6

Masonry-2: Brick Masonry

61. INTRODUCTION

Rrick masonry

1s

made of brick

units, bonded together

mponents of brick masonry are therefore

Bricks

i e Mortar

with mortar.

Two essential

The mortar used for brick masonry should have the same H6

characteristics as discussed

in Chapter 5 for stone masonry. Mortar acts as a cementing material and unites the

inividual brick units together

to act as

may_ be used in brick masonry.

Cement mortar

homogeneous

2

Cement-lime mortar

Mud mortar

5

a

4

mass.

Following types of mortar

Lime mortar

Lime-surkhi mortar and

Mud mortar is used only for low-rise buildings which carry light loads. Cement

mortars are used for high-rise buildings, where strength is of prime importance. Linme

mortar and lime-surkhi mortars are used for all types of construction.

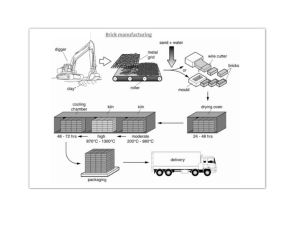

Bricks are manufactured by moulding clay in rectangular blocks of uniform predetermined size, drying them and then burning them in a kiln. Clay is a plastic earth,

constituted largely of sand and alumina with traces of chalk, iron, manganese dioxide

etc. Good bricks should be thoroughly burnt so that they become hard and durable.

Satisfactory burning of bricks is ascertained by a hard ringing soumd emitted when two

bricks are struck together. The bricks should be free from cracks, chips, and large particles

of

ime. The strength of brick masonry

chiefly depends

upon: () quality of bricks, ü)

yof mortar_and (iüi) method of bonding used. Unbonded wall, even constructed

WIthgood quality bricks and good quality mortar has little strength and stability.

Brick masonry is sometimes preferred over other types of masonry due to the

following reasons

.

n

All the bricks are of uniform size and shape, and hence they can be laid

any definite

pattern.

4. Brick units are light in weight and small in size. Hence these can be easily

handled by brick layers by

.

hand.

Bricks do not need any

dressing&

4The.art of brick laying can be understood very easily, and even unskilled

masons

Mas

masons.

can do the brick masonry. Stone masonry construction requires highly skilled

(167)

BUILDING CONSTRUCTIO

168

unlike stones which are availahla

Bricks are easily available at all sites,

do not require transportation from long distoy

at quarry sites. Due to this, they

done with bricks.

6 Ornamental work can be easily can be

easily constructed in brick mae

7.

partition walls and filler walls

5

distances,

masonry.

Light

6.2. TYPES OF BRICKS

7

Bricks used in_masonry can _be of two types

u

Traditional.bricks.

Modular bricks.

Traditional bricks are thosewhich have not been standardizéd in size. The dimensions

nsions

of traditional bricks vary from place to place. Their length varies trom 20 to 25 C

Cm,

width varies from 10 to 13 cm and thickness varies from 5 cm to 1.5 cm. The common

adopted nominal size of traditional brick is 23 cmx 11.4 cm * 7.6 cm (9"x43

a

proximately.

Modular bricks. conform to the size laid down by Bureau of Indian Standard

Institution, India. Any brick which is of the same uniform size as laid down by B+S

is known as the modular brick. The nominal size of the modularbrick is

20 cmx 10 cmx 10 cm while the actual size of the brick is 19 cm x 9 cm x 9 cm Nominal

sizeincludes the mortar thickness.Masonry modular bricks are economical to manufacture

require less area for drying, and staking, and requires less brick work for the same

surface area of the wall, in comparison to conventional bricks. The masonry with modular

bricks thus workout to be cheaper.

Classes of bricks

Quality wise, masonry

bricks are classified into three

bricks (ü)

Second class bricks and (iii)

Third class bricks.

() First class bricks.

First class bricks are those

which strictly conform to

the

classes: () First class

(a) Single bull nose

(b) Double bull nose

() Cow nose

standard size of modular bricks,

i.e.. 19 cm

9 cm x 9 cm actual

size, such that ten layersof

x

(d) Curved

(e) Coping brick

() Bird's mouth

brick laid in mortar will form

masonry of 1 metre height. Good

bricks are manufactured from

good quality plastic earth which

is free from saline

deposits.

They are of good uniform colaur.

