ENGINEERING

HEAT AND MASS

TRANSFER

ENGINEERIN G

HEAT AND MASS

TR ANSFER

BY

MAHESH M. RATHORE

Energy Auditor and Chartered Engineer,

Professor and Head, Mechanical Engineering

SNJB’s K.B. Jain

College of Engineering, Chandwad

Maharashtra, India

BENGALURU Ɣ CHENNAI Ɣ COCHIN Ɣ GUWAHATI Ɣ HYDERABAD

JALANDHAR Ɣ KOLKATA Ɣ LUCKNOW Ɣ MUMBAI Ɣ RANCHI Ɣ NEW DELHI

BOSTON (USA) Ɣ ACCRA (GHANA) Ɣ NAIROBI (KENYA)

ENGINEERING HEAT AND MASS TRANSFER

Copyright © by Laxmi Publications (P) Ltd.

All rights reserved including those of translation into other languages. In accordance with the Copyright (Amendment) Act, 2012, no part of this

publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise. Any such act or scanning, uploading, and or electronic sharing of any part of this book without the permission of the

publisher constitutes unlawful piracy and theft of the copyright holder’s intellectual property. If you would like to use material from the book

(other than for review purposes), prior written permission must be obtained from the publishers.

Printed and bound in India

Typeset at Goswami Associates

First Edition: 2004; Second Edition: 2006; Third Edition: 2015; Reprint: 2016

ISBN 978-81-318-0613-5

Limits of Liability/Disclaimer of Warranty: The publisher and the author make no representation or warranties with respect to the accuracy or

completeness of the contents of this work and specifically disclaim all warranties. The advice, strategies, and activities contained herein may not

be suitable for every situation. In performing activities adult supervision must be sought. Likewise, common sense and care are essential to the

conduct of any and all activities, whether described in this book or otherwise. Neither the publisher nor the author shall be liable or assumes

any responsibility for any injuries or damages arising herefrom. The fact that an organization or Website if referred to in this work as a citation

and/or a potential source of further information does not mean that the author or the publisher endorses the information the organization or

Website may provide or recommendations it may make. Further, readers must be aware that the Internet Websites listed in this work may have

changed or disappeared between when this work was written and when it is read.

PUBLISHED IN INDIA BY

113, GOLDEN HOUSE, DARYAGANJ,

NEW DELHI - 110002, INDIA

Telephone : 91-11-4353 2500, 4353 2501

Fax : 91-11-2325 2572, 4353 2528

www.laxmipublications.com info@laxmipublications.com

Branches

All trademarks, logos or any other mark such as Vibgyor, USP, Amanda, Golden Bells, Firewall Media, Mercury, Trinity, Laxmi appearing in this

work are trademarks and intellectual property owned by or licensed to Laxmi Publications, its subsidiaries or affiliates. Notwithstanding this

disclaimer, all other names and marks mentioned in this work are the trade names, trademarks or service marks of their respective owners.

&

Bangalore

080-26 75 69 30

&

Chennai

044-24 34 47 26,

24 35 95 07

&

Cochin

0484-237 70 04,

405 13 03

&

Guwahati

0361-254 36 69,

251 38 81

&

Hyderabad

040-27 55 53 83,

27 55 53 93

&

Jalandhar

0181-222 12 72

&

Kolkata

033-22 27 43 84

&

Lucknow

0522-220 99 16

&

Mumbai

022-24 91 54 15,

&

Ranchi

0651-220 44 64

24 92 78 69

C—10720/015/08

Printed at: Narain Printers & Binder, Noida

Contents

1.

CONCEPTS AND MECHANISMS OF HEAT FLOW

1.1.

1.2.

1.3.

1.4.

1.5.

1.6.

1.7.

1.8.

1.9.

1.10.

1.11.

1.12.

2.

24–41

Generalised One Dimensional Heat Conduction Equation ................................................................................... 24

Three Dimensional Heat Conduction Equation ..................................................................................................... 26

Initial and Boundary Conditions ............................................................................................................................ 30

Summary ................................................................................................................................................................... 39

Review Questions ....................................................................................................................................................... 40

Problems .................................................................................................................................................................... 40

STEADY STATE CONDUCTION WITHOUT HEAT GENERATION

3.1.

3.2.

3.3.

3.4.

3.5.

3.6.

3.7.

3.8.

4.

What is Heat Transfer ? ............................................................................................................................................. 1

Modes of Heat Transfer .............................................................................................................................................. 2

Physical Mechanism of Modes of Heat Transfer ...................................................................................................... 2

Laws of Heat Transfer ................................................................................................................................................ 3

Combined Convective and Radiation Heat Transfer ............................................................................................... 7

Thermal Conductivity ................................................................................................................................................. 8

Isotropic Material and Anisotropic Material .......................................................................................................... 12

Insulation Materials ................................................................................................................................................. 14

Thermal Diffusivity .................................................................................................................................................. 17

Heat Transfer in Boiling and Condensation ........................................................................................................... 20

Mass Transfer ........................................................................................................................................................... 20

Summary ................................................................................................................................................................... 20

Review Questions ....................................................................................................................................................... 21

Problems .................................................................................................................................................................... 21

CONDUCTION—BASIC EQUATIONS

2.1.

2.2.

2.3.

2.4.

3.

1–23

Plane Wall ................................................................................................................................................................. 42

Electrical Analogy of Heat Transfer Rate Through a Plane Wall ........................................................................ 43

Multilayer Plane Wall .............................................................................................................................................. 44

Thermal Contact Resistance .................................................................................................................................... 64

Long Hollow Cylinder ............................................................................................................................................... 68

Critical Thickness of Insulation on Cylinders ........................................................................................................ 81

Hollow Sphere ........................................................................................................................................................... 86

Summary ................................................................................................................................................................... 94

Review Questions ....................................................................................................................................................... 95

Problems .................................................................................................................................................................... 95

STEADY STATE CONDUCTION WITH HEAT GENERATION

4.1.

4.2.

42–99

100–135

The Plane Wall ........................................................................................................................................................ 100

The Cylinder ............................................................................................................................................................ 113

v

vi

CONTENTS

4.3.

4.4.

4.5.

5.

HEAT TRANSFER FROM EXTENDED SURFACES

5.1.

5.2.

5.3.

5.4.

5.5.

5.6.

5.7.

5.8.

6.

