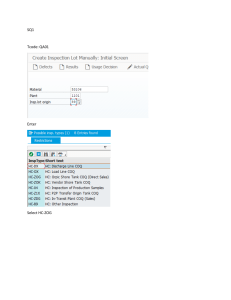

QRCODE OPINION OF ITAIPU BINACIONAL APPROVED RESPONSIBLE APPROVED W/ COMMENTS NOT APPROVED [LOGIN] CANCELED [LOGIN] INFORMATIVE FIT FOR SIGNATURE THE APPROVAL OF THIS DOCUMENT DOES NOT EXEMPT THE CONTRACTED OF YOUR COMPLETE RESPONSIBILITY FOR THE FULFILMENT OF CONTRACTUAL OBLIGATIONS DATE DOCUMENT ISSUED IN DIGITAL FORMAT ONLY CONFIRM AUTHENTICITY THROUGH THE ITAIPU BINACIONAL TECHNICAL ARCHIVE SYSTEM No. DESCRIPTION PROOFREADER(S) APPROVAL DATE REVIEWS AT INITIAL ISSUE TECHNOLOGICAL UPDATE – PAT_OBJ1 ISSUER 4500063671 - INSPECTION AND TEST PLAN PROJECT/AUTHORSHIP [LOGIN];[LOGIN] VERIFICATION APPROVAL INSPECTION AND TESTING PLAN [LOGIN] DATE CODE OF THE ISSUER 01/01/2018 - FORMAT ITAIPU CODE A4 XXXX-XX-XXXXX-P PAGE REVISION RX - INSPECTION AND TEST PLAN AT SUBCONTRACTOR'S CODE REV RESP. TECHNICIAN REV. OF ITAIPU REV. OF THE ISSUER INSPECTION AND TESTING PLAN CODE OF THE ISSUER: CREA REV. OF SUBCON. DESCRIPTION SIGNATURE PROOFREADER ITAIPU CODE VERIFICATION APROVATION PAGE 2 DATE REVISION - INSPECTION AND TEST PLAN AT SUMMARY 1 OBJECTIVE ............................................................................................................................... 4 2 SCOPE ...................................................................................................................................... 4 3 REFERENCE DOCUMENTS ......................................................................................................... 5 4 APPLICABLE STANDARDS .......................................................................................................... 5 4.1 4.2 NATIONAL / INTERNATIONAL STANDARDS......................................................................................... 5 BRAZILIAN REGULATORY STANDARDS ................................................................................................ 5 5 TEST REQUIREMENTS ............................................................................................................... 5 6 CAPTION .................................................................................................................................. 6 7 PREPARATORY DOCUMENTATION ............................................................................................ 8 8 RAW MATERIAL & COMPONENTS ............................................................................................. 9 9 MANUFACTURING PROCESS ................................................................................................... 10 10 FACTORY ACCEPTANCE TEST (FAT) .......................................................................................... 11 11 FINAL DOCUMENTATION (DATA BOOK) .................................................................................. 13 12 PACKAGING AND SHIPPING .................................................................................................... 13 13 ATTACHMENTS ...................................................................................................................... 14 14 GENERAL CONSIDERATIONS ................................................................................................... 14 INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 3 REVISION - INSPECTION AND TEST PLAN AT 1 OBJECTIVE Detail the set of tasks, inspections, and tests that must be performed on XXXXXXXX equipment, specifically for XXXXXX, as presented in Workstatement. 