed switch (ET0 )

ø16

ø20

ø25

ø32

ø40

ø50

ø63

-

-

SSG

ø12

ø16

ø20

ø25

ø32

ø40

ø50

ø63

ø80

ø100

1.5 to 5.5

1.5 to 4.5

3 to 8

3 to 9

3 to 8

3 to 9

3 to 9

3 to 9

4 to 10

4 to 10

3 to 6

3 to 7

4.5 to 8

4.5 to 8

4.5 to 8

5 to 8.5

5.5 to 9.5

5.5 to 9.5

6 to 10

6 to 10

1.5 or less

1.0 or less

5 to 8

4 to 9

6 to 14

5 to 14

5 to 12

6 to 14

7 to 15

7 to 15

9 to 15

9 to 15

3 or less I-1049

Cylinder switch

Compact cylinder ● Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

Ending

Ending 33

Cylinder switch

Operating range and hysteresis of each cylinder model with switch

Model No.

Compact cylinder

SSD

Compact cylinder

SSD-T1L

Small direct mounting cylinder

MDC2

MDC2-X

MDC2-Y

Small cylinder/suction pad

MVC

Compact cylinder

SMG

Small compact cylinder

MSD-*L

MSDG-L

Ending

Ending 34

Bore

size

(mm)

Proximity switch

Operating range

Hysteresis

1-color type 2-color type 1-color type 2-color type

(Unit: mm)

Reed switch

Operating range

Hysteresis

Page

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T2YD, T1 ), reed switch (T0 , T5 , T8 )

ø12

ø16

ø20

ø25

ø32

ø40

ø50

ø63

ø80

ø100

ø125

ø140

ø160

1.5 to 5.5

1.5 to 4.5

3 to 8

3 to 9

3 to 8

3 to 9

3 to 9

3 to 9

4 to 10

4 to 10

4 to 10

4 to 10

4 to 10

3 to 6

3 to 7

4.5 to 8

4.5 to 8

4.5 to 8

5 to 8.5

5.5 to 9.5

5.5 to 9.5

6 to 10

6 to 10

8 to 10

8 to 10

8 to 10

1.5 or less

1.0 or less

5 to 8

4 to 9

6 to 14

5 to 14

5 to 12

6 to 14

6 to 14

7 to 15

7 to 15

9 to 15

9 to 15

9 to 15

9 to 15

3 or less I-1065

-

8 to 11.5

9 to 13.5

9.5 to 14

9 to 13

9 to 14

11 to 16

13 to 18

3 or less I-1065

Applicable switch: Reed switch (ET0 )

ø16

ø20

ø25

ø32

ø40

ø50

ø63

-

-

Applicable switch: Proximity switch (F2 , F3 ), reed switch (F0 )

ø6

ø8

ø10

ø6

ø8

ø10

ø6

ø8

ø10

1.5 to 3.5

-

1.0 or less

-

3.5 to 6.0

1.0 or

less

2.0 to 3.5

-

1.0 or less

-

5.5 to 7.5

1.0 or

less

1.5 to 3.5

-

1.0 or less

-

4.5 to 6.0

1.0 or

less

I-1327

Applicable switch: Proximity switch (F2 , F3 ), reed switch (F0 )

ø6

ø10

1.5 to 3.5

-

1.0 or less

-

3.5 to 6.0

4.5 to 6.0

1.0 or

less

I-1353

Applicable switch: Proximity switch (K2 , K3 , K3P , K2Y , K3Y ), reed switch (K0 , K5 )

ø6

ø10

ø16

ø20

ø25

ø32

1.5 to 7

1.5 to 7

1.5 to 7

2.5 to 9

3.5 to 11

3.5 to 11.5

3.5 to 7.5

3.5 to 7.5

4.5 to 8.5

5 to 9

5.5 to 9.5

1.5 to 10.5

2 or less

1.5 or less

3 to 9.5

3.5 to 9.5

4 to 11

5 to 12.5

6.5 to 14

5.5 to 14

3 or less I-1365

Applicable switch: Proximity switch (F2 , F3 ), reed switch (F0 )

ø6

ø8

ø12

ø16

1.5 to 3.0

1.5 to 3.5

1.5 to 3.5

1.5 to 3.5

-

1.0 or less

-

5 to 6

5.5 to 6.5

5.5 to 7.5

4.5 to 7

1.0 or

less

I-1397

Cylinder switch

Operating range, hysteresis

Operating range and hysteresis of each cylinder model with switch

Flat compact cylinder

FCS-L

FCH-L

FCD-L

FCD-DL

FCD-KL

Stopper cylinder

STK

Brake cylinder

ULKP

Brake cylinder

ULK

Brake cylinder

JSK2

Brake cylinder

JSM2

Tie rod cylinder with brake

JSG

Bore

size

(mm)

(Unit: mm)

Reed switch

Operating range

Hysteresis

Page

Applicable switch: Proximity switch (M2V, M3V, M3PV, M2WV, M3WV), reed switch (M0V, M5V)

ø25

ø32

ø40

ø50

ø63

ø25

ø32

ø40

ø50

ø63

9 to 12

9 to 12

8.5 to 12

8 to 12

8 to 12

6 to 12

6 to 12

6 to 12

6 to 12

6 to 12

6 to 11

6 to 11

6 to 11

6 to 11

6 to 11

5 to 11

5 to 11

5 to 11

5 to 11

5 to 11

1.5 or less

1.5 or less

1.0 or less

1.0 or less

7 to 8.5

7 to 8.5

7 to 8.5

6.5 to 8.5

6.5 to 8.5

7 to 12

7 to 12

7 to 12

7 to 12

7 to 12

3 or less

I-1455

3 or less

Applicable switch: Proximity switch (T2 , T3 , T3P , T2J , T2W , T3W , T2Y , T3Y , T1 ), reed switch (T0 , T5 , T8 )

ø20

ø32

ø40

ø50

3 to 8

3 to 8

3 to 9

3 to 9

4.5 to 8

4.5 to 8

5 to 8.5

5.5 to 9.5

1.5 or less

1.5 or less

6 to 14

5 to 12

6 to 14

6 to 14

3 or less I-1491