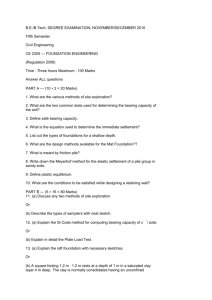

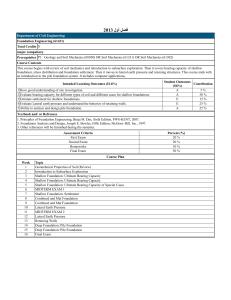

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/309014331 A case study of embankment retaining wall in Ontario Conference Paper · October 2016 CITATIONS READS 3 2,065 3 authors: Laifa Cao S.M. Peaker Ryerson University WSP Canada Inc. 35 PUBLICATIONS 417 CITATIONS 15 PUBLICATIONS 36 CITATIONS SEE PROFILE Shaheen Ahmad Abdul Wali Khan University Mardan 47 PUBLICATIONS 1,102 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: undrained shear strength of soil View project Using in-situ tests in glacial till View project All content following this page was uploaded by Laifa Cao on 12 October 2016. The user has requested enhancement of the downloaded file. SEE PROFILE A case study of embankment retaining wall in Ontario Laifa Cao, Scott Peaker & Shaheen Ahmad WSP Canada Inc., Toronto, Ontario, Canada ABSTRACT This paper presents a case study of an embankment retaining wall. The retaining wall was designed to be up to 6m in height comprising six layers of rock-filled gabion baskets with base width of up to 4m founded on a very stiff to hard silty clay to clayey silt till. Three years after wall construction, vertical settlement of up to 138mm and lateral movement of up to 413mm were recorded at the face of the retaining wall. The significant lateral movement induced cracking in the road pavement structure. The wall stability and bearing capacity were reviewed. It was found that the wall was underdesigned for overturning, sliding and global stabilities; and soil bearing capacity was overestimated. The settlement was found mainly due to the consolidation and overstressing of the founding soils, whereas wall rotation and sliding as well as compaction and expansion of the stone baskets contributed to the significant lateral movement. Improvements for such retaining wall design are recommended. RÉSUMÉ Cet article présente une étude de cas d’un mur de soutènement de talus. Le mur de soutènement a été conçu pour atteindre 6 m de hauteur formée de six couches de gabions remplis de roches avec largeur de base jusqu'à 4 m, fondée sur un très raide d’argile limoneuse dur à limon argileux jusqu'à. Trois ans après la construction du mur, règlement vertical jusqu'à 138 mm et un mouvement latéral de 413mm ont été enregistrés à la face du mur de soutènement. Le mouvement latéral significatif induite par fissuration dans la structure de chaussée routière. La stabilité du mur et portance ont été examinées. Il a été constaté que le mur a été underdesigned pour des stabilités renversement, coulissantes et mondiales; et sol capacité portante a été surestimé. La colonie est trouvé principalement en raison de la consolidation et sursollicitation des sols fondateurs, tandis que le mur rotation et glissement ainsi que compactage et l’expansion des ensembles de Pierre a contribué à l’important mouvement latéral. Améliorations pour une telle structure de mur de soutènement sont recommandées. 1 INTRODUCTION Roadway embankments approach a bridge are often constrained by retaining walls due to limited space in the right of way. Flexible retaining walls such as reinforced earth wall and gabion wall are generally used as they are considered to be tolerant of the ground settlement under the weight of embankment fill. However, if the ground conditions are not properly assessed, ground settlement and lateral movement of such retaining walls could significantly affect the serviceability of the roadway. This paper presents a case study of an embankment retaining wall. The retaining wall was designed to be up to 6m in height comprising six layers of rock-filled gabion baskets with base width of up to 4m founded on a very stiff to hard silty clay to clayey silt till over firm to very stiff silty clay till. Three years after wall construction, vertical settlement of up to 138mm and lateral movement of up to 413mm were recorded at the face of the retaining wall. The significant lateral movement induced cracking in the road pavement structure. The wall stabilities, soil bearing capacity, ground settlement under the embankment fill, and wall lateral movement were reviewed. It was found that the wall was underdesigned for overturning, sliding and global stabilities; and soil bearing capacity was overestimated. The settlement was attributed mainly to the consolidation and overstressing of the founding soil under the weight of embankment fill, whereas the wall rotation and sliding as well as compaction and expansion of the stone baskets contributed to the significant lateral movement. Possible remedial options for the retaining wall are discussed. Improvements for such retaining wall design are recommended. 