US008717374B2

(12) United States Patent

(10) Patent No.:

Nixon

US 8,717,374 B2

(45) Date of Patent:

(54) METHODS AND APPARATUS TO DISPLAY

6,618,630 B1

PROCESS CONTROL INFORMATION

6,772,204 B1

(75) Inventor: Mark Nixon, Round Rock, TX (US)

(73) Assignee: Fisher-Rosemount Systems, Inc.,

(*) Notice:

9/2003 Jundt et al.

8/2004 Hansen

6,948,159 B2

9, 2005 Born et al.

6,970,771 B1

1 1/2005 Preiss et al.

7,146,230 B2

12/2006 Glanzer et al.

7,178,103 B2

2/2007 Humphrey et al.

7.213,478 B2

Round Rock, TX (US)

7,251,534 B2

7,289,861 B2

Subject to any disclaimer, the term of this

7,317,952 B2

patent is extended or adjusted under 35

U.S.C. 154(b) by 900 days.

5/2007 Harada et al.

7, 2007 Walls et al.

10/2007 Aneweer et al.

1/2008 Bhandiwad et al.

(Continued)

FOREIGN PATENT DOCUMENTS

(21) Appl. No.: 12/880,887

(22) Filed:

May 6, 2014

Sep. 13, 2010

EP

1691.245

8, 2006

EP

2221 685

8, 2010

(Continued)

(65)

Prior Publication Data

US 2012/OO62577 A1

OTHER PUBLICATIONS

Mar. 15, 2012

State Intellectual Property Office, Search Report, issued for Great

Britain application serial No. GB11 13796.5, on Dec. 12, 2012, 4

(51) Int. Cl.

G06T I/00

G06T I5/00

G06F 5/00

(2006.01)

(2011.01)

(2006.01)

(52) S.C.

pageS.

(Continued)

34.5/522; 34.5/5O1

(58) Field of Classification Search

Primary Examiner — Jacinta M Crawford

s

(74) Attorney, Agent, or Firm – Hanley, Flight &

USPC ............... 70235.36.38, 108,119, 120, 122,

Zimmerman, LLC

702/123, 182–185; 709/220 222; 34.5/501,

34.5/522

See application file for complete search history.

(56)

(57)

Example methods and apparatus to display process control

information are disclosed. A disclosed example method

includes receiving a request to view process control informa

tion associated with a field device, accessing, via a database,

a device description file associated with the field device,

wherein the device description file is formatted to conform to

an Electronic Device Description Language (EDDL), and

generating a display for the process control information using

the device description file, wherein the device description file

includes a script extension that conditionally displays a

graphic if a portion of the process control information

matches a condition within the Script extension.

References Cited

U.S. PATENT DOCUMENTS

5,050,088 A

5,390,314 A

9, 1991 Buckler et al.

2f1995 Swanson

5,428,525 A

6/1995 Cappelaere et al.

5,796,602 A

5,801.942 A

5,828,851 A

8, 1998 Wellanet al.

9, 1998 Nixon et al.

10, 1998 Nixon et al.

6.256,635 B1

6,330,517 B1

7/2001 Arrouye et al.

12/2001 Dobrowski et al.

6,446,202 B1

9, 2002 Krivoshein et al.

6,581,101 B2

6/2003 Villalpando

ABSTRACT

23 Claims, 11 Drawing Sheets

a

m

32

108

r

w

w

00

SCRIPT

ENERATOR

102-s /

M

a

SPLAY

INTERFACE

WorksTATION

s

O

-a

V

M

US 8,717,374 B2

Page 2

(56)

References Cited

U.S. PATENT DOCUMENTS

7401,086 B2

2002/0041289

2003/004.8287

2003/O135508

2003/02O8587

2003/0236577

2004/0059851

2004/O 117775

2004/O123091

2004/0225491

2004/O23O327

2004/0230582

2004/O23O899

2004/0243933

2005, OO15176

2005/0055681

2005, 0071522

2005, 0071851

2005/O149478

2005/0172220

2006, OO74499

2006/0111794

2006, O190112

2007, OO16896

2007 OO67725

2007.0075916

2007/0078540

2007/0106761

2007/O139441

2007. O1571.83

2007/O165031

2007/0179645

2007/0244583

2007/O25552O

2007/0282463

2008/008O395

2008. O112388

2008. O189441

2008/0234837

2008/0320402

2009 OO77539

2009,0183139

2009/0204458

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

T/2008

4, 2002

3, 2003

T/2003

11, 2003

12, 2003

3, 2004

6, 2004

6, 2004

11, 2004

11, 2004

11, 2004

11, 2004

12, 2004

1/2005

3, 2005

3, 2005

3, 2005

7/2005

8, 2005

4, 2006

5, 2006

8, 2006

1/2007

3, 2007

4, 2007

4, 2007

5/2007

6, 2007

7/2007

7/2007

8, 2007

10/2007

11/2007

12, 2007

4, 2008

5/2008

8, 2008

9, 2008

12, 2008

3, 2009

T/2009

8, 2009

Chorafakis et al.

Hatch et al.

Little et al.

Chorafakis et al.

Sauer

Clinton

Donaires

Born et al.

Das

Chang

Opheim et al.

Pagnano et al.

Pagnano et al.

Becker et al.

Harada et al.

Gadre

DeGroot

Opheim

Fahy

Humphrey et al.

Hamidpour

WySuphet al.

Buesgen et al.

Wittmer et al.

Cahill et al.

Bump et al.

Bump et al.

Beoughter et al.

Lucas et al.

Pazel et al.

Gilbert et al.

Nixon et al.

Rachut

Becker et al.

Hodson et al.

Law et al.

Garrett et al.

Jundt et al.

Samudrala et al.

Isenmann et al.

Booth

Foti et al.

Wiese et al.

2009,0271726

2009,0276486

2009,0292996

2009/0306964

2010, 0121999

A1

A1

A1

A1

A1

10/2009

11/2009

11/2009

12/2009

5/2010

Gavimath et al.

Tandon et al.

Anne et al.

Bonnet et al.

Isenmann et al.

FOREIGN PATENT DOCUMENTS

GB

GB

JP

2472141

2479036

2003.108220

1, 2011

9, 2011

4/2003

OTHER PUBLICATIONS

Unknown Author, “Why Should You Choose EDDL: Easier Calibra

tion.” EDDL, www.eddl.org Mar. 3, 2008 (2 pages).

Rolf Birkhofer, XML for Automotion Devices, A Multi-Schema

Approach, XML Europe, May 21-25, 2001 (33 pages).

Terry Blevins, “EDDL Overview.” NeSSI Meeting, EDDL, Feb. 16,

2007 (69 pages).

Martin Fowler, “Language Workbenches: The Killer-App for

Domain Specific Languages?” martinfowler.com; Jun. 12, 2005 (24

pages).

Karlsruhe, “Welcome to the NAMUREDDL Workshop with ECT.”

EDDL, May 22, 2006 (47 pages).

“PROFIBUSTechnology and Application-System Description.” Oct.

2002, 42 pages.

“SIMATIC Component based Automation—Getting Started with

SIMATIC iMap.” published by SIEMENS, Dec. 2002, 84 pages.

UK Intellectual Property Office, “Examination Report” issued in

connection with Application No. GB1002596.3, May 31, 2013, 3

pageS.

