19.0 Release

Lecture 3: Finite Rate Models

ANSYS Fluent Combustion Modeling

1

© ANSYS, Inc.

Approaches for Modeling Reacting Flows

• Simplify the chemistry*

– Considers global chemical reaction mechanism

• Finite Rate/Eddy Dissipation model

• Decouple chemistry from flow (Fast Chemistry models – Da >> 1)*

– Use progress variable (C) approach

• Premixed model

– Use mixture fraction (Z) approach

• Non-Premixed model

– Use progress variable and mixture fraction approach

• Partially Premixed model

• Model detailed chemistry (Finite Rate Chemistry models – Da ~ 1 )

–

–

–

–

2

CPU intensive (large number of transport equations + stiff kinetics)

Stiff chemistry solvers allow larger time steps to be used

Chemistry Acceleration tools help to speed up the calculation

This includes :

• Laminar Finite Rate model

• Eddy Dissipation Concept model

• Composition PDF Transport model (see appendix)

* Covered in another lecture

© ANSYS, Inc.

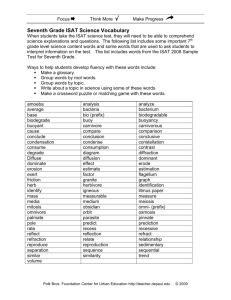

Reacting Flow Models in Fluent

Flow Configuration

Premixed Combustion

Non-Premixed

Combustion

Partially Premixed

Combustion

Chemistry

Finite-Rate/Eddy-Dissipation Model (Species Transport)

3

Fast Chemistry

Closures

Premixed Combustion

Model

Reaction Progress

Variable

Non-Premixed Model

Mixture Fraction

Partially Premixed Model

Reaction Progress Variable

+

Mixture Fraction

Chemical Equilibrium

Steady Laminar Flamelet Model

Finite Chemistry

Closures

Flamelet Generated Manifold Model (Premixed/Diffusion)

Finite Rate

Chemistry

Models

Laminar Finite-Rate Model (Species Transport)

© ANSYS, Inc.

Unsteady Laminar Flamelet Model

Eddy-Dissipation Concept (EDC) Model (Species Transport)

Composition PDF Transport Model

Challenges in Reacting Flows Modeling - Chemistry

• Realistic chemical mechanisms cannot be described

by a single reaction equation

– Tens of species, hundreds of reactions

– Known in detail for only a limited number of fuels

• Stiff kinetics (wide range of reacting time scales)

Premixed methane/air laminar flame

NO is slow

H2O2 is fast

4

© ANSYS, Inc.

chemical

equilibrium

Detailed Chemical Kinetics

• For a given fuel, detailed chemical kinetics is provided through a detailed, skeletal, or

•

reduced mechanism

A detailed mechanism consists of

– A large number of species (e.g., reactants, intermediate, radicals)

– A large set of elementary reactions

• Detailed mechanisms can be shortened by eliminating unimportant species and

•

•

•

5

reactions; this leads to a smaller set of species and reactions, called skeletal

mechanisms

Detailed/Skeletal mechanisms can be further simplified using some assumptions such

as quasi-steady state assumptions (QSSA); this leads to so-called reduced mechanisms

Detailed chemical kinetics are numerically stiff: a large spread in reaction time scales

Special numerical methods required (stiff chemistry solvers)

© ANSYS, Inc.

Finite-Rate Chemistry

Forward reaction rate:

Backward reaction rate:

6

© ANSYS, Inc.

Finite-Rate Chemistry

• Compatible mechanisms

– Detailed/Skeletal mechanisms

• Fluent can import a CHEMKIN chemical mechanism file

– Reduced mechanisms

• FLUENT built-in QSSA reduced mechanisms

– ARM9 and ARM19 for methane combustion

• General QSSA reduced mechanisms

– User Defined Function

• Reactions

– Arrhenius with reversible reactions and third body efficiencies

– Pressure dependent reactions (Lindemann, Troe and SRI)

• Low pressure and high pressure rates with blending functions

• Molecular transport

– Critical in subsonic laminar flames since it determines mixing and flame

speeds

– For laminar flames kinetic theory is recommended

• Leonard-Jones parameters can be obtained from the CHEMKIN transport

database (e.g., transport.db or transport.dat)

7

© ANSYS, Inc.

