National Board Certification of Pressure Relief Devices Program

advertisement

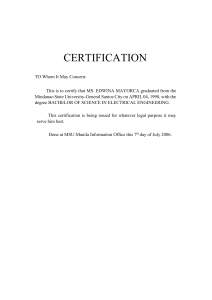

NATIONAL BOARD CERTIFICATION OF PRESSURE RELIEF DEVICES Description of Program and Basic Requirements The National Board of Boiler & Pressure Vessel Inspectors 1055 Crupper Avenue Columbus, Ohio 43229-1183 Phone: (614) 888-8320 FAX: (614) 848-3474 ______________________________________________________________________________________________________________________________ NB-501 REV.7 (07 12) Page 1 of 5 National Board Certification of Pressure Relief Devices Description of Program and Basic Requirements ____________________________________________________________________________________ NATIONAL BOARD CERTIFICATION OF PRESSURE RELIEF DEVICES Description of Program and Basic Requirements __________________________________________________________________________________ I. Introduction Thank you for your interest in the National Board Certification Program and Authorization to use the National Board “NB” mark and ASME Code Symbol Stamp with appropriate designator. This program accredits manufacturers of pressure relief devices and assemblers of pressure relief valves which are designed, constructed, tested and marked in accordance with specified Codes recognized by the National Board. The purpose of this program is to provide the industry with a means to identify those pressure relief devices which are of types that the National Board has certified. The “NB” mark signifies that the relieving capacity or flow resistance and performance of the device type have been determined in accordance with the applicable construction code under National Board supervision. This program also provides the industry with a means to identify those organizations which have established and demonstrated an adequate quality system for the new construction of pressure relief devices. The general procedure for certification of pressure relief devices involves both the National Board and the American Society of Mechanical Engineers (ASME). The ASME recognizes the National Board as its designated organization with regard to the ASME stamp with “V”, “HV”, “UV” and “UD” designators. In order to obtain National Board Certification, the following criteria must be met: 1 2 3 The pressure relief device must be manufactured and stamped in accordance with one of the codes of construction accepted by the National Board and; The manufacturer’s or assembler’s quality system must be accepted by a representative of the National Board and; Each device type to which the “NB” mark and the applicable code symbol will be applied shall have successfully completed the design review, rating factor testing and testing of production samples. ______________________________________________________________________________________________________________________________ NB-501 REV.7 (07 12) Page 2 of 5 National Board Certification of Pressure Relief Devices Description of Program and Basic Requirements ____________________________________________________________________________________ II. Application Process Authorization to apply the “NB” mark and ASME code symbols requires the following items be submitted: 1. Application must be made to the accreditation department of the ASME to obtain the applicable code symbol stamp and certificate of authorization. They will respond with detailed information concerning their accreditation process and applicable fees. The address for ASME is: ASME International Accreditation Department Three Park Avenue New York, New York 10016 Telephone: (212) 591-8461 An on-line system for this activity is available at: https://login.asme.org/caconnect/home.cfm 2. Application NB-502 must be made for each device type to the Pressure Relief Department of the National Board of Boiler and Pressure Vessel Inspectors to obtain capacity certification of that device type and permission to use the “NB” mark. The attached application should be completed for this purpose and submitted with a non-refundable application fee of $110 to: THE NATIONAL BOARD TESTING LABORATORY 7437 PINGUE DRIVE WORTHINGTON, OHIO 43085 Telephone: (614) 888-8320 Fax: (614) 848-3474 III. Design Review When submitting the device type application for National Board certification, manufacturers are requested to submit detailed engineering approved assembly drawings of the device arrangement. These drawings shall include a parts list with material designations and additional information as necessary to complete the design review (i.e. spring design calculations, drawings of valve options, such as bellows, lifting levers variations, hard and soft seat variations, alternate inlet or outlet configurations, etc.) (cont’d) ______________________________________________________________________________________________________________________________ NB-501 REV.7 (07 12) Page 3 of 5 National Board Certification of Pressure Relief Devices Description of Program and Basic Requirements ____________________________________________________________________________________ A review of the device design and the application will be made to verify that the minimum mechanical and material requirements of Construction code have been met. From this review a determination will be made as to the test media and number, sizes and set pressures of devices which must be tested to establish the certified capacity rating for the device type. Please note that for pressure relief valves, compressible and incompressible fluids will be considered under separate certifications. IV. Initial Certification Testing (Manufacturers only) The manufacturer shall then arrange for testing of the devices specified above at the National Board Testing Laboratory or at an alternative laboratory accepted by the National Board. The purpose of these tests is to establish the rating factor used to determine the certified capacity of the device or the system in which it is used. In addition to supplying the required number and sizes of devices, the manufacturer must submit detailed drawings of components critical to the flow path for each size of device tested. Testing and the evaluation of results will be made in accordance with the requirements of the specified code of construction. Initial capacity certification testing should be successfully completed before a visit is made by a National Board representative to the manufacturing facility. V. Quality System Review The applicant must make arrangements to have National Board representative visit the applicant’s facilities after; 1 2 Initial certification testing by the manufacturer has been successfully completed and, The National Board has received notification from ASME that the application for obtaining the code symbol stamp has been received from the manufacturer or assembler. During this visit, the representative will review the written description of the quality system and observe a demonstration of its implementation. VI. Production Certification Testing At the time of your quality system review, sample production devices will be selected for testing at a National Board accepted Testing Laboratory in accordance with the code of construction. The purpose of these tests is to demonstrate that the methods of construction, assembly and testing will yield devices which meet the performance requirements