180–233

Approximate Solution ............................................................................................................................................. 180

Analytical Solution ................................................................................................................................................. 199

Transient Temperature Charts: Heisler and Gröber Charts .............................................................................. 206

Transient Heat Conduction in Semi Infinite Solids ............................................................................................ 219

Transient Heat Conduction in Multidimensional Systems ................................................................................. 222

Summary ................................................................................................................................................................. 227

Review Questions ..................................................................................................................................................... 228

Problems .................................................................................................................................................................. 228

PRINCIPLES OF CONVECTION

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

7.7.

7.8.

7.9.

7.10.

7.11.

7.12.

7.13.

7.14.

7.15.

136–179

Types of Fins ........................................................................................................................................................... 136

Fin Selection and Applications .............................................................................................................................. 137

Governing Equation ................................................................................................................................................ 137

Fin Performance ...................................................................................................................................................... 151

Approximate Solution of Fin: Concept of Corrected Fin Length ........................................................................ 154

Error in Temperature Measurement by Thermometers ..................................................................................... 167

Design Considerations for Fins ............................................................................................................................. 170

Summary ................................................................................................................................................................. 174

Review Questions ..................................................................................................................................................... 175

Problems .................................................................................................................................................................. 175

TRANSIENT HEAT CONDUCTION

6.1.

6.2.

6.3.

6.4.

6.5.

6.6.

7.

Hollow Cylinder with Heat Generation and Specified Surface Temperatures ................................................. 114

The Sphere ............................................................................................................................................................... 126

Summary ................................................................................................................................................................. 131

Review Questions ..................................................................................................................................................... 132

Problems .................................................................................................................................................................. 132

234–265

Mechanism of Heat Convection ............................................................................................................................. 234

Classification of Convection ................................................................................................................................... 234

Convection Heat Transfer Coefficient ................................................................................................................... 235

Convection Boundary Layers ................................................................................................................................. 238

Laminar and Turbulent Flow ................................................................................................................................ 239

Momentum Equation for Laminar Boundary Layer ............................................................................................ 241

Energy Equation for the Laminar Boundary Layer ............................................................................................ 243

Boundary Layer Similarities ................................................................................................................................. 245

Determination of Convection Heat Transfer Coefficient ..................................................................................... 248

Dimensional Analysis ............................................................................................................................................. 248

Physical Significance of the Dimensionless Parameters ..................................................................................... 253

Turbulent Boundary Layer Heat Transfer ........................................................................................................... 257

Reynolds Colburn Analogy for Turbulent Flow Over a Flat Plate ..................................................................... 260

Mean Film Temperature and Bulk Mean Temperature ...................................................................................... 260

Summary ................................................................................................................................................................. 261

Review Questions ..................................................................................................................................................... 263

Problems .................................................................................................................................................................. 263

vii

CONTENTS

8.

EXTERNAL FLOW

8.1.

8.2.

8.3.

8.4.

8.5.

8.6.

9.

10.

293–332

Flow Inside Ducts ................................................................................................................................................... 293

Hydrodynamic Considerations ............................................................................................................................... 293

Thermal Considerations ......................................................................................................................................... 296

Heat Transfer in Fully Developed Flow ................................................................................................................ 298

General Thermal Analysis ..................................................................................................................................... 299

Heat Transfer in Laminar Tube Flow ................................................................................................................... 303

Flow Inside a Non-circular Duct ............................................................................................................................ 307

Thermally Developing, Hydrodynamically Developed Laminar Flow ............................................................... 310

Heat Transfer in Turbulent Flow Inside a Circular Tube ................................................................................... 311

Heat Transfer to Liquid Metal Flow in Tube ....................................................................................................... 325

Summary ................................................................................................................................................................. 326

Review Questions ..................................................................................................................................................... 329

Problems .................................................................................................................................................................. 329

NATURAL CONVECTION

10.1.

10.2.

10.3.

10.4.

10.5.

10.6.

10.7.

11.

Laminar Flow Over a Flat Plate ............................................................................................................................ 266

Reynolds Colburn Analogy: Momentum and Heat transfer Analogy for Laminar Flow Over Flat Plate ....... 271

Turbulent Flow Over a Flat Plate ......................................................................................................................... 271

Combined Laminar and Turbulent Flow .............................................................................................................. 272

Flow Across Cylinders and Spheres ...................................................................................................................... 281

Summary ................................................................................................................................................................. 288

Review Questions ..................................................................................................................................................... 289

Problems .................................................................................................................................................................. 289

INTERNAL FLOW

9.1.

9.2.

9.3.

9.4.

9.5.

9.6.

9.7.

9.8.

9.9.

9.10.

9.11.

266–292

333–371

Physical Mechanism ............................................................................................................................................... 333

Definitions ............................................................................................................................................................... 334

Natural Convection Over a Vertical Plate ............................................................................................................ 335

Empirical Correlations for External Free Convection Flow ............................................................................... 338

Simplified Equations for Air .................................................................................................................................. 355

Natural Convection in Enclosed Spaces ............................................................................................................... 361

Summary ................................................................................................................................................................. 366

Review Questions ..................................................................................................................................................... 367

Problems .................................................................................................................................................................. 367

CONDENSATION AND BOILING

372–401

11.1. Condensation ........................................................................................................................................................... 372

11.2. Laminar Film Condensation on a Vertical Plate ................................................................................................. 373

11.3. Condensation on a Single Horizontal Tube .......................................................................................................... 375

11.4. Turbulent Filmwise Condensation ........................................................................................................................ 377

11.5. Condensate Number ............................................................................................................................................... 377

11.6. Dropwise Condensation .......................................................................................................................................... 378

11.7. Film Condensation Inside Horizontal Tubes ........................................................................................................ 378

11.8. Boiling ...................................................................................................................................................................... 385

11.9. Pool Boiling Regimes .............................................................................................................................................. 385

11.10. Mechanism of Nucleate Boiling ............................................................................................................................. 388

11.11. Pool Boiling Correlations ....................................................................................................................................... 389

11.12. Forced Convection Boiling ...................................................................................................................................... 396

11.13. Summary ................................................................................................................................................................. 398

Review Questions ..................................................................................................................................................... 399

Problems .................................................................................................................................................................. 399

viii

12.

