ASM Handbook Volume 13 Corrosion (Corrosion of Stainless Steels)

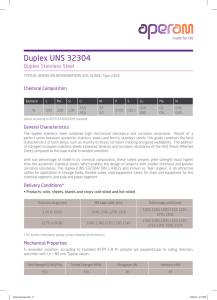

advertisement