They are well burnt: hard ring

ing sound is emitted when twwo

bricks are struck together. They

have straight edges and even

surfaces.They arefree from

cracks,chips,flawsand nodules

of lime. When Immersed in

(g) Cant

(h) Double cant

)Plinth stretcher

(k) Plinth header

(Splaystretcher)

(i) Squint

() Dog leg

(splay header)

FIG/6.1. SPECLALLY-SHAPED BRICKS

MASONRY-2: BRICk MASONRY

for

169

hour, they do not absorb water more than

one-sixth of their weign

wing,

they

do not show any sign of

n

(ii) Second class bricks. Second classafilorescence

bricks also conform to the standard

at they are slightl, irregular in

but

S17

and colour. They are also

shape

burnt,

fully

sound

ringing

1s emited when two bricks are struck together. When immersedana

in

wat

ater for one hour, they do not absorb water more

than

er

one

one-fourth of their weight.

(jii) Third class bricks. These are the

one which are

quite irregular in ther

size, shape and finish. They are not burnt

due

to

fully,

which they are of reddish-yellow

colour. These bricks have low

Moulded

crushing strength. They are not used for quality brick-masonry.

are those which are

manufactured in specjal

used for giving

architectural shapes. Such bricks are

used 1or

courses, sloping walls etc.

6.1

bricks. Moulded bricks

shapes and sizes to be

copings, cornices, string

specially-shaped bricks.

Fig.

shows

some

commonly

used

6.3. SOME DEFINITIONS

1.

Stretcher.

A stretcher is the

longer face of the brick (i.e. 19 cm x 9 cm) as

seen in the elevation of the wall. A course of

bricks in which all the bricks are laid

as stretchers on facing is known as a

stretcher course or

course.

2. Header. A header is

the shorter face of the brick

stretching

Quoin

ie. 9 cm x 9 cm) as seen in the

elevation of the wall. A' course

of bricks in which all the bricks

are laid as headers on the facing

is known as header course or

heading course.

3. Lap. Lap is the hori

zontal distance between the vertical joints of successive brick

courses.

4. Perpend. A perpend

15

an imaginary vertical

which includes the

line

vertical joint

separating two adjoining bricks.

Perpend

Racking

back

Quoin headers||

T

Stretcher course

Header course

Quoin closer

Vertcal joint

5. Bed. Bed is the lower

surface (19 cm x 9 cm) of the

brick when laid flat.

Toothing

Stretcher course

FIG. 6.2. ELEVATION OF A BRICK WALL.

6. Closer. It is a portion of a brick with the cut made longitudinally, and is

used to close up bond at the end of the course. A closer helps in preventing the

1 . s of successive sources (higher or lower) to come in a

vertical line. Closers may

be

of various types, defined below.

1. Queen-closer. It is a portion of a brick obtained by cutting a brick lengthwise

W o portions (Fig. 6.3 6). Thus, a queen- closer 1s a brick which is half as wide

as the full brick. This is also known as queen-closer-half When a queen-closer is broken

ato two pieces, it is known as queen-closer-quarter. Such a closer is thus a brick

plece which is one-quarter of the brick size (Fig. 6.3 c).

BUILDING CONSTRUCTION

170

of

8. King closer. It is the portion of a brick which is so cut that theis wid

equal

one

of

its end is half that

full

to the

centre

the

width

of

(Fig.

one

obtained by

It

6.3 d). It is thus

other (lay) side.

the centre of the

Bevelld

closer. It is a special form

of a king closer in which

the

whole length

length of

of th

the

whole

the

brick (ie..

has half-header

and

sd, metal

pice

a

Cdgeb

uC

tA

u te f i g d g .

K

------**

stretcher face)

is bevelled in such a way

that half width is

between

end and

half-stretcher face.

9.

a

at the other end

while the width

brick,

full

cutting the triangular piece

(a) Full brick

(b) Queen

closer(Half)

(c) Queen- doser (Quanter)

main

tained at one end and full

width is maintained at the

45° to 60

other end (Fig. 6.3 e).

10. Mitred closer.

It is a portion

of a brick

whose one end is cut

splayed or mitred for full

(d) King closer

(c) Bevelled closer

(g) Half bat

(h) Three quarter bat

() Mitred closer

width. The angle of splay

may vary from 45° to 60°.

Thus, one longer face of

the mitred closer is of full

length of the brick while

the other longer face is

smaller in length (Fig. 6.3

.

