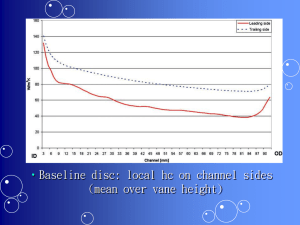

![Daniel Straightening Vanes[1]](http://s2.studylib.net/store/data/027107545_1-dfc6f416131c12049b3c0d6927f04ea1-768x994.png)

Straightening Vane Brochure Overview Uses Bundle Types Carbon Steel Vanes Size and Type of Installation Line Type Vane Dimensions Flanged Type Vane Dimensions Stainless Steel Vanes Size and Type of Installation Line Type Vane Dimensions Flanged Type Vane Dimensions Installing a Line Type Vane Product Overview STRAIGHTENING VANES CATALOG 1100 REDUCE FLOW DISTURBANCE AND IMPROVE YOUR ORIFICE METERING CONDITIONS Daniel Straightening Vanes are installed in the upstream section of meter tubes to reduce flow disturbance preceding the orifice plate. Disturbance is often created by complex piping or valves which precede the orifice metering section. As flow passes through the vane bundle, the disturbance is straightened and smoothed to a normal flow pattern. Straightening Vanes are economical because their use often allows sufficient reduction of upstream meter tube length, so that a smaller building or enclosure is possible. (See Daniel Meter Tube Catalog Section "D" for meter tube lengths.) Daniel Straightening Vanes are manufactured in a variety of sizes, in carbon steel and stainless steel. They are in accordance with recommendations of the A.G.A. and A.S.M.E., as well as numerous other societies and associations. Three standard vane bundles are shown in the document entitled "Standard Straightening Vane Bundles." Each type bundle is available in a Flange Model and a Line Model. The tubes in each Daniel vane bundle are welded at both ends at each point of tangency. Tube inlets and outlets are reamed to permit minimum pressure drop. Special spacer lugs on each vane bundle assure a perfect fit in the meter tube. The Flange Model is held in the line by a flange ring which is clamped between two pipe line flanges. Straightening Vane Uses (Stainless Steel) Daniel Stainless Steel Straightening Vanes Stainless steel vanes are particularly useful in meter tubes handling corrosive flows, in buried meter tubes, or in tubes having condensate problems. The standard material for these Daniel vanes is 304 stainless steel. Standard Straightening Vane Bundles CROSS-SECTION END VIEW Size and Type of Vane Installation (Carbon Steel) Carbon Steel Straightening Vanes NOTE: Ring Flange Model is same O.D. dimension as raised face of flange. For RTJ Flanges, ring fits inside standard ring gasket. Specify Flange Rating. Line Model Straightening Vane (Carbon Steel) #1100L -- Line Type Line Size Bundle Type** inches Line I.D. B O.D. of Vane inches O.D. of Tubes inches A Length of Vane? inches inches Wall Number of Thickness Tubes of Tubes inches Number and Size of Screws inches Approx. Weight lbs. 2 I I 2.067 1.939 6 6 1 31/32 1 7/8* 21/32 21/32 .095 .095 7 7 1--3/8 x 3/4 1--3/8 x 3/4 2 2 3 II II 3.068 2.900 8 8 2 7/8 2 3/4 19/32 9/16 .049 .049 19 19 1--3/8 x 3/4 1--3/8 x 1 3 3 4 II III III III 4.026 3.826 6.065 5.761 10 10 12 12 3 