[IAEA Nuclear Energy Series No. NW-T-1.3] Management of Disused SRSs

advertisement

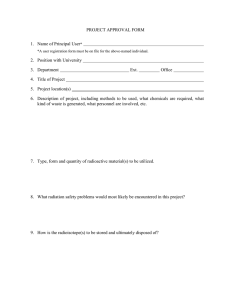

![[IAEA Nuclear Energy Series No. NW-T-1.3] Management of Disused SRSs](http://s2.studylib.net/store/data/027069884_1-f5f66260cb389a2f3e83b5ef26c0ce8d-768x994.png)