Japan Intellectual Property Office, “Office Action.” issued in connec

tion with Application No. 2010-032263, Oct. 29, 2013, 2 pages.

State Intellectual Property Office of China, "Office Action.” issued in

connection with Application No. 2010101291966, Sep. 23, 2013, 7

pageS.

Philippines Intellectual Property Office, “Official Action.” issued in

connection with Application No. 120 10000052, Jan. 20, 2012, 2

pageS.

European Patent Office, “European Search Report” issued in con

nection with Application No. 10154029.2, Oct. 6, 2011, 6 pages.

UK Intellectual Property Office, “Search Report” issued in connec

tion with Application No. GB1002596.3, Jun. 8, 2010, 4 pages.

U.S. Patent

May 6, 2014

Sheet 1 of 11

US 8,717,374 B2

^

100

132

108

SCRIPT

GENERATOR

WORKSTATION

N

PROCESS CONTROL SYSTEM

1

109

7

CONTROLLER

/

7

DEVICE

F.

(ASDissolved

\2 Oxygen

e.g. Glucose

:

Charge

;: :

eg. Media la

as a sma mass so

/

U.S. Patent

May 6, 2014

Sheet 2 of 11

TO

APPLICATION

^

—

ZOL

||

0

||

0

US 8,717,374 B2

U.S. Patent

300

May 6, 2014

US 8,717,374 B2

Sheet 3 of 11

Ya

~ r- ae^*

8

isSEF

N

ss

s

SW

8xx

k

k

k

s

s

S

S

i

S

S

S

S

S

systsreiss

xxxxxxxxxxxxxxxxxxxxxxx-xx

i

is siefed

)

ississi

is petty asfinities

8

V

FIG. 3

R

324

U.S. Patent

May 6, 2014

Sheet 4 of 11

|

US 8,717,374 B2

U.S. Patent

May 6, 2014

Sheet 5 of 11

US 8,717,374 B2

CONFIGURE/SETUP OF DEVICE TANK 101

(C) G)

1.

HTTP:/DASERVER/DEVICEFTANK 101

V

HOME > DEVICE > CONFIGURE > MANUAL SETUP > TANK GRAPHIC

506

508

CONFIGURE

GUIDED SETUP I LEVEL

TNK 101

MANUAL SETUP

ALERT SETUP

TEMP

CALIBRATION

TAG

504

TNK101

LOWERRANGE

UPPERRANGE

OVERVIEW

SERVICE TOOLS

COMPARE

VOLUME CONVERSION

%level = 100"(level 156.3 gal.)

516

FIG. 5

DEVICES

HTTP:IDASERVERITANK 101

TANK 101

LEVEL

TNK101

TEMP

TAG

TNK101

LOWERRANGE

UPPERRANGE

FIG. 6

V

U.S. Patent

May 6, 2014

Sheet 6 of 11

US 8,717,374 B2

CONFIGURE/SETUP OF DEVICE TANK 101

(G) G) X ?.

HOME > DEVICE > CONFIGURE > STATUS SETUP > TANK GRAPHIC

CONFIGURE

GUIDED SETUP

STATUS MICROCHART - TANK 101

MANUAL SETUP

STATUS SETUP

CALIBRATION

TIMELINE

504

OVERVIEW

SERVICE TOOLS

COMPARE

- 702

PROPERTY

EXPAND TIME LINE EVERY 1000

MS WHILE VIEWED

TRIGGER

ENABLED

PERIOD

1000

NAME

S

TK TR 101

AUTO RESET

YES

ACTION SCRIPT timeline. Width = 10

FIG. 7

U.S. Patent

800

Y

May 6, 2014

Sheet 7 of 11

US 8,717,374 B2

S

802

RECEIVE AREOUEST TO VIEW PROCESS

CONTROL INFORMATION

/N

804

DETERMINE AN IDENTIFIER OF A FIELD

DEVICE ASSOCIATED WITH THE RECUEST

LOCATE AN EDD FILE BASED ON THE

IDENTIFIER

806

EXECUTE INSTRUCTIONS WITHIN THE EDD

FILE TO CREATE A DISPLAY FILE

808

ACCESS PROCESS CONTROL INFORMATION

REFERENCED BY THE EDD FILE

810

EXECUTE SCRIPT EXTENSIONS SPECIFIED

WITHIN THE EDD FILE

812

814

DOES A CONDITION OF A SCRIPT

EXTENSION MATCHA PORTION OF

THE PROCESS CONTROL

INFORMATION?

YES

LOCATE A GRAPHIC REFERENCED BY THE

CONDITION

ADD THE GRAPHIC TO THE DISPLAY FILE

ADDITIONAL CONDITIONS TO

PROCESS2

FIG. 8A

U.S. Patent

800

May 6, 2014

Sheet 8 of 11

US 8,717,374 B2

Y

RENDER THE DISPLAY FILE TO GENERATE A

DISPLAY OF THE REOUESTED PROCESS

822

CONTROL INFORMATION

TRANSMIT THE RENDERED DISPLAY FILE

TO A USER INTERFACE TO DISPLAY THE

PROCESS CONTROL INFORMATION WITHIN

AN APPLICATION

YES

RECEIVE ARECRUEST TO VIEW

ADDITIONAL PROCESS CONTROL

INFORMATION?

FIG. 8B

824

826

U.S. Patent

900

May 6, 2014

Sheet 9 of 11

US 8,717,374 B2

Y

/N

902

RECEIVE INFORMATIONASSOCIATED WITH

AFIELD DEVICE

EDD FILE ALREADY EXISTS?

NO

904

YES

CREATE AN EDD FILE BASED ON

INFORMATIONASSOCIATED WITH

THE FIELD DEVICE

RETRIEVE THE EDD FILE FROM THE

EDD LIBRARY

DETERMINE CONDITION(S) BASED ON THE

INFORMATION THAT IDENTIFY WHEN

PROCESS CONTROL INFORMATION FORM

THE FIELD DEVICE IS TO BE DISPLAYED AS

A GRAPHIC

910

ACCESSA DATABASE FORSCRIPT

912

EXTENSION(S) THAT MATCH THE

DETERMINED CONDITIONS

YES

MATCHING SCRIPT EXTENSIONST

914

NO

CREATE SCRIPTEXTENSION(S) BASED ON

916

THE CONDITION

INCLUDE THE SCRIPT EXTENSION(S)

WITHIN THE EDD FILE

FIG. 9A

918

U.S. Patent

900

May 6, 2014

Sheet 10 of 11

US 8,717,374 B2

Y

SCAN THE EDD FILE FOR ERRORS

NO

ERROR(S) DETECTED?

920

922

YES

TRANSMITANERROR MESSAGE

924

RECEIVE INSTRUCTIONS TO CORRECT THE /- 926

ERROR(S)

TRANSLATE THE EDD FILE TO A FORMAT

SPECIFIED BY PROCESS CONTROL

PERSONNEL

928

TOKENIZE THE EDD FILE

930

STORE THE EDD FILE TO THE EDD LIBRARY

YES

ADDITIONAL EDD FILES TO PROCESS

NO

N/

END

FIG. 9B

932

934

U.S. Patent

May 6, 2014

Sheet 11 of 11

US 8,717,374 B2

P12

PROCESSOR

P16

P14

P22

I/O

P18

P26

DEVICE

I/O

CONTROLLER

MEMORY

CONTROLLER

P32

I/O

DEVICE

P20

NETWORK

INTERFACE

P28

SYSTEM

MEMORY

MASS STORAGE

MEMORY

P24

P25

FIG. 10

P30

US 8,717,374 B2

1.

