IEEE JOURN.4L OF SOLID-ST.iTE CIRCUITS, VOL.

2456

[5’1

[61

[71

switching delays using CMOS/

in 1971 Int. Solid-State

Circuit Conj., Dig. Tech. Papers, p. 225,

E. J. Boleliy and J. E. Meyer, “High-performance

low-power

CMOS

memories

using

silicon-on-sapphire

technology,”

IEEE

J. Solid-State

Circuits

(Special

Issue on Micropower

Electronics),

vol. SC-7, pp. 135-145, Apr. 1972.

R. W. Bower, H. G. Dill, K. G. Aubuchon, and S. A. Thompson, ‘[MOS field effect transistors by gate masked ion implantation,”

IEEE

!t’’rams. Electron

Devices,

vol. ED-15, pp.

757-761, Oct. 1968.

J. Tihanyi,

“Complementary

ESFI MOS devices with gate

self adjustment

by ion implantation,”

in Proc. 5,th Iwt. Conj.

Microelectronics

in Munich,

Nov.

27–29, 1972. MunchenWien, Germany:

R. Oldenbourg

Verlag, pp. 437447.

E. J. Boleky,

“The performance

of complementary

MOS

transistors on insulating

substrates,” RCA Rev., vol. 80, pp.

372-395,

5>

OCTOBER 1974

1970.

formation

in an insulated

gate field

[81 K. Goser, ‘[Channel

effect transistor ( IGFET)

and its emrivalent circuit .“ Sienzen.s

Forschungsund Entwiclclungsbekhte,

no. 1, pp.’ 3-9, 1971.

“Accurate

metallization

[91 A. E. Ruehli and P, A. Brennan,

capacitances for integrated

circuits and packages,” IEEE

J.

Solid-State

Circwits

(Corresp.), vol. SC-8, pp. 289-290, Aug.

1973.

(Siemens

Netzwerk

Analyse

Programm

Paket),

[101 SINAP

Siemens AG, Munich, Germany.

‘[Aufteilung

der Gate-Kanal[111 K, Goser and K. Steinhubl,

Design

H.

DENNARD,

RIDEOUT,

Michael Pomper,

238 of this issue.

Jeno Tlhanyi,

for

238 of this issue.

of Ion-Implanted

Very

ROBERT

NO.

Kapazitat

auf Source und Drain im Ersatzschaltbild

eines

und Ent wicldwrgsMOS-Transistors,”

Siemenx Forxchungsberichte

1, no. 3$ pp. X4-286, 1972.

[121 J. R. Burns, “Switching

response of complementary+symmetry MOS transistors logic circuits,”

RCA

Rev.,

vol. 25,

pp. 627481, 1964.

[131 R. w. Ahrons and P. D. Gardner, ‘[Introduction

of technology and performance

in complementary

symmetry

circuits,” IEEE

J. Solid-State

Circuits

(Special Issue on Technology

jor Integrated-Circuit

Design),

vol. SC-5, pp. 24–29,

Feb. 1970.

[141 F. F. Fang and H. Rupprecht,

“High performance

MOS integrated

circuits

using ion implantation

technique,”

presented at the 1973 ESSDERC,

Munich,

Germany,

[31 E. J. Boleky, ‘%ubnanosecond

SOS silicon-gate

technology,”

[41

SC-9,

Small

H.

Absfracf—This

paper considers

the design, fabrication,

and

characterization

of very small MOSI?ET switching devices suitable

for digital integrated

circuits using dimensions

of the order of 1 p.

Scaling relationships

are presented which show how a conventional

MOSFET

can be reduced in size. An improved small device structure is presented

that uses ion implantation

to provide shallow

source and drain regions and a nonuniform

substrate doping profile. One-dimensional

models are used to predict the substrate

doping profile

and the corresponding

threshold

voltage versus

source voltage characteristic.

A two-dimensional

current transport

model is used to predict the relative degree of short-channel

effects

for different

device parameter

combinations.

Polysilicon-gate

MOSFET’S

with channel lengths as short as 0.5 ~ were fabricated,

and the device characteristics

measured and compared with predicted values. The performance

improvement

expected from using

these very small devices in highly miniaturized

integrated

circuits

is projected.

Manuscript

received May 20, 1974; revised July 3, 1974.

The aubhors are with the IBM T. J. Watson Research Center,

Yorktown

Heights, N.Y. 10598.

and

please see p.

biogra~hy,

please

see p.

with

Dimensions

GAENSSLEN,

BASSOUS,

a photograph

and biography,

MOSFET’S

Physical

LIEMBER, IEEE, FRITZ

MEMBER) IEEE, ERNEST

for a photograph

AND ANDRE

HWA-NIEN

YU,

R. LEBLANC,

LIST

MEMBER, IEEE, V. LEO

MEMBER, IEEE

OF SYMBOLS

a

Inverse

D

threshold characteristic.

Width of idealized step function

semilogarithmic

slope of subpro-

fde for chaDnel implant.

AW,

Work

function

difference

and substrate.

Dielectric

constants

for

between

gate

silicon

and

silicon dioxide.

Drain current.

Boltzmann’s

Unitless

constant.

scaling

constant.

MOSFET

Effective

channel length.

surface mobility.

Intrinsic

carrier

concentration.

Substrate acceptor concentration.

Band bending in silicon at the onset of

strong

voltage.

inversion

for zero substrate

et al. : ION-IMPLANTED

DENN.4m

MOSFET’S

257

*,

Built-in

(1

Charge

Q.,,

Effective

t ox

Gate oxide thickness.

T

Vd, v,, v.,

junction

potential.

oxide charge.

Absolute

VaubDrain,

Vd.

V,-.”b

v,

w.,Wd

Source

w

MOSFET

Source

temperature.

relative

voltage

depletion

layer

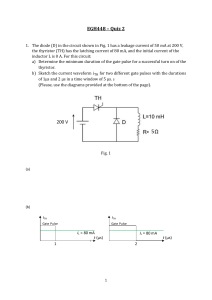

Fig. 1. Illustration

of device scaling principles

with K = 5. (a)

Conventional

commercially

available

device

structure.