Mechanism Import (encrypted and unencrypted)

CHEMKIN format mechanisms can be

imported in two ways:

1) Unencrypted mechanisms

– All species, reaction rates, thermodynamic and

transport data are visible to user

– It does not need a separate license

2) Encrypted Model Fuel Library (MFL)

mechanisms

– Only species list is visible to user

– Reaction rates, thermodynamic and transport data

are hidden to protect IP

– It requires a Model Fuel Library license file

8

© ANSYS, Inc.

Detailed Chemistry Models

• Available Models

– Laminar finite rate

– EDC model

– PDF transport

• Detailed kinetics are used to model

– Flame ignition and extinction

– Pollutants (NOx, CO, Soot, UHCs)

– Slow (non-equilibrium) chemistry

• Chemistry acceleration tools

–

–

–

–

–

9

ISAT (In-situ Adaptive Tabulation)

Chemistry agglomeration/clustering

Dimension reduction

DMR (Dynamic Mechanism Reduction)

Parallel load balancing

© ANSYS, Inc.

The upper limit for the number of

species allowed in FLUENT is 700

Numerical Methods - Stiff Chemistry

• Density based solver

– Advance species and temperature simultaneously over time step

– Use Implicit for subsonic flames

– Use Explicit for supersonic flames (detonations, explosions)

• Pressure based solver

– For unsteady flows, fractional time stepping algorithm is used

– For steady simulations the reaction rate is approximated as

1 t

R Ri dt

t 0

*

i

– Default value for t is set to one-tenth of the minimum convective or diffusive time-scale in

the cell

– It can be modified via the solve/set/stiff-chemistry text command

• ISAT (In-situ Adaptive Tabulation) algorithm and other chemistry

acceleration tools can be used to speed up the simulations

10

© ANSYS, Inc.

Laminar Finite-Rate Model

• Laminar flames

– Non-premixed (diffusion flames)

• Fuel and oxidizer diffuse into the reaction zone, then burn

– Premixed

• Fuel and oxidizer mixed molecularly, then burn

• Moving reaction front - usually thin and difficult to model

• Deflagrations

– Subsonic: very difficult to model since the flame speed depends on the chemistry as well as

the molecular diffusion parameters, and the flame zone must be resolved

• Detonations

– Supersonic: ignition due to heat release behind shock. Simpler to model than deflagrations

since the shock is not resolved, and molecular transport is not essential

– Requires density based solver

• Turbulent flames

– No turbulence-chemistry interaction is considered

– Commonly used with LES

11

© ANSYS, Inc.

Eddy Dissipation Concept (EDC) Model

• Gran and Magnussen (1996)

– Comb. Sci & Tech, 119, pp.191-127

• Detailed chemistry in turbulent flames

– EDC is a turbulence-chemistry interaction model

• Accounts for complex chemistry with arbitrary

chemical mechanisms

– Computationally expensive since realistic chemical

mechanisms are invariably stiff

– Assumes reaction occurs in small scales

12

© ANSYS, Inc.

EDC Theory

• Length fraction of small scales:

2.1377 2

k

1/ 4

Re t1/ 4

• Life-time of small scales:

t 0.4082

t Kolmogorov

• Reaction in small scales proceeds as a constant pressure-enthalpy

reactor:

dYk* w k

*

dt

– Initial condition: Yk* Yk

– Final state:

t=t

• Mean reaction rate in mean species equation:

– Mean species relax to fine scale species over time t

– Species and temperature in small scales denoted by *

13

© ANSYS, Inc.

2

*

Sk

(

Y

k Yk )

3

t (1 )

Sandia Flame D

• Experiment

– Non-premixed methane, piloted, turbulent diffusion flame

– Sandia Flame D

• Geometry

– Axi-symmetric grid with 2352 quad cells

• Turbulence

• Standard k-e with Ce1=1.52, Sct=1.0

– Pope’s correction

• Chemistry

– 19 species ARM with NO

14

© ANSYS, Inc.

EDC Results - Sandia Flame D

Mean Temperature

15

© ANSYS, Inc.

Mean YO2

EDC Results - Sandia Flame D

Mean YCO

16

© ANSYS, Inc.