31/32 3 3/4 5 15/16 5 5/8 13/16 3/4 1 3/16 1 1/8 .049 .049 .049 .049 19 19 19 19 1--3/8 x 1 1--3/8 x 1 1/4 1--1/2 x 1 1/4 1--1/2 x 1 1/4 6 1/2 6 1/2 18 1/2 18 1/2 8 II II 8.071 7.981 16 16 7 29/32 7 29/32 1 5/8 1 5/8 .065 .065 19 19 1--1/2 x 1 1--1/2 x 1 1/4 34 1/2 34 1/2 10 III 10.136 20 10 2 .083 19 1--1/2 x 1 1/4 53 1/2 II III III II III 10.020 12.090 12.000 11.938 13.250 20 24 24 24 28 9 3/4 11 7/8 11 7/8 11 9/16 13 1/8 2 2 3/8 2 3/8 2 3/8 2 5/8 .083 .083 .083 .083 .083 19 19 19 19 19 1--1/2 x 1 1/4 2--1/2 x 1 1/2 2--1/2 x 1 1/2 2--1/2 x 1 1/4 2--1/2 x 1 1/2 53 1/2 77 77 77 100 18 20 24 26 II III II II II II III 13.000 15.250 15.500 17.250 19.250 23.250 25.250 28 32 32 36 40 48 52 12 3/4 15 14 19/32 17 1/32 18 27/32 23 1/8 25 2 5/8 3 3 3 1/2 3 7/8 4 3/4 5 .083 .188 .188 .188 .188 .188 .188 19 19 19 19 19 19 19 2--1/2 x 1 1/2 2--1/2 x 1 3/4 2--1/2 x 1 1/2 2--1/2 x 1 1/4 2--1/2 x 1 1/4 2--1/2 x 1 1/4 2--1/2 x 1 1/2 100 268 268 378 468 693 796 30 34 36 III II III 29.250 33.250 35.250 60 68 72 28 3/4 32 13/16 35 5 3/4 6 3/4 7 .188 .250 .188 19 19 19 2--1/2 x 1 1/2 2--1/2 x 1 1/2 2--1/2 x 1 1/2 1273 1860 1559 6 12 14 16 *O.D. has been turned down on lathe. ?Bundle length for Flange and Line Model is the same. **Bundle type is determined by tubing size availability and is not optional. NOTE: Other sizes, materials, shapes, and types of Vanes can be supplied at extra cost. Prices and specifications on request. ABOVE SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. When Ordering, Please Specify: 1. Catalog Number 2. Line I.D. 3. Quantity Flange Model Straightening Vane (Carbon Steel) #1100F -- Flange Type Line Size Bundle Type** B O.D. of Vane inches O.D. of Tubes inches A Length of Vane? inches I 2.067 6 1 31/32 21/32 .095 7 2 1/2 I 1.939 6 1 7/8* 21/32 .095 7 2 1/2 3 II II 3.068 2.900 8 8 2 7/8 2 3/4 19/32 9/16 .049 .049 19 19 4 4 4 II III 4.026 3.826 10 10 3 31/32 3 3/4 13/16 3/4 .049 .049 19 19 7 1/2 7 1/2 6 III III 6.065 5.761 12 12 5 15/16 5 5/8 1 3/16 1 1/8 .049 .049 19 19 20 1/2 20 1/2 8 II II 8.071 7.981 16 16 7 29/32 7 29/32 1 5/8 1 5/8 .065 .065 19 19 37 37 10 III II 10.136 10.020 20 20 10 9 3/4 2 2 .083 .083 19 19 57 57 12 III III 12.090 12.000 24 24 11 7/8 11 7/8 2 3/8 2 3/8 .083 .083 19 19 81 81 II 11.938 24 11 9/16 2 3/8 .083 19 81 14 III II 13.250 13.000 28 28 13 1/8 12 3/4 2 5/8 2 5/8 .083 .083 19 19 105 105 16 III II 15.250 15.500 32 32 15 14 19/32 3 3 .188 .188 19 19 274 274 18 20 24 26 30 34 36 II II II III III II III 17.250 19.250 23.250 25.250 29.250 33.250 35.250 36 40 48 52 60 68 72 17 1/32 18 27/32 23 1/8 25 28 3/4 32 13/16 35 3 1/2 3 7/8 4 3/4 5 5 3/4 6 3/4 7 .188 .188 .188 .188 .188 .250 .188 19 19 19 19 19 19 19 386 477 704 814 1295 1880 1582 inches 2 Line I.D. inches Wall Number of Thickness Tubes of Tubes inches Approx. Weight lbs. *O.D. has been turned down on lathe. ?Bundle length for Flange and Line Model is the same. **Bundle type is determined by tubing size availability and is not optional. NOTE: Other sizes, materials, shapes, and