Metal Cutting Simulation by Finite Element Method Thesis

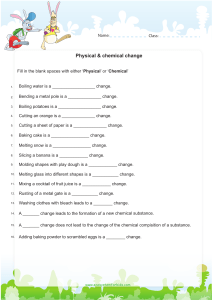

advertisement