Mean YNO

Chemistry Acceleration Tools

• Detailed chemistry calculations are

•

computationally expensive

Chemistry acceleration tools are available to

speedup the Chemistry Solvers

–

–

–

–

–

17

In Situ Adaptive Tabulation (ISAT)

Chemistry Agglomeration

Dimension Reduction

DMR (Dynamic Mechanism Reduction)

Parallel: Dynamic Load Balancing

© ANSYS, Inc.

In situ adaptive tabulation (ISAT)

• To use ISAT, FLUENT employs splitting schemes to separate

reaction from other physical processes

• The governing equations for reaction sub-step are a set of stiff

ODEs, and typically, this set of ODEs needs to be solved millions of

t

times in a simulation

w

Yk* Yk

k

dt

0

Each integration is computationally expensive

– Typically tens or hundreds of milliseconds CPU time

• Integration corresponds to a mapping x f, where x is the initial

composition vector and f is the composition after reaction

fractional step

– End state is a unique function of initial state

x : {Y1, Y2,…YN,T,p} f : {Y1*, Y2*,…YN*,T* }

18

© ANSYS, Inc.

In situ adaptive tabulation (ISAT)

• Integration could be avoided if we could build a table of these mappings

– For example, this is done for the non-premixed mixture fraction model, where the table has 3

dimensions

• mean f, variance of f, and mean enthalpy h

• For general chemistry with N species, tabulating the whole composition space

is not practical

– N+3 dimensions

– For M grid points in each dimension, MN+3 table points

– Example: M=10, N=7 requires 1010 table points

• However, only a small part of the composition space is accessed

• Tabulate only where required (In-Situ)

• Tabulation errors are controlled (Adaptive Tabulation)

• Table is constructed during the simulation

19

© ANSYS, Inc.

ISAT: Performance

• Chemistry acceleration of 10 to 1000

• Typical speed-up is 100

– This is substantial!

– A hundred-fold speed-up means that a simulation that takes three months to run can be

completed in one day

– ISAT is more efficient for steady state simulation

• But, chemistry calculation using ISAT involves numerical errors

– ODE integration error; controlled by ODE parameters (The default settings are sufficient for

most problems)

– ISAT interpolation error; controlled by ISAT error tolerance

20

© ANSYS, Inc.

ISAT: Best Practice

• Memory

– User specifies the table size (in Mb)

– In general, set the ISAT table size to a large fraction of your

maximum available memory

• Accuracy

– Default ISAT tolerance is 0.001; this value is relatively large,

which allows faster convergence. There is a large performance

penalty in specifying an error tolerance smaller than what is

needed to achieve acceptable accuracy in thermo-chemical

solutions

• For steady state problems:

– Obtain a converged solution with relative large ISAT tolerance

(e.g., default value), then decrease it gradually and judiciously to

obtain accurate thermo-chemical solutions

21

© ANSYS, Inc.

ISAT: Best Practice (cont’d)

• For unsteady problems

– For small calculations, perform an accuracy study by running the

calculation with different ISAT error tolerances

– For large calculations, obtain the necessary ISAT error tolerance

by performing an accuracy study for the considered mechanism

in a separate, similar but simple test case

• Efficiency

– For transient problems such as those in IC engines or during the

initial transient to steady-state in steady-state problems, it may

be more efficient to clear the ISAT table periodically

– In general, it is not beneficial to save ISAT table and reuse it in

another calculation. Building the ISAT table from scratch in a

calculation is preferred

22

© ANSYS, Inc.

Chemistry Agglomeration (Cell Clustering)

• In CFD calculations of reactive flows, a lot of

•

cells or particles have “similar” composition

Chemistry Agglomeration: Average cells that

are close in composition space i.e. similar

temperatures and mass fractions

– Call stiff chemistry solver (or ISAT) solver to calculate

the reaction step

– Fewer calls to stiff chemistry solver (or ISAT)

• Map reaction step back to original cells

23

© ANSYS, Inc.