types of Vanes can be supplied at extra cost. Prices and specifications on request. ABOVE SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. When Ordering, Please Specify: 1. Catalog Number 2. Line I.D. 3. Quantity Size and Type of Vane Installation (Stainless Steel) Daniel Stainless Steel Straightening Vanes NOTE: Ring Flange Model is same O.D. dimension as raised face of flange. For RTJ Flanges, ring fits inside standard ring gasket. Specify Flange Rating. Line Model Straightening Vane (Stainless Steel) #1104L -- Line Type Line Size Bundle Type inches Line I.D. B O.D. of Vane inches O.D. of Tubes inches A Length of Vane? inches inches Wall Number of Thickness Tubes of Tubes inches Number and Size of Screws inches Approx. Weight lbs. 2 I 2.067 6 1.875 .625 .083 7 1--3/8 x 3/4 1 3 4 6 8 III II III II II 3.068 4.026 6.065 8.071 7.981 8 10 12 16 16 2.815 3.952 5.940 7.904 7.904 .563 .813 1.188 1.625 1.625 .049 .049 .049 .065 .065 19 19 19 19 19 1--3/8 x 3/4 1--3/8 x 1 1/4 1--1/2 x 1 1/4 1--1/2 x 1 1--1/2 x 1 1/4 2 3/4 4 1/4 7 3/4 28 28 10 II 10.020 20 9.727 2 .065 19 1--1/2 x 1 1/4 43 ?Bundle length for Flange and Line Model is the same. NOTE: Other sizes, materials, shapes, and types of Vanes can be supplied at extra cost. Prices and specifications on request. ABOVE SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. When Ordering, Please Specify: 1. Catalog Number 2. Line I.D. 3. Quantity Flange Model Straightening Vane (Stainless Steel) #1104F -- Flange Type Line Size Bundle Type inches 2 3 4 6 8 10 I III II III II II II Line I.D. B O.D. of Vane inches O.D. of Tubes inches A Length of Vane? inches 2.067 3.068 4.026 6.065 8.071 7.981 10.020 6 8 10 12 16 16 20 1.875 2.815 3.952 5.940 7.904 7.904 9.727 .625 .563 .813 1.188 1.625 1.625 2 inches Wall Number of Thickness Tubes of Tubes inches .083 .049 .049 .049 .065 .065 .065 ?Bundle length for Flange and Line Model is the same. NOTE: Other sizes, materials, shapes, and types of Vanes can be supplied at extra cost. Prices and specifications on request. ABOVE SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. When Ordering, Please Specify: 1. Catalog Number 2. Line I.D. 3. Quantity 7 19 19 19 19 19 19 Approx. Weight lbs. 1 1/2 3 3/4 5 1/4 9 3/4 31 31 46 Method of Installing Line Model Vane As shown in the cross-section view below, the Line Model vane is first located in the pipe with its welded pad squarely beneath the tapped hole. An Allenhead set screw is installed so that it seats into a counter sunk hole in the welded pad. The screw is tightened to exert pressure on the welded pad, clamping the vane bundle securely in the line. To seal off the tapped hole in the pipe, a half-coupling is located over the set screw and a steel pipe plug inserted and tightened. The 3/8" set screw is 3/8" -- 16 N.C., and the 1/2" set screw is 1/2" -- 13 N.C. A nominal charge is made for factory installation of Line Model vanes. These vanes are intended for horizontal installation only. For vertical service, contact factory.