of the code of construction and that the device will meet or surpass the flow rating for which it was certified. ______________________________________________________________________________________________________________________________ NB-501 REV.7 (07 12) Page 4 of 5 National Board Certification of Pressure Relief Devices Description of Program and Basic Requirements ____________________________________________________________________________________ VII. Issuance of Certifications and Certificates Upon successful completion of the review and production certification testing, the National Board will notify the ASME and recommend issuance of the applicable code symbol stamp and certificate of authorization. Additionally, the National Board will issue a capacity certification and permission to use the “NB” mark on the devices of the type certified. This certification will be listed in the National Board Publication, Pressure Relief Device Certifications, NB-18. Once permission is granted, the “NB” mark would be applied to the device nameplate by the authorized organization as shown in the facsimile below: Code of Construction Symbol marked here Stamping in this area shall comply with the requirements of the applicable code of construction VIII. Additional Information For additional information on the program requirements, please refer to the National Board Publication, Pressure Relief Device Certifications, NB-18. Fees and expenses of shop reviews and device testing will be paid by the applicant. A schedule of National Board fees and a listing of National Board accepted laboratories will be made available upon request. The applicant should contact the ASME and alternative laboratories for their applicable fees. If you should have any questions, please feel free to contact the offices of the Pressure Relief Department located at the National Board Testing Laboratory. Also, visit our WEB site at www.nationalboard.org or contact us by E-mail at: prdinfo@nationalboard.org. Enclosures -Application for NB Pressure Relief Device Certification, NB-502 ______________________________________________________________________________________________________________________________ NB-501 REV.7 (07 12) Page 5 of 5 National Board Certification of Pressure Relief Devices NB-501 Supplement for Nuclear Pressure Relief Devices The NB-501 document is written as a general guide for all pressure relief device Manufacturers or Assemblers that wish to be accredited to be able to apply the “NB” mark to devices which have been certified in accordance with one of the accepted Codes of Construction. The Capacity Certification program also applies to pressure relief valves to be certified under ASME Code Section III (Ref: NX-7738). Differences in the application of the certification requirements when ASME Section III is the Code of Construction are outlined below. I. Introduction 1. The National Board is the designated organization for capacity certification of pressure relief devices intended to bear the ASME stamp with “NV” designator in addition to the other stamps listed. 2. The acceptance of the quality system for use of the ASME stamp with “NV” designator stamp will be done by an ASME review team instead of a representative of the National Board. 3. Assemblers are not applicable to ASME Section III. II. Application Process This information is the same as main document. III. Design Review This information is the same as main document. IV. Initial Certification Testing 1. The initial certification testing is similar to the testing to other Code Sections except that in many cases the valve design scope may exceed accepted test laboratory pressure or capacity limits. In those cases the test program is done by flow testing scale models which may be functioning or non-functioning. When scale models are tested, full sized valves must also be tested to demonstrate valve function (set pressure, blowdown, repeatability of performance) and lift. The demonstration of function testing will be conducted at a facility that is mutually agreeable between the valve manufacturer and the National Board. The facility does not have to be ASME accepted since valve flow rate will not be measured during these tests. 2. If the design includes sizes that can be tested for operation and capacity at an accepted flow test facility, additional demonstration of function testing may be required for larger sizes or higher set pressures. Testing to demonstrate valve performance under all expected operating fluid conditions, the expected range of inlet pressure losses, and discharge back pressure conditions may also be needed. V. Quality System Review 1. The quality system review for use of the ASME stamp with “NV” designator stamp will be performed an ASME review team instead of a National Board representative. 2. A copy of the ASME stamp with “NV” designator Certificate of Authorization must be supplied to the National Board to verify that the quality system has been reviewed. 3. The quality program shall include provisions for: A. Assuring that capacity certification has been achieved for each design where the Code stamp is to be applied. B. Submission of changes in design that affect flow path, lift, or valve performance to the National Board for review to determine if additional testing is required. C. Documenting application of the Code Symbol stamp by completion of the NV-1 Data Report Form. D. Reconciling current capacity certification requirements with the Code date of record for the items being produced. National Board Capacity Certification will be documented against the current Code edition. VI. Production Certification Testing 1. Testing of production valves does not apply to designs being certified for Section III service only. 2. Valve designs may be certified to multiple ASME Code Sections when the performance requirements are the compatible. In this case the most stringent requirements of the Code Sections being considered shall apply, and the production certification requirements shall be successfully completed before the type certification is issued. Renewal of the type certification shall be performed at the interval specified by the referencing Code to allow the Section III certification to be renewed. 3. To renew the certification of a valve design for Section III service only, the manufacturer must submit the current application form, supply the most current valve assembly drawing, and certify that the flow path, lift and performance of the valve design have not been changed. VII. Issuance of Certifications and Certificates 1. Issuance of the “NV” Certificate of Authorization will be done by ASME upon notification from the review team of successful completion of the review of the quality program for use of the ASME stamp with “NV” designator. 2. Upon successful completion of a capacity certification test program, and receipt of a copy of the “NV” Certificate of Authorization, the National Board will issue a capacity certification letter for each design tested, and data on the valve type will be added to our NB-18 document. 3. A National Board “NB” Certificate of Authorization is also issued to the manufacturer. VIII. Additional Information This information is the same as main document, except information about shop reviews is not applicable. File: NB-501 Nuclear Supplement 7-12 Rev0.docx