2 SCOPE This document applies to the components listed below : EQUIPMENT INSPECTION AND TESTING PLAN CODE OF THE ISSUER: PART NUMBER DESCRIPTION ITAIPU CODE PAGE 4 REVISION - INSPECTION AND TEST PLAN AT 3 REFERENCE DOCUMENTS NUMBER 4 APPLICABLE STANDARDS 4.1 NATIONAL / INTERNATIONAL STANDARDS NUMBER 4.2 DOCUMENT DESCRIPTION BRAZILIAN REGULATORY STANDARDS NUMBER 5 DOCUMENT DESCRIPTION DOCUMENT DESCRIPTION TEST REQUIREMENTS Not applicable INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 5 REVISION - INSPECTION AND TEST PLAN AT 6 CAPTION ITEM H1 INSPECTION CLASS H2 F NA A REPRESENTATIVES LEVEL OF PARTICIPATION IN THE INSPECTION B ITEM DESCRIPTION CUSTOMER TESTIMONY POINT – INSPEÇÃO CLASS 1 THE NOTIFICATION FOR INSPECTION IS MANDATORY AND MUST BE ISSUED BY THE CMI TO ITAIPU. CUSTOMER WITNESS POINT – INSPEÇÃO CLASS 2 THE NOTIFICATION FOR INSPECTION IS MANDATORY AND MUST BE ISSUED BY THE CMITO ITAIPU. INSPEC O INTERNALMANUFACTURER NO NOTIFICATIONFOR INFORMATION IS REQUIRED. NOTAPPLICABLE NO NOTIFICATIONFOR INFORMATION IS REQUIRED. MANUFACTURER AND/OR SUPPLIER EXECUTE - RESPONSIBLE FOR PERFORMING THE INSPECTION. CMI AND/OR REPRESENTATIVES TESTIFY - RESPONSIBLE FOR WITNESSING THE INSPECTION. C CMI AND/OR ITAIPU REPRESENTATIVES AND/OR REPRESENTATIVES TESTIFYING - RESPONSIBLEFOR WITNESSING THE INSPETION. RC DECLARATION OF CONFORMITY OR CERTIFICATE OF CONFORMITY RI TEST REPORT OR CERTIFICATE OF INSPECTION OR INSPECTION RECORD RF PHOTO REPORT NA NOT APPLICABLE ISSUANCE OF INSPECTION DOCUMENT RECORD TYPE 2.1 2.2 REGISTRY CLASSIFICATION 3.1 3.2 % DEGREE OF INSPECTION LT CO INSPECTION AND TESTING PLAN CODE OF THE ISSUER: TYPE 2.1 – DECLARATION OF CONFORMITY REGISTRATION OF PRODUCT CONFORMITY WITHOUT INCLUSION OF TEST RESULTS, AND THE VALIDATION OF THE INSPECTION RECORD, CARRIED OUT BY THE MANUFACTURER OR SUBSUPPLIER. TYPE 2.2 – TEST REPORT REGISTRATION OF PRODUCT CONFORMITY WITH THE INCLUSION OF TEST RESULTS, BASED ON A NON-SPECIFIC INSPECTION, I.E. INSPECTION CARRIED OUT BY THE MANUFACTURER ACCORDING TO ITS OWN PROCEDURES, IN ORDER TO ASSESS WHETHER OR NOT THE PRODUCTS DEFINED BY THE SAME PRODUCT SPECIFICATION AND RESULTING FROM THE SAME PRODUCTION PROCESS SATISFY THE REQUIREMENTS OF THE ORDER, BEING VALIDATION OF THE INSPECTION RECORD, CARRIED OUT BY THE MANUFACTURER OR SUB-SUPPLIER. TYPE 3.1 – CERTIFICATE OF INSPECTION OR INSPECTION RECORD REGISTRATION OF PRODUCT CONFORMITY WITH THE INCLUSION OF TEST RESULTS, BASED ON A SPECIFIC INSPECTION, THAT IS, INSPECTION CARRIED OUT BY THE MANUFACTURER ACCORDING TO THE SPECIFICATIONS OF THE PRODUCT STANDARD OR THE SPECIFICATIONS DEFINED FOR THE ORDER, BEING VALIDATION OF THE REGISTRATION MADE BY THE AUTHORIZED INSPECTION REPRESENTATIVE OF THE MANUFACTURER, INDEPENDENT OF THE MANUFACTURER'S DEPARTMENT OR SUB-SUPPLIER. TYPE 3.2 – CERTIFICATE OF INSPECTION OR INSPECTION RECORD REGISTRATION OF PRODUCT CONFORMITY WITH THE INCLUSION OF TEST RESULTS, BASED ON A SPECIFIC INSPECTION, THAT IS, INSPECTION CARRIED OUT BY THE MANUFACTURER IN ACCORDANCE WITH THE SPECIFICATIONS OF THE PRODUCT STANDARD OR THE SPECIFICATIONS DEFINED FOR THE ORDER, BEING VALIDATION OF THE REGISTRATION MADE BY THE AUTHORIZED INSPECTION REPRESENTATIVE OF THE MANUFACTURER, BELONGING TO AN INDEPENDENT AREA OF PRODUCTION OR BY AN INSPECTOR DESIGNATED BY THE BODY THAT ACCOMPANIED THE RESPECTIVE INSPECTION. SAMPLING (%) - INDICATES THAT THE DEGREE OF INSPECTION ADOPTED SHOULD BE SAMPLING, BEING INDICATED TO THE SAMPLING APPLIED FOR THE EXECUTION OF THE INSPECTION. LOT - INDICATES THAT THE DEGREE OF INSPECTION ADOPTED SHOULD BE BATCH INSPECTION. IF APPLICABLE, INDICATE THE NUMBER OF LOT(S) TO BE INSPECTED, WHICH IS INDICATED IN THE REMARKS FIELD OF ITEM 7 AND 8. RACE - INDICATES THAT THE DEGREE OF INSPECTION ADOPTED SHOULD BE INSPECTION BY RACE. IF APPLICABLE, INDICATE THE NUMBER OF THE RACE(S) TO BE INSPECTED, WHICH IS INDICATED IN THE REMARKS FIELD OF ITEM 7 AND 8. ITAIPU CODE PAGE 6 REVISION - INSPECTION AND TEST PLAN AT NA INSPECTION AND TESTING PLAN CODE OF THE ISSUER: NOT APPLICABLE - INDICATES DEGREE OF INSPECTION NOT APPLICABLE. THIS TYPE OF INSPECTION DEGREE SHOULD BE ADOPTED