CONTENTS

THERMAL RADIATION: PROPERTIES AND PROCESSES

402–433

12.1. Theories of Radiation .............................................................................................................................................. 402

12.2. Spectrum of Electromagnetic Radiation ............................................................................................................... 403

12.3. Black Body Radiation ............................................................................................................................................. 403

12.4. Spectral and Total Emissive Power ....................................................................................................................... 404

12.5. Surface Absorption, Reflection and Transmission ............................................................................................... 404

12.6. Black Body Radiation Laws ................................................................................................................................... 406

12.7. Emissivity ................................................................................................................................................................ 413

12.8. Radiation from a Surface ....................................................................................................................................... 419

12.9. Radiosity .................................................................................................................................................................. 421

12.10. Solar Radiation ....................................................................................................................................................... 423

12.11. Summary ................................................................................................................................................................. 429

Review Questions ..................................................................................................................................................... 431

Problems .................................................................................................................................................................. 431

13.

RADIATION EXCHANGE BETWEEN SURFACES

434–485

13.1

13.2.

13.3.

13.4.

13.5.

13.6.

13.7.

13.8.

Radiation View Factor ............................................................................................................................................ 434

Black Body Radiation Exchange ............................................................................................................................ 451

Radiation from Cavities .......................................................................................................................................... 453

Radiation Heat Exchange between Diffuse, Gray Surfaces ................................................................................ 455

The Radiation Exchange between Three Surface Enclosures ............................................................................. 458

Radiation Heat Transfer in Three Surface Enclosures ....................................................................................... 467

Radiation Shields .................................................................................................................................................... 470

Temperature Measurement of a Gas by Thermocouple: Combined Convective and

Radiation Heat Transfer ........................................................................................................................................ 475

13.9. Summary ................................................................................................................................................................. 477

Review Questions ..................................................................................................................................................... 478

Problems .................................................................................................................................................................. 479

14.

HEAT EXCHANGERS

486–553

14.1. Classification of Heat Exchanger .......................................................................................................................... 486

14.2. Temperature Distribution ...................................................................................................................................... 489

14.3. Overall Heat Transfer Coefficient ......................................................................................................................... 489

14.4. Fouling Factor ......................................................................................................................................................... 491

14.5. Heat Exchanger Analysis ....................................................................................................................................... 493

14.6. Log mean Temperature Difference Method .......................................................................................................... 494

14.7. Multipass and Cross Flow Heat Exchangers ........................................................................................................ 496

14.8. The Effectiveness-NTU Method ............................................................................................................................. 511

14.9. Rating of Heat Exchangers .................................................................................................................................... 517

14.10. Sizing of Heat Exchangers ..................................................................................................................................... 517

14.11 Compact Heat Exchangers ..................................................................................................................................... 536

14.12. Plate Heat Exchanger (PHE) ................................................................................................................................. 540

14.13. Requirements of Good Heat Exchanger ................................................................................................................ 541

14.14. Heat Exchanger Design and Selection .................................................................................................................. 542

14.15. Practical Applications of Heat Exchangers .......................................................................................................... 543

14.16. Heat Pipes ................................................................................................................................................................ 543

14.17. Summary ................................................................................................................................................................. 545

Review Questions ..................................................................................................................................................... 547

Problems .................................................................................................................................................................. 547

ix

CONTENTS

15.

MASS TRANSFER

554–591

15.1. Introduction ............................................................................................................................................................. 554

15.2. Modes of Mass Transfer ......................................................................................................................................... 554

15.3. Comparison between Heat and Mass Transfer .................................................................................................... 555

15.4. Concentrations, Velocities and Fluxes .................................................................................................................. 555

15.5. Fick’s Law of Diffusion ........................................................................................................................................... 558

15.6. General Mass Diffusion Equation ......................................................................................................................... 561

15.7. Boundary Conditions .............................................................................................................................................. 563

15.8. Mass Diffusion Without Homogeneous Chemical Reactions .............................................................................. 564

15.9. Mass Diffusion with Homogeneous Chemical Reactions ..................................................................................... 576

15.10. Convective Mass Transfer ...................................................................................................................................... 577

15.11. Dimensional Analysis of Convective Mass Transfer ............................................................................................ 580

15.12. Evaporation of Water into Air ............................................................................................................................... 581

15.13. Summary ................................................................................................................................................................. 588

Review Questions ..................................................................................................................................................... 589

Problems .................................................................................................................................................................. 590

16.

EXPERIMENTS IN ENGINEERING HEAT TRANSFER

Expt.

Expt.

Expt.

Expt.

Expt.

Expt.

Expt.

Expt.

Expt.

Expt.

Expt.

Expt.

1

2

3

4

5

6

7

8

9

10

11

12

Thermal Conductivity of Metallic Rod ........................................................................................................... 592

Thermal Conductivity of Insulating Powder ............................................................................................... 595

Thermal Conductivity of Composite Wall ................................................................................................... 597

Natural Convection Experiment .................................................................................................................... 599

Forced Convection Experiment ...................................................................................................................... 601

Heat Transfer from Pin Fins .......................................................................................................................... 603

Stefan Boltzmann Constant ........................................................................................................................... 606

Measurement of Emissivity of a Test Surface .............................................................................................. 607

Heat Exchanger Experiment .......................................................................................................................... 609

Critical Heat Flux ............................................................................................................................................ 613

Heat Pipe .......................................................................................................................................................... 615

Thermocouples Calibration Test Rig ............................................................................................................. 617

Review Questions ............................................................................................................................................. 619

APPENDIX

Appendix A.

A.1

A.2

A.3

A.4

A.5

A.6

A.7

A.8

A.9

A.10

A.11

A.12

INDEX

592–619

621–645

Thermophysical Properties of Matter .............................................................................................................. 621

Thermophysical Properties of Selected Metallic Solids .................................................................................. 622

Thermophysical Properties of Selected Non-metallic Solids .......................................................................... 626

Thermophysical Properties of Common Materials .......................................................................................... 628

(a) Structural Building Materials ..................................................................................................................... 628

(b) Insulating Materials and Systems .............................................................................................................. 629

(c) Industrial Insulation .................................................................................................................................... 630

(d) Other Materials ............................................................................................................................................ 632

(e) Properties of Common Materials ................................................................................................................. 633

Thermophysical Properties of Gases at Atmospheric Pressure ..................................................................... 634

Thermophysical Properties of Saturated Liquids ........................................................................................... 638

Thermophysical Properties of Saturated Liquid-Vapour, 1 atm ................................................................... 639

Thermophysical Properties of Saturated Water .............................................................................................. 640

Thermophysical Properties of Liquid Metals .................................................................................................. 641

Emissivities of Some Surfaces .......................................................................................................................... 642

(a) Metals ............................................................................................................................................................ 642

(b) Non-metals .................................................................................................................................................... 643

Solar Radiative Properties for Selected Materials .......................................................................................... 644

Diffusion Coefficient of Gases and Vapours in Air at 25°C and 100 kPa ...................................................... 644

Molal Specific Volumes and Latent Heats of Vaporization for Selected Liquids at their

Normal Boiling Points ....................................................................................................................................... 645

647–651

Preface to the Third Edition

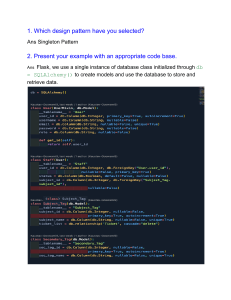

The first edition of Comprehensive Engineering Heat Transfer was published in 2000. It was written principally

to cater syllabi of Pune and North Maharashtra Universities.