(b)

Scaled-down device structure.

relatively

forming

over

the

monly

a decrease

optical

used

new

contact

in

the

techniques,

widely

used

while

ing

for

X-ray

[6]

Full

realization

of

tion

lithographic

new

device

be

the

of

order

leads

These

undesirable

large

the

portion

gate

is

the

For

these

short-channel

down

the

source

ess,

junction

dimensions,

in

device

drain

can

(e.g.,

etc. )

also

an

characteristics.

depletion

along

over

the

most

a reduction

in

turns

a

under

on,

the

which

has

been

shown

be avoided

by

scaling

gate

with

insulator

the

thicknhorizontal

decreasing

the substrate

the

doping

con-

paper

small

device

for very small

all-implanted

a simple

centration

MOSFET’S.

of doping

profile in the channel

creased in a controlled

atoms

allows

First,

introduce

strate

structure

sensitivity

the substrate

con-

doping

region under the gate to be inmanner. When combined with a

reduced

or drain-

the scaling

principles

MOSFET

to obtain

capable

of improved

of the

per-

scaling

are based on two analytical

model

that

predicts

for long channel-length

two-dimensional

current-transport

the device turn-on

ap-

The predicted

compared

;vith

mensional

simulation,

experimental

the

that

from

both

data.

of chan-

analyses

Using

sensitivity

the

of

and a

predicts

as a function

results

tools:

the sub-

devices,

model

characteristics

nel length,

the

are

two-di-

design

to

Yarious parameters

is shown. Then, detailed attention

is

design,intendedfor zero substrate

givcll to all alternate

which

offers

of the

some

advantages

The

concise

circuits

in

principles

dccreming

lIOSFET

the-art

of

manner

the

the

switching

n-channel

with

the paper

that

device

general

size

respect

concludes

improvements

DEVICE

the ability

a low

thresh-

has significantly

(e.g., drain-to-gate

one-dimensional

from integrated

to accurately

a

proach is then presented. Next, the fabrication

process

for an improved

scaled-down

device structure

using ion

implantation

is described. Design considerations

for this

of this paper is to show how

leads to an improved

design

scaled-down

gives

verification

performance

of ion implantation

main-

combination

a thicker

Experimental

sion

A major consideration

the use of ion implantation

The

with

structure

a 200-A

is to be reduced to 1 ~.

favor-

while

design

to a conventional

Finally,

length

of very

are more

effects,

begins by describing

are applied

old control.

if the channel

formation

which

all-implanted

capacitances

bins,

is required

which

and reliably.

can be fabricated

and which

[7],

[8].

Applying

this scaling approach to a

centration

properly designed conventional-size

MOSFET

shows that

gate insulator

bias.

be traded

capacitances).

formance.

FET

substrate

It

proportionately

and increasing

a very

the

is

This

the

regions

an

voltage

thickness

sheet resistance.

in

channel

if desired, which has well-controlled

to-substrate

source-

of

of 350-A

reproducibly

allows

device which

old characteristics,

char-

can then

to short-channel

features

gate insulator

the

extend

device

these

which

drain

voltages.

effects

of

devices

applications,

the

respect

an acceptable

dimensions

when

silicon

effect

depth,

voltages

the

the

dimensions

while

length)

and

at which

high

vertical

reducing

switching

voltage

by

applied

in

“short-channel”

threshold

aggravated

that

that

channel

region

electrode.

using

significant

the

of

undesirable

the

become

surrounding

gate

is known

with

implantation

interelectrode

switching

circuits

ion

switching

which

and

gate insulator

source and drain

this

(“backdate”)

sensitivity”

shallow

of

high-resolu-

development

“substrate

Second,

taining

print-

fabrication,

MOSFET

changes

changes

regions

[1] – [4]

structures

reduced

able

dimensions.

integrated

(i.e.,

new

the

design,

small

the

capability.

these

substrate,

of the threshold

tends to be easier to fabricate

been

projection

and

small

the

1 p. It

has

starting

the sensitivity

off for a thicker

times

Of

writing

requires

very

very

spacing

to

of

This

is com-

fabrication

technologies,

digital

of

today.

optical

benefits

concerns

for

to-drain

the

for

paper

which

high-resolution

techniques

acterization

of

and

for

ten

doped

reduces

to changes in the source-to-substrate

patterns

to

industry

pattern

exhibited

designs,

optimized

suitable

[5]

five

approach

device

lithography

also

This

beam

circuit

of

masking

experimental

have

can

linewidth

semiconductor

electron

techniques

integrated

in

lightly

implant

lithographic

semiconductor

offer

(b)

width.

INTRODUCTION

N

N~=25x10’6/cm

a

(a)

widths.

resolution

_-

-

NA=5 x 10’5/cm3

to substrate.

voltage.

drain

channel

=.

~N+o

.___,

to source.

relative

and

&*200A

-OILhp

‘+

5P

L’l

volt-

a

Gate threshold

HIGH

GATE

:N+

___,

1,

/l

/L\

‘+

--0

source, gate and substrate

ages.

Drain voltage

EW

tox=loooh

GATE ~

on the electron.

and

devices.

lllOSFET

to thresh-

with

to

use these very

a discus-

be expected

small

FET’s.

SCALING

scaling

design

increasing

Fig.

[9]

[7],

[8]

trends

to

the

in

a

a

followed

performance

1 compares

with

show

be

a state-ofscaled-down

of

258

IEEE

clevice

be

clesignecl

described

1 (a)

following

later.

is reasonably

vices

It

by

uses

substrate

voltage

sensitivity.

tant

criterion

source

thethreshold

digital

because

voltage

the

rameters

mum

give

bias. It would

a

and (2) prevent

mately

of 5 X 10’5

increased

value

of sub-

is an imporemploying

difficult

if

a factor

of

increases

by more than

illustrated

in Fig.

the channel

length

arises primarily

plied

the penetration

of approximately

modify

of the

12-15 V this pene-

the surface potential

lower the threshold

In

order

values

the potential

three

all

variables:

linear

faCtOr

dimension,

clirnensions

K, e.g.,

refer

to

new

il~cludes vertical

ness, junction

scaled-down

dimensions

(i.e., Na’

a

device,

length

=

~Na).

The

obtained

using

reduction

in channel

The scaling

parameters

example,

thickdi-

Second, the voltdoping

concen-

the same scaling

in Fig.

corresponds

factor

1 (b’) was

to the desired

length to 1 p,.

were developed

by observing

that the depletion layer widths in the scaled-down

device

arc reducecl in proportion

to the device climensions due to

the reducecl potentials

ancl the increased doping. For example,

w,’

The

{[2cs,(V~’

threshold

voltage

in clirect pro~ortion

that the clcvicc will

reducecl

voltage

voltage

equation

V,’

=

V,-,,,JK)l/CIKN.

+

at turn-on

(1)

}”2 m w,/Ic.

[9]

is also decreased

to the reduced device voltages

so

function

properly

in a circuit with

levels.

This

is shown

for the scaled-down

(tO=/KCOf) { –Q,.,,

+

across the source

by the threshold

device.

[~~,,~K~a(+s’

+

region

that

the MOSFET

due to the

h] (.V.’/n,

or drain

under

).

tOx/K-

w/K

V,

L/ii

—

–

equation

~7t –

K

—

)

by a, factor

of

assuming

no

is reduced

slightly

applied

voltages,

Actually,

the mobility

impurity

scattering

electric

field

of

field

given

(Vet/K)

by

=

(3)

Id/K

for any given

K,

in

set

mobility.

clue to increased

doped substrate.

the scaling

patterns

distribution

[9]

change

in the heavier

to generalize

clevice

above. For

vd/~

is seen to be reduced

electric

junctions,

the gate, can be re-

clescribe the MOSFET

current

(–)(

P,,,e..

and

approach

current

is maintained

to in-

clensity.

in the

The

scaled-

clown device except for a change in scale for the spatial

coordinates.