FOR DOCUMENTATION VERIFICATION. ITAIPU CODE PAGE 7 REVISION - INSPECTION AND TEST PLAN AT 7 PREPARATORY DOCUMENTATION 7.1 ANALYSIS OF PROCEDURES, QUALIFICATIONS AND CERTIFICATIONS REQUIRED ITEM DESCRIPTION OF THE INSPECTION TYPE DA INSPECTION ACTION / REGISTRATION 1 2 3 4 5 ACCEPTANCE CRITERIA APPLICABLE DOCUMENTS OBSERVATIONS INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 8 REVISION - INSPECTION AND TEST PLAN AT 8 RAW MATERIAL & COMPONENTS ITEM DESCRIPTION OF THE INSPECTION TYPE DA INSPECTION ACTION / REGISTRATION 1 2 3 4 5 ACCEPTANCE CRITERIA APPLICABLE DOCUMENTS OBSERVATIONS INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 9 REVISION - INSPECTION AND TEST PLAN AT 9 MANUFACTURING PROCESS ITEM DESCRIPTION OF THE INSPECTION TYPE DA INSPECTION ACTION / REGISTRATION 1 2 3 4 5 ACCEPTANCE CRITERIA APPLICABLE DOCUMENTS OBSERVATIONS INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 10 REVISION - INSPECTION AND TEST PLAN AT 10 FACTORY ACCEPTANCE TEST (FAT) ITEM DESCRIPTION OF THE INSPECTION TYPE DA INSPECTION ACTION / REGISTRATION 1 2 3 4 5 ACCEPTANCE CRITERIA APPLICABLE DOCUMENTS OBSERVATIONS INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 11 REVISION - INSPECTION AND TEST PLAN AT 10.1 ACCEPTANCE CRITERIA – TABLES (WHERE APPLICABLE) TABLE 1 TABLE 3 TABLE 2 TABLE 4 INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 12 REVISION - INSPECTION AND TEST PLAN AT 11 FINAL DOCUMENTATION (DATA BOOK) ITEM DESCRIPTION OF THE INSPECTION ACTION / REGISTRATION TYPE DA INSPECTION 1 2 3 4 5 ACCEPTANCE CRITERIA APPLICABLE DOCUMENTS OBSERVATIONS ALL RECORDS DEFINED IN THE INSPECTIONAND TESTING PLAN, AS WELL AS ALL INTERNAL CONTROLS OF THE MANUFACTURER OF THE COMPONENTS CONTAINED IN BATCH 1 – CABLING MUST BE CONTAINED IN THE MANUFACTURING DATA BOOK. THE DRAWINGS RELEVANT TO THE EQUIPMENT AND THECALIBRATION CERTIFICATES OF THE INSTRUMENTS USED IN THE INSPETSHALL BE CONTAINED IN THE DATABOOK. IN THE RELEASEOF THE EQUIPMENT, THE DATA BOOK MUST BE MADE AVAILABLE TO THE CMI THROUGH ITS REPRESENTATIVES (PARTNERS, SUPPLIERS AND/OR SUB-SUPPLIERS) TO MAKEACONEX ACONEX AVAILABLE. 6047-43-T0214-P – QUALITY MANAGEMENT PLAN; 12 PACKAGING AND SHIPPING ITEM DESCRIPTION OF THE INSPECTION TYPE DA INSPECTION ACTION / REGISTRATION 1 2 3 4 5 ACCEPTANCE CRITERIA APPLICABLE DOCUMENTS OBSERVATIONS INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 13 REVISION - INSPECTION AND TEST PLAN AT 13 ATTACHMENTS 6983-PIT-T0454-P - TECHNOLOGICAL UPDATE - PAT_OBJ1 - RTA - AUTOMATION TECHNOLOGY NETWORK AND COMMUNICATION SYSTEMS - LOT I - CABLING - DATAWAVE - TEST PROCEDURE; 6983-81-T0455-P - TECHNOLOGICAL UPDATE - PAT_OBJ1 - RTA - AUTOMATION TECHNOLOGY NETWORK AND COMMUNICATION SYSTEMS - LOT I - CABLING - TECHNICAL SPECIFICATIONS MANUFACTURER; 6983-50-T0456-P - TECHNOLOGICAL UPDATE - PAT_OBJ1 - RTA - AUTOMATION TECHNOLOGY NETWORK AND COMMUNICATION SYSTEMS - LOT I - CABLING - TYPE TEST REPORT. 14 GENERAL CONSIDERATIONS (A) INSPECTIONS WITH ITAIPU TESTIMONY To carry out the inspections with testimony of ITAIPU, the inspector must inspect the manufacture of the equipment, in accordance with the following items (Item 10.7.2.4 of document 6047-43-T0214-P – QUALITY MANAGEMENT PLAN): Approval of the inspection plan, tests and initial evaluation of the control and quality system; Periodic checks of manufacturing procedures for effective confirmation of application; Inspection of the supply and/or verification of the inspection records meeting at least: Adequacy of the raw materials with the standards and specifications indicated in the Technical Specifications; adequacy of the parts and assembly manufactured with the Technical Specifications, approved drawings, contract standards and good engineering practice and periodic inspection of the project and production