METHODS AND APPARATUS TO DISPLAY

PROCESS CONTROL INFORMATION

FIELD OF THE DISCLOSURE

The present disclosure relates generally to process control

systems and, more particularly, to methods and apparatus to

display process control information.

BACKGROUND

Process control systems, like those used in chemical, petro

leum or other processes, typically include one or more pro

cess controllers and input/output (I/O) devices communica

tively coupled to at least one host or operator workstation and

to one or more field devices via analog, digital or combined

analog/digital buses. The field devices, which may be, for

example, valves, valve positioners, Switches and transmitters

(e.g., temperature, pressure and flow rate sensors), perform

process control functions within the process such as opening

or closing valves and measuring process control parameters.

The controllers receive signals indicative of process measure

ments made by the field devices, process this information to

implement a control routine, and generate control signals that

are sent over the buses or other communication lines to the

10

15

with the field device.

25

field devices to control the operation of the process. In this

manner, the controllers may execute and coordinate control

strategies or routines using the field devices via the buses

and/or other communication links communicatively coupling

the field devices.

30

Information from the field devices and the controllers may

be made available to one or more applications (i.e., routines,

programs, etc.) executed by the operator workstation (e.g., a

processor-based system) to enable an operator to perform

desired functions with respect to the process, such as viewing

the current state of the process (e.g., via a graphical user

interface), evaluating the process, modifying an operation of

the process (e.g., via a visual object diagram), etc. Many

process control systems also include one or more application

stations. Typically, these application stations are imple

mented using a personal computer, workstation, or the like

that is communicatively coupled to the controllers, operator

workstations, and other systems within the process control

system via a local area network (LAN). Each application

station may execute one or more strategies, routines, or appli

cations that perform campaign management functions, main

tenance management functions, virtual control functions,

diagnostic functions, real-time monitoring functions, safety

related functions, configuration functions, etc. within the pro

cess control system.

Electronic device description language (EDDL) files are

commonly used within process control systems to provide a

structured and/or standardized format to describe and specify

BRIEF DESCRIPTION OF THE DRAWINGS

40

45

50

55

FIG. 1 shows a block diagram illustrating an example

process control system including an example display inter

face and an example Script generator.

FIG. 2 shows functional block diagrams of the example

display interface and the script generator of FIG. 1.

FIG. 3 shows a diagram of an example Script extension

architecture within an EDD file that may be processed by the

example display interface of FIG. 1.

FIG. 4 shows a diagram of an example composite structure

of script extensions within an EDD file that may be processed

by the example display interface of FIG. 1.

FIGS. 5-7 show an example user interface displaying

graphics generated by the example display interface of FIGS.

1 and 2 based on conditions within script extensions.

FIGS. 8A, 8B, 9A, and 9B are flowcharts of example

processes that may be used to implement the example display

interface and/or the script generator of FIGS. 1 and/or 2.

FIG. 10 is a block diagram of an example processor system

that may be used to implement the example methods and

apparatus described herein.

DETAILED DESCRIPTION

60

Although the following describes example methods and

apparatus including, among other components, software and/

or firmware executed on hardware, it should be noted that

SUMMARY

Example methods and apparatus to display process control

information are described. In one example, a method includes

receiving a request to view process control information asso

An example apparatus includes an electronic device

description processor to access, via a database, a device

description file associated with a field device, wherein the

device description file is associated with an Electronic Device

Description Language (EDDL). The example apparatus also

includes a graphics processor to generate a display for the

process control information using the device description file

and process control information received from the field

device, wherein the device description file includes a script

extension that instructs the graphics processor to display a

graphic if a portion of the process control information

matches a condition within the script extension.

35

functions of field devices. Process controllers and/or work

stations may use EDDL files to facilitate interpretation, con

trol and/or management of field devices. Additionally, pro

cess controllers and/or workstations may utilize EDDL files

to generate graphical representations of process control infor

mation output from the field devices. In this manner, EDDL

files specify a visualization of process control information

based on parameters associated with field devices.

2

ciated with a field device. The example method also includes

accessing, via a database, a device description file associated

with the field device, wherein the device description file is

formatted to conform to an Electronic Device Description

Language (EDDL). The example method further includes

generating a display for the process control information using

the device description file, wherein the device description file

includes a script extension that conditionally displays a

graphic if a portion of the process control information

matches a condition within the Script extension.

In another example, a method includes receiving informa

tion associated with a field device and determining a condi

tion within the information that identifies when process con

trol information from the field device is to be displayed as a

graphic. Additionally, the example includes creating a script

extension based on the condition to display the graphic when

the process control information from the field device matches

the condition. Further, the example method includes storing

the Script extension to a device description file associated

65

these examples are merely illustrative and should not be con

sidered as limiting. For example, it is contemplated that any

or all of the hardware, Software, and firmware components

could be embodied exclusively in hardware, exclusively in

Software, or in any combination of hardware and Software.

Accordingly, while the following describes example methods

US 8,717,374 B2

3

and apparatus, persons of ordinary skill in the art will readily

appreciate that the examples provided are not the only way to

implement Such methods and apparatus. For example, while

the example methods and apparatus are described in connec

tion with displaying process control information, the example

method and apparatus are more generally applicable and may

be implemented to display information associated with any

automation system, batch processing system, manufacturing

system, industrial control system, safety instrumented sys

tem, etc.

Process control systems generally include controllers to

perform routines, control strategies, and/or algorithms that

manage field devices located in the control system. The field

devices may be, for example, valves, valve positioners,

Switches and transmitters, and may perform process control

functions such as opening or closing valves and measuring

process control parameters. In addition to managing field

devices, controllers may generate process control informa

tion based on data received from the field devices. The pro

cess control information may include process statistics,

alarms, monitoring information, process trend information,

diagnostic information, field device status information, and/

or messages from the field devices.

Controllers transmit process control information to appli

cations operating on workstations so that operators may man

age the process control system. Typically, applications dis

play process control information as at least one graphical data

representation in a user interface. Data representations are

helpful to operators as these data representations typically

display process control information graphically in the form of

charts, graphs, data tables, list boxes, graphical symbols, text,

etc. The data representations and corresponding text within

the user interface are generally displayed in a format and/or

language associated with a locale of an operator viewing the

information.

In many known systems, workstations display process con

trol information from field devices via corresponding elec

tronic device description (EDD) files. In many instances, the

EDD files are transported to a process control environment

along with a corresponding field device. In some examples,

the EDD files may be included within a field device and

uploaded to a process control system upon installing the field

device into the process control system. In these instances, a

controller may store the EDD files. Alternatively, each work

station coupled to the process control system may store a local

copy of the EDD files. In other examples, process control

personnel may store EDD files to a central database and

access the EDD files to display process control information

from a corresponding field device.

Currently, many widely used process control communica

tion protocols support the use of EDD files conforming to an

Electronic Device Description Language (EDDL) standard.

These process control protocols include, for example, Foun

10

devices.