11. Bat. It is the

) Bevelled bat

FIG. 6.3. VARIOUS FORMS OF BRICK PORTIONS.

portion of the brick cut across the width. Thus, a bat is smaller in length than the

full brick. If the length of the bat is equal to half the length of the original brick,

it is known as half bat (Fig. 6.3 g). A

three-quarter-bat (Fig. 6.3 h) is the one havin8

its length equal to three-quarters of the length of a full brick.

If a bat has its width

bevelled, it is known is bevelled bat (Fig. 6.3 i).

12. Arris._It is the edge of a brick.

13. Bull nose It is a special moulded brick with one

edge rounded (single bul

nose, Fig. 6.1 a) or with two edges rounded (double bull

nose, Fig. 6.1 b). These are used

in copings or in such positions where rounded

corners are

to sharp arises

14. Splays, These are special moulded bricks which are preferred

Splay stretcher {plinth stretcher) and splay header (plinth often used to form inplinu

header) are shown

F1

6.1 g) and k) respectively.

15. Dogleg or angle. It is also special form of moulded bricks (Fig. b.

which are used to ensure a satisfactory bond at

quoins which are at an angle oun

than

right angle. The

he angle and

than right

of the faces forming the

angle. These

ary according

lengths

dogleg vary

are

accor

to requirements.

preferred to mitred closer.

It 18 a corner or

16. Quoin.

the external angle on the face

side of a wall. Generaly

171

MASONRY-2: BRICKMASONRY

quoins

are

are

at

rght

angles.

But in

some cases, they

may be at angles

greater than

90° also.

17. Frog or kick. A frog is an indentation in the face of a brick to form a

brick is laid with

holdingthe mortar. When

frog is only on one face, that

key for

ehat face on the top. Sometimes, frogs are provided on both the faces. However, no

(as a rule) and

brick has two

are provided in wire-cut bricks. A

Goos

ahand-made brick has only one frog.

frogs

pressed

18. Racking back. It is the termination of a wall in a stepped fashion, a

shown in

Fig.

6.2.

19. Toothing.

It is the termination of the wall in such a fashion that each

bond if the wall

end projects, in order to

is continued horizontally at a later stage (Fig. 6.2).

provide adequate

alternate course at the

6.4. BONDS IN BRICK WORk

Bond is the interlacement of bricks, formed when they lay (or project beyona)

those immediately below or above them. It is the method of arranging the bricks in

courses so that individual units are tied together and the vertical joints of the successive

courses do not lie in same vertical line. Bond of various types are distinguished by

their elevation or face appearance. Bricks used in masonry are all of uniform size

will result.

Ifthey are not arranged (or bonded) properly, continuous vertical joints

An unbonded wal, with its continuous vertical joints has little strength and stability.

Bonds help in distributing the concentrated loads over a larger area. Since bricks are

is easily performed.

Small units, having uniform dimensions, the process of bonding

be observed:

should

rules

Rules for bonding For getting good bond, the following

1. The bricks should be of uniform size. The length of the brick should be twice

obtained. Good bond is not possible

its width plus one joint, so that uniform lap is

if lap is non-uniform.

2. The amount of

lap

should be minimum

4

brick

along

the

length of the

andbrick across the thickness of the wal

in special locations.

3. Use of brick bats should be discouraged, except

header should coincide with the

4. In alternate courses, the centre line of

below o r above it.

line of the stretcher, in the course

the same

should be

5.

The

vertical

centre

perpend.

used

should be used only in the facing; they should not be

joints in the

6. The stretchers

wall

alternate

along

courses

n the hearting. Hearting should be done in headers only.

7. It is

preferable to provide

every sixth

sides of the wall.

of

Types of bonds. Following are the types

1.

3.

Stretcher bond.

English bond.

5.

Facing bond.

7.

Brick on edge bond.

9

Raking bond.

11. Garden wall bond.

2.

4

6.

8

10.

course a s a

header course

provided

Header bond.

bonds

in brick

Flemish bond.

English cross bond.

Dutch bond.

Zigzag bond.

on

both the

work

BUILDING CONSTRUCTION

172

6.5. STRETCHER BOND

Stretcher bond or

stretching bond is the

one in which all the

bricks are laid as

stretchers on the faces

2

of walls. The length of

the bricks are thus

along the directionof

the wall. This pattern

(b) Elevation

(a) Isometric view

is used only for those

walls which have thickness of half brick (i.e.

