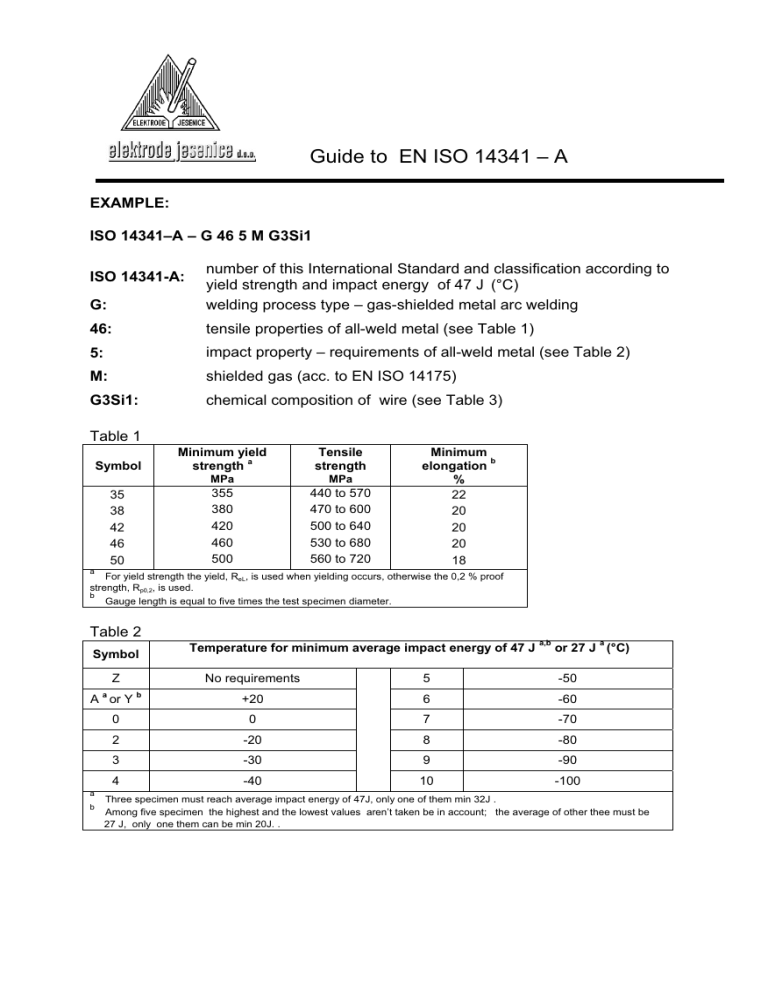

Guide to EN ISO 14341 – A EXAMPLE: ISO 14341–A – G 46 5 M G3Si1 G: number of this International Standard and classification according to yield strength and impact energy of 47 J (°C) welding process type – gas-shielded metal arc welding 46: tensile properties of all-weld metal (see Table 1) 5: impact property – requirements of all-weld metal (see Table 2) M: shielded gas (acc. to EN ISO 14175) G3Si1: chemical composition of wire (see Table 3) ISO 14341-A: Table 1 Symbol 35 38 42 46 50 Minimum yield strength a Tensile strength MPa MPa 355 380 420 460 500 440 to 570 470 to 600 500 to 640 530 to 680 560 to 720 Minimum elongation b % 22 20 20 20 18 a For yield strength the yield, ReL, is used when yielding occurs, otherwise the 0,2 % proof strength, Rp0,2, is used. Gauge length is equal to five times the test specimen diameter. b Table 2 Symbol Temperature for minimum average impact energy of 47 J a,b or 27 J a (°C) Z No requirements 5 -50 A a or Y b +20 6 -60 a b 0 0 7 -70 2 -20 8 -80 3 -30 9 -90 4 -40 10 -100 Three specimen must reach average impact energy of 47J, only one of them min 32J . Among five specimen the highest and the lowest values aren’t taken be in account; the average of other thee must be 27 J, only one them can be min 20J. . Guide to EN ISO 14341 – A Table 3 — Symbol for chemical composition of wires Chemical composition, mass % a,b, c symbol C Si Mn P S G0 Ni Cr Mo V Cu Al Ti+Zr Any other defined requirements G2Si 0,06 to 0,50 to 0,90 to 0,14 0,80 1,30 0,025 0,025 0,15 0,15 0,15 0,03 0,35 0,02 0,15 G3Si1 0,06 to 0,70 to 1,30 to 0,14 1,00 1,60 0,025 0,025 0,15 0,15 0,15 0,03 0,35 0,02 0,15 G3Si2 0,06 to 1,00 to 1,30 to 0,14 1,30 1,60 0,025 0,025 0,15 0,15 0,15 0,03 0,35 0,02 0,15 G4Si1 0,06 to 0,80 to 1,60 to 0,14 1,20 1,90 0,025 0,025 0,15 0,15 0,15 0,03 0,35 0,02 0,15 G2Ti 0,04 to 0,40 to 0,90 to 0,14 0,80 1,40 0,025 0,025 0,15 0,15 0,15 0,03 0,35 0,05 to 0,05 to 0,20 0,25 G2Al 0,08 to 0,30 to 0,90 to 0,14 0,50 1,30 0,025 0,025 0,15 0,15 0,15 0,03 0,35 0,35 to 0,75 0,15 G3Ni1 0,06 to 0,50 to 1,00 to 0,14 0,90 1,60 0,020 0,020 0,80 to 1,50 0,15 0,15 0,03 0,35 0,02 0,15 G2Ni2 0,06 to 0,40 to 0,80 to 0,14 0,80 1,40 0,020 0,020 2,10 to 2,70 0,15 0,15 0,03 0,35 0,02 0,15 G2Mo 0,08 to 0,30 to 0,90 to 0,12 0,70 1,30 0,020 0,020 0,15 0,15 0,40 to 0,60 0,03 0,35 0,02 0,15 G4Mo 0,06 to 0,50 to 1,70 to 0,14 0,80 2,10 0,15 0,40 to 0,60 0,03 0,35 0,02 0,15 0,025 0,025 0,15 a If not specified: Cr < 0,15%; Cu 0,35 %; V 0,03 %. Copper from steel and copper from coating shall not exceed 0,35 % (mass). b Single values shown in the table are maximum values. c The results shall be rounded to the same number of significant figures as in the specified value using the rule A in accordance with Annex B of ISO 31-0:1992.