The second revised and enlarged edition was published in year 2005, in which I had tried to incorporate the

relevance of heat and mass transfer applicable to Mechanical, Chemical, Aerospace, Civil Engineering, Computer Science,

Information Technology, Biotechnology, Pharmacology, and Alternative Energy generation.

Confronted with economic realities, many colleges and universities have set clear priorities. In recognition of its

value and applications to society, investment in engineering education has increased. Pedagogically, there is reintroduced

emphasis on the fundamental principles that are the foundation for lifelong learning. The important and sometimes

dominant role of heat transfer in many applications, particularly in conventional as well as in alternative energy generation

and concomitant environmental effects, has reaffirmed its relevance.

In preparing third edition, I have attempted to incorporate recent heat transfer research at a level that is appropriate

for an undergraduate student. I have strived to include new examples and problems that motivate students with interesting

applications, but whose solutions are based firmly on fundamental principles. We have remained true to the pedagogical

approach of previous editions by retaining a rigorous and systematic methodology for problem solving. I have tried to

continue the tradition of providing a text that will serve as a valuable, everyday resource for students and practicing

engineers throughout their careers.

Approach and Organization

Previous editions of the text have adhered to four learning objectives:

1. The student should adopt the meaning of the terminology and physical principles associated with heat transfer.

2. The student should be able to describe relevant transport phenomena for any process or system involving heat

transfer.

3. The student should be able to use requisite inputs for calculating heat transfer rates and/or material

temperatures.

4. The student should be able to develop representative models of processes and systems and draw conclusions

concerning process/system design or performance from the attendant analysis.

Moreover, as in previous editions, specific learning objectives for each chapter are clarified, as are means by which

achievement of the objectives may be assessed. The summary and glossary at the end of each chapter highlight key

terminology and concepts developed in the chapter and poses questions designed to test and enhance student

comprehension.

What’s New in the Third Edition?

In order to reduce the volume and cost of book, it is prepared in two columns and two colours to make it attractive

and interesting. The constructive criticisms and suggestion sent by users have been amalgamated. Answer(s) to almost

all problems presented for practice at the end of each chapter are provided.

Chapter-by-Chapter Content Changes

Chapter 1, Concepts and Mechanisms of Heat Flow is re-written and modified to accentuate the significance of

heat transfer in various contemporary applications. It has also been improved to elaborate the complementary nature of

heat transfer and thermodynamics. The economic thickness of insulation is augmented with a new section with the help

of cost and year of service. Two more sections on heat transfer in boiling and condensation and mass transfer are included

at the end of chapter.

Chapter 2, deals with Conduction-Basic equations and their applications with the help of boundary conditions. In

this edition, the boundary conditions are elaborated with extensive graphical support. The radiation and interface boundary

conditions are incorporated.

Chapters 3, 4 and 5 have undergone extensive revision and some examples are reorganized in order to give them

justification. Some parallel illustrations are withdrawn from these Chapters.

xi

xii

PREFACE

Chapter 6, Transient Conduction was substantially modified in the previous edition and has been augmented in

this edition with a streamlined presentation of the methods. The multi-dimensional, semi-infinite body transient heat

transfer has been restructured.

Chapter 7, Principles of Convection includes clarification of how temperature-dependent properties should be

evaluated when calculating the convection heat transfer coefficient. Specifically, presentation of the similarity solution

for flow over a flat plate has been simplified.

Chapter 8, External Flow has been updated and reduced in length. New results for flow over noncircular cylinders

have been added, replacing the correlations of previous editions. The discussion of flow across circular tubes has been

reduced, abolishing redundancy without sacrificing content.

Chapter 9, Internal Flow; entry length correlations have been updated and rearranged.

Chapter 10, Free Convection include a new correlation for free convection from flat plates, replacing a correlation

from previous editions. The discussion of boundary layer effects has been modified.

Aspects of Boiling and Condensation have been updated to incorporate recent advances in, for example, external

condensation on finned tubes in Chapter 11, Condensation phenomena and heat transfer rates are explained. The coverage

of forced convection condensation and related enhancement techniques has been expanded.

The concepts of emissive power, irradiation, radiosity, radiation function and net radiative flux are presented in

Chapter 12, Radiation: Properties and Processes. The coverage of environmental radiation has undergone substantial

revision, with the inclusion of separate discussions of solar radiation, the atmospheric radiation balance, and terrestrial

solar irradiation. Concern for the potential impact of anthropogenic activity on the temperature of the earth is addressed.

Chapter 13, Radiation Exchange Between Surfaces highlights the difference between geometrical surfaces and

radiative surfaces, a key concept that is often difficult for students to appreciate. Increased coverage of radiation exchange

between diffused grey surfaces, included in older editions of the text, has been retained. In doing so, radiation exchange

between differentially small surfaces is briefly introduced.

The content of Chapter 14, Heat Exchangers is experiencing a resurgence in interest due to the critical role such

devices play in conventional and alternative energy generation technologies. Much of the coverage of compact heat

exchangers included in the previous edition was limited to a specific heat exchanger. Although general coverage of

compact heat exchangers have been retained.

Chapter 15, Mass Transfer has been entirely revised extensively from the previous edition. General mass diffusion

equation and boundary conditions are restructured. Concept of solubility, permeability, mass diffusion with and without

homogeneous chemical reaction, steady state diffusion through a plane membrane, water vapour migration have been

incorporated in new sections.

Chapter 16, Experiments in Engineering Heat Transfer have been updated in the interest of students to cater

curriculum. Appendix is added as it was in previous edition.

—Author

Acknowledgements

We wish to acknowledge and thank many of our colleagues in the heat transfer community. In particular, we

would like to express our appreciation to Prof. (Dr.) R. M. Warkhedkar, Govt. Engg. College Karad (M.S.), Prof. S. B.