9 cm), such as those

used as partition walls,

Diok

sleeper walls, division

walls or chimney

stacks. The bond is not

possible if the thick-

2, 4, 6-- -courses

1,3,5- -Courses

(c) Plan

(d) Plan

FIG. 6.4. STRETCHER BOND.

ness of the wall is

more.

6.6. HEADER BOND

Header bond or heading bond is

the one in which all the bricks are laid as

headers on the faces of walls. The width

of the brick are thus

along the direction

of the wall. The

pattern

is used only when the

thickness of the wall is

equal to one brick (i.e..

4

18 cm). The overlap is usu3

ally kept equal to half the

width of brick (i.e. 4 cm).

This is achieved by using

2

I

1

AtBat

A

(a) Isometric view

three-quarter brick bats in

(b) Elevation

each alternate courses as

quoins. This bond does not

have strength to transmit

pressure in the direction

of the length of the wall.

As such, it is unsuitable

for load bearing walls.

However, the bond is specially useful for curved

brick work where the

stretchers, if used, would

project beyond

the face of

TILIID

Bats

4

2,4,6 courses

(c) Plan

Bat

1,3,6-- -courses

FIG. 6.5. HEADER BOND

(d) Plan

MASONRY-2:BRICK MASONRY

173

the wall and would necessitate inconvenient cutting, This is also used in construcuon

of footings.

6.7. ENGLISH BOND

This is the most commonly used bond, for all wall thicknesses. This Dona

considered to be the

strongest. The bond

con-

sists of alternate

courses

and stretchers.

of headers

In this bond, the vertical

jointa

of the

header

Q

10

HHHHTTTAA

9 S S

8 HE

6 HE

other; sinmilarly, the ver

5 Ss

tical joints of the stretcher

4HE

courses also come overr

3 s

each other. In order to

2 H

break the vertical joints

in the successive courses,

s

course

Stretcher

course

|S

a

1 Ss

Header

S|s

LILEA

7 |s

courses come over each

T|HHHEH

I

S| s

sSs

S=Stretcher; H =Header; Q= Queen closer

it is essential to place

FIG. 6.6. ENGLISH BOND.

queen closer after the first

header (quoin header) in each heading course. Also, only headers are used for the

hearting of thicker walls. Fig. 6.6 shows the general elevation of the English bond.

Fig. 6.7 and 6.8 shows English bonds for walls of various thicknesses

Essential

Features. Following are the essential features of English bond.

1. Alternative courses will show either headers or stretehers in elevation.

2. Every alternate header comes centrally over the joint between two stretchers

in course below.

3. In the stretcher course, the stretchers have a min. lap of th their length

over headers.

4. There is no continuous vertical joint.

5. Walls of even multiple of half bricks (i.e. 1 brick thick wall, 2-bricks thick

wall, 3-bricks thick wall) present the same appearance on both faces. Thus a course

showing stretchers on the front face will also show stretchers on the back face.

6. Wall of odd multiple of half bricks (i.e. 1/ brick thick wall, 2 ; brick thick

wall etc.) will show stretchers on one face and headers on the other face

7. The hearting (middle portion) of each of the thicker walls consists entirely

of headers.

8. At least every alternate transverse joint is continuous from face to face.

9. A header course should never start with queen's closer, as it will get displaced.

he queen's closer should be placed just next to the quoin header. Queen's closers

are not required in stretcher courses.

10. Since the number of vertical joints in the header course are twice the number

of vertical joints in the stretcher course, the joint in the header course are made thinner

an

the joints

in

the

stretcher

course.

atTLDING cONSTRUCTION

174

Header

Stretcher course

course

Queens oloser (Q)

Stretcher

-Header course

s

course

I S S

1,3,5- -courses

(a) Plan for

2, 4, 6 - - COurses

1 brick thick wall

LS| SL

L

2,4,6--- COurses

1,3,5- -CoursesS

(b)

Plan for

1

brick thick wall

H

Q

S|S|S

1,3,5---COurses

o

2,4,6-- -courses

(c) Plan for 2 brick thick wall

B.

