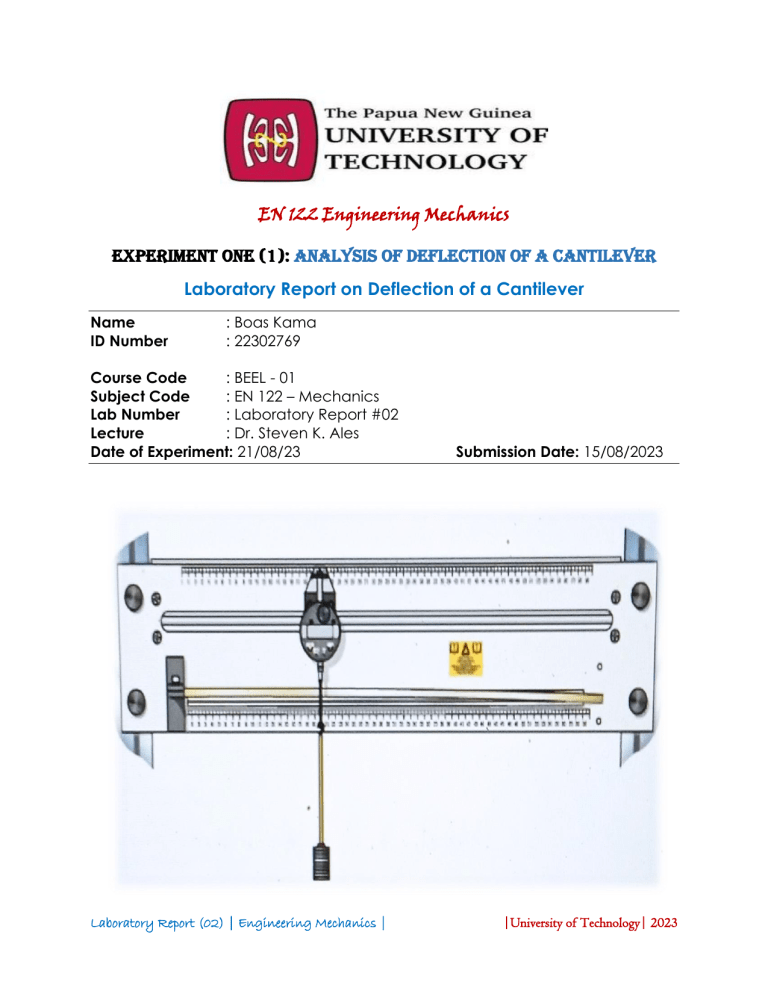

EN 122 Engineering Mechanics Experiment One (1): Analysis of Deflection of a cantilever Laboratory Report on Deflection of a Cantilever Name ID Number : Boas Kama : 22302769 Course Code : BEEL - 01 Subject Code : EN 122 – Mechanics Lab Number : Laboratory Report #02 Lecture : Dr. Steven K. Ales Date of Experiment: 21/08/23 Laboratory Report (02) | Engineering Mechanics | Submission Date: 15/08/2023 |University of Technology| 2023 Laboratory Report Experiment 1: ANALYSIS OF DEFLECTION OF CANTILEVERS Abstract Deflection in a cantilever is the deviation of the free end of the beam from its original position. The deflection can be measured by comparing the free end with the tangent line thought the fixed end of the beam. The deflection depends on the load, the length, the cross-section, and the materials of the beam. The maximum deflection occurs when the load is located at the free end of the beam. Introduction In this modern civilized world, the engineers are the back bone of the development with the aid of technologies. Engineering’s varies under different categories brings to life the processed materials by way of designing and building designed plans by in collaborating them together to achieved an optimal output as lively essence of infrastructure demanded by societies. On that juncture, the infrastructures development project is economical so structural engineers need to know the pros and cons of it. The Deflection of cantilevers is a vital standard procedure where it helps engineers who deals and engineered structures must follow and equipped with. As structures are design and build to withstand loads and pressures exerted on it, it needs proper approached with skilled personal to deals with. Therefore, the lab set up of Deflection of beams and cantilever equipment is a standard for engineers to run lab tests. It is a rigid structural element that is supported at one end and free at another end. A cantilever beam bend downwards when it is subject to vertical loads. It can be subjected to point load, uniform load, or varying load. Irrespective of types of load it bends downwards. This bending creates tension in the upper fiber and compression in the lower fibers. In this experimental set up, the three different types of beam used are Brass, Steel and Aluminum. When load exerted to the free end of the cantilever frame set up, the beam undergoes deformation due to the bending movements along its length This deflection is a critical consideration in structural engineering. Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Objectives Certainly, here are the main objectives of the Deflection of Cantilever. The primary objective of deflection of cantilevers is to calculate the internal forces (tension and compression) that develop in the beam when loaded by careful analysis of beams used in structures. This helps engineers understand how the beams bear the load and assists in selecting appropriate materials with its required loads. Overall, the objectives of deflection of cantilevers typically revolve around understanding how forces or applied pressures are transmitted through beams, ensuring structural integrity using this foundational knowledge to create safe and efficient engineering designs by understanding beams behaviors and to verifies the theoretical prediction of loading effects for proper documentation and reporting for engineering design consideration as in terms of structural analysis. To give students hands on experience with the exposer of laboratory set up. Equipment’s or Materials ✓ STR4 Beam Deflection Test Rig Equipment ✓ Specimen (Brass, Steel, Aluminum) ➢ Specimen Data • Length – 200 mm • Weigh – 19 mm • Depth - 3 mm ✓ Weights (10 g) ✓ Digital deflection registering Meter ✓ Hook Wire/ Hanger4 (10 g) ✓ Note books ✓ Pencil / Pens Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Experimental Procedures/ Method 1. Check and inspect the Beam Deflection Test Rig with all the loads (mass) with the hanger are in place and also beam specimen (Brass, Steel, Aluminum) are made available in the lab. 2. Insert Brass beam bar into the clipper and adjust it till it reaches 200 mm in length. 