15

cols, and/or reset information. Manufacturers offield devices

form and/or structure for host workstations and/or handheld

25

30

35

40

45

50

55

devices to access and display process control information

independent of a communication protocol and/or a device

operating system (e.g., Windows, Android, Blackberry OS,

iOS, etc.). Through the relatively wide use of the EDDL with

field devices, process control personnel may select best-in

class field devices for use in a process control system regard

less of a protocol and/or type of the process control system.

Field device designers may use an EDD file to define where

parameters associated with a field device are to be displayed

within an application displayed via a user interface. The dis

play information may include a type of graphical representa

tion based on a type of parameterized process control infor

mation. EDD files may also include EDDL Methods, which is

a scripting language based on a Subset of American National

Standards Institute (ANSI) C programming language that is

used to Support step-by-step field device setup, interactive

field device setup, and/or calibration procedures. Using EDD

files, field device manufacturers can enable process control

personnel to access field devices within the full scope of the

field device functionality, where all menus and parameters

appear as intended by the manufacturer.

To define an EDD file, field device manufacturers may

specify specific locations within an application where graphi

cal representations of process control information from a field

device are to be displayed. Further, process control personnel

may edit an EDD file to reflect their preferences and/or to

reflect conditions within a process control system. However,

many known EDD files are static in regards to the definition

and display of graphics (e.g., graphic representations of pro

cess control information). In other words, the graphics are

displayed within an application regardless of the process

control information because EDD files may not support con

ditionally displaying graphics based on the process control

information.

60

trol information associated with a field device. In this manner,

EDDL may be used by process control personnel to integrate

field devices with process control systems, thereby creating

an interoperable environment where process control informa

tion from field devices may be accessed by workstations (e.g.,

processors, servers, computers, etc.) and/or handheld devices

The EDDL is a text-based language that may be used to

describe characteristics, parameters, and/or functions of field

devices. This functionality may include, for example, menu

system descriptions, general device information, diagnostics,

performance analysis information, operational statistics,

parameterization information, range setup information,

simulation parameters, override information, calibration trim

information, monitoring information, device security proto

use the EDDL to create EDD files that provide a standardized

dation Fieldbus, Hart Communication Foundation, and Profi

bus. Further, the Field Device Integration (FDI) standard may

support the use of the EDDL to create a common toolset used

by process control personnel to manage field devices com

municatively coupled together within control systems.

The EDDL provides a universal method of creating EDD

files to access diagnostic information, status information,

asset management information, and/or any other process con

4

(e.g., field communicators, cell phones, Smartphones, lap

tops, netpads, etc.). The workstations and/or the handheld

devices may use the process control information in combina

tion with EDDL formatted EDD files to configure field

devices, calibrate field devices, diagnose issues associated

with the field devices, and/or provide data, status information,

and/or alarms for user interface displays. In this manner, the

EDD files enable applications operating on workstations and/

or handheld devices to display graphical representations of

process control information generated by corresponding field

65

Further, many graphics are relatively static by not enabling

a user to change graphic properties (e.g., size, text, color,

transparency, placement within a user interface, etc.) and/or

features associated with graphics while viewing process con

trol information. For example, an EDD file may specify that a

bar chart showing a pump speed is to be displayed in a center

of a user interface and the bar chart is to have a height of 3

inches. Currently, a user viewing this bar chart may be

restricted by EDD files from moving the bar chart to another

location within the user interface, changing the height of the

bar chart, changing a color within the bar chart, etc.

US 8,717,374 B2

5

The example methods and apparatus described herein

implement Script extensions that may be implemented within

EDD files to conditionally display graphics based on process

control information generated by field devices. The example

Script extensions may also be embedded or implanted within

EDD files to enable users to modify displayed graphics by

defining graphical properties and/or parameters that may be

changed based on information (e.g., mouse clicks on a

graphic) provided by a user.

Script extensions are instructions within an EDD file that

generate a graphic to display in a user interface based on

process control information from a field device matching

and/or satisfying one or more conditions. For example, the

example methods and apparatus described herein may utilize

expressions on attributes and/or properties associated with

one or more field devices as a script extension to display a

graphic. The methods and apparatus described herein may

also utilize event handlers as Script extensions to display a

graphic when a predefined event occurs within a field device.

Further, the example methods and apparatus described herein

may be implemented within an EDD file as a method and/or

function Script extension to display a value, update parameter

reference(s), and/or store calculated values information based

on portions of process control information from a field device

matching a predefined condition.

Additionally, the example methods and apparatus

described herein may utilize one or more converter script

extensions to convert process control information into a

graphic if a portion of the process control information gener

ated by a field device matches a predefined condition. A script

extension may also include a trigger script extension that

displays a graphic when periodically changing process con

trol information matches a condition (e.g., a threshold). In

Some examples, the script extensions may be defined within a

composite structure of an EDD file and interact with other

instructions and/or functions to display process control infor

6

within the EDD file and Store the EDD file to a database

10

include the calculations and/or functions within the field

15

USC.

The example methods and apparatus described herein may

use conditions to generate script extensions within EDD files.

For example, Some conditions may be implemented by trig

ger Script extensions, while other conditions may be

implanted by converter and/or event handler script exten

sions. In other examples, conditions may be implemented by

function and/or expression script extensions. In yet other

examples, conditions may be implemented within script

extensions using a combination of the different types of script

extensions and/or other types of Script extensions. Upongen

erating Script extensions, the example methods and apparatus

described herein imbed and/or include the script extension

devices. Because workstations and/or handheld devices typi

cally have more processing power than field devices, device

manufacturers may implement, via the Script extensions

within EDD files, relatively more complex graphics and/or

functions. Further, the example script extensions enable field

device manufacturers to provide differentiation in their

devices in regards to the graphical representations of the

process control information utilized as tools to Support and

maintain the field devices.

25

30

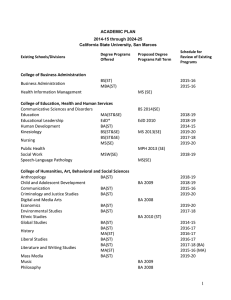

FIG. 1 shows a block diagram of an example process con

trol environment 100 including an example display interface

102. The example display interface 102 renders graphics for

display using script extensions included within EDD files.

The display interface 102 is associated with a process control

system 104. Additionally, the display interface 102 may be

implemented by and/or included within a workstation 106. In

other examples, the display interface 102 may be included

within a server, a processor, a distributed computing network,

and/or any other computing device(s) that may be communi

catively coupled to the workstation 106.

The illustrated example also includes a server 107 hosting

a script generator 108. The script generator 108 creates script

extensions within EDD files based on conditions associated

35

mation.

To create the example script extensions, the example meth

ods and apparatus described herein determine conditions

within process control information that identify when graph

ics are to be displayed. In some examples, process control

designers may define conditions based on preferences for

displaying graphics. Conditions may include, for example,

thresholds for displaying an indicator graphic to warn a user

that some process control information from, or parameter

values associated with, a field device is approaching and/or

has exceeded a limit. Conditions may also include, for

example, events specified within process control information

that indicate a graphic is to be displayed to represent the

event. In another example, conditions may include lists of

conversions to change a portion of process control informa

tion into a corresponding graphic. Additionally, conditions

may specify when certain parameters may be modified by a

accessible by workstations and/or handheld devices.