-B

HQ

H

1,3,5 -

- COurses

2, 4,8-- -cOurseS

(d) Plan for 2

briok thick wall

S STRETCHER FACING; H =HEADER FACING; Q = QUEENS CLOSER

B1 = QUARTER BAT (QUARTER QUEEN'S CLOSER

FIG. 6.7. ENGLISH BOND

MASONRY-2: BRICK MASONRY

175

End

LaSs|s|

1,3, 5

End

courses

2,4,6-

(a) Plan for

Coursess

1brickthick wall

-0-End

End

QTKQ s s

1,3,5-- - COurses

2, 4,6-- -courses

(b) Plan for 2 brick thick wall

B2 B3

B

Q

O

End

End

HH |

Is|s|s|s|

1.3.5-

2,4,6- -cOurses

courses

(c) Plan for 25 brick thick wall

Isl

End

Q

H

End

S

2,4, 6- cOurses

1,3,5-- coursees

(d)

S STRETCHER FACING

Plan for 3-brick thick wall

H

HEADER FACING;

= QUEENS CLOSER

B1 BAT; B2= BAT; Bs BAT

FIG. 6.8. ENGLISH BOND. (ALTERNATIVE ARRANGEMENTS)

6.8. FLEMISH BOND

In this type of bond, each course is comprised of alternate headers and stretchers.

Every alternate course starts with a header at the corner (i.e. quoin header). Quoin

closers are placed next to the quoin header in alternate courses to develop the face

ap. Every header is centrally supported over the stretcher below it.

Flemish bonds are of two types

)

Double flemish bond

(iü)

Single flemish bond.

BUILDING CONSTRUCTO

176

HL

10 HE-OI

bond

1. Double flemish

9S

LL

S

H

8 H-Q

7SL

6 H-O

In the double flemish

the

bond, each course presents

both in the

s a m e appearance

front face as well as in the

back face. Alternate headers

and stretcher are laid in each

course. Because of this, double

flemish bond presents better

appearance than English bond.

5SL

H

Ls

4 H-OL

2 HE-Q

N

HS H

S

H

I S I A s H_ S]

FIG. 6.9. DOUBLE FLEMISH BOND (ELEVATION

Fig. 6.9 shows the general elevation of flemish bond, for all the wall thicknesses. Fig.6.10

shows the double flemish

bond in plan, for walls of

various thicknesses.

features of double flemish bond

Special

s

H

1. Every course con-

sists of headersand

stretchers placed alter-

Q

s

IuA

1,3, 5-

nately.

2, 4,6---COurses

- COursesS

(a) Plan for one brick thick wal

2. The facing and

backing of the wall, in each

course, have the same ap-

B2

pearance.

3. Quoin closers are

used next to quoin headers

in every alternate course.

B

S

4. In walls having

thickness equal to odd mul-

H SL

B1,3,5--- cOurses

2,4, 6 -courses

(b) Plan for 1 brickthick wall

tiple of halfbricks, half bats

and three-quarter bats are

amply used.

5. For walls having

thickness equal to even

multiple of half bricks, no

bats are required. A header

or stretcher will come out

as header or stretcher on

H

S

Q

B

B

InA

H

S

1,3,5 - cOurses

the same course in front

2, 4,6--cOurses

(c) Plan for 2 brick thick wall

as well as back faces.

S

STRETCHER; H =HEADER

B2=HALF BAT

Q

QUEENS CLOSER

B3=BRICK B1 =QUARTER BAT

FIG. 6.10. DOUBLE FLEMISH BOND.

MASONRY

BRICK:

MASONRY

177

2. Single femish bond Single flemish bond is omprised of double flemish bond

facing and

and English bond backing and

in each course.

bond thus

th English bond and appearance of flemish bond.This

strength

of the

However,

this

strength of

English

hearting

uses

bond

the

can

be used forthose

walls

having thickness

is done with

at

least equal to 1

brick. Double flemish

facing

good quality expensive bricks.

bricks can

cheaperflemish

sed for backing and hearting. Fig. 6.11 shows the However,

plan of single

bond

od

for various thicknesses of the wall,

Q.

S

K S]

B

1,3,5 courses

2, 4,6

courses

(a) Plan for 1 brickthiek wal

SHsH

B2

1,3, 5-

courses

2,4,6

COurses

(b) Plan for 2 brick thick wall

S= stretcher; Q

Queen's closer

B2-HALF BAT; Bs-BRICK; B1=QUARTER BAT

FIG. 6.11. SINGLE FLEMISH BOND.

Comparison of English

Bond and Flemish Bond

1. English bond is stronger than flemish bond for walls thicker than 1

brick.

