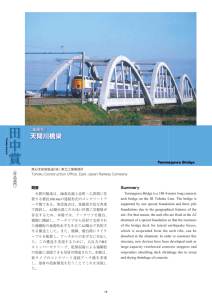

AlP Conference Proceedings pubs.aip.org/aip/acp Volume 2789 Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them (PTLICISIWS-2022) Namangan, Uzbekistan • 5 -6 May 2022 Editors • Sherzod Korabayev, Plekhanov Aleksey, Huseyin Kadoglu, Salikh Tashpulatov and Nosir Yuldashev AIP Conference Proceedings Volume 2789 ISBN: 978-0-7354-4499-7 ISSN: 0094-243X pubs.aip.org/aip/acp A lP Publishing AIP Conference Proceedings Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them Volume 2789 Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them (PTLICISIWS-2022) Namangan, Uzbekistan 5-6 May 2022 Editors Sherzod Korabayev Nam angan Institute o f Engineering and Technology, N am angan, Uzbekistan Plekhanov Aleksey R u ssian Sta te University A .N .K osigin, Moscow, Russia Huseyin Kadoglu Ege University, Bornova, Turkey Salikh Tashpulatov Tashkent Institute of Textile and Light Industry, Tashkent, Uzbekistan Nosir Yuldashev Fergana Polytechnic Institute, Fergana, Uzbekistan Sponsoring Organizations Namangan Institute of Engineering and Technology Russian State University A.N.Kosigin Ege University Tashkent Institute of Textile and Light Industry Fergana Polytechnic Institute All papers have been peer reviewed. AIP Publishing Melville, New York, 2023 AIP Conference Proceedings To learn more about AIP Conference Proceedings visit http://proceedings.aip.org Volume 2789 Editors Sherzod Korabayev Nosir Yuldashev N am angan Institute of Engineering and Technology Fergana Polytechnic Institute Technology o f Textile Products Power Engineering 7, K a sa n sa y Street 8 6 Fergana N am angan, 1 6 0 1 1 5 Fergana, 1 5 0 1 0 7 Uzbekistan Uzbekistan Em ail: sherzod.korabayev@ gm ail.com Em ail: sanjar.tojim irzaev@ gm ail.com Plekhanov Aleksey Ru ssian State University A.N .Kosigin Textile Engineering 3 3 Sa d o vn ich eskaya, Building 1 Moscow, 1 1 7 9 9 7 R u ssia Em ail: vonahelp@ m ail.ru Huseyin Kadoglu Ege University Textile Engineering 12 Youth Street Bornova, 3 5 0 4 0 Turkey Em ail: Huseyin.kadoglu@ ege.edu.tr Salikh Tashpulatov Tashkent Institute of Textile and Light Industry International Affairs 5, Shoh jahon Tashkent, 1 0 0 0 0 0 Uzbekistan Jizzakh Polytechnic Institute D epartm ent o f Textile Engineering 4, Islom Karimov Jizzak, 1 3 0 1 0 0 Uzbekistan Em ail: ssth61@ m ail.ru Authorization to photocopy items for internal or personal use, beyond the free copying permitted under the 1978 U.S. Copyright Law (see statement below), is granted by the AIP Publishing LLC for users registered with the Copyright Clearance Center (CCC) Transactional Reporting Service, provided that the base fee of $30.00 per copy is paid directly to CCC, 222 Rosewood Drive, Danvers, MA 01923, USA: http://www. copyright.com. For those organizations that have been granted a photocopy license by CCC, a separate system of payment has been arranged. The fee code for users of the Transactional Reporting Services is: 978-0-7354 -4 4 9 9 -7 /2 3 /$ 3 0 .0 0 Д 1Р © 2023 AIP Publishing LLC Publishing No claim is made to original U.S. Government works. Permission is granted to quote from the AIP Conference Proceedings with the customary acknowledgment of the source. Republication of an article or portions thereof (e.g., extensive excerpts, figures, tables, etc.) in original form or in translation, as well as other types of reuse (e.g., in course packs) require formal permission from AIP Publishing and may be subject to fees. As a courtesy, the author of the original proceedings article should be informed of any request for republication/reuse. Permission may be obtained online using RightsLink. Locate the article online at http://proceedings.aip.org, then simply click on the RightsLink icon/“Permissions/Reprints” link found in the article abstract. You may also address requests to: AIP Publishing Office of Rights and Permissions, 1305 Walt Whitman Road, Suite 300, Melville, NY 11747-4300, USA; Fax: 516-576-2450; Tel.: 516-576-2268; E-mail: rights@aip.org. ISBN 978-0-7354-4499-7 ISSN 0094-243X Printed in the United States of America Spontaneous polymerization of a monomer based on 1-chloro-3-piperidine-2-propanol with methacrylic acid Nilufar Pulatova and Oytura Maksumova 040073 Investigation of adsorption processes of sulfur compounds with natural gas in modified forms of clinoptilotite Nilufar Sarimsakova, Normurot