By utilizing the example script extensions within EDD

files, the example methods and apparatus described herein

enable process control personnel and/or field device manu

facturers to design applications that display process control

information in a more comprehensive and/or complete man

ner. In other words, the example Script extensions enable

device manufacturers to provide calculations and/or func

tions to be executed on a workstation rather than attempting to

40

45

50

55

60

with the process control system 104. While the script genera

tor 108 is shown within the server 107, in other examples, the

script generator 108 may be included within the workstation

106 and operate in parallel with the display interface 102.

The example workstation 106 and/or the example server

107 of FIG. 1 may include any computing device such as a

personal computer, a laptop, a server, a controller, a personal

digital assistant (PDA), a micro computer, etc. The example

workstation 106 may also include any mobile computing

device such as, for example, a cell phone, a Smartphone, a

PDA, a netpad, a field communication, etc. The workstation

106 and/or the server 107 may be implemented using any

Suitable computer system or processing system (e.g., the pro

cessor system P10 of FIG. 10). For example, the workstation

106 could be implemented using a single processor personal

computer, single or multi-processor workstations, etc.

The example process control system 104 may include any

type of manufacturing facility, process facility, automation

facility, safety instrumented facility, and/or any other type of

process control structure or system. In some examples, the

process control system 104 may include multiple facilities

located at different locations. Additionally, the example pro

cess control environment 100 may include other process con

trol systems (not shown) that may be included within the

same facility and/or located at a different facility.

The example process control system 104 includes a con

troller109 that may be communicatively coupled to the work

station 106 and/or the server 107 via a local area network

65

(LAN) 110. The LAN 110 may be implemented using any

communication medium and/or protocol. For example, the

LAN 110 may be based on a hardwired or wireless Ethernet

communication scheme. However, any other Suitable com

munication medium and protocol could be used. Further

US 8,717,374 B2

7

more, although the LAN 110 is shown, more than one LAN

and/or wireless network and appropriate communication

hardware may be used to provide redundant communication

paths.

The process control environment 100 may include a fire

wall (not shown) to provide remote workstations (e.g., work

stations outside of the process control environment 100)

access to EDD files and/or process control information within

the process control environment 100. The process control

environment 100 may also include one or more routers (not

shown) to communicatively couple workstations (not shown)

to the LAN 110. The routers may also communicatively

couple multiple process control systems.

The process control system 104 also includes field devices

112 (e.g., input and/or output devices). The field devices 112

may include any type(s) of process control component(s)

capable of receiving inputs, generating outputs, and/or con

trolling a process. The field devices 112 may include control

devices Such as, for example, valves, pumps, fans, heaters,

coolers, and/or mixers to control a process. Additionally, the

field devices 112 may include measurement or monitoring

devices such as, for example, temperature sensors, pressure

gauges, concentration gauges, fluid level meters, flow meters,

and/or vapor sensors to measure portions of a process. The

10

trol values, data values, alarm information, text, status infor

15

25

via inputs 114 to execute a specified command and cause a

change to the process implemented and/or controlled by the

field devices 112. Furthermore, the field devices 112 measure

30

35

workstation 106. The EDD files describe characteristics,

functions, parameters, and/or features of the field devices

112. The EDD files are stored to an EDD library 120. The

EDD library 120 may be implemented by Electronically

Erasable Programmable Read-Only Memory (EEPROM),

Random Access Memory (RAM), Read-Only Memory

(ROM), and/or any other type of memory. The EDD files may

be stored to the EDD library via the controller 109 and/or by

process control personnel via the server 107. The workstation

106 can access the EDD library 120 for EDD files to deter

mine how to display process control information associated

with the field devices 112. Process control designers and/or

engineers may use the workstation 106 and/or the Script gen

erator 108 to modify the EDD files based on display prefer

ences and/or setup configurations of the process control sys

40

45

50

55

user interface 132 may include a graphical window (e.g., an

application programming interface (API)) that may be dis

played within the workstation 106 to show process control

information displayed as graphical representation(s) (e.g.,

functional block diagrams and/or schematics). The worksta

tion 106 may be capable of displaying more than one user

interface 132 that may be communicatively coupled to the

display interface 102.

In the example of FIG. 1, the script generator 108 identifies

conditions within process control information from the field

devices 112 and/or identifies conditions within EDD files

60

devices 112 and convert the data into communications

capable of being processed by the example controller 109.

Likewise, the I/O device 122 may convert data or communi

cations from the controller 109 into a data format capable of

being processed by the corresponding field devices 112.

In some examples, the controller 109 may also transmit

process control information from the field devices 112 to a

database 124. The database 124 may be implemented by

Electronically Erasable Programmable Read-Only Memory

(EEPROM), Random Access Memory (RAM), Read-Only

Memory (ROM), and/or any other type of memory. The pro

cess control information may be stored and/or organized

based on an associated field device. For example, output

values (e.g., process control information) associated with a

PS101 pump speed parameter of a pump with a PUMP01

identifier may be stored within the database 124 indexed by

the PUMP01 identifier and the PS101 parameters. A EDD file

that references the PS101 parameter may access the database

124 to search for process control information stored in asso

ciation with the PS101 parameter.

The example workstation 106 may access the example

database 124 to display stored process control information.

Other workstations and/or handheld devices (not shown) may

also access the database 124 for process control information.

In this manner, any computing device with access to the

process control environment 100 may access the database 124

to graphically display process control information.

The example workstation 106 and/or other workstations

with access to the process control system 104 may be config

ured to view, modify, and/or correct one or more processes

within the process control system 104 via one or more appli

cations. In the illustrated example, an application 130 is dis

played via a user interface 132. Applications may include an

enterprise view application, a graphics studio application, an

explorer application, and/or any other type of process control

based application. These applications 130 display informa

tion within the workstation 106 via the user interface 132. The

tem 104 and/or the field devices 112.

While the EDD library 120 is shown as being separate from

the controller 109, in some process control environments the

library 120 may be included within the controller 109, the

workstation 106, and/or the server 107. In these examples, the

controller 109 may locally access EDD files to operate a

control routine and/or algorithm. Alternatively, the worksta

tion 106 and/or the server 107 may locally access EDD files to

display corresponding process control information.

The process control system 104 also includes an I/O device

122 (e.g., one or more I/O cards) to receive data from the field

mation, diagnostic information, error messages, parameters,

events, and/or device identifiers.

field devices 112 receive instructions from the controller 109

process data, environmental data, and/or input device data

and transmit the measured data via outputs 116 to the con

troller 109 as process control information. This process con

trol information may include the values of variables corre

sponding to measured outputs from the field devices 112.

The field devices 112 may also include EDD files that are

accessible by the controller 109, the server 107, and/or the

8

The example controller 109 of FIG. 1 operates one or more

control routines (e.g., process control algorithms, functions,

and/or instructions) to manage the field devices 112 within

the process control system 104. The control routines may

include process monitoring applications, alarm management

applications, process trending and/or history applications,

diagnostic applications, batch processing and/or campaign

management applications, statistical applications, streaming

Video applications, advanced control applications, safety

instrumented applications, etc. The example controller 109

transmits process control information (e.g., resources) to the

workstation 106. The process control information transmitted

by the controller 109 may include, for example, process con

65

associated with the field devices 112. The script generator 108

accesses the EDD files from the EDD library 120. The

example Script generator 108 creates a script extension based

on the conditions and inserts and/or includes the Script exten

sion within the appropriate EDD file. The script generator 108

may then store the modified EDD file to the EDD library 120.

The script generator 108 is described in further detail in

conjunction with FIG. 2.

