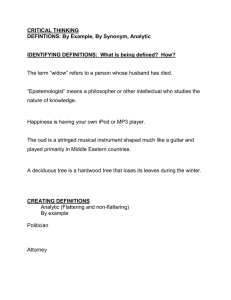

A common complaint from logistics managers is leveled at supply chain automation, and it goes something like this: How can we manage our logistics processes if we don’t know how to measure them? Alignment of demand and supply management was supposed to have been solved by now thanks to software applications and new e-business practices. However, in an era characterized by large inventory write-offs and a growing suspicion about the perceived value of enterprise-wide supply chain solutions, logistics professionals have every right to insist on demonstrable return-on-investment (ROI) from the systems they’ve implemented. So how do you evaluate supply chain performance? To answer that question, analyst firm IDC partnered with Logistics Today to survey the logistics landscape and bring some clarity to the situation. This article provides a practical guide on how to measure and monitor logistics operations, based on exclusive research undertaken by this magazine and IDC, and supplemented with additional market research and competitive intelligence from IDC. An analytic application, as IDC defines it, must meet each of the following three conditions: Process support. Packaged application software that structures and automates a group of tasks pertaining to the review and optimization of business operations (i.e., control) or the discovery and development of new business (i.e., opportunity). Separation of function. Can function independently of an organization’s core transactional applications, yet can be dependent on such applications for data and may send results back to these applications. Time-oriented, integrated data from multiple sources. Extracts, transforms and integrates data from multiple sources (internal or external to the business) — supporting a time-based dimension for analysis of past and future trends — or accesses such as a database. The definition of analytic applications includes business applications for planning, forecasting and modeling that relate to specific business subjects spanning industries or specific to industries: Financial/BPM analytic applications. Analytic applications designed to measure and optimize financial performance and/or establish and evaluate an enterprise business strategy. CRM analytic applications. Analytic applications designed to measure and optimize customer relationships. Operational analytic applications. Analytic applications designed to measure and optimize the production and delivery of a business’ products and/or services. A closed-loop applications model developed by IDC emphasizes the importance of linking transactional systems with analytic systems. The five major steps of the closed-loop application model are: Track. Process of extraction, transformation, loading and integration of data into a data warehouse. Analyze. Process of analyzing the data using business intelligence tools such as query and reporting, multi-dimensional analysis, and data mining. Model. Process of formulating models based on the analysis using various descriptive and predictive statistical methods and resulting in scoring or other models used in decision making. Decide. Process of arriving at a decision based on analysis and preexisting or newly developed models that often combines individual and group input facilitated by collaboration tools or personal interaction. Act. Process of acting on the decision based on the particular business process being addressed. Examples include: launching a new marketing campaign based on the analysis of previous campaign results, customer behavior, new promotional plan or inventory levels; approving or denying a request for credit based on past financial activity; re- negotiating sourcing contracts based on supplier delivery trends, product quality, and warranty activity trends, etc. While the adoption of transactional applications for supply chain automation is high, the benefits that organizations can derive from automating the related decision-making processes remain largely untapped. The return on investment from analytic applications can be substantial. In fact, analytic projects that focus on operations or supply chain processes have the highest median ROI (277%) as compared to those related to CRM (55%) or finance (139%) processes. SCM analytic applications enable the monitoring and analysis of operational data generated through such activities as inventory, warehousing, logistics, order management procurement, materials management and manufacturing. The analysis guides decisions on adjustments to operations that are then monitored, continuing a virtuous circle. This linking of analytics to operations and ongoing measurement is the key to maximizing ROI. As organizations look beyond optimizing short-term processes, further efficiencies are gained by expanding their view to a broader time horizon and a view across the entire supply chain. It is here that analytic applications for SCM become important as a competitive differentiator. Continuous management and improvement of the supply chain are feasible only through the applications of such a system, and analytic applications make the deployment of such systems feasible. The key to the comparatively high ROI in supply chain managementrelated analytic processes seems to be the highly focused and defined nature of issues to be solved and relatively shorter decision-making cycles than in other areas of the enterprise. For example, using analytic applications to analyze and improve product production quality, negotiate better sourcing contracts with suppliers, align demand and production plans and forecasts, and optimize delivery routes and inventory levels can result in immediate bottom-line benefits to organizations. The adoption of various types of software for analysis of both planning and procurement data are the most commonly used software tools for enabling analytic processes in procurement and planning functions. The next most frequently used applications are business intelligence software and enterprise applications (ERP, SCM, CRM). These results were not unexpected. Spreadsheets (e.g., MS Excel) remain pervasive as analysis tools in organizations of all sizes and industries. However, spreadsheets bring with them numerous problems as companies strive towards decision process automation. An optimal analytic application is one that creates an environment of controlled empowerment— empowering decision makers (e.g., managers, analysts) to analyze data without ongoing reliance on the information technology (IT) department. Just-in-time data availability without “special” requests to IT should be the norm. Analytic applications enable interactive query and reporting that allow for analysis of data across various dimensions instead of static reports produced by IT at set time intervals. At the same time the IT department should have control over centralized development, maintenance and management of such analytic applications. While spreadsheets do provide users with the flexibility to perform various types of data manipulation tasks (e.g., sorting, filtering, charting, pivot tables), they fail to provide centralized control that is crucial from the corporate perspective. The resulting environments include standalone, spreadsheet-based applications that usually lead to inefficiencies in data integration, reconciliation, collaboration among end-users, application development and IT staff utilization. The inefficiencies in turn result in dissatisfaction with existing software. Spreadsheets or software provided by enterprise applications vendors prompts the highest level of dissatisfaction with end users. At the same time end users seem to be most satisfied with business intelligence software for procurement analytics and planning functions. Clearly a disconnect still exists between the type of applications most often deployed for the two analytic functions discussed above — the software with the highest adoption levels results in the highest levels of dissatisfaction among users. Organizations of all sizes are facing an increasingly competitive environment where speed and accuracy of decision making has the potential of providing competitive advantage. Latest market research suggests that many companies are unprepared to face this economic environment based on the types of tools they employ to support both strategic and tactical decision-making processes. Companies should be increasingly turning to analytic applications to help them measure, analyze and optimize business performance, and to leverage existing investments in transactional systems. Such applications support activities beyond the scope of transactional systems and are currently provided by business intelligence and specialty analytic applications, as well as ERP systems. The decision on where to acquire analytic applications will depend on each company’s internal resources, existing IT environment and feature/functionality mix of various applications. However, as stand-alone systems, analytic applications will not have the desired impact and will fail to provide the expected return on investment. Feedback from analytics must lead to corrective action that impacts business operations. If it does not, there is no clear way to measure its impact on the business. Thus analytic applications must do more than provide information — they must guide the decision-making process, leading to actions that improve business performance. To maximize the business benefits, users should ensure they: • Enable the decision makers, not just technical analysts, to be direct users of the analytic applications. • Focus on teams, not just the individual, so there is collaborative support guiding the decision process. • Track the decisions and evaluate their effectiveness. • Capture the decision-making processes of the best performers to preserve employee expertise. Process support is one of the defining characteristics of analytic applications. Dan Vesset is the research manager of analytics and data warehousing at analyst firm IDC (www.idc.com). He can be reached at dvesset@idc.com.