Fayzullaev, and Khayotkhon Bakieva 040074 Determination of the composition and properties of the components of polymer gels in electrolyte solutions Khamza Trobov, Nikolai Ferapontov, Mikhail Tokmachev, Gulnoza Tursunova, and Khusniddin Karimov 040075 Research of human-computer interaction in the modern education system Dilnoz Ruzieva, Ulugbek Sodikov, and Sodikjon Mukhlisov 040076 The interaction of vitagenic experience, computer and a human in a smart systems Nodira Rustamova 040077 Control mechanism of eliminate noise and improve visual perception of the image Saida Beknazarova, Shaxislam Joldasov, Ozoda Abdullayeva, and Dilshod Mamasoatov 040078 Conducting engineering-geological researches on bridges located in our country and diagnosing their super structures, methods of eliminating identified defects Olmos Zafarov, Doston G’ulomov, and Zuxriddin Murodov 040079 Conducting engineering and geological research on the design and construction of buildings and structures in saline areas Zafar Maxkamov, Olmos Zafarov, Jamshid Xudoyberdiyev, Elbek Urishbayev, and Jo’rabek Ravshanov 040080 Soil composition in the construction of engineering structures, their classification, assessment of the impact of mechanical properties of soils on the structure Ravshan Bobojonov, Olmos Zafarov, and Jaxongir Yusupov 040081 The research on road dust and particles caused by traffic (on the example Jizzakh city) Kubaymurad Ismayilov, Zebo Alimova, Ixtiyorjon Asqarov, and Kamola Karimova 040082 Determination of thermal conductivity and thermal resistance of fire-resistant and heat-insulating wall materials made on the basis of industrial waste Kamol Abdusamatov and Azizbek Bakhodirov 040083 Groundwater flow modeling in urban areas Zokhidjon Abdulkhaev, Mamadali Madraximov, Axror Akramov, and Aybek Arifjanov 040084 Influence of soil contaminated with heavy metals on decorative trees Nilufar Kobulova, Misliddin Halmatov, and Muxtorjon Xodjakulov 040085 Conducting Engineering-Geological Researches on Bridges Located in Our Country and Diagnosing their Super Structures, Methods of Eliminating Identified Defects O l m o s Z a f a r o v a), D o s t o n G ’u l o m o v b), Z u x r i d d i n M u r o d o v c) Jizzakh Polytechnic Institute, Jizzakh, Uzbekistan a Corresponding author: olmos.zafarov@mail.ru b>bigfire8088@gmail. com czuxriddinmuradov@gmail. com Abstract. This article presents information and research on the conduct of engineering and geological surveys on the bridges of our country and the diagnosis of their superstructures, methods of eliminating identified defects. The article also mentions the bridge, located Jizzakh (highway 4P38) - Pakhtakor - Dustlik.- Gagarin - Highway M39 (918 km) - 4 +35 km of highway 0P164 which passes through the Sangzor River, built according to outdated design standards and given information on inspection and elimination of defects of the bridge, which is in disrepair. Keywords. Bridge repair, superstructure, sulfite-alcohol composition, regulatory loads, technological cracks, cementpolymer mortar. INTRODUCTION The Decree of the President of the Republic of Uzbekistan No. PP-5083 dated April 21, 2021 "On additional measures to actively attract investment in the field of geology, the transformation of network enterprises and the expansion of the mineral and chemical base of the republic" was adoptedin order to develop the field of geology. Inaddition, accepted new waysto transform the enterprises of the geological industry on the basis of advanced international experience, to introduce an effective management system in them, to reduce the cost of geological exploration aimed at discovering new mineral deposits, to increase the inflow of foreign direct investment in order to develop new jobs in industry. In the world and in our country, the construction of transport facilities is often carried out in difficult engineering and geological conditions, including in regions consisting of salt marshes. Such cereals occupy large areas of the earth's surface, in particular Australia, America, Mexico, Egypt, Pakistan, India, China, Iran, Kazakhstan, Uzbekistan, Russia, as well as a number of European countries and almost all three climatic zones. Therefore, the study of the properties of salt gratings, in particular, the assessment of the stagnation of transport structures built in them, is one of the urgent