T

Mixture fraction, f

Example: Chemistry Agglomeration for Sandia Flame D

# of cells

Agglomeration setting

# of chemistry cal. Per

iteration

CPU Time

Speed-up

2352

No

2352

2970

1

2352

T + 3 species; 0.01

~700

1080

2.75

2352

T + 3 species; 0.02

~520

840

3.54

2352

T + 3 species; 0.03

~395

610

4.87

2352

T + 3 species; 0.04

~314

540

5.5

Ref: Goldin, Ren, Zahirovic, A cell agglomeration algorithm for accelerating detailed chemistry in CFD,

Combustion Theory and Modelling, 2009.

24

© ANSYS, Inc.

Dynamic Mechanism Reduction (DMR)

• Recall, at each flow iteration* or time-step…

– FLUENT calls ODE solver to solve chemistry at each cell

• Dynamic Mechanism Reduction:

– Decrease ODE solver time (tODEsolver) by reducing number of species/reactions (Nspecies, Nreactions)

– Evaluate kinetic rates before calling ODE solver

• Drop species and reactions with negligible contributions

– Solve smaller ODE set

• Compositions of dropped species are “frozen” throughout ODE solve

– Fewer reaction rates need to be evaluated during ODE solve

• Potentially different mechanism per cell, per flow iteration or time-step

• Mechanism reduction method: DRG (Directed Relation Graph)

– T.Lu and C.K. Law, 2005

*number of flow iterations per chemistry solve can be adjusted in UI

25

© ANSYS, Inc.

Dynamic Mechanism Reduction (DMR)

• DMR is enabled in the Integration Parameters panel or in TUI

• Can be combined with any other acceleration tools like ISAT or Chemistry Agglomeration

• Compatible with any detailed chemistry model like LFR, EDC or transported PDF

26

© ANSYS, Inc.

Example: DMR in Sandia Flame D

• DMR post processing related quantities

• Large concentration of chemically active cells in a small region of

the domain which gives a high potential for reduction techniques

• Mechanism: 53 species / 325 reactions (methane flame)

Temperature

Speedup factor = 1.97

Reduced Number of Species

27

© ANSYS, Inc.

Reduced Number of Reactions

DMR : Tips and Tricks (cont’d)

• Steady state solver: start with higher value for the Error

•

•

28

tolerance to allow larger speedup and reduce it based on the

expected accuracy

Transient solver: run a simplified problem (1D geometry with

same chemistry) to analyze how the Error Tolerance will

impact on the scalars profiles and then use the same Error

Tolerance on the real problem

In general, combination of ISAT and DMR gives the best

performance but note DMR can only give better performance

in particular cases where ISAT tables are not revisited quite

often, for example, in transient simulation.

© ANSYS, Inc.

DMR : Tips and Tricks (cont’d)

• Post processing (cells values): (steady solver) run for the converged

solution without enabling the DMR related post processing

quantities. Once converged, enable those settings with TUI and run

for one single iteration. (transient solver) Need to enable the

settings before running the transient case.

- If ISAT enabled, cells showing reduced number of species/reactions equal to

0 means that ISAT retrieve has been performed

- Can display those cells by clipping to a range of 0 to 0

- Can display the cells where DMR is used by clipping to a range of 1 to global

maximum value

29

© ANSYS, Inc.

Dimension Reduction

• Reduces the number of transport equations (representative species) solved,

and reconstructs the ‘unrepresented’ species using chemical equilibrium

• Specify the represented species : Nr (12 is default) – user input

– Solve Nr transport equations + unrepresented element mass fraction equations

• Unrepresented species Nun = N - Nr

• For each reaction step:

– Nun are computed by constrained chemical equilibrium

– Integrates the full mechanism but maps only the Nr species

• Available only with ISAT

– Decreases the number of dimensions in the table

• Limitations

– Equilibrium assumption for unrepresented species (not a good assumption for pollutant

formation)

30

© ANSYS, Inc.

Solution Strategies for Detailed Chemistry

• Initial conditions and set up

– A poor initial condition might cause the stiff chemistry solver to fail

– A good initial solutions can be calculated using relax to equilibrium, non-premixed, or eddy

dissipation models, that would provide a good initial guess (temperature and species) for the

stiff chemistry solver

• ISAT tolerance

– For steady state problems, start with the default 1e-3 and increase the table size from the

default 100 MB

– To fully converge the solution decrease the ISAT tolerance and make sure that the solution is

independent from any table interpolation error

• EDC model, Laminar-Finite Rate (with stiff chemistry solver), Eulerian

Composition PDF (with stiff chemistry solver)

– For some cases, the models tend to converge slowly, to speed up the convergence change the

Aggressiveness Factor

– Aggressiveness Factor

• Between 0 (most robust but slowest convergence) and 1

• The default for the Aggressiveness Factor is 0.5

31

© ANSYS, Inc.