Patil of MET’s IoE. Nashik, Prof. H. R. Thakare of SNJB’s CoE. Chandwad, Prof. D. H. Dubey of B.S. Deore CoE. Dhule,

Prof. P. A. Deshmukh of R.S. CoE Pune and many friends, students, users whose constructive suggestions helped me to

improve the text and to bring out this edition.

I would like to extend my gratitude to administration and executive management of SNJB’s Late Sau. K. B. Jain

College of engineering, Neminagar, Chandwad (M.S.), India, for providing me facilities, moral support and cherish

cooperation during the preparation of this manuscript.

I also take the opportunity to express my heartiest thanks to Mr. Saurabh Gupta, Managing Director, Laxmi

Publications (P) Ltd. New Delhi, who adapted my desire to bring this volume in two columns and two colours, even after

three proof readings of manuscript.

In closing, I am deeply grateful to my spouse and children, Dr. Ankit, and Pratik for their endless love and

patience.

A human creation can never be perfect. Some mistakes might have crept in the text. My effort in writing the book

will be rewarded, if readers send their constructive suggestions and objective criticism with a view to improve the usefulness

of the book.

—Author

xiii

Nomenclature

A

Area normal to heat transfer, m2

h

Plank’s constant

Ac

Cross-sectional area, m2

hfg

Specific enthalpy of vaporization, J/kg

hrad, hr

Radiation heat transfer coefficient, W/m2.K

I

Electrical current, A, radiation intensity,

W/m2.sr

Isc

Solar constant, W/m2

i

Electric current density, A/m2

J

Radiosity, W/m2

JA

Diffusion flux, kgmol/m2.s

Afin

Fin surface area,

Ap

Profile area, m2

m2

m2

As

Surface area,

Aun fin

Area or bare (un-finned) surface, m2

Ano fin

Area of surface without fin, m2

a

Acceleration, m/s2

Bi

Biot number

Bo

Bond number

Ja

Jacob number

C

Heat capacity rate, W/K, specific heat of solids,

J/kg. K

Kc

Mass transfer coefficient, m/s

k

Thermal conductivity, W/m.K

CA

Molar concentration of species A in a mixture

L

Length, thickness, fin height, m

CD

Drag coefficient

Lc

Characteristic length, corrected lenght, m

Cp

Specific heat of liquids, J/kg. K

Le

Lewis number

Cf

Coefficient of friction

LMTD

Log mean temperature difference, °C

Co

Condensation number

M

Molecular number, kg/kgmol

D, d

Diameter, m

m

Mass, kg

m

Mass flow rate, kg/s

mf

Mass fraction

m2/s

DAB

Mass diffusivity,

Dh

Hydraulic diameter, m

E

Emissive power, W/m2

E′

Rate of energy, W

F

Force, N

N

Number of tubes

Nfin

Number of fins

Nu

Nusselt number

Number of transfer units

Fo

Fourier number

NTU

Fi–j

Radiation view factor

P

Perimeter, m, power, W

f

Friction factor

Pe

Peclet number

f0–λ

Blackbody radiation function

Pr

Prandtl number

G

Irradiation, W/m2

P

Pressure, N/m2

Gr

Grashof number

Q

Heat transfer rate, W

Gz

Graetz number

q

Heat flux, W/m2

g

Acceleration due to gravity, m/s2

R

Specific gas constant, J/kg.K

go

Uniform heat generation per unit volume,

W/m3

Ru

Universal gas constant = 8314, J/kgmol. K

H

Height, m

Ra

Rayleigh number

h, hc

Convection heat transfer coefficient, W/m2.K

Rcont

Contact resistance, K/W

Re

Reynolds number

xiv

xv

CONTENTS

Re

Electrical resistance, ohms

Rf

Fouling resistance,

m2.K/W

Rth

Thermal resistance, K/W

rcr

Critical radius, m

ri

Inner radius, m

ro

Outer radius, m

r, θ, z

Cylindrical coordinates

r, θ, φ

Spherical coordinates

S

Shape factor for two dimensional heat

conduction, m

Sc

Schmidt number

Sc

Solar constant

Sh

Sherwood number

St

Stanton number

Kinematic viscosity, momentum diffusivity,

m2/s, frequency

ρ

Mass density, kg/m3, reflectivity of the radiating

surface, electrical resistively, Ω-m

ρi

Mass concentration of ith species in a mixture

σ

Stefan Boltzmann constant, W/m2.K4, surface

tension, N/m

τ

Shear stress, N/m2, transmissivity

ω

Solid angle, sr

Subscripts

T

Temperature, °C or K

t

Time, s

U

Overall heat transfer coefficient, W/m2.K

u, v

Mass average velocity components, m/s

V

Volume of solid, m3

u

Fluid velocity, m/s

v

Specific volume, m3/kg

w

Depth, width, m

x, y, z

Cartesian coordinates

x

Local distance, m

xcr

Critical distance, m

xe

Hydrodynamic entry length, m

yi

Mole fraction of ith species

b

c

cr

cond

conv

D

e

f

fg

g

H

h

i

L

l

lm

M

m

max

o

Greek Letters

α

Thermal diffusivity, m2/s

β

Volumetric expansion coefficient, K–1

δ

Thickness of velocity

characteristic length, mm

δth

Thickness of thermal boundary layer, mm

ε

Emissivity of the radiating surface, effectiveness

of heat exchanger

εfin

Fin effectiveness

∈H

Turbulent diffusivity for heat transfer

∈M

Turbulent diffusivity for momentum

ηf, ηfin

Fin efficiency

ηtotal

Total fin efficiency

θ

Temperature difference, °C

κB

Boltzmann constant

λ

Wavelength, µm

µ

Dynamic viscosity, kg/m.s

boundary

ν

layer,

R

rad

s

sat

sky

sur

th

α

v

x

λ

∞

ρ

τ

blackbody

Cross-sectional area

Critical

Conduction

Convection

diameter

excess, emission

fluid properties

Phase transformation

saturated vapour

heat transfer

hydraulic, hot

inner surface, initial condition, tube inlet

condition, incident radiation

Based on characteristic length

saturated liquid

log mean condition

momentum transfer

mean value

maximum

centre or mid-plane condition, outer, tube outlet

condition

radiaton surface

radiation

surface condition

saturated condition

sky condition

Surroundings condition

thermal

absorbed

vapour condition

local condition

spectral

free stream condition

reflected

transmitted

UNITS AND DIMENSIONS

BASE UNITS:

QUANTITY

UNITS

DIMENSION

Length

Mass

Time

Electric current

Temperature

metre

kilogram

second

ampere

kelvin

m

kg

s

A

K

radian

steradian

rad

sr

metre per second squared

radian per second squared

radian per second

square metre

Volt

Ohm

joule

joule per kelvin

newton

hertz

joule

ampere

watt

watt per steradian

joule per kilogram-kelvin

pascal

watt per metre-kelvin

meter per second

cubic metre

Joule

m/s2

rad/s2

rad/s

m2

W/A

Ω

J or N.m

J/K

Nor kg.m/s2

Hz or 1/s

J or N.m

A

W or J/s

W/sr

J/kg-K

N/m2

W/m–K

m/s

m3

J or N.m

SUPPLEMENTARY UNITS:

Plane angle

Solid angle

DERIVED UNITS:

Acceleration

Angular acceleration

Angular velocity

Area

Electric potential difference

Electric resistance

Energy

Entropy

Force

Frequency

Heat energy

Magnetomotive force

Power

Radiation Intensity

Specific heat

Stress

Thermal conductivity

Velocity

Volume

Work

xvi

a

ω

θ

A

V

Re

E

s

F

v

Q

emf

P

I

CP

σ

k

u

V

W

SYMBOLS

Greek Alphabets

A

B

Γ

D

E

Z

H

Θ

α

β

γ

δ

ε

ζ

η

θ

∃

Alpha

Beta

Gamma

Delta

Epsilon

Zeta

Eta

Theta

there exists

I

K

Λ

M

N

Ξ

O

Π

ι

κ

λ

µ

ν

ξ

ο

π

V

Iota

Kappa

Lambda

Mu

Nu

Xi

Omicorn

Pi

for all

P

Σ

T

Y

Φ

X

Ψ

Ω

ρ

σ

τ

υ

ϕ

χ

ψ

ω

Rho

Sigma

Tau

Upsilon

Phi

Chi

Psi

Omega

Metric Weights and Measures

LENGTH

10 millimetres

10 centimetres

= 1 centimetre

CAPACITY

10 millilitres

= 1 centilitre

= 1 decimetre

10 centilitres

= 1 decilitre

10 decimetres

= 1 metre

10 decilitres

= 1 litre

10 metres

= 1 dekametre

10 litres

= 1 dekalitre

10 dekametres

= 1 hectometre

10 dekalitres

= 1 hectolitre

10 hectometres

= 1 kilometre

10 hectolitres

= 1 kilolitre

VOLUME

AREA

1000 cubic centimetres

= 1 centigram

100 square metres

= 1 are

1000 cubic decimetres

= 1 cubic metre

100 ares

= 1 hectare

100 hectares

= 1 square kilometre

WEIGHT

10 milligrams

ABBREVIATIONS

= 1 centigram

kilometre

km

10 centigrams

= 1 decigram

metre

10 decigrams

= 1 gram

centimetre

cm

10 grams

= 1 dekagram

millimetre

mm

10 dekagrams

= 1 hectogram

kilolitre

10 hectograms

= 1 kilogram

litre

100 kilograms

= 1 quintal

millilitre

10 quintals

= 1 metric ton (tonne)

tonne

t

m

kl

l

ml

kilogram

gram

are

kg

g

a

hectare

ha

centiare

ca

xvii

1

Concepts and Mechanisms

of Heat Flow

1.1. What is Heat Transfer ? 1.2. Modes of Heat Transfer. 1.3. Physical Mechanism of Modes of Heat Transfer—Conduction

—Convection—Radiation. 1.4. Laws of Heat Transfer—Law of conservation of mass : Continuity equation—Newton’s second

law of motion—Laws of thermodynamics—Fourier law of heat conduction—Newton’s law of cooling—The Stefan Boltzmann

law of thermal radiation. 1.5. Combined Convective and Radiation Heat Transfer—Equation of state. 1.6. Thermal

Conductivity—Variation in thermal conductivity—Determination of thermal conductivity—Variable thermal conductivity.

1.7. Isotropic Material and Anisotropic Material. 1.8. Insulation Materials—Superinsulators—Selection of insulating

materials—The R-Value of insulation—Economic thickness of insulation. 1.9. Thermal Diffusivity. 1.10. Heat Transfer in

Boiling and Condensation. 1.11. Mass Transfer. 1.12. Summary—Review Questions—Problems—Multiple Choice Questions.

Objective of this chapter is to:

• give an introduction to heat transfer rate, heat

flux,

• elaborate three modes of heat transfer—conduction, convection and thermal radiation,

• offer an introduction of physical laws of heat

transfer,

• enlighten thermal conductivity, R value, thermal

conductors and insulators.

The science of Thermodynamics deals with the

amount of heat transfer as system undergoes a process

from one equilibrium state to another, without any

information concerning the nature of interaction or the

time rate at which it occurs. Heat Transfer is a branch

of thermal science which deals with analysis of rate of

heat transfer and temperature distribution taking place

in a system as well as the nature of heat transfer. The

design of boilers, condensers, evaporators, heaters,

refrigerators, and heat exchangers, requires considerations of the amount of heat to be transmitted as well as

the rate at which heat is to be transferred. The successful

operation of equipment component such as turbine

blades, walls of combustion chambers, etc. depends on

the cooling rate, in order to avoid their metallurgical

failure. A heat transfer analysis must also be accounted

in the design of electronic components, electric machines,

transformers, and bearings to avoid the overheating and

damage of equipment.

1.1.

WHAT IS HEAT TRANSFER ?

Its simple answer is the definition of heat or heat energy.

Heat is a form of energy in transit due to

temperature difference. Heat transfer is transmission

of energy from one region to another region as a result

of temperature difference between them. Whenever

there exists a temperature difference in mediums or

within a media, heat transfer must occur.

The amount of heat transferred per unit time is

called heat transfer rate and is denoted by Q. The

heat transfer rate has unit J/s which is equivalent to

Watt.

When the rate of heat transfer Q is available, then

total amount of heat energy transferred ∆U during a

time interval ∆t can be obtained from

∆U =

∆t

∫0

Qdt = Q∆t (joule)

…(1.1)

The rate of heat transfer per unit area normal to

direction of heat flow is called heat flux and is expressed

as;

q=

Q

(W/m2)

A

…(1.2)

Steady and Unsteady State Heat Transfer

For analysis of heat transfer problems, two types of heat

transfer are considered—steady state and unsteady

1

2

ENGINEERING HEAT AND MASS TRANSFER

state. In case of steady state heat transfer, the

temperature at any location on the system does not vary

with time. The temperature is function of space

coordinates only, but it is independent of time.