tasks. When using transport structures, as well as highways and transport structures built on saline soils, groundwater levels are formed under them due to natural and artificial factors. As a result of an increase in the groundwater level and an increase in the moisture content of the foundation soil, an uneven destruction of the structure occurs. This leads to excessive spending of time. More than 90% of bridges and pipelines in Uzbekistan are built of reinforced concrete, most of them are made of precast reinforced concrete. Currently, the use of monolithic reinforced concrete is expanding. Increasing the level of industrialization in bridge construction is carried out through the use of more advanced technological techniques, the transformation of construction into machine production, that is, the organization of construction based on modern methods and the use of effective technologies, as well as increasing the level of mechanization of work and the use of economically cheap structures. Problems in the Textile and Light Industry in the Context o f Integration o f Science and Industry and Ways to Solve Them AIP Conf. Proc. 2789, 040079-1-040079-5; https://doi.org/10.1063/5-0145756 Published by AIP Publishing. 978-0-7354-4499-7/$30.00 040079-1 Engineer must take into account the natural and climatic conditions of the territory, diagnostics, as well as the type of soil, in projecting of bridges. The bridge, located on 4+35 km of highway 0P164, “Jizzakh (highway 4R38) - Pakhtakor - Dustlik- Gagarin Highway M39 (918 km)”, which passes through the Sangzor River in the Jizzakh region, was built around 1965. The superstructure of the bridge is 3 x 16.76 m . The bridge, located on the road of the second technical category, has overall dimensions of g-7.55 m and two sidewalks of 1.0 m each. The bridge consists of three spans. The bridge's superstructure consists of six "T"-shaped spans with prestretched reinforcement with a length of 16.76 m. Spans are interconnected by means of monolithic reinforced concrete joints in the immediate vicinity of the roadway plate. The width of the bridge is 20.0 m, the total length of the bridge is 50.88 m. FIGURE 1. The general view of the bridge METHOD OF RESEARCH In recent years, the growth of heavy loads and the increasing need for their delivery to the necessary places, a decrease in the quality of construction work for certain reasons and an unsatisfactory level of issues of their repair, maintenance in good condition lead to an almost twofold reduction in the service life of bridges and other road structures. And this, in turn, requires additional costs to maintain their condition at a satisfactory level. As a rule, the performance of these works is also assigned to road engineers. In our republic, most of these structures were built in the 50s and 60s, and most of them either do not fully meet modern requirements, or recently it has become difficult to withstand the weight of developing large-sized transport, the dimensions of which are also small, which in turn requires taking the necessary measures or strengthening structural elements, increasing the width etc. requires expansion. The superstructure of the bridge consists of precast reinforced concrete, the movement which is carried out above of it, designed for standard loads H-18 and HK-80. Reinforced concrete of class B25 was used as a highstrength building material. Superstructure consist of 6 "T" -shaped frame spans, not previously stretched. The sidewalk is made of prefabricated porous slabs of ICE. The width of the pedestrian path is 100 sm. The type of bridge bed is asphalt concrete. The total thickness of road surface is 18-22 sm. The shore and intermediate bridge supports are installed in two rows. The support area is 30x35 cm. The racks of the middle supports have a length of 3.20 m . The upper part of the supports is combined with a monolithic reinforced concrete screed. Table top dimensions: length - 10.30 m, width - 120 cm, height - 45-50 cm. The foundation is mounted on natural soil in a monolithic massive way. Beams in bridge intermediate devices are 040079-2 mounted on metal cushions in a tangential way. The calculation of the supports is carried out by a zero picket fence, the calculation of the types of piles and pillars is carried out from left to right along the kilometer. According to representatives