and the preparation of the respective reports; To call for inspection, consider: Inspections under MERCOSUR For inspection within the scope of MERCOSUR, the call must be made at least 15 (fifteen) calendar days in advance, to the first event subject to inspection – Firm date. Inspections outside MERCOSUR For inspection outside MERCOSUR, the call must be made at least 60 (sixty) calendar days in advance, to the first event subject to inspection – Firm date. Inspection reprogramming If inspection is not possible on the scheduled date, ITAIPU must be notified at least 7 (seven) calendar days in advance for supply under MERCOSUR and twenty (20) calendar days for material from other countries. In the absence of compliance with this requirement, any costs of cancellation or rebooking of tickets must be reimbursed by CMI under the responsibility of the representatives (partners, suppliers and / or sub-suppliers), as well as the costs of re-inspection. (B) NON-COMPLIANCE The issuance of Non-Compliance Records may occur more frequently in situations where there is verification of activities performed or verification of products delivered by CMI in the following stage of the enterprise: Factory Acceptance Test – (TAF of systems, equipment or materials), carried out in various locations, and may be in the factory or in the laboratory for this purpose. Nonconformities may be issued for non-observance of non-compliance, according to the table: Non-Conformities, During: Reference in the Technical Specification or Workstatement Factory Inspection (*) Established Requirements Reference in Design Criteria References in the Executive Project ETAPA reference document Established Criteria for Manufacturing Executive Manufacturing Project and other documents,... Inspection and Test Plan (*) For nonconformities identified in the factory inspection process, their resolution is usually less costly than those identified in other steps given the greater availability of resources to be applied to your solution. Also in relation to the subject, the procedure established for the factory inspection prevents the release of equipment or system with any noncompliance observed (Item 10.12 of document 6047-43-T0214-P – QUALITY MANAGEMENT PLAN); INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 14 REVISION - INSPECTION AND TEST PLAN AT (C) DOCUMENTATION LANGUAGE All documents must be submitted in the Portuguese language or Spanish and there must be standardization within the same system. The English language must be exceptionally accepted for catalogs, certificates and test reports if they are not issued in Portuguese or Spanish (Item 10.7.1 of document 6047-43-T0214-P – QUALITY MANAGEMENT PLAN); (D) INSPECTION PROCESSES At any time, CMI and ITAIPU reserve the right to inspect any intermediate stage of the manufacturing process, and may have access to all reports and test results, relating to quality control and inspection of materials, assembly of components and auxiliary equipment that are part of the supply, even if the dates of the tests and verifications in intermediate stages, do not coincide with the dates provided in the manufacturing and delivery schedule. In the need for re-inspection on previously rejected materials or equipment, CMI and ITAIPU may require special tests related to non-compliance, at no additional cost to CMI and ITAIPU. (E) CALIBRATION, MEASUREMENT AND TESTING EQUIPMENT/INSTRUMENTS All calibration, measurement and testing equipment/instruments used in the manufacturing process must be calibrated by accredited laboratories and with their respective certificates within the validity periods of the date of inspection and these must be contained in the DATA BOOK. INSPECTION AND TESTING PLAN CODE OF THE ISSUER: ITAIPU CODE PAGE 15 REVISION