Furthermore,

the electric field strength

at

any

corresponding

V’/x’.

Thus,

changed

locity

is un?hanged

velocity

due to scaling

effects

will

From

hence,

any

in both

fixed

current

by scaling,

saturation

per unit

ve-

neglecting

crystal

lattice

is reduced

of channel

This is consistent

=

is also un-

devices,

due to the

V/c

because

at any point

(3), since the clevice current

channel

K, the

is unchanged

and,

be similar

cliff erences

dimensions,

by

point

the carrier

microscopic

width

with

IV

the same

sheet density of carriers (i.e., electrons per unit gate area)

moving at the same velocity.

In the vicinity

of the clrain,

the carriers

extent

=

slightly

(2kT/q)

may be scaled as demonstrated

~,_

clude

reduction

increasing

in (1)

approxi-

K.

It is possible

by the same factor

clesign shown

relationships

drop

characteristics

scaling

as the horizontal

the substrate

using

5 which

K =

First,

unitless

This

and width.

Third,

agnin

in

such as gate insulator

to the device are reduced

(e.g., V~S’ = Vd,,/K).

tration

is increased,

smaller

doping.

the primed

etc., as well

of channel

ages applied

by

where

for

a transformation

and

reduced

&’K,

depth,

by

voltage,

are

t,ox’ =

the

mensions

scaled

suitable

appearing

since they rcxnain

=

poten-

V,,,,,) /K. Thus,

by scaling clown the apbias more than the other applied voltages,

All of the equations

and significantly

voltage.

to clesigl~ a new device

L, the device is

of

(~,, +

substrate

d

will

actually

CIUCeC{

by

pa-

1974

for zero substrate

the *’ terms

eloping since ~0’ @ *,’

1 (a),

region surrounding

the clrain into the area

controlled

by the gate electrode. For a maxi-

ch-ain voltage

tration

that

or across the depletion

design

OCTOBER

(i.e., the surface

inversion

exact scaling

of the source voltage.

the

CIRCUITS,

However,

the fixed substrate bias supply normally

used

with n-channel

devices can be adjusted

so that (~,,’ +

L to about, 5 p. This

from

appear

constant,

V,,,,; ) =

circuits

becomes

in the silicon

at the onset of strong

a

switching

limit

depletion

normally

to

is the band bencling

tial)

the design

clevice

restriction

with

OF SOLIC)-STATE

p-type

substrates)

the work function

difference

A~Vf is

of opposite sign, ancl approximately

cancels out *,J. ~.’

2 V relative

doping

sensitivity

two o~er the full range of variation

For

chosen

to give an acceptable

in

followers

detech-

thickness

bias

The substrate

Fig.

diffusion

insulator

A substrate

to

in

a~ailable

conventional

I:r of approximately

to the source potential.

cm-3 is low enough

principles

shown

of commercially

using

ancl substrate

doping

scaling

structure

a 1OOO-A gate

gate threshold

strate

device

larger

typical

fahricatecl

niques.

the

The

JOURFJ.iL

Thus,

will

move away

in the new device,

the clensity

bc higher

from

the surface

to a lesser

due to the shallower

of mobile

carriers

in the space-charge

per unit

region

complementing

the higher density

clue to the heavier doped substrate,

cliffusions.

volume

around

the

will

drain,

of immobile

charge

Other scaling rela-

tionships

in Table

for power density, delay time, etc., are given

I ancl will be discussed in a subsequent section

on circuit

performance.

In order to verify

Vs-s,,,/K)]’”}

the scaling

relationships,

two sets of

experimental

+

In

(2)

creased

the reduction

insulator

the voltage

cases of interest

opposite

to that

+

~.’)

in Tt is primarily

thickness,

and doping

(AJVf

tOx/K,

while

due to the de-

devices

were fabricated

with gate insulators

o

of 1000 ancl 200 A (i. e., K = 5). The measured drain voltage

characteristics

of these devices, normalized

to W/L = 1,

the

are

=

V,/K.

(~)

changes

in

terms tend to cancel out, In most

(i.e., polysilicon

of the substrate

gates of doping

or aluminum

type

gates on

shown

quite

of

the

confirms

in

similar

smaller

the

Fig.

when

~

9.

clevice

scaling

The

plotted

tin-o

sets

with

voltage

reduced

predictions.

by

of

characteristics

and

a factor

In

Fig.

current

of

2,

five,

the

are

scales

which

exact

DENNARD et at. : ION-IMPbiNTED

MOSFET’S

259

1,5~

GATEVOLTAGE [V]

20

tox=100ox

10-

L

*w=5p

v~ub=-?v

+= sO.65V

0.5-

5

Q

0

5

15

10

20

DRAINVOLTAGE[V]

(a)

GATE VOLTAGE[v]

0.3

0.2

3

.

0 IF

+ ~

o

0

I

2

3

4

DRAIN VOLTAGE[v]

(b)

Expcrimentzd

drain voltage characteristics

ventional,

and (b) scaled-down structures shown

malized to W/L = 1.

Fig.

for (a) conin Fig. 1 nor-

2.

drain

3.5

voltage

is large

charact cristics

=10001!

=5V

tox

3.0

‘ds

When

linear

VSu~=-7V

2.5

the

to cause pinchoff

expected

linear

and the

relationship,

proj ccted to intcrccpt

the gate voltage axis this

relationship

defines a threshold

voltage useful for

most logic circuit

1#, =0,65V

fid

enough

exhibit

design purposes.

Onc area in which the dcvicc characteristics

fail to scale

is in the subthrcshold

pr weak inversion

region of the

2,o

[#A] ’’2,,5

turn-on

characteristic.

dependent

1.0

B@ow threshold,

on V, with

a, [10], [11] which

an inverse

1,, is exponentially

scmilogarithrnic

for the scaled-down

slopc,

device is given

by

0.5

,

(

4

.8

1,2

flv,’

volts

a ()dccadc

1.6

= d log,, 1,,’

GATE VOLTAGE[V]

Fig. 3. Experimental

turn-on

characteristics

for conventional

and scaled-down devices shown in Fig. 1 normalized

to W/L

= 1.

match

on

the

current

since

there

is some

tude

of the

channel

istics

(see

with

width

an

approximate

shows

for

dcviccs

with

threshold

five

~~

and

voltage

is

verified

versus

the

length

Appendix).

larger

scale

L1orc

and

Icngth

the

heavier

in

scaled-down

Fig.

accurate

which

of ten

doped

from

the

SIIOJVS

tllc

for

the

cases

‘(on”

a

the

factor

of

cxpcrirncntal

the

larger

clcvice.