2. Flemish bond gives more pleasing appearance than the English bond.

3. Broken bricks can be used in the form of bats in Flemish bond. However,

more mortar is required.

4. Construction with Flemish bond requires greater skill in comparison to English

bond.

6.9. FACING BOND

This bond is used where bricks of different thickness are to be used in the facing

and backing of the wall. In this bond, a header course is provided after several stretcher

different in the facing and backing, the vertical

courses. Since the thickness of bricks are

is kept equal to the least common multiple

1stance between the successive header courses

and facing bricks. Thus, if the nominal thickness of facing

the

otDricks

of backing

thickness

is 10 cm and that of backing bricks 1scm, the header course is provided

BUILDING CONSTRUCTION

206

3. The thickness of wall should not be less than 1/6 of the storey heighe

4. For basement walls, the thickness should not be less than one-third the heieho

of retained soil above basement level, nor should it be less than the thickness of wa

at ground floor plus 10 cm.

5. Table 6.6 is applicable for walls built of bricks or concrete blocks, using li

lime

mortar (1:3), or cement mortar (1:6) or composite mortar (1:2:9).

6.27. TYPICAL STRUCTURES IN BRICK WORK

Following are the common structures constructed in brick-work:

1.

2.

Piers

Walls

3.

Footings

Buttresses

5.

Thresholds

Window sills

8.

7.

Corbels

9.

Jambs

3.

10.

11. Brickwork curved in plan

12.

13. Retaining walls and breast walls

Copings

Ornamental brick work

Brick nogging

14. Fire places and flues

15.

Chimneys

16. Arches

17.

Lintels

18. Cavity walls.

Out of these, walls, piers and footings have already been discussed in earlier

articles of this chapter. Fire places and flues, chimneys, arches, lintels and cavity walls

have been discussed in separate chapters.

6.28. BUTRESSES

Buttresses are

piers that are provided

to resist thrusts from

roof

trusses

or

strengthen main walls

or boundary walls.

Taey give lateral support to the main load

bearing walls. They

are usually in the form

of projections and are

1

Section

Section

(a) Splayed capping

(b) Tumbled in capping

FIG. 6.39. BUTTRESSES

usually completed

with cappings. Two forms of cappings: i) splayed capping, and (ii) tumbled-in-capping

are shown in Fig. 6.39.

Buttresses are usually designed to resist overturning moment due to lateral thrus

Their thickness is found in such a way that the resultant of the vertical and later

loads remain within the middle third of the section so that no tension is develo

Buttresses must be constructed along with the walls so that they are bonded to

wall course by course.

6.29. THRESHOLDS

mal

door

the extern

Threshold consists of the arrangement of one or more steps outside the

thresho

1wo TOrns of thresholds are shown in Fig. 6.40. Each step of

opening.

MASONRY-2: BRICKMASONRY

207

should be constructed

Door

with slight outward-

slope

so

that the rain

str

done in cement mortar.

It is preferable too use

some sort of hard finishing on the top ofeach

Stepsp

GL.SU

G.L.

Concrete

constructed at the last

MIRYS

¥

wwwzXIKLA

sRE

step. Thresholds are

building

Floor

Steps

con-

struction should be

stage of

Door

opening

water can be easily

drained off. The

Floor

opening

Wall

(b)

(a)

FIG. 6.40. THRESHOLDS.

con-

struction, when other construction activities have almost come to an end.

6.30. WINDOW SILLS

A sill provides a suitable finish to the window opening and it affords a protection

to the wall below. A great many external sills in modern buildings are constructed

of bricks laid on edge, or of roofing tiles, both of which harmonize well with brick

walling. Fig. 6.41 shows vertical section and part elevation of two type of sills

The following points should be kept in mind in constructing brick sills:

1. The sills of windows, on external walls, should be properly weathered (slope

1 in 6) to drain off rain water.

Reveal

The projection of sill, if any, should

Reveal|

Wood frame

not be less than 50 mm and should

be suitably throated.

2. Bricks for the sills should

Brick on

edge

be hard, well burnt and set in ce

ment motar.

3. The top surface of the brick

sills should be provided with suitable finish.

4. In sills made of tiles, tiles

Drip

(a) Brick on edge sill

w

are laid in cement mortar and in

two courses, breaking joint as in-

Wood jamb

Wood frame

dicated in elevation (Fig. 6.41 6).

