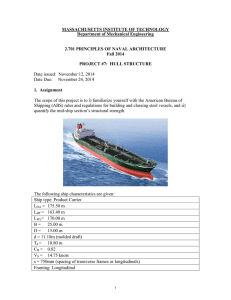

ABS Rules for Survey After Construction 2007 Part 7

advertisement