3. Attached the digital deflection registering meter and loses its node or pointer onto the beam bar and see it must be zero, if not adjust using the origin button till its reading reaches zero. 4. Apply a load of 100 g on the hanger and hang it on the specimen beam bar and record the reading. Put the result in table form and register the reading accordingly to the specimen. 5. Use 200g, 300g, 400g and 500g of load which is required then record the reading accordingly. 6. Repeat the same procedures with the other two beam bars (Steel and Aluminum). Pictured below is Beam Deflection Cantilever Test Equipment in the lab. Mechanical Engineering Lab – Unitech PNG Figure A. Beam Deflection Cantilever Test Fig. Laboratory Report (02) | Engineering Mechanics | Figure B. The Schematic diagram of the Beam Deflection Test Fig. |University of Technology| 2023 Figure C. Loads used in the experiment. Weights in hanger. Figure B. Shows the hanger, beam bars & loads all assemble. Figure D. The three-specimen used in the experiment. Brass, Steel and Aluminum and a steel ruler for taking measurement. Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Results Table 1. Results are tabled here. No # 1 2 3 4 5 Specimen Brass Steel Aluminium Mass (Kg) Def (mm) Mass (Kg) Def (mm) Mass (Kg) Def (mm) 100 0.6 100 0.29 100 1.61 200 1.15 200 0.55 200 2.49 300 1.68 300 0.51 300 3.29 400 2.21 400 1.07 400 4.02 500 2.78 500 1.33 500 4.78 The results of the three specimens are recorded and tabulated accordingly. Graph 1. The Graphical representation of the data tabulated above. GRAPH OF DEFLECTION OF CANTILEVERS 6 DEF (MM) 5 4 3 2 1 0 0 100 200 300 400 500 600 MASS (KG) Brass Def (mm) Steel Def (mm) Aluminium Def (mm) Table 1.1. The conversion from Mass to Newton. Mass (grams) 100 200 300 400 500 Load (Newton) 0.98 1.96 2.94 3.92 4.91 Table 2. Here attached therein is the conversion from mass to newton. Formula used to convert Mass (kg) to Load (Newton). [Given Mass ÷ 1000] x [9.81] acceleration due to gravity Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Calculations. Formula used to Calculate Second Moment of Area I = b3xh/12 Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Table 1.2 below is for Brass Specimen Deflections Materials / Specimens E = 100 Nm-2 I = 42.75x10-12 m Brass Specimen B = 3 mm H = 19 mm Mass (g) 0 100 200 300 400 500 Theoretical Deflection (mm) 0 mm 0. 61 mm 1.2 mm 1.8 mm 2.5 mm 3.1 mm Actual Deflection (mm) 0 mm 0.6 mm 1.12 mm 1.68 mm 2.21 mm 2.78 mm Graph A. The graph below shows the Actual and Theoretical Deflection of the Brass. Brass Deflection Gaph 3.5 Deflection 3 2.5 2 1.5 1 0.5 0 0 100 200 300 400 500 Actual Deflection (mm) 0 0.6 1.12 1.68 2.21 2.78 Theoretical Deflection (mm) 0 0.61 1.2 1.8 2.5 3.1 Mass (g) Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Table 1.3. Table below shows Steel Specimen Deflections Materials / Specimens E = 210 Nm-2 I = 42.75x10-12 m Mass (g) 0 100 200 300 400 500 Actual Def (mm) 0 0.29 0.58 0.9 1.1 1.5 Steel Specimen B = 3 mm H = 19 mm Theoretical Def (mm) 0 0.29 0.55 0.51 1.07 1.33 Graph B. The graph below shows the Actual and Theoretical Deflection of the Steel specimen. Steel Deflection Graph 1.6 1.4 Deflection (mm) 1.2 1 0.8 0.6 0.4 0.2 0 0 100 200 300 400 500 Mass (g) Actual Def (mm) Laboratory Report (02) | Engineering Mechanics | Theoretical Def (mm) |University of Technology| 2023 Table 1.4. Table below shows Aluminum Specimen Deflections Materials / Specimens E = 70 Nm-2 I = 42.75x10-12 m Aluminum Specimen B = 3 mm H = 19 mm Mass (g) Actual Def (mm) Theoretical Def (mm) 0 0 0 100 1.61 0.87 200 2.49 1.75 300 3.29 2.62 400 4.02 3.5 500 4.78 4.38 Graph C. The graph below shows the Actual and Theoretical Deflection of the Aluminum specimen. Aluminium Deflection Graph 6 Deflection (mm) 5 4 3 2 1 0 0 100 200 300 400 500 Mass (g) Actual Def (mm) Theoretical Def (mm) Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Discussion To analyze the deflection of cantilever beams made of Brass, Steel, and Aluminum, we will consider a simple case where a uniform load is applied to the free end of each beam. The deflection of each beam can be calculated using the formula given above in the calculation section. Brass Cantilever: Given Brass's moderate modulus of elasticity and yield strength, it may exhibit moderate deflection under a given load. However, its ductility allows it to deform without undergoing catastrophic failure, making it suitable for applications where some deformation is acceptable. Steel Cantilever: Steel's high modulus of elasticity and yield strength suggest that it will have minimal deflection compared to Brass and Aluminum under the same load. Steel's stiffness and strength make it ideal for applications requiring minimal deflection and high load-bearing capacity. Aluminum Cantilever: Aluminum's low modulus of elasticity implies that it will undergo more significant deflection than Brass and Steel under the same load. However, its lightweight nature can make it preferable for applications where weight is a critical factor, even if some deflection is acceptable. Therefore, this experiment helps engineers to understand the concept with specific parameters according to design and specification before the approvals of the implementation of the projects. The Mythology and procedures of the experiments implicates the loads suspended onto the structure under different loads and condition to which the structure must go true for it to be durable and to give confidents to implement the design structures. Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Conclusion Cantilever beams are common structural elements used in various engineering applications, such as bridges, buildings, and machine components. Understanding the deflection behavior of different materials is crucial for designing and optimizing such structures. The deflection behavior of cantilever beams made of Brass, Steel, and Aluminum depends on the material properties and the applied load. Steel, with its high modulus of elasticity and yield strength, is the stiffest and exhibits the least deflection. Brass, while less stiff than steel, offers good ductility. Aluminum, with its low modulus of elasticity, will exhibit the most significant deflection but is lightweight. Engineers must consider these material characteristics when selecting materials for cantilever beam applications to ensure that the chosen material can meet the structural and performance requirements of the specific project Referencing 1. Google Search engine. http://www.Google.com 2. Dr. Steven K. Ales, PhD Mechanical Engineering Department. “Deflection of Cantilever’’ [Lab Instruction Guide & Notes]. (2023) PNG Unitech 3. http;//www.engineersdaily.com>3... Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023 Appendix The units used and the physical quantities of measurements used to measure parameters in this lab report is all tabulated below. The International System of Units (SI). Name Meters Kilogram Newton Pascal Square Meter Quantity Length Mass Force Pressure Area Symbols m kg N Pa m2 The gravitational force acted on a body under normal condition is called gravity. The acceleration due to gravity (g) is; g = 9.81 m/s2 Laboratory Report (02) | Engineering Mechanics | |University of Technology| 2023