[ 12]

and

shi~)

of

room

the

This

istic

thereby

In

The

to

and

particular

the

above,

concern

of

to

cause

mobility

current

scaling

rclation-

devices

for

does

the

lT70uld

surface

one

behavior

property

but this

effective

design

the linear

reduce the operating

~/K),

the

invalidate

subthreshold

nonscaling

is of

in

order

temperature

the

(i.e., T’ =

increase

(3).

to also extend

to ~ one could

in (4)

<% significant,

that

original

Shon-nj

( 11]. In an attempt

relationships

temperature

chip

in mobility

That

state

scaling

dcviccs

same

pcrccnt

by

magni-

character-

substrate.

correctly

For

the

is the same as for the original

lJaramctcr

~ is important

to dynamic

memory

circuits

because it determines the gate voltage excursion rcq~lired

to go froln tile low Current “off” state to the high current

fortuitous

in the

on

characteristics

devices.

be

data

dimensions

scales

3,

to

to normalize

reduction

turn-on

thought

uncertainty

used

also

~T.

is

experimental

which

must

not

accept

scale’

subthreshold

Ininiaturc

operation

the,

at

fact

as desired.

character-

dynamic

menl-

IEEE

260

t~*

JOURNAL

OF SOLID-STATE

under

the gate electrode

drain

are then

and

drain

extend

(a)

With

would

tend

would

cause

to

by the

merge

punchthrough

lower

\

I

1

V,,,=

at

junctions

tern

which

in

high

avoids

1974

further

the

into

these

lighter

doped

doped

chosen

which

in the

extreme,

However,

the

electric

field

favorable

when

regions

material

or,

voltages.

effects

is properly

the

control

drain

and

surface

these depletion

lighter

a more

doped

4(b),

for the case of a

regions under the source

of threshold

give

concentration

-Iv

much

heavier

deeper junctions

a loss

OCTOBER

at the edges of the source

inhibited

layer, roughly

pictured

in Fig.

turned-off

device. The depletion

substrate.

CIRCUITS,

the

shal-

substrate

patdoping

when it is not too

(i.e.,

light),

The

device

planted

width

[cf.

)

gives

-..

“.-.

circuits

which

require

low

source-to-drain

Fig.

scaling

In’

with

contrast,

just

presented

a l-,P channel

the

the

capability

shown

in Fig.

4 (b).

initial

substrate

corresponding

afforded

The

doping

length

shown in Fig.

improved

is lower

process

study

mask

process

n-channel

when the device

the

is turned

surface

on with

on the device.

sensitivity

With

this

doped

region

depletion

layer

the source grounded.

the gate insulator

to as much ‘as 350A

improvement

thickness

and still

maintain

low

implanted

implanted

n+ regions

p-type

surface

of depth

layer.

The

in substrate

gate

Though

the eventual

depletion

drain

design

in

device

channel

MOS~ET’s

for the

ion-implanted

MOS-

now be described.

to

fabricate

on

a test

lengths

A four-

polysilicon-gate,

chip

ranging

which

from

contains

0.5 to 10 p.

aim is to use electron-beam

For

this

to

the

regions

purpose

for the gate pattern

which

are

7.5 x 1015cm-’).

isolation

in

ing

dry

pattern

silicon

After

x

FET’s

growth

of the

about

for the thick

here, and be-

are available.

gate

The

(i.e.,

is not described

presented

techniques

only

as 1.5 p

processing.

2 CI. cm

of fabrication

to the work

surface.

All

oxide,

the channel

implantations

in order

Follow-

low

Next,

energy

oxide

n“ source

layer.

performed

diffusion

a 3500-A

thick

of

poly -

doped n’, and the gate regions

and

drain

by a high energy

10’5 atoms/cm’)

same 350-A

were

to restrict

implantation,

layer was deposited,

deep were formed

(4

was

adj scent

after gate oxide growth

the implanted

regions.

silicon

subsequent

The method

suitable

is required

as small

B“ ions were

low dose (6.7 x 101’ atoms/cmz)

into the wafers, raising the boron doping near

(40 keV),

implanted

the

the

between

thermal

resolution

uses lines

resistivity

as it is not essential

cause several

high

which

reduced

substrate

delineated.

is to use shal-

comparable

for maximum

will

used

with

can be increased

a reasonable

threshold

voltage as will be shown later.

Another aspect of the design philosophy

gate field,

ment.

Thus, when the source is biased above ground potential,

the depletion’ layer will extend deeper into the lighter

doped substrate,

and the additional

exposed “bulk”

charge will be reasonably

small and will cause only a

modest increase in the gate-to-source

voltage required to

turn

was

MOSFET’s

devices

oxide

within

performance

gate oxide and the expected

ION-IMPLANTED

fabrication

face layer

be completely

OF

used in this

starting

heavier

the

to 3 V for the sc-sled-down

FET’s

used throughout

the unimplanted

structure

of Fig. 4(a).

The concentration

and the depth of the implanted

surthis

but

a design objective

compared

the

also

uses an

is

of four, and an implanted

boron surface layer having a

con’eentration

somewhat

greater than the concentration

are chosen so that

over

a factor

device

by about

gate

gate insulator

exposure, it was more convenient

to use contact masking with high quality

master masks for process develop-

by ion implantation

ion-implanted

that

design

capacitance,

for the thicker

FABRICATION

lead to the

polysilicon

The thicker

of Fig. 4(a).

leakage

DEVICE DESIGN

considerations

device structure

utilizing

gate

increase,

4(b),

The

ION-IMPLANTED

the

was set at 4 V for the ion-implanted

voltage

cross sections for (a) scaled-down device struccorresponding

ion-implanted

device structure.

of

regions.

self-

process which

in this respect is offset by the decreased

threshold

,y~~=-lv

currents.

4 (a).

reduced

benefit

. . . . . . . . . . . . . . .1(

.. . . . . . .

layer

from the substrate

by the ion implantation

overlap

To compensate

4. Detailed

ture, and (b)

The

the

the ion-im-

depletion

and 4(b) ], and due to the natural

source and drain

-...

7.5x lo15cnl-3

Fig.

will

4(a)

with

increased

the source and drain

afforded

reduces

.

p-Si

1

ory

Figs.

are reduced

due to the

separating

alignment

(b)

capacitances

structure

As”

implantation

During

regions

(100 keV),

this

2000-A

high dose

through

step, however,

the

the

DENNARD

ei!

al.:

ION-IMPLANTED

MOSS13T’s

261

V,(fo, vw~=-l) [v]

z:~

,,-.,

_

:\

6-

t5

m‘E ~ ~

l!i

!

ORIGINAL

IMPLANT

\, i

Ns

;

~

e

-i

~

X3 -/

Z*

+IOEALIZED

STEP

FUNCTION

;

\\

:

‘1

;,

;

/

2+

#

4

I-

0

AFTER

ANNEALING

~ \l‘.,

_

‘...

tdb

Fig. 5. Predicted substrate doping profile for basic ion-implanted

device design for 40 keV BI1 ions implanted

through the 350-A

gate insulator.