US 8,717,374 B2

The example display interface 102 of FIG. 2 generates

graphical representations of process control information from

the field devices 112 based on EDD files stored within the

EDD library 120. The display interface 102 transmits the

graphical representations to the application 130 for display

via the user interface 132. In this manner, a user of the work

station 106 may view process control information associated

with the field devices 112. To display process control infor

mation, the example display interface 102 may receive a

request from a user of the workstation 106 to view informa

tion associated with the field devices 112 and/or a specific

field device within the process control system 104. In other

examples, the display interface 102 may receive process con

trol information from the controller 109 and identify which of

the field devices 112 correspond to the information.

The example display interface 102 then accesses the EDD

library 120 for EDD files associated with the requested field

devices 112. The display interface 102 reads the EDD files for

instructions regarding how process control information is to

be displayed. In some instances, the EDD files may include

instructions for displaying menu(s) as part of the application

130. The EDD files may provide descriptions of functionality

for each item within the menu(s). The EDD files may also

include instructions defining how graphic(s) are to be dis

played within the application 130. For example, an EDD file

may include instructions defining dimensions, layout, for

matting, data fields, and/or placement of a table. In another

example, an EDD file may include instructions defining

dimensions, layout, formatting, placement, data fields, and/or

placement of a graph and/or chart. In yet other example, an

EDD file may link and/or reference a graphic to be displayed

within the application 130.

To display a graphic within the application 130 and/or any

other application, the example display interface 102 of FIG. 1

uses instructions within the EDD file to construct, format,

and/or position the graphic. In some examples, the EDD file

may include an instruction that specifies a certain graphic is to

be displayed. The EDD file may include a reference and/or a

link to a database of graphics that the display interface 102

accesses to locate the referenced graphic. In this manner, the

display interface 102 may display pre-made graphics (e.g.,

clip art, pictures, animations, etc.) that are referenced within

the EDD file. Thus, a graphic in a database may be concur

rently displayed by workstations within the process control

environment 100. The example display interface 102 may

also render the referenced graphic with corresponding pro

cess control information for display within the application

10

15

the measured values.

25

30

35

40

45

50

information stored within the database 124 and/or the con

troller 109. For example, an EDD file describing a table

graphic may include references for each of the table cells to a

parameter (e.g., process control information). The reference

may include a directory location within a memory, a location

55

within a hierarchical data scheme, an Internet address of a

server hosting process control information (e.g., a server

associated with the OPC), and/or a location within the con

troller 109 specified by parameters that correspond to the

process control information. The display interface 102 uses

the links and/or references to insert and/or combine the pro

cess control information with graphics. The display interface

102 may then render the graphics with the process control

information using instructions within EDD files to display the

process control information graphically within the applica

tion 130 via the user interface 132.

By including script extensions within EDD files, the

example display interface 102 enables field device designers

to specify relatively complex graphics to display within the

application 130 that would otherwise be impossible and/or

difficult to define within instructions stored within the field

130.

The example display interface 102 of FIG. 1 combines

graphics with process control information by using refer

ences and/or links within the EDD files to process control

10

In addition to implementing statically defined graphics, the

example display interface 102 may read and/or execute

instructions within the EDD files that include script exten

sions. By executing the script extensions, the display inter

face 102 executes conditional instructions for displaying pro

cess control information. In many instances, the workstation

106 and/or any other processor that may include the display

interface 102 typically has more computing powerfor execut

ing relatively complex instructions. Thus, an expression,

event handler, function, method, converter and/or trigger that

may consume a relatively large amount of processing band

width may be expressed within EDD files executed by, for

example, the workstation 106, thereby reducing processing

requirements of the field devices 112. For example, the dis

play interface 102 may execute relatively complex computa

tions, expressions, functions, and/or methods in script exten

sions (e.g., triple integral functions, a Bayesian statistical

analysis, Analysis of Variance statistical models, etc.). By

offloading processing to the workstation 106, device manu

facturers can focus the processing power of the field devices

112 for measuring environmental and/or process control con

ditions within the process control system 104 and reporting

60

65

devices 112. For example, the display interface 102 may

execute event handlers and/or converters that specify display

ing one or more graphics only if process control information

from the field devices 112 matches one or more specified

conditions. In other examples, the display interface 102 uses

event handler script extensions to enable users of the work

station 106 to specify and/or modify how certain graphics are

displayed. In yet other examples, the display interface 102

may use method script extensions to write process control

information to database(s) and/or memory(s) within the pro

cess control environment 100 if a portion of the process

control information matches one or more conditions. In fur

ther examples, the display interface 102 may use trigger Script

extensions to execute a set of instructions if a portion of the

process control information changes incrementally (e.g., a

timer) to match one or more conditions.

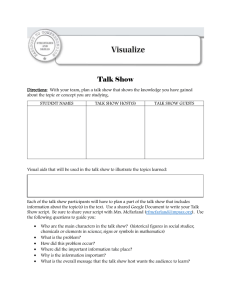

FIG. 2 shows functional block diagrams of the example

display interface 102 and the script generator 108 of FIG. 1.

While the EDD library 120 and the database 124 are shown

external to the display interface 102 and the script generator

108, in some examples, the library 120 and/or the database

132 may be included within the display interface 102 and/or

the script generator 108. In other examples, the display inter

face 102 and/or the script generator 108 may include local

copies of the library 120 and/or the database 132.

The example script generator 108 creates EDD files includ

ing Script extensions. The example script generator 108 may

generate multiple EDD files concurrently or, alternatively,

process EDD files in series. To create, modify, view and/or

edit EDD files stored within the EDD library, the example

script generator 108 includes an editor 202. The example

editor 202 may function as an interface to enable a field device

developer and/or process control personnel to check for Syn

tax and/or logical errors within the EDD files. In examples

where the EDD files are in an Extensible Stylesheet Language

Transformation (XSLT) format and/or an Extensible Markup

Language (XML) format, the editor 202 may be implemented

using XMLSpy(R) from Altova R. In these other examples, the

editor 202 may convert the EDD files from an XML and/or

US 8,717,374 B2

11

XSLT format into a HyperTextMarkup Language (HTML)

file. The display interface 102 may then access HTML for

matted EDD files in examples where the workstation 106 is

communicatively coupled to the EDD library 120 via the

Internet.

To create EDD files, the example editor 202 may access the

EDD library 120 and/or the database 124 for information

describing functionality of the field devices 112. In other

examples, a user may utilize the editor 202 to create an EDD

file based on specifications associated with the field devices

112. For example, the editor 202 may invoke a text editing

application that a device designer may use to create an EDD

file. In other examples, the editor 202 may be a routine and/or

algorithm that generates EDD files based on the inputs 114,

the outputs 116, process control information stored within the

database 124, and/or any additional information associated

with the field devices 112. For example, the editor 202 may

identify types of outputs from a field device and create an

EDD file to display outputted process control information

based on the output type. In some examples, the editor 202

may be used to create an EDD file that describes features

and/or functionality of one of the field devices 112. In other

examples, the editor 202 may create an EDD file that

describes features and/or functionality of the field devices

112 collectively and/or the process control system 104.