The lower course of tiles should

be provided

with continuous nibs

Tiles

Tiles

which form a perfect drip, past

Joint Joint

which no dripping rain water can

find its way.

5. It is preferable to provide

damp proofing course below the

window sill so that moisture does

not enter inside the structure.

(b) Tile sill

FIG. 6.41. BRICK AND TILE SILLS.

BUILDING CONSTRUu

RUCTION

208

6.31. CORBELS

Corbels are constructed to provide bearing for floor beams, girders and jack

Brick corbels are constructed by projecting bricks of each course from a wallarche

corbel course should not

Each

Stone

project more than 5 cm

from the corbel below,

lintel

and the total projection

of the corbel should not

project more than the

thickness of the wall.

Headers are used to

e

walla

form each corbel course,

and they should break

joint with the course be- Section

Elevation

low. Bricks used for cor(a) Continuous corbels

bel construction should

be of good quality and

Section

Section

(b) Isolated corbels

FIG. 6.42. CORBELS.

superior workmanship

for its construction should be used.

Corbels can be either continuous or can be isolated. Fig. 6.42 (a) shows

two

of continuous corbel. Fig. 6.42 (b) shows an isolated

corbel.

6.32. COPINGS

furms

Copings are provided io

serve

as

a

protective coverings

top. Coping throws

to walls at its

the rain water clear off the wall.

Bull nose

brick

Chamfered Half round Saddle back Tile or stone

brick

brick

(b)

(c)

brick

Sometimes, special moulded

bricks are used for coping,

having

proper weathering and throating.

If copings are made of

regular

bricks, they are to be properly

shaped. Bricks used for coping

should be hard and strong

enough

to resist

weathering actions. The

(a)

joints in the coping should be

fewer. They should be

invariably

constructed to cement mortar.

Fig. 6.43 shows

633. JAMBS

Jambs

crecsing

FIG. 6.43. COPINGS.

some common

types of brick copings

the vertical sides of the

openings left in the walls to receive doo

windows, fire-places etc. These are

built cither square

through or with a reces A

square through jamb is used

when there is sheltered

only

weakness in joint between the frame

opening. Otherwise, any

and

the

brickwork will let the rain water

A recessed jamb is better

tn

because the projecting nib of brickwork

through which rain may otherwise be driven to

protects

the inside. Recessed jambs are lso

known as rebated jumbs. The recess

may be either on the inside of the jamb O the

are

MASONRY -2: BRICK MASONRY

Qutside.

If it 1s on

inside,

209

then

he frame which is set within it

from outside. If the recess is on the outside,

will be partly

concealed

(a) Square - through jamb

the whole of the frame will be

visible. A square through jamb may

its outside face in

have splay at

AAAAE

ILAHZ

which it is known as splayed jamb.

Jambs may be constructed either

in English bond or in Flemish bond.

T

LHA

The square jambs in brick work

HHAAR

(b) Splayed jamb

(c) Rebated jamb with outside recess

are constructed as stopped ends.

For construction of brick jambs

with proper bond to avoid con-

A

ANN

tinuous vertical joints, it is es-

INHLHL

sential to use bevelled bats and

(d) Rebated jamb with inside recess

king, queen or bevelled closers.

FIG. 6.44. VARIOUS FORMS OF JAMBS.

6.34. ORNAMENTAL BRICK wORK

Ornamental brick work can be obtained by the use of special types of bricks

(moulded bricks), mortars of different colours, mortar joints of different thickness and

different arrangement of bricks, so as to get pleasing appearance. Sometimes, bricks

LULIL

(c)

(a)

Y

(b)

(a)

(a) VERTICAL PANELS

(b) DIAGONAL PANEL

(c) QUOINS

ORNAMENTAL BRICK WORRK

FIG. 6.45. EXAMPLEs OF

BUILDING CONSTRUCTION

210

of different

thicknesses a r e

with sharp and

in

can be used

used to

give

architectural treatment.

appearance.