Fig. 6. Calculated

and experimental

substrate sensitivity

characteristics for non-implanted

devices with 200- and 350-A gate

insulators,

and for corresponding

ion-implanted

device with

350-A gate insulator.

polysilicon

ing, the boron

plant,

gate masks

absorbing

the channel

all of the As”

etching

process

used to delineate

sloping

sidewall

which

ions underneath

(or source)

allows

overlap

implantations

sulating

contact

layer

greatly

regions,

and

2000-A

contact

source and drain

regions

during

the final

an annealing

annealing

modeling

substrate

atoms/cm~

oxide,

doping

channel

is shown

cent

of

the

in Fig.

incident

were 50 O/D

for the

a final

in-

using

Then,

regions

the

were de-

and delineated.

shallow

implanted

by a suitably

penetration

is 6.5

x

of the

implantation

function

For

40 keV

[ 131. After

profile

for

5. Since

10~1 atoms/cm2.

sian

deviation

CHANNEL)

dose,

were

The

is given

added

B“

the

due to

metaliza-

in forming

to the

ions,

taken

the heat

the

by

the

background

projected

as 1300

treatments

ANALYSIS

on

A and

6.7

the

oxide

dose

representation

in

lightly

3 per-

the

doping

500

silicon

at the

dashed

range

gate

and

time

Gaus-

level,

iV~.

standard

i%, respectively

of the subsequent

process-

the

final

offers

the advantage

parameters.

inter-

concentration.

For

to use a simple,

ideal-

of the doping

profile,

predicted

that

The

profile

rather

well

it can be described

three

profiles

by a few

shown

in Fig.

5

all have the same active dose.

Using the step profile,

old voltage

tions

a model

has been developed

of Poisson’s

equation

[11 ], The

the vertical

with

dimension

effects. Results

plots

condi-

considers

account

voltage

only

for horizontal

of the model

the threshold

solutions

boundary

model

and cannot

thresh-

piecewise

appropriate

Fig.

6 which

for determining

from

one-dimensional

short-channel

are shown

versus

in

source-

to-substrate

bias for the ion-implanted

step profile shown

in Fig. 5. For comparison,

Fig. 6 also shows the substrate

characteristics

a 200-A

doping,

X 10’1

350-A

absorbs

concentration

the

it is convenient

simple

sensitivity

density.

the 40 keV,

active

surface

ap-

step. After

incident

the

and

(LONG

implant

purposes

ized, step-function

with

The

reflect from the silicon-oxide

raise

proximates

to decrease the fast-state

ONE-DIMENSIONAL

thereby

out the

step of 400 “C for 20 min

gas was performed

in the silicon

and

spreading

was accomplished

junction

at

face

using

as shown by the solid line in Fig. 5. ‘The step profile

was deposited

the

the

11 min

deposition.

to

to avoid

diffusing

were obtained

out the

was applied

directly

chosen metallurgy

alloying

a computer

program

developed

by F. F. Morehead

of

our laboratories.

The program assumes that boron atoms

profiles

to anneal

holes to the n+ and polysilicon

Electrical

by the heavier

in a

of ASP5

and 40 fI/D

thick

chemical-vapor

as shown

dashed line. These predicted

follow

the AS’5 implant,

and the metalization

tion

at 900°C,

sheet resistances

areas. Following

oxide

steps that

adequate

without

and drain

low-temperature

fined,

20 min

doses. Typical

the source

polysilicon

penetration

is redistributed

The

to be of the order of 0.2

processing

is more than

damage

implanted

for

the im-

there.

the gates results

a slight

is estimated

include

which

implantation

from

the edges of the gates, The gate-to-drain

p, The high temperature

1000°C,

region

dose incident

and

for

gate insulator

for

gate insulator

a hypothetical

like

stant background

the

the implanted

doping

nonimplanted

and a constant

device

device

background

having

structure

a 350-A

and

like the nonimplanted

a con-

structure.

The nonirnplanted

200-A case exhibits

a low substrate

sensitivity,

but the magnitude

of the threshold

voltage

is also low. On the other

hand,

the nonimplanted

350-A

case shows a higher threshold,

but with an undesirably

high substrate sensitivity.

The ion-implanted

case offers

both

a sufficiently

high

threshold

voltage

and a reason-

ably low substrate sensitivity,

particularly

for V~.S,,I~>

1 V. For Vs..,,,,, < 1 V, a steep slope occurs because the

262

IEEE

surface

inversion

the depletion

not

exceed

planted

tion

layer

region

~,

the

step

V..,,,,,

V,.,u,b

reasonably

200-A

allows

higher

adequate

conditions

relatively

the

implanted

design margin

level

bias

so that,

which

the threshold

will

for

//

//

+//

//

+//

+/’

‘T-

10-s

+1

4’

I

g

a

K

n

i

/

;1

~ ,8(3 ~vfie~Qd~

y{~,~l’

10-9

is

/-EXPERIMENTAL,

L=9,75p

h86p J.17Y I

,~-lo If

0.0

0,2

0.4

0.6

1.2

I ,0

0.8

.1.4

GATE VOLTAGE, Vg (V)

which

worst

case.

reduce

the

still

,+f

,+

/’r’f’

voltage

design

under

effects

as required

of

to 4 V)

10-7

U

K

K

~

range

the threshold

enough so that the device can be turned

conduction

H“

~-

slowly

substrate

1974

OCTOBER

lop

1,2+

,+/

Vd ❑4V

v,u~=-IV

-m

substrate

potential

However,

considerably),

im-

10-6

to the slope of the non-

(e.g., short-channel

threshold

~

the deple-

doped

CIRCUITS,

CALCULATED,——

L= 0,8/L

gate does

doped

OF SOLID-STATE

,~-5

while

over the operating

similar

for

the

heavier

a fixed

(e.g., ground

design.

is significantly

the

then increases

with

low and very

implanted

under

the lighter

sensitivity

of the source voltage

is obtained

1 V, at inversion

>

Thus,

– 1 V, the substrate

of

into

voltage

[11],

silicon

width

now extends

and thethreshold

with

in the

For

region.

region

in the channel

JOURNAL

Fig. 7. Calucu!at.ed

acteristic

for basic

lengths with V,u, z

be high

and experimental

subthreshold

turn-on charion-implanted

design for various channel

– 1 V, V. z 4 V.

off to a negligible

dynamic

memory

given

Fig.

ap-

r

1

i

i

,

1

I

1

1

plications.

Experimental

results

measurements

10 ,p) which

agree

this

have

result,

well

with

10’1 atoms/cm2

x

of 40 kel’

rather

than

and 6,7

drain

by

the

into

gate.

which

uniform

data

curve.

design

CHANNEL)

A

value

due

channel

this

which

been

[14],

the

leads to

developed

problem

is

an electric

field

the ioncurrent

transport

[16]

utilized.

The

Chang

strate

of Kennedy

computer

program

and P. IIwang

doping

The

profiles

numerical

calculate

and Mock

was

current

the turn-on

the

was

by

abrupt

W.

sub-

for these devices.

transport.

behavior

vice by a point-by-point

[15],

modified

[171 to handle

considered

model

was used to

de-

of the device

cur-

rent I“or increasing

values of gate voltage.