Mathematically, for rectangular coordinate system ;

T = f(x, y, z)

...(1.3)

During steady state conditions, the heat transfer

rate is constant and there is no change of internal energy

of the system. For example, the heat transfer in coolers,

heat exchangers, heat transfer from large furnaces, etc.

In unsteady state heat transfer, the temperature

varies with time as well as position. The temperature is

a function of time and space coordinates.

Mathematically, for rectangular coordinates ;

T = f(x, y, z, t)

...(1.4)

During unsteady state or transient heat transfer,

rate of heat transfer varies with time due to change in

internal energy of the system. Most of the actual heat

transfer processes are unsteady in nature , but some of

them are considered in steady state to simplify them.

For example, heat transfer from hot coffee left in a room,

cooling and heating process, etc. are transient processes.

The heat transfer may be one, two or three

directional, depends upon the configuration of the

system considered.

1.2.

MODES OF HEAT TRANSFER

When the temperature gradient exists in a medium,

which may be solid, liquid, or gas, heat transfer occurred

is called conduction. In contrast, the convection refers

to heat transfer that will occur between a surface and a

moving medium, when they are at different temperatures. The third mode of heat transfer is thermal

radiation. All surfaces at finite temperature emit energy

in the form of electromagnetic waves. The thermal

radiation can also occur in absence of any medium.

1.3.

PHYSICAL MECHANISM OF MODES OF

HEAT TRANSFER

1.3.1. Conduction

The conduction occurs usually in the stationary

mediums. It is the mode of heat transfer in which energy

exchange takes place from a region of high temperature

to that of low temperature by direct molecular

interactions and by the drift of electrons. The heat

conduction may be viewed as the transfer of energy from

more energetic molecules to adjacent less energetic

molecules of a substance. When a fast moving molecules

from a region of high temperature collide with slower

moving molecules from a region of lower temperature,

the heat energy transfer takes place between them. The

low energy molecules absorb energy and thus their

temperature is increased and the temperature of high

energy molecules is lowered.

The conduction heat transfer in liquids and gases

occurs due to collisions and diffusion of molecules during

their random motion. However, the nature is much more

complex.

The temperature gradient is the potential for heat

conduction. If a body in any phase exists a temperature

gradient, will definitely have the conduction heat

transfer.

1.3.2. Convection

The convection is a mode of heat transfer in which the

energy is transported by moving fluid particles. The

convection heat transfer comprises two mechanisms.

First is transfer of energy due to random molecular

motion (diffusion) and second is the energy transfer by

bulk or macroscopic motion of the fluid (advection). The

molecules of fluid are moving collectively or as aggregates thus carry energy from high temperature region

to low temperature region. Therefore, the faster the fluid

motion, the greater the convection heat transfer.

Convection heat transfer may be classified

according to nature of fluid flow.

If the fluid motion is artifically induced by a

pump, fan or a blower, that forces the fluid over a surface

to flow as shown in Fig. 1.1(a), the heat transfer is said

to be by the forced convection.

Heated

plate

Tw

Q

Fan

Air at T¥

Fig. 1.1. (a) Forced convection of air (Tw > T∞)

If the fluid motion is set-up by buoyancy effects,

resulting from density difference caused by temperature

difference in the fluid as shown in Fig. 1.1(b), the heat

transfer is said to be by the free or natural convection.

For example, a hot plate vertically suspended in stagnant cool air, causes a motion in air layer adjacent to

the plate surface because of temperature difference in

air gives rise to density gradient which in turn sets-up

the air motion.

3

CONCEPTS AND MECHANISMS OF HEAT FLOW

Q

Heated

plate

Tw

T¥

Q

Fig. 1.1. (b) Natural or free convection of air (Tw > T∞ )

It is the conservation of mass equation for steady

state incompressible fluid flow. In general, the mass flow

) is expressed as ;

rate ( m

= ρuAc

m

...(1.5)

2

where, Ac = cross-sectional area of flow (m ),

ρ = fluid density (kg/m3),

u = fluid velocity (m/s).

The volume of a fluid flowing through a pipe or

duct per unit time is called volume flow rate or

and is expressed as ;

discharge rate, denoted by V

=uA = m

V

c

ρ

1.3.3. Radiation

Thermal radiation is the energy emitted by a substance

because of its temperature. The radiation energy emitted

by a body is transmitted in the space in the form of

electromagnetic waves according to Maxwell wave

theory or in the form of discrete photons according to

Max Plank’s theory. Both concepts have been used in

analysis of radiation heat transfer. Regardless of the

form of substance (solid, liquid or gas) the emission of

energy is due to change in electron configuration of the

constituent molecules. While the transfer of energy by

conduction or convection requires the presence of

material medium, radiation does not. In fact, the

radiation heat transfer is more efficient in vacuum.

Thermal radiation occurs in the region of wavelengths

0.1 µm to 100 µm on electromagnetic spectrum.

1.4.

LAWS OF HEAT TRANSFER

Like all subjects in physical science, some fundamental

and subsidiary laws are also used in heat transfer

analysis.

The fundamental laws, which are used in broad

area of applications are :

1. The law of conservation of mass,

2. Newton’s second law of motion,

3. First and second laws of thermodynamics.

The subsidiary laws, which are based on

experimental facts are :

4. Fourier law of heat conduction,

5. Newton’s law of cooling,

6. Stefan Boltzmann law for thermal radiation,

7. Equation of state.

1.4.1. Law of Conservation of Mass : Continuity Equation

It states that the mass of an incompressible fluid system

is constant in absence of nuclear reaction.

…(1.6)

1.4.2. Newton’s Second Law of Motion

It states that the rate of change of momentum in any

direction is always equal to sum of all external forces

acting on the body in such direction.

The momentum = mass flow in particular

direction × directional velocity

d(mv)

The rate of change of momentum =

dt

Newton’s second law of motion :

d(mv)

ΣFx =

...(1.7)

dt

1.4.3. Laws of Thermodynamics

In heat transfer analysis, the first and second laws of

thermodynamics are useful. The first law of

thermodynamics states that the energy can neither be

created nor be destroyed, only its form can be changed.

In fact its quantity remains constant in either form.