of the responsible organization, there were no accidents on the bridge during exploitation. The need for the correct solution of these issues generates the need to solve rather complex organizational work and economic tasks, or dictates the need to develop technical and economic guidelines for the expansion of the facility, determining the order and timing of work, organizational and technical orientation, creating a raw material base and, if necessary, their readiness for mass use. these include the expansion of structures, the strengthening of their elements, the repair of worn-out ones, the mechanization of work as far as possible, the effective use of new materials and new methods, as well as the performance of all work with high quality. The determination of the carrying capacity of structures with large weights, which appeared in later times, was also the responsibility of the guidebooks. For the correct solution of these issues, engineers need to know perfectly the designs of various types of structures being erected, how their design is carried out, construction technology and how to properly use the structures being erected. The quality of the diagnosed artificial structures largely depends on the good organization and full-fledged performance of geodetic, marking and control and measuring works at all stages of construction. Geodetic and marking works during the construction of small and medium bridges and pipelines are carried out by a contractor or an engineer of the production and technical department. Assessment of the condition of the coating is the main issue of choosing technical solutions for the work. Based on this, it became known that the protective properties of the coating are judged by its appearance. The loss of the coating's ability to protect the metal from corrosion wear is determined according to Table 1. TABLE 1. Assessment of the protective properties of the coating Marks Coating wear surface, % destruction metal corrosion 1 2 Up to 5 Up to 1 3 4 5 5-25 25-50 Above 50 1-5 5-15 Above 15 Coating wear surface by sizes destruction depth diameter of corrosion sites, mm No destruction The outer layer destruction is visible Up to 0,5 when it is 10 times bigger The outer destroyed layer is visible 0,5-1,0 Decomposition to a primer layer 1,0-3,0 Decomposition to the surface to be Above 3,0 painted The degree of elimination of defects identified as a result of diagnostics, cleaning of metal from rust and remnants of old paint is determined based on the requirements for surfaces, depending on the type of paint (Table 2). TABLE 2. Requirements for the preparation of surfaces for repair work as a result of diagnostics Degree of surface preparation I Degree of purification from contamination and corrosion products Complete cleaning of paintwork and corrosion products Features of prepared surfaces II Cleaning of old paint coatings, rust residues, whitewash when moving large pieces Loss of oxides to the second degree (it is impossible to see without instruments). Surface preparation continues in the same way as preparation for a new product On the surface of the coating there remain: individual points of rust, small pieces of scale that fit snugly to the base, fragments similar in color to rust in places where there used to be rust III Faulty parts of old paint coatings, separated from the base Undamaged fragments of paintwork on the surface of structures that are tightly adjacent to the base 040079-3 RESEARCH RESULTS When diagnosing superstructure of bridge, the following was established: the intermediate bridge structures are precast reinforced concrete, the movement is upper, designed for standard loads of H-18 and k-80. Reinforced concrete of class B25 was used as a high-strength building material. The total length of the superstructure is 16.76 m, and they consist of six "T"-shaped beams, not stretched. The beams are interconnected at the level of reinforced concrete slabs. The design range is 16.10 m. The height of the dam is 100 cm . The thickness of the conductive plate is 15 cm. The distance between the fins of the conductors is from 165 cm to 183 cm. FIGURE 2. Overview of defects in bridge superstructure As a result of the diagnostics , the following was revealed: - welding seams on the edges of paving slabs and on poles are broken. This is due to the dynamic effects of passing by the