Calculated

results are shown in Fig. 7 for two values of channel

longlength in the range of 1 p., as well as for a relatively

channel

device

with

L

to a width-to-length

=

ratio

of 4 V was used in all

rcdllccd

shifts

to the

order

to a lower

threshold

and a drain

cases. As the

voltage

characteristics

behavior.

This

current

level

identified

at

from

jected

is

acteristics

substrate

threshold,

in

all

cases

with

MOSFET’S

can

also

be

the

manner

device

current

the

the

computed

of

Fig.

prochar-

3 they

gave

a resultant

The technique

pendix.

small

various

and

show

Another

short

devices

tially

constant

amount

L

>

were meas-

the

different

data

from

7

curves,

values of L.

is shown

is plotted

threshold

further

in Fig.

calculated

2 p, and falls

with

model.

in the Ap-

of this

as L is decreased

dccrca.ses more rapidly

Vt,

lengths

are plotted

voltage

The

at

used

is described

the somewhat

the threshold

for

in

A was

the chan-

with

of presentation

length.

10-7

determining

results

agreement

considering

form

small

error

with

current

of the two-dimensional

experimental

good

of

channel

for experimentally

for very

‘Ike

designs considered

gave a higher

the value

lu-ed to test the predictions

of channel

Vqz

actual

When

concentrations

with

tion

m

in

the

V*.

so, for simplicity,

make

(a linear

plotted

0.75 V. Some of the other

occurs at about

Id

as

4 X 10-8 A at threshold

for all device lengths. The band

bending, +,, at this threshold

condition

is approximately

8 where

a transi-

3

voltage,

were

especially

of the

Fig.

threshold

Fig.

tion from the exponential

subthreshold

behavior

response on this semilogarithmic

plot) to the

square-law

length

characteristic

due to a lowering

The threshold

the turn-on

voltage

channel

of 1 p, the turn-on

of threshold

design with

nel length

cases were normalized

of unity,

gate voltage

voltage.

10-7 A where

10 ,fl. All

Fig. 8. Experimental

and calculated

dependence

voltage on channel length for basic ion-implanted

V,.b = –1 v, v. = 4 v.

heavier

of the ion-implanted

computation

910

by the non-

pattern

that is difficult

to approximate.

For

implanted

case, the two-dimensional

numerical

model

12345678

SOURCE-DRAIN SPACING, L (MICRONS)

of the

controlled

have

structure

the

for the

penetration

normally

behavior

profile

lengths,

to account

to

region

I_J???5

ANALYSIS

short-channel

for the ion-implanted

doping

higher

some models

for

These

was used to achieve

is inadequate

lowering

the

account

implant

sufficiently

While

complicated

6 from

(i.e., L =

calculated

the slightly

model

voltage

field

effects.

the

(SHORT

For devices with

one-dimensional

in

long devices

1011 atoms/cm2.

x

TWO-DIMENSIONAL

threshold

also

no short-channel

reasonably

35 keV, 6

are

made on relatively

voltage

in

as a funcis essen-

by a reasonably

2 to 1 p, and then

reductions

in L, For

DENNARDet

ION-IMPLANTEDMoSF@i3

al.:

263

CALCULATED THRESHOLD VOLTAGE

vd=+4v

“9

[ VOLTS ) FOR Ids = 10-7 AMPERES

y_?-.~

L=o.8p

BASIC

laop

N+

lo2p

10p

DESIGN

(a)

]

7.5E15

J v,”~‘ ~ Vm

?

DEEPER

~+

m

N+

SOURCE/ORAIN

----

JUNCTIONS

Fig.

9.

Experimental

implanted

Curve

tracer

V, gate

circuit

drain

design

with

parameters;

voltage

(U

than

give V~ = l. O&

alone.

applications

This

on a given

chip,if

istics

nel length

are shown

condition.

The general

tochipdue

effects

short-channel

taken

from

energy

atoms/cm2,

respectively.

degree of control

drain

larger

observed

results

threshold

voltage

indicated

voltages.

simulations

in Fig.

as a function

The first perturbation

of channel

Viewed

device

length

would

(from

1.0 to 1.2 p) to obtain

design.

junctions

in perspective.

This

voltage

another

of

for the

representa-

to give an apfor the shorter

way, the minimum

puts

a threshold

the value

Another

was considered

lighter

by

concentration

The results

values

length

have to be increased

the basic

same threshold

The

has been discussed thus far.

in threshold

devices in Fig. 10(b).

higher

Su

im-

parameters.

tabulates

for

a factor

in the

comparable

to

shallower

perturbation

from

Fig. 10. Threshold

voltage

calculated

using two-dimensional

rent transport

model

for various

parameter

conditions.

band voltage

of –1.1

V is assumed,

considering

is about

more

that. the boron

20 percent

short-channel

calculated

pared

effects

values

to the basic design.

good substrate

is completely

depleted

[Fig.

the

1O(C) ].

to be similar

to the

show

concentration

[Fig.

appreciably

for this

tions.

This

with

Also,

with

region,

threshold

concentration

[Fig.

to

give

10(d) ]. With

case for

with

a device

the

same

the shallower

a

long-channel

profile,

and

onlY

less

depth

lines

turn-on

from

layer

In

L

may

the drain

is controlled.

into

this

due

the source

drop across those j unc-

silicon

conditions,

under

near

+$, appears

help prevent

the

0.8 p. is

of the basic

around

and doping

in the

fact,

=

is apparently

widths

particularly

the band bending,

which

improvement

these bias

tion

heavier

effect.

important

at threshold,

as deep, wiih

for this case

less short-channel

the same as for an L = 1.0 ,p. device

about

much

half

source.

such a cascj again

10 (e) 1. The calculations

case of deeper j unc~ions. The next possible departure from

the basic design is the use of a shallower boron implantaonly

a grounded

to give the same long-chan-

a heavier

the lower voltage

give

with

have

doped region

with

nel threshold

and drain

device

to

implanta-

bias and still

considers

depletion

layer

com-

The last design perturbation

to the reduced

surface

the

thresholds

since the heavier

at turn-on

that

However,

the shallower

of 2, with

devices proved

region,

With

sensitivity

layer

channel

identical

design.

a slightly

in the silicon

occur.

to use zero substrate

depletion

in the

would

show almost

tion it is possible

threshold

the

dose implanted

curA flat-

less in this case, it was expected

was the use of a sub-

a long-channel

for smaller

by 20 percent

of the

:TRATE

@vm

in Figs.

and 6.0 X 10’1

depth to 0.4 ,P. This was found

doping

drain

to the basic design was an increase

reduction

basic design which

for

channel

10(a) is an idealized

Fig.

is the

No ex-

were also used to test

10 which

tion for the basic design that

in junction

chansource

data

a B“

of the design to various

are given

preciable

using

.

character-

a I.I-,P

devices.

and dose of 35 keV

The two-dimensional

the sensitivity

for many

of different

with

were

devices

plantation

strate

to this short-

as large as 4 V. The experimental

were

is reason-

9 for the grounded

traneous

6-9

be set

shape of the characteristics

for much

voltages

this

MOSFET

same as those observed

P

0.3 pwould

be tolerable

indeed

in Fig.

xj=o.4p

4

an expected

voltage

The experimental

for an ion-implanted

voltage

of L could

over

because of the tracking

can be achieved.