The example editor 202 of the illustrated example creates

script extensions within EDD files. A script extension data

base 204 stores a library of predefined script extensions. The

script extension database 204 may be implemented by Elec

tronically Erasable Programmable Read-Only Memory (EE

PROM), Random Access Memory (RAM), Read-Only

Memory (ROM), and/or any other type of memory. In some

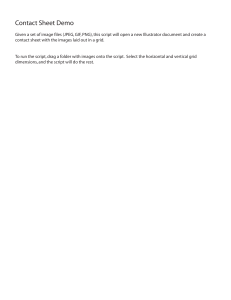

examples, the Script extension database 204 may store script

extensions within a script architecture (e.g., the script exten

sionarchitecture shown FIG. 3) and/or a composite structure

(e.g., the composite structure shown in FIG. 4) that specify

how Script extensions are utilized based on global sets of

10

15

25

30

35

information associated with the field devices 112. In other

examples, the Script extensions may be stored as a list that the

editor 202 uses to select a script extension that matches one or

more conditions within process control information. In the

illustrated example, the script extension database 204

includes examples of Script extensions including, for

example, expressions, event handlers, functions, methods,

converters, and/or triggers.

To create script extensions within an EDD file, the example

editor 202 identifies conditions within process control infor

40

45

mation stored within the database 124 and/or features and/or

functions associated with the field devices 112. The example

editor 202 identifies a condition based on instances that indi

cate a graphic is to be displayed and/or a set of instructions is

to be executed in response to some portion of process control

information matching a threshold and/or a predefined event.

The editor 202 may also examine syntax of the EDD files to

identify conditions. For example, the editor 202 may identify

conditions based on lexemes that indicate, for example,

strings of letters, strings of numbers, punctuation marks,

mathematical operators, etc.

Upon determining a condition, the example editor 202 of

FIG.2 accesses the script extension database 204 to match the

condition to a script extension. The editor 202 may match a

condition to a script extension by determining a script exten

50

55

60

sion architecture and/or structure that resembles and/or

includes the condition. In other examples, a user of the editor

202 may select a script extension based on an understanding

of the condition. The example editor 202 then copies the

selected Script extension and inserts and/or includes the script

12

extension within the EDD file(s). In this manner, the editor

202 links a portion of an EDD file to an inserted script exten

Sion. For example, the editor 202 may use names of param

eters, properties, and/or attributes of process control informa

tion within a mathematical expression Script extension of an

EDD file to calculate a value to be displayed as a graphic.

Upon creating script extension(s) within EDD file(s), the

example editor 202 transmits the EDD file(s) to a compiler

206. The example compiler 206 of FIG. 2 processes, com

piles, checks, and/or translates the EDD file(s) with the script

extension(s) for storage within the EDD library 120 and/or for

use by the example display interface 102. The example com

piler 206 includes a scanner 208 that uses any number and/or

type(s) of algorithm(s), logic and/or methods to scan and/or

parse EDD files to identify syntax errors, protocol errors,

and/or lexemes. The scanner 208 provides the lexemes to a

tokenizer 210 to convert EDD file(s) to a compressed binary

format. Any errors detected by the scanner 208 may be com

municated to a field device designer via the editor 202. Based

on a type of error detected by the scanner 208, the example

editor 202 provides tools for a field device designer to test

and/or debug the detected errors. The editor 202 enables the

field device designer and/or other process control personnel

to edit EDD file(s) to correct any detected errors. In this

manner, the example scanner 208 enables a field device

designer to test and/or simulate a user interaction with EDD

file(s), which may result in improved quality of the EDD

file(s).

Using any number and/or type(s) of algorithm(s), logic

and/or method(s), the example tokenizer 210 of FIG. 2 pro

cesses the lexemes identified by the scanner 208 to identify

particular tokens (e.g., classifiable strings of input charac

ters). For example, the scanner 208 may identify a string-of

letters lexeme representing, for example, a sentence, which

the example tokenizer 210 demarcates and/or separates into

one or more compressed binary words. Each token identified

by the tokenizer 210 has both a value (e.g., the actual name of

a variable) and a type (e.g., a variable, an operator, a number,

etc.), thereby enabling the tokenizer 210 to compress EDD

file(s) into a binary format. The compressed format may

prevent tampering and/or Subsequent processing issues by

process control personnel. Because the tokenized EDD files

are relatively small, tokenized files for many field devices can

be stored in a limited flash memory of a handheld device

and/or the workstation 106.

The example script generator 108 of FIG. 2 also includes

an interpreter 212 to translate EDD file(s) into a vendor and/or

system specific form. While many EDD files that support the

EDDL standard are utilized by process control systems, the

interpreter 212 may be used to translate some EDD files to a

proprietary process control standard and/or any other stan

dard requested by a process control manager. The script gen

erator 108 may utilize the interpreter 212 to convert an EDD

file to a format compatible with the process control system

104 and/or applications within the workstation 106. For

example, the interpreter 212 may convert some EDD files to

an HTML format that may be accessed by a web browser. In

some examples, the interpreter 212 may translate an EDD file

prior to the tokenizer 210 compressing the EDD file. In other

examples, the interpreter 212 may translate compressed

binary EDD files. The example interpreter 212 may use any

number and/or type(s) of algorithm(s), logic and/or

method(s) to translate EDD files into a corresponding speci

fied format.

65

Upon Scanning, tokenizing, and/or translating EDD files,

the example compiler 206 of the illustrated example stores the

EDD file(s) to the EDD library 120. In some examples, the

US 8,717,374 B2

13

compiler 206 may store multiple translated versions of the

same EDD file, thereby enabling different applications asso

ciated with different formats and/or operating systems to

access a compatible EDD file to display process control infor

mation. In other examples, the compiler 206 may store a

compressed binary version and an uncompressed version of

an EDD file, thereby enabling a user to select an EDD file

based on memory constraints of a device.

The example of FIG. 2 also shows the example display

interface 102, which accesses the EDD library 120 for EDD

files to display process control information. In some

examples, the display interface 102 may periodically access

the EDD library 120 to store EDD files locally to a handheld

device and/or the workstation 106. In this manner, a user may

view graphics of process control information without having

a device communicatively coupled to the LAN 110. In other

examples, the display interface 102 accesses the EDD library

120 for EDD files any time a request to view process control

10

15

information is received.

The example display interface 102 may concurrently pro

cess multiple requests to view process control information

from workstations (e.g., the workstation 106). Alternatively,

the example display interface 102 may process a single

request to view process control information. In these alterna

tive examples, multiple display interfaces 102 may be

accessed to process multiple requests. While the example

display interface 102 is described in connection with the

workstation 106, the display interface 102 may operate with

25

other workstations and/or devices that are associated with the

process control environment 100 of FIG. 1.

To receive a request to view process control information

graphically, the example display interface 102 includes a

receiver 220. The example receiver 220 is communicatively

coupled to the user interface 132 within the workstation 106.

The receiver 220 receives requests from a user to view process

control information.

30

35

control information via the workstation 106 and/or the user

interface 132. A user selects to view process control informa

tion by entering an identifier associated with the desired infor

mation into a request and/or search field. For example, a user

may enter an identifier of a field device. In another example,

a user may enter an area and/or a collection of field devices

within the process control system 104. In yet another

example, a user may specify an identifier (e.g., a variable

name) of a parameter to view process control information

associated with the parameter.

A user may also specify process control information by

browsing to a desired object (e.g., a listing of a field device,

component, area, etc.) within a data directory. For example, a

user may utilize an open function and navigate a directory to

a desired field device. In yet other examples, a user may view

process control information by selecting a graphical repre

40

requests.