wheels of the car and the disruption of the compensators; - there is a partial loss of the protective layer of concrete, as well as the opening of the reinforcement in some places; - there are technological cracks and breakdowns caused by cooling of the intermediate device; - as a result of waterproofing violations, areas prone to corrosion appear on the concrete surface. CONCLUSIONS A study conducted to study their salinity characteristics and the degree of salinity associated with the amount of initial plaster and the degree of salt leaching during prolonged exposure to water based on salt gratings of buildings and structures allows us to draw the following conclusion. The following recommendations have been developed for the repair of the bridge superstructure and the restoration of its technical condition: 1. Restoration of deformation seams, treatment with metal brushes of cracks formed earlier on the plate of the carriageway; 2. Repair intermediate devices, seal cracks with concrete with polymer-cement mixture. Injection with epoxy resin, if the cracks are not more than 0.5 mm; 3. Reinforcement of strong beam defects by metal levers; 4. Repair of the pedestrian path and installation of railings according to regulatory rules; 5. Cleaning the surface of intermediate devices from residual alkalis. To restore the destroyed reinforced concrete span of the bridge, two categories of materials should be used: 040079-4 type I - compositions that form solid coatings after application to concrete, similar in properties to cement stone (cement-sand mortars, polymer-cement compositions); Category II-rubber-like elastic compounds (compounds of the “filler" type, nitrite, rubber-bituminous compounds, epoxy, compositions based on perchlorovinyl resins) that do not break down with significant deformations. It is recommended to use cement-sand mortars and concretes with the addition of sulfite-alcohol fixed SSB. Sulfite-alcohol inert SSB improves hydration of solution particles, increases their adhesion to old concrete, mineral components and fittings. Repair and restoration of reinforced concrete structures with a thickness of the restored layer up to 60 mm is recommended to be carried out from mortar, and concrete structures with a thickness of 60 mm or more. As a result of the conducted research, it was established that the technology of preparation of cement-polymer mortar should be carried out as follows: 1. For the preparation of cement-polymer solutions, M400 Portland cement (GOST 10178-85) should be used as a binder, sand (GOST 8736-93) should be used as a filler; 2. The content of powdery and clay mixtures should not exceed 1%. The cement-sand ratio should be 1:3; 3. Mixing of the binder (cement) and filler (sand) is carried out in shovel mixers or concrete mixers with forced mixing in a dry state for 3-5 minutes until a homogeneous mass is obtained; 4. SSB additives in an amount of 0.2% by weight of cement are dissolved in water. The resulting solution is gradually introduced into a dry mixture of cement and sand, thoroughly mixed until a homogeneous mass is obtained, then mixed with water so that the ratio of water and cement is W: C < 0.45. REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. Dmitriev V.V., Yarg L.A. Methods and quality of laboratory study of soils: textbook / V.V. Dmitriev, L.A. Yarg. -M.: KDU, 2008. - 502 p. Trofimov V. T., Koroleva V. A. Laboratory work on soil science. -M.: KDU, University book, 2017. - 654 p. Trofimov V. T. et al. Ground science. -M., Publishing House of Moscow State University, 2005. - 1024 p. Muzaffarov A. A., Fanarev P. A. Engineering and geological support for the construction of highways, airfields and special structures. Tutorial. M.: MADI, 2016. -180 p. Wesley Cook, Bridge Failure Rates Consequences and Predictive Trends” 2014. Blank, S. A., M. M. Blank, and H. Kondazi. 2014. “Chapter 3: Concrete Bridge Construction,” Bridge Engineering Handbook, Second Edition: Construction and Maintenance, eds. W. F. Chen and L. Duan, CRC Press, Boca Raton. Ch. S. Raupov. “Operation, testing and rehabilitation of transport facilities” Volume 2, 2016. S.S. Salikhanov “Design and construction of transport facilities”, Volume 1, 2018. MSHN 32-2004 MSHN 32-2004 "Instructions for determining the load-bearing capacity of existing reinforced concrete beams of road bridges". 040079-5