(b)

“

L = 1.3 *

would

ion12.2 ~,

0.5 V apart.

value

Forexample,

basic

W =

.30 Q, drain

1 ,P so that,

O.l Vfromchip

effect

devices

ofL

resistance

each

for

1.1 p, and

of L, the threshold

ably well controlled.

circuit

load

the nominal

greater

range of deviation

channel

characteristics

—1 V, L =

V in 8 steps

applications

somewhat

voltage

Vs.~ =

the

the

source

across this

where

is

where

depletion

the penetration

region

the

gate

of field

the

device

IEEEJouRNALoF soLm-STATECIRCUITS,

264

1.2

1

[

i

I

I

i

,<p:*--————

—*—

~ Lo -1

0

~ 0.8

I

1

I

OCTOBER 1974

*—*

k—

2

~

%’

a

i

~ 0,6.+

f

o

1

>

20 KeV,6Ellcm”2

2 0.4 g

Fig.

VOLTS (EXI?)

+ Vd = 0,05

g 0,2 I

11

0.0

01234

● Vd =4 VOLTS (EXH

A Vd =4 VOLTS (THEORY)

I

I

I

I

I

678910

L?(p)

1

t

11.

Experimental

voltage

on channel

and

calculated

length

for

dependence

ion-implanted

of

zero

I

threshold

substrate

bias

design.

CHARACTERISTICS OF THE ZERO SUBSTRATE

‘“’r————————————l

BIAS DESIGN

Since the last

be better

worthwhile

mental

and tested

obtain

10”

atoms/cm2

implanted

[11].

11 and corresponds

for a small

length,

channel

Data

4 V applied

much

on source-to-substrate

Bll

well

voltage

fully.

of

to the

to

it is

Experi-

were

In this

implant

layer

on threshold

less variation

as expected.

appears

effects,

design

lengths.

to the drain

very

drain

10(e)

more

to this

a shallower

1OOO-A depth

showing

its properties

various

6.0 x

in Fig.

of short-channel

corresponding

with

devices with

Data

shown

in terms

to review

devices

20 keV,

design

behaved

built

case a

was used to

voltage

in Fig.

calculated

values.

of threshold

The dependence

with

channel

of threshold

voltage

bias is shown in Fig. 12 for differ-

a constant

show that

low value for this measurement.

The results

the substrate

sensitivity

is indeed about the

voltage

was held at

same for this design with zero substrate bias as for the

original

design with V.u~ = —1 V. Note that the smaller

characteristic

values

with

of source

The turn-on

design,

a somewhat

both

I?ig. 13 for

flatter

relatively

(and drain)

experimental

different

lower

substrate

sensitivity

thresholds

for the zero substrate

and calculated,

values

of L. The

design

offers

version,

old

improved

turn-on

with

suitable

gate to ground.

gravates

design

For

the turn-on

if the device

for

[18].

with

V@

such

strong

is turned

elevated

Thus,

=

in-

subthresh-

applications

characteristic

Furthermore,

the situation

the basic

preferred,

control

is offset by the flatter

characteristic.

noise margin

barely

threshold

this advantage

the

of Fig.

13 is

off by bringing

its

temperature

ag-

for dynamic

memo~,

– 1 V presented

earlier

bias

are shown

relatively

in

small

shift in threshold for the short-channel

devices is evident;

however, the turn-on rate is considerably

slower for this

case than for the V,ub = – 1 V case shown in Fig. 7. This

is due to the fact that the depletion

region in the silicon

under the gate is very shallow for this zero substrate bias

case so that a large portion of a given gate voltage change

CIRCUIT PERFORMANCE WITH SCALED-DOWN DEVICES

The

very

performance

small

improvement

MOSFET’S

in

expected

integrated

from

circuits

of

using

com-

parably

small dimensions

is discussed in this section.

First, the performance

changes due to size reduction alone

are obtained

from the scaling

considerations

given earlier.

The influence

on the circuit

performance

due to the

structural

changes of the ion-implanted

design is then

discussed.

is dropped across the gate insulator

capacitance

rather

than across the silicon depletion

layer capacitance.

This

Table I lists the changes in integrated

circuit performance which follow from scaling the circuit

dimensions,

is discussed

voltages,

in some detail

for these devices

is

at high

voltage.

characteristics

Fig.

12. Substrate

sensitivity

characteristics

for ion-implanted

zero substrate

bias design with

channel

length

as parameter.

is also given in this figure,

of L, The drain-to-source

show

Vsource

-substrate

(VOLTS)

for these

is presented

ent values

devices

~,o,

o

approximately

in another

paper [11 ]. The consequence for dynamic

memory

plications

is that, even though the zero substrate

apbias

and substrate

doping

in the same manner

as the

device changes described with respect to Fig. 1. These

changes are indicated

in terms of the dimensionless

scal-

DENNASDet at.: 10N-1MH,.4NTED

iWOSFET’S

,.-5

,

265

,

20 KeV,6EII

TABLE

cm-z

SCALING

]o-6 . V,=4V

v$,~=o

Parameter

.

/.

W%~~ENTAL

Line

+

resistance,

Normalized

,0-8

L=l.lp .

10-9

~.li)o(

*)

Line

Line

L=lOp

A

;

CTvj

,[

o

R~

=

pL/Wt

drop

0.2

0.4

1.0

0.6 .0.8

vg [v]

1.4

1.2

pacitances

are driven

ances V/I

giving

1

TABLE

SCALING RESULTS

or Circuit

device

density

circuits

from

or circuit

Power

Power

L, W’

Na

K2

II,

are necessarily

of the more

1/.

1/.

VC/Z

dissipation/circnit

density

VI/A

VI

etching,

l/K

constant

very small

which

1

comparable

volubility

would

It

K. Justifying

be tedious,

is argued

so

that

miniaturized

these results

only

circuits

This follows

in digital

MC)SFET

ance

circuits

V/I

of each device

lower

given

voltage

the supply

by

a voltage

is unchanged

is made that parasitic

negligible

examined

to the reduced

are either

level

is given.

are reduced

because the quiescent

detail

in the

supply

or unchanged

subsequently.

voltages

by scaling,

The circuits

because

by

resistance

the device

of a given

K.

factor

constant

ages. The response time

scaling.

An

are

will

line

ages are reduced

Noise

margins

generated

at

density

voltage

Vt

which

by the lower

signal

to the same

but

voltage

at

volt-

because of the reduction

which

the electrode

by K’ in the area of these com-

is partially

spacing

by

cancelled

K

by the decrease

due to thinner

insulating

directly

with

the

current

levels) ~ but

to the lower

operating

limited

by

its

is K

volt-

transmission

time

constant

in a scaled-down

causes

a

circuits,

latively

minor,

of

is increased

concern,

these conductivity

but

micron

circumvented

the power

conductor

reliability

they

in high

buses and

significant

The

by

K,

conventional

problems

become

dimensions.