Upon receiving a request to view process control informa

tion, the example receiver 220 transmits the request to an

EDD processor 222. The example EDD processor 222 parses

the request into information to identify EDD files. The EDD

processor 222 uses the information to access the EDD library

120 to search for EDD files that match the requested process

control information. For example, a request for process con

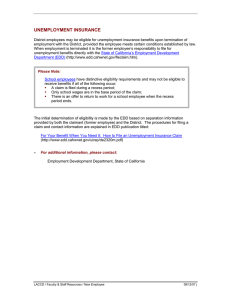

The example graphics processor 224 generates graphics to

display via the user interface 132 by executing instructions

within the EDD file(s). The graphics processor 224 may

execute instructions to determine any menu, display, and/or

format information. The information may be used by the

graphics processor 224 to create a display file and/or to format

a template to display process control information. The menu

information may also include menu functions and/or options

that are available to be displayed with the user interface 132.

The menu functions may include, for example, options for

configuring a field device, viewing process control informa

tion generated by a field device, and/or any other information

associated with the a field device.

45

50

sentation and/or an identifier associated with the information

via the user interface 132. Alternatively, a user may enter a

website address that includes and/or lists process control

information. A user may then select a desired process control

object listed within the displayed webpage. In some

examples, a user may select multiple process control objects.

In these examples, the process control objects may be

included within a single request or, alternatively, multiple

14

trol information may include a Rosemount(R) field device

pressure sensor type and a PRS02 identifier of the pressure

sensor. The EDD processor 222 searches for EDD files that

define functionality for a Rosemount(R) field device pressure

sensor. The EDD processor 222 also searches EDD files that

include definitions specifically for the PRS02 device. In some

instances, a title and/or a file name of the EDD file may

include the type and/or the identifier. In other instances, meta

data associated with the EDD file may include the type and/or

the identifier. In yet other instances, the EDD processor 222

may have to search text within the EDD files for a matching

type and/or identifier.

After locating EDD file(s) that match requested process

control information, the EDD processor 222 forwards the

EDD file(s) to a graphics processor 224. The example graph

ics processor 224 generates a display for the requested pro

cess control information using the EDD file(s). The example

graphics processor 224 also accesses the database 124 for the

requested process control information. In some examples, the

graphics processor 224 may use links and/or references

within the EDD file(s) to locate corresponding process con

trol information within the database 124. Additionally or

alternatively, the graphics processor 224 may use identifiers

and/or other information included within a request from a

user to locate corresponding process control information

within the database 124. In these other examples, the graphics

processor 224 matches the located process control informa

tion to portions of the EDD file(s) that utilize the process

55

The example graphics processor 224 also reads EDD file(s)

for references to process control information processed by the

controller 109 of FIG. 1. In some examples, portions of an

EDD file may include a link, a file directory, and/or an iden

tifier that corresponds to process control information. For

example, the EDD file may include a pump speed data field.

The EDD file may also include a link to a pump speed param

eter and/or variable calculated by the controller 109. The

example graphics processor 224 uses the link to request the

pump speed value from the database 124 or alternatively, the

controller 109. The graphics processor 224 may then insert

the pump speed value into a corresponding EDD file togen

erate agraphical representation of the pump speed value (e.g.,

process control information). The graphical representation

may include, for example, a gauge displaying the pump

speed. In other examples, the graphics processor 224 may use

links, references, data locations and/or identifiers within an

60

EDD file to access corresponding process control information

from the database 124.

65

The example graphics processor 224 uses EDD file(s) to

generate a display file. The display file specifies, for example,

locations of process control information, graphical represen

tations of requested process information, and/or data fields.

To display the process control information as one or more

graphics, the graphics processor 224 uses formatting and/or

US 8,717,374 B2

15

graphic instructions within EDD file(s) to generate a display

file. Some EDD file(s) may define attributes of, for example,

a chart, graph, and/or a table that the graphic processor 224

reads to generate the described graphic. The graphics proces

sor 224 then inserts, embeds, and/or otherwise includes cor

responding process control information into properties and/

or attributes of the graphic as a display file. A renderer 228

executes the display file to generate the described graphic

with the corresponding process control information.

In some examples, EDD file(s) may reference a predefined

graphic that is stored in a graphics database 226. In these

examples, the graphics processor 224 uses a link, reference,

and/or identifier to locate a corresponding graphic within the

graphics database 226. The graphics processor 224 then

makes a copy of the graphic and includes the graphic within

the display file to be rendered by the render 228. In other

examples, the graphics processor 224 may link the graphic to

the display file and insert and/or embed process control infor

mation into attributes and/or properties associated with the

graphic So that the renderer 228 may display the graphic with

the process control information via the user interface 132.

The example graphics processor 224 also executes Script

extensions within the EDD file(s). The script extensions

instruct the graphics processor 224 to display a graphic if a

portion of the process control information matches a condi

tion within the script extension. If the condition matches the

process control information, the graphics processor 224 may

access the graphics database 226 for a corresponding graphic.

For example, an EDD file may include a function script exten

sion that specifies that an alert graphic is to be displayed if an

output indicates a pump speed exceeds 90% of the maximum

pump speed. If a user requests to view process control infor

mation associated with the pump, the graphics processor 224

executes an EDD file associated with the pump to determine

which process control information to access from the data

base 124. The graphics processor 224 then uses the pump

speed process control information to execute a function script

extension (e.g., compare the pump speed to the maximum

value of 90%). If the graphics processor 224 determines the

pump speed matches the condition by exceeding 90%, the

graphics processor 224 uses a reference within the function

Script extension to a graphic within the graphic database 226

that is to be displayed. The graphics processor 224 accesses

the graphic from the database 124 to include the graphic

within a display file.

The example graphics processor 224 of FIG.2 may execute

an event handler within a script extension to display a graphic

when a process control event specified within process control

information matches a condition. Additionally, the graphics

processor 224 may execute a function within a script exten

sion to write a value to a data source when the process control

information matches a condition. The graphics processor 224

may also display the written value within a graphic. In this

example, the graphics processor 224 may write a value cal

culated via the EDD file to the database 124. In other

examples, the graphics processor 224 may write the value to

a memory within the workstation 106. Further, the graphics

processor 224 may execute a converter within a script exten

sion to display a graphic by changing a portion of process

control information into a graphic if the portion of the process

control information matches a condition. Also, the graphics

processor 224 may execute a trigger within a script extension

to display a graphic when a portion of process control infor

mation incrementally changes to reach a condition.

After the graphics processor 224 has created a display file

by executing EDD file(s) including Script extensions, the

graphics processor 224 transmits the display file to the ren

10

15

25

30

35

40

45

50

55

16

derer 228. While the example renderer 228 is shown within

the display interface 102 of FIG. 2, in other examples where

the display interface 102 may be separate from a device to

display process control information, the renderer 228 may be

located within the device. In these examples, the graphics

processor 224 transmits the display file (e.g., via the Internet

and/or the LAN 110) to the renderer 228.

The example renderer 228 processes (e.g., renders) the

display file into a format that is viewable by a user via, for

example, the user interface 132. The example renderer 228

may generate a display based on a display size of a device

(e.g., the workstation 106) that will display graphic(s) of the

process control information. After rendering the display file,

the example renderer 228 transmits the rendered display to

the application 130 within the workstation 106 to display