Finite rate solver: CHEMKIN CFD

• Chemkin CFD is recommended for encrypted mechanism (substantial speed up)

• Ability to combine Dynamic Cell Clustering (DCC) with ISAT (using Chemkin-CFD solver option)

• Extend DCC to steady-state flows

− Significant time savings with combination of options (~70%)

− Accuracy maintained with options in combination

Temperature contours

Baseline

DCC + ISAT

32

© ANSYS, Inc.

Example

comparisons for

Sandia Flame D

Summary

• Model detailed chemistry (Finite Rate Chemistry models – Da ~ 1 )

– Laminar Finite Rate model

– Eddy Dissipation Concept model

– Composition PDF Transport model

• Chemistry acceleration tools

–

–

–

–

–

In Situ Adaptive Tabulation (ISAT)

Chemistry Agglomeration

Dimension Reduction

Dynamic Mechanism Reduction (DMR)

Parallel: Dynamic Load Balancing

• Several tutorials available for these models

33

© ANSYS, Inc.

Appendix

34

© ANSYS, Inc.

Composition PDF Transport Model

•

The Composition PDF Transport model is used to incorporate finite-rate chemistry in turbulent flames

– Accounts for complex chemistry with arbitrary chemical mechanisms

– Same purpose as the EDC model

– More rigorous treatment of turbulence-chemistry interaction, but more expensive

•

The PDF (Probability Density Function) represents the fraction of time that the fluid spends at each

species, temperature and pressure state

•

The mean reaction rate can be calculated from the PDF as:

1

k

w

•

Hence, if the PDF is known, the thermo-chemistry is closed

•

Solve a transport equation for the single-point, joint PDF

1

w

k

0 0

P dYN dY1 dT

0

– The Lagrangian method

– The Eulerian method

– The Lagrangian method is strictly more accurate than the Eulerian method, but requires significantly longer run time to

converge

•

35

Only available with the pressure-based solver

© ANSYS, Inc.

The Lagrangian method: Solution Algorithm

• PDF equation is high dimensional

– Ndim = N species + 1 energy = N+1 dimensions

– Cannot solve by FD/FV/FE method

PDF change due to scalar

convection by turbulence

(turbulent scalar flux)

PDF change due to

molecular

mixing/diffusion

• Monte Carlo Method is used in solving the PDF transport equation

– Particles move randomly

• through physical space due to particle convection

• through composition space due to molecular mixing and reaction

– Fractional steps solution for convection, diffusion, and reaction (using the stiff chemistry solver)

– Three mixing models are available

• Interaction by Exchange with the Mean (IEM)

• Modified Curl

• Euclidean Minimum Spanning Tree (EMST)

36

© ANSYS, Inc.

Composition PDF Transport Example

• Experiment

– Non-premixed methane, piloted, turbulent diffusion flame

– Sandia Flame D

• Geometry

– Axisymmetric grid with 2352 quad cells

• Turbulence

– Standard k-e with Ce1=1.52, Sct=1.0

• Pope’s correction

• Mixing

– IEM and Modified Curl with Cf=2

• Chemistry

– 16 species skeletal mechanism

37

© ANSYS, Inc.

PDF Transport Example: Flame D

Temperature

38

© ANSYS, Inc.

Mean

Temperature

RMS

Temperature

Mean CO

Red symbol: Experiment, Blue solid line: Modified Curl, Green dashed line: IEM

39

© ANSYS, Inc.

The Eulerian Method: Solution Algorithm

• The composition PDF of (Nspecies +1)-dimension (species and enthalpy) is

•

•

•

represented as a collection of Ne delta functions (or modes)

The Eulerian PDF transport equations are derived by substituting the

assumed PDF into the closed composition PDF transport equation

The Eulerian transport equations for probability (magnitude of the nth

mode) and probability weighted conditional mean of composition are

derived using the DQMOM and are solved

Mixing model

– Interaction by Exchange with the Mean (IEM)

• Only the two-mode formulation is available

– Only applicable to problems with two distinct streams

40

© ANSYS, Inc.