In

are refor

problems

may

linebe

performance

circuits

by

the use of n+ doped

avoiding

by widening

lines for signal propagation.

swings,

Due to the reduction in dimensions, all circuit elements

(i.e., interconnection

lines as well as devices) will have

their capacitances

reduced by a factor of K. This occurs

ponents,

limit

assumptions

speeds inherent

in the scaled-down

devices when signaI

propagation

over long lines is involved, Also, the current

properly

are reduced,

these

be

operate

noise coupling

solid

R~C, which is unchanged by scaling; however, this makes

it difficult

to take advantage

of the higher switching

as well if each parameter

internally

for

where

of an unterminated

is characteristically

to

becomes

in such a line is therefore

decreased

levels

divider

widths

accuracy.

the

down

considerations

Under

drop

in comparison

on

to remain

films

lines

line increases

The IR

(with

greater

metal

scattering

scaling

MOSFET

the same time

impurity

because

and is also reasonable

in conductivity.

K.

(e.g.j

is considered

semiconducting

the resistance

scales as shown in (2), and furthermore

because the

reduced

tolerance spreads on Vt should be proportionately

percentage

and

increase

threshold

in (2) is controlled

doped

widths

the mean free path

to the thickness),

arise

of the conductors

the

for

(until

times

elements

which

any

of problems

requirements

conductivity

levels

of two or more devices, and because the resist-

assumption

either

treatment

voltages

in proportion

or some intermediate

consisting

a. simplified

all nodal

voltages.

here in great

with

is reasonable

circuit

is decreased only by

resolution

dimensions

degenerately

ing factor

along

by K2,

even if many

area of conductors

the thicknesses

reduced

levels,

Since the

K8.

unchanged.

a number

while the length

etc. ). The

1/.

1 /K2

a re-

integrated

the cross-sectional

stringent

by

Thus,

is essentially

in Table

by

1/.

ca-

resist-

with

is also reduced

on a given

problem

the fact that

K

device

and current

constant,

are placed

is decreased

Factor

reduced

times

is improved

remains

It is assumed here that

dlmensiontO.,

concentration

V

1

unchanged

transition

product

area of a given

the power

As indicated

PERFORMANCE

Scaling

by the

These

duced by K’ due to the reduced voltage

I

Parameter

widths.

in the delay time of each circuit by a

power dissipation

of each circuit is re-

so the power-delay

FOR CIRCUIT

layer

decreased

sultant reduction

factor of K. The

and experimental

subthreshold

turn-on

charion-implanted

zero substrate

bias design.

Capacitance

EA It

Delay time/circuit

K

K

depletion

chip, the cooling

Device

Doping

Voltage

Current

Factor

K

IR~/V

response time R~C

current

density

I/A

more

Device

Scaling

voltage

and reduced

.

“

13. Calculated

acteristics

for

LINES

.

,0-10

Fig.

II

FOR INTERCONNECTION

/

,0-7

~

&

RESULTS

in

films

Use of the

paper

will

give

ion-implanted

similar

devices

performance

considered

improvement

in this

to that

of the scaled-down

device with K = 5 given in Table I.

For the implanted

dcviccs with the higher operating voltages (4 V instead

(0.9 V instead

of 3 V)

and higher

of 0.4 V), the current

threshold

level will

voltages

be reduced

IEEEJOURNALOFSOLID-STATE

CIRCUrrS,OCTOBER

1974

266

to (Vg — T’t) ‘/tox

to about

in proportion

current

in the scaled-down

per circuit

ate about

devices,

a factor

ing ancl dec~:ased

such

essentially

junction

depth.

so that

in a typical

12

I

I

1

J

II -

im-

will

show

substrate

dop-

Some capacitance

the

circuit

lines

overall

would

847

capacitance

and for the directly

+/

~

be

be somewhat

20 KeV,6EII Cniz

Vg=Vt+ 0.5 VOLTS

V,j =0.05 VOLTS

v~ub=f)

9–

ele-

would

+/:

10-

–

z

x6 z

z

& 5-

less

of two. The delay time per circuit which

to VC/I

thus appears to be about the

same for the implanted

micron

lines

interconnection

unchanged

improvement

less in the

due to the lighter

as metal

than a factor

is proportional

of two

and n+ interconnection

the same improvement

ments

of the

is thus about the same in both cases. All device

capacitances

planted

80 percent

device. The power dissipation

scaled-down

/!

+

+/

4-

devices shown in Fig. 4,

L= Lma~k-AL

/

1

3/

NJMMARY

This

paper

has considered

characterization

vices.

of very

These

solution

integrated

lithographic

pattern

writing.

leads

some

an all ion-implanted

formance.

A

with

a l-P

lower

circuits

ion-implanted

an n-channel

control,

4 x

350-A

10’5 atoms/cm’

~gate insulator,

– 1 V. Also

tended

from

from

the

using

for

presented

of view

an increased

sizable

MOSFET

source-folmemories.

bias

that

subthreshold

implant,

substrate

small

MOSFET)S

comparably

small

dimensions

in

of

in-

suffers

range.

Finally

A

technique

channel.

perimental

length

for

determining

L for very

data is described

small

the

used

to determine

L.

that

pendent

intercept

the device

channel

=

(Al)

LP.m

turned

sheet

on in the below-pinchoff

resistance

is relatively

inde-

versus L~,,k will

of L. Then, a plot of w&han

t,he Lm.,ll axis at AL because AL = L~.~~ — L,

where AL is the processing

reduction

sion

etching.

due to exposure

and

is illustrated

The experimental

14 were obtained

in the mask dimenAn

example

of this

in Fig. 14.

of W and l?,,,.

values

as follows.

First,

used in Fig.

the sheet resistance

of the icm-implanted

n+ region was determined

using a

relatively

large four-point

probe structure.

Knowing

the

n+ sheet resistance

drain

resistance

allows

us to compute

the source and

R. and R., and to deduce W from

of a long, slender,

ance can be calculated

R,,hnn= VC,,J1,

circuits

n+ line. The channel

the

resist-

from

= (V, – I,(R,

+ R. + 2Rc + R1omi))/Id,

(A2)

of

was projected.

DETERMINATION

technique

length,

from

where Rc is the contact

resistance

of the source or drain,

and Rla,,l is the load resistance of the measurement

circuit. Id was determined

at VO = Vt + 0.5 V with a small

APPENDIX

EXPERIMENTAL

0, and with

region,

resistance

attractive

but

expected

integrated

a

bias

design

is more

turn-on

was

that used a 35

implant,

a 100

control

improvement

very

of experimental

on the observation

technique

turn-

sensitivity

source/drain

an applied

4

where li,(.~~~ 1s the channel resistance, and pCl,~~the sheet

resistance of the channel. For a fixed value of V~ — Vt >

proved

of subthreshold

of threshold

performance

Illustration

WR.w

degree of

was an ion-implanted

zero substrate

the point

14.

channel

device paof the study

high-density

lMOSFET