The second law of thermodynamics states that

the energy cannot be upgraded, or heat energy cannot

flow from a body at lower temperature to a body at

higher temperature. In other words, the second law of

thermodynamics talks about the quality of energy, not

of quantity like first law of thermodynamics.

1.4.4. Fourier Law of Heat Conduction

Whenever, a temperature gradient exists in a body, there

is an energy transfer from the high temperature region

to low temperature region by conduction. The Fourier

law states that the rate of heat conduction per unit area

(heat flux) is directly proportional to the temperature gradient.

Q dT

∝

dx

A

or

Q

dT

=−k

dx

A

or Q = −kA

dT

dx

...(1.8)

4

ENGINEERING HEAT AND MASS TRANSFER

where, Q = rate of heat transfer in W,

A = heat transfer area in

direction of heat flow,

m2

(T1 − T2 )

dT

=–

L

dx

; normal to

dT

= temperature gradient in °C/m ; slope of

dx

temperature curve on T–x diagram,

k = constant of proportionality, called the

thermal conductivity of material in W/m.°C

or W/m.K.

The minus sign is inserted to make the natural

heat flow, a positive quantity. According to the second

law of thermodynamics, the heat energy always flows

in the direction of decreasing temperature, thus the temperature gradient dT/dx becomes negative.

...(1.10)

Example 1.1. The wall of a furnace is constructed from

15 cm thick fire brick having constant thermal

conductivity of 1.6 W/m.K. The two sides of the wall

are maintained at 1400 K and 1100 K, respectively.

What is the rate of heat loss through the wall which is

50 cm × 3 m on a side?

Solution

Given : A furnace wall with

T1 = 1400 K, T2 = 1100 K

A = 50 cm × 3 m = 0.5 × 3 = 1.5 m2

k = 1.6 W/m.K

L = 15 cm = 0.15 m.

A simple case of one dimensional steady state

heat flow through a plane wall is shown in Fig. 1.2. For

constant thermal conductivity k and heat transfer area

A, equation (1.8) can be written as ;

T1 = 1400 K

W

k = 1.6 ——

m·K

Q

dx = – kdT

A

L = 15 cm

T2 = 1100 K

T

Fig. 1.3. Schematic of furnace wall

T(x)

T1

dT

Q

A

Q

wall.

T2

0

x

dx

L

Fig. 1.2. One dimensional steady state

conduction through a plane wall

Integrating above equation within the limits as ;

Q

A

or

z

L

0

dx = – k

z

T2

T1

dT

Q

L = – k(T2 – T1)

A

(T1 − T2 )

...(1.9)

L

Comparing with equation (1.8), the temperature

gradient is linear and is given by

or

Q=kA

To find : Heat loss through the wall.

Assumptions :

1. Steady state conditions.

2. One dimensional heat conduction through the

3. Constant properties.

Analysis : According to Fourier law of heat conduction, equation (1.9)

(T1 − T2 )

Q = kA

L

Using numerical values

(1.6 W/m.K) × (1.5 m 2 ) × (1400 K − 1100 K)

Q=

(0.15 m)

= 4800 W. Ans.

Example 1.2. To determine thermal conductivity of

hydrogen, a hollow tube with a heating wire concentric

to the tube is often used. Essentially the gas between the

wire and the wall is a hollow cylinder and an electric

current passing through the wire acts as a heat source.

Determine thermal conductivity of the gas, using following data :

T1 = wire temperature = 200°C,

5

CONCEPTS AND MECHANISMS OF HEAT FLOW

T2 = tube wall temperature = 150°C,

I = current in the wire = 0.5 A,

V = voltage drop over 0.3 m section of wire

= 3.6 V,

r2 = tube radius = 0.125 cm,

r1 = wire radius = 0.0025 cm,

L = length of the wire = 0.3 m.

Solution

Given : Hollow cylinder of hydrogen gas with

T1 = 200°C,

T2 = 150°C,

I = 0.5 A,

V = 3.6 V

r2 = 0.125 cm,

r1 = 0.0025 cm, L = 0.3 m.

0.125 cm

L = 0.3 m

Q

= h(Ts – T∞)

A

or

Q = hA(Ts – T∞)

...(1.11)

where, Ts = surface temperature, °C,

T∞ = fluid temperature, °C,

A = surface area for convection heat transfer,

m2,

h = constant of proportionality, is called

the heat transfer coefficient. It is measured in W/(m2.K)

or W/(m2.°C).

or

q=

y

Fluid

Fluid temperature

profile

T¥

Heater wire

h

Fig. 1.4. Hydrogen filled tube with concentric heating wire

To find : Thermal conductivity of hydrogen gas.

Assumptions :

1. Steady state heat conduction.

2. Heat conduction in radial direction only.

3. Constant properties.

Analysis : The Fourier law of heat conduction for

radial system is given as ;

Q

dT

=–k

dr

A

where, A = 2πrL

and

Q = VI = (3.6 V) × (0.5 A) = 1.8 W

Hence

z

r2

r1

dr

=–k

r

z

T2

T1

FG IJ = – k(T

H K

r

Q

ln 2

2 πL

r1

or

or

Q

2πL

2

dT

– T1)

Q ln(r2 /r1 )

2πL (T1 − T2 )

Substituting numerical values,

k=

k=

(1.8 W) × ln(0.125/0.0025)

2π × (0.3 m) × (200°C – 150°C)

= 0.075 W/m.K. Ans.

1.4.5. Newton’s Law of Cooling

It is the fundamental law for heat convection and it

states that the rate of heat transfer is directly

proportional to the temperature difference between a

surface and a fluid, or mathematically

Q

∝ (Ts – T∞)

A

x

Plate at Ts

Fig. 1.5. Temperature profile in convection heat transfer

The value of heat transfer coefficient depends on

the properties of fluid as well as fluid flow conditions.

Fig. 1.5 shows a temperature profile in convection heat

transfer. Table 1.1 shows typical values of heat transfer

coefficient for some fluid flow conditions.

TABLE 1.1. Typical values of heat transfer

coefficient h

Fluid flow condition

h (W/m2.K)

Air (1 bar, free convection)

Air (1 bar, forced convection)

Water (free convection)

Water (forced convection)

Vapourisation of water

6

10

500

600

2500

–

–

–

–

–

30

200

1000

8000

1,00,000

Condensation of steam

4000 – 25,000

Example 1.3. Hot air at 150°C flows over a flat plate

maintained at 50°C. The forced convection heat transfer