Even

present more pleasing

of the bricks is also important

suitable pattern. Texture

but smooth face bricks are preferred

angular faces

a

mad

brio

coloured

Machine

ka

ough

better appearance,

n

produce deep sh

joints

frequent.

dust storms a r e

is used only for

areas, where

ornamental brick work

The

appearance.

better

and thus give

stones produce a much better e

fect.

combination of bricks, tiles and

work. Sometimes, a

ornamental brick work.

of

Fig. 6.45 gives few examples

sandy

textured bricks

give

Recessed

more

CURVED IN PLAN

6.35. BRICK WORK

as in construction of chimnev

sometimes required, such

Brick work curved in plan is

built exactly in the same mann

work curved in plan is

Brick

etc.

flues

soak pits,

is 6 metres or less, all coursea

es

but where the inner radius

as for general brick work,

should be of headers

with bricks cut to ra-

dius. For large work,

specially

moulded

bricks should be used

in lieu of bricks cut

to radius. Standard

bricks, if used would

give very wide joints.

In case of unimportant

works such as lining

to soak pits and cess

pools, circular brick

works of inner radius

2, 4,6-- - coursesS

1,3, 5- Courses

FIG. 6.46. CIRCULAR BRICK WORK

(1-BRICK

WALL)

less than 6 m may be built like brick work straight on plan or to a curve exreeding

6 metre inner radius. These specifications also apply to brick work polygonal in plan.

be

Where water tightness is required, moulded bricks, or bricks cut to radius should

with

used. Where water tightness is not a major consideration, bricks may be laid

varying joints.

Fig.

6.46 shows the

plan of

alternate

plan. The shape of the brick work

can

courses

of

1

brick thick wall circular in

be maintained either

by

a

template

of thin

board of wood, or by using a trammel.

6.36. BRICK NOGGING

Brick nogging is the term used to denote brick work built up between woode

quarters or framing. Fig. 6.47 shows brick nogging. The uprights or posts are

mm x 120 mm in size, placed at a central distance of 1.50 metres apart. The horz0

members are ribs of planking (known as nogging member) 100 mm x 50 mm,

at 900 mm vertical distance apart. All the faces of the timber in contact with

150

ed

masonry is well-coated with boiling coaitar (two coats) and the faces of timber eaid

to view, on completion, is given three coats of specified paint. The bricks are

in the openings of the framework and are placed in such a way that equal projecuar

of timber are left on both the sides. Brick work is done in lime or cement mor

tions

MASONRY-2:BRICK MASONRY

211

Wire nails

for bonding

-Angles

Horizontal

cement

Plaster

or

lime

work

B

r

i

c

k

in

sides

both

plastered

m o r t a r

FIG. 6.47. BRICK N0GGING.

After the completion of brick work, the surfaces of brick work is kept thoroughly wetted

before plastering. Nails are deiven into the ledge of the timber frame work to give

a hold to the cementlime plaster with which both faces of the brick work is then

finished off, of a thickness to be flush with the faces of the posts. The plastering

is cured for three weeks. If the wooden members are of shorter width and the entire

exposed surface is to be plastered, a metal lath is fixed on both the sides of nogging

and the entire area is then plastered. This arrangement will check the plaster from

peeling off from the wooden members.

6.37. RETAINING WALLS AND BREAST WALLS

A retaining wall is a wall of increasing thickness, which is constructed to retain

artificial filling (mostly earth fill) to one side. A breast wall is similar to retaining

wall, but it is constructed to protect natural sloping ground from the cutting action

of weathering agents. Fig. 6.48 (a) shows a retaining wall and a breast wall in respective

positions. The method of designing both the walls is the same ; only the function

of each is different. The following salient points are note worthy:

1. Because of the increase of earth pressure with the depth of fill, the section

ot retaining wall/breast wall increases from top to bottom. Generally, the back of the

wall is stepped while the face is kept either vertical or inclined.

UILDING CONSTRUCTION

212

CTION

Cut

Fill

(a)

Breast wall

Retaining wall

Face

Weep hole

Back

Weep hole

G.L

(c)Retaining wall

(b) Breast wall

TNZZAZN

3

Plan at top

Section A\B

(d) Counterfort retaining wall

FIG. 6.48.

2. Breast walls are some times j.0ovided with batter on both sides, as shown

in Fig. 6.48 (6).

3. When the height of fill is large,

simple retaining walls become uneconomical.

In that case, lateral supports are

provided, on earth side, at regular interval

4 metres). Such a wall is known as

counterfort

as shown in Fig.

retaining wall,

b.*o

(d). The counterforts must be tied to the main wall with internal irou ties to counterac

any tendency to fräcture at the junction.

4. As a thumb rule, the thickness of wall at

any depth h below the fill leve

may be kept between 0.33 h to 0.4 h, depending upon the conditions of the nue

material.