In situ adaptive tabulation (ISAT)

• Thermodynamic state of fluid characterized by

– Mass fractions of species (Yi), Enthalpy (h) and Pressure (P)

• Broad class of flow P ~ P0 (Reference pressure)

• Species and temperature represented by a composition

– (Y1, Y2, Y3 …… YN , T)

• Each as a point in D-dimensional composition space

– D degree of freedom

• Evolution of

– M is rate of change due to transport

– S is rate of change due to chemical reaction

Evolution of in a composition space

• As t , the trajectory tends to chemical equilibrium

– Linear approximation

• To calculate reaction mapping, R( ) for other points close by 0

41

© ANSYS, Inc.

ISAT Functioning

Initially, reacting flow code provides ISAT with

• Time step size, t

• Error Tolerance, tol

• Scaling matrix, B

– It is used to calculate errors

• During calculation, reacting flow code gives a

query to ISAT, q

• ISAT returns, corresponding mapping within

required accuracy, R( q)

42

© ANSYS, Inc.

t, B, tol

Reacting

Flow Code

q

R( q)

ISAT

ISAT Functioning (cont’d)

• ISAT passes the composition ( 0) and time

0

step size (t ) to Mapping Module

• Mapping module does direct integration

and returns mapping R( 0) and mapping

gradient matrix A( 0) to ISAT

• ISAT stores this record in the form of

•

binary tree

At each leaf

, there is a record

– Fixed data: Point ( 0); Reaction Mapping R( 0);

Mapping gradient A( 0)

– Changing data: EOA (ellipsoid of accuracy)

information

• At each node

, there is a information

about cutting plane

43

© ANSYS, Inc.

ISAT

R( 0), A( 0)

Mapping

Module

ODE Solver

+

Chemistry

ISAT Algorithm

Reacting

Flow Code

0

First Query ( 0)

ISAT

R(

0),

A(

Mapping

Module

0)

Initiate binary tree with single leaf (Exact value of Mapping)

New Query ( q)

R( q)

Reacting

Flow Code

Linear Approx. Get R( q)

Yes

ISAT

Direct Integration

Traverse binary tree

Return R( q)

Look for

( 0 ) ( q )

& check

q

( ) within EOA

Retrieve*

* Retrieves are very quick, Grows are slow and Adds are slow

44

© ANSYS, Inc.

Yes

No

Grow EOA

Growth*

Calc.

< tol

No

Add new entry

R ( q)

Addition*

Dynamic Mechanism Reduction (DMR) Details

•

Start from a list of target species

–

•

Fluent uses by default 3 target species (“h” + 2 species with largest mass fractions)

Step 1: Compute normalized contribution of each non-target species B to overall

production of each target species A

Species B is retained in the mechanism if and only if

where epsilon is a specified

error tolerance (by default 0.01). Larger values of epsilon imply faster simulation but less

accurate mechanism (and vice versa)

Step 1 produces the dependent set of the target species (direct contributors)

45

© ANSYS, Inc.

Dynamic Mechanism Reduction (DMR) Details

• Step 2: In the next step, DRG identifies indirect contributors, which are species that directly

impact the dependent set, rather than the targets. This process is continued for each new

specie added to the mechanism until no new specie qualifies to be added to the mechanism.

The resulting set of species constitutes the reduced mechanism.

•

Step3: All reactions that do not involve any of the retained species are eliminated and only

the retained reactions are included in the reduced mechanism.

-> lower dimensional ODE system is solved with the reduced number of species and reactions

given by DRG

User controls :

- Epsilon (0.01)

- Target Species List (“h”,” ”,” ”) (*)

Post processing related quantities:

- DRG reduced number of species (*)

- DRG reduced number of reactions (*)

(*) accessible in the TUI :

define/model/species/integration-parameters

46

© ANSYS, Inc.

Species Interface : dealing with large number of species

Allows to specify a small list of species used in

boundary conditions

•

•

47

© ANSYS, Inc.

Option to choose a subset of species as monitor species

Simplifies the Residual reporting