2 SITE CONDITIONS CONSTRUCTION AND RETAINING WALL The site of the approach embankments of a road bridge (road over rail) is located in Ontario, Canada. Due to the road bridge replacement and road widening, the approach embankments needed to be reconstructed. Since the east side of the embankment was constrained by private property, a retaining wall was required to be constructed to retain the embankment fill. A geotechnical investigation (by others) including borehole drilling, standard penetration tests (SPT) and laboratory testing of soil index parameters was carried out to support the design of the bridge and retaining wall. In general, the subsurface conditions encountered at the site consist of 3.0 to 5.6m thick, loose to compact sandy silt fill extending to El. 96.0 to 94.4m, underlain by about 5.5 to 7.6m thick, very stiff to hard silty clay to clayey silt till extending to El. 90.6 to 86.8m, which in turn is underlain by firm to very stiff silty clay till to El. 79.7 to 79.2m. The firm to very stiff silty clay is underlain by hard clayey silt till or very dense silt till to sandy silt till. The water contents were 9% to 17% for the sandy silt fill, 12% to 16% for the very founded on the very stiff to hard silty clay to clayey silt till at El. 95.5 to 94.1m. Soil parameters including friction angle, unit weight, and coefficient of lateral earth pressure were also recommended in the geotechnical investigation report. Based on the soil bearing capacity and parameters recommended in the geotechnical investigation report, a gabion retaining wall was designed to be up to 6m in height comprising six layers of gabion baskets with base width of up to 4m founded at El. 94.3m on the very stiff to hard silty clay to clayey silt till. A typical cross section of the gabion wall is shown in Figure 2. The wall face and base had an inclination angle of 6o (i.e. 1H:9.5V) in order to increase the base resistance and resisting moment. The wall was designed with 1m height of fill in front of the wall toe. A drainage pipe was also proposed behind the wall. It is noted that the wall was designed to retain a 1V:2H slope backfill above the wall. The new fill height at the road centre was about 2.8m (above the existing level prior to bridge replacement) and the maximum new fill height at the edge of the road was about 7.8m. The gabion retaining wall was constructed in the summer of 2007. Figure 1. Soil profile and SPT N-values at the site stiff to hard silty clay to clayey silt till, and 17% to 18% for the firm to very stiff silty clay till. It is noted that the pocket penetrometer tests on the firm to very stiff silty clay till only showed the undrained shear strengths of about 25 kPa, indicating a relatively weak condition of the firm to very stiff silty clay till. Field vane shear strength testing was not undertaken by the geotechnical consultant. The groundwater level was at El. 87.8 to 86.9m during the investigation. Figure 1 shows soil profiles and SPT Nvalues. The geotechnical report recommended an allowable bearing capacity of 200 kPa and factored ULS (ultimate limit states) bearing capacity of 300 kPa for a retaining wall Figure 2. A typical section of designed gabion wall 3 FIELD OBSERVATIONS Shortly after the gabion wall was constructed and the road was opened, longitudinal pavement cracks were observed. In response, a movement monitoring program of the gabion retaining wall was initiated. The monitoring points were steel bars driven into rock-filled gabion baskets along the top of the retaining wall. The measurements started in November 2007, a few months after the completion of the retaining wall construction. The development of vertical settlement of up to 138 mm and horizontal deflection of up to 413mm had been recorded by July 2010. Photo 3. Tensile cracks above wall and tilted guide rail Photo 1. Wall tilt near abutment (the top of fence post was pushed laterally) A field visit of the site was carried out in June of 2010 to examine the condition of retaining wall. There were visual signs that both vertical and lateral movements were being experienced by the retaining wall and the approach embankment. The maximum height of the wall was measured as 4.8 m instead of 5.0 m above the natural ground level. The tilt of wall was observed as shown in attached Photo 1. Uneven settlement was observed in the CSP culvert underlying the north approach fill as shown in attached Photo 2. Longitudinal cracks had developed in the pavement and granular fill along the side of the gabion wall as shown in attached Photo 3. 4 REVIEW OF RETAINING WALL DESIGN The stability of the east retaining wall including bearing, sliding, overturning and global stabilities, vertical settlement and lateral movement were reviewed using the available data. A parametric approach to the analysis, using a plausible range of soil shear strengths and unit weights was applied. The unit weight of the foundation soil and backfill was taken as 20 or 22 kN/m3. The friction angle was taken as 30o or 32o for the foundation soil, 40o for the friction between gabions, 15o or 16o for the friction between the wall and the backfill, and 22o or 29o for the friction between the wall and foundation soil. The lower bound values were generally similar to those proposed in the geotechnical investigation report for this project. Analyses of the following four cases were carried out: (1) 6m high gabion wall as designed with lower bound of soil parameters; (2) 6m high gabion wall as designed with higher bound of soil parameters; (3) 5.8m high gabion wall measured on July 23, 2010 with lower bound of soil parameters; (4) 5.8m high gabion wall measured on July 23, 2010 with upper bound of soil parameters. For each case, two groundwater level (GWL) scenarios were modelled, one with GWL assumed at El. 87.8m (lower GWL, the groundwater level measured in the monitoring well during the geotechnical investigation) and another with GWL at the base of wall (higher GWL). 4.1 Photo 2. Separated and sagged culvert below approach fill Bearing Capacity It is well known that the soil bearing capacity of an earth retaining structure is not only controlled by the founding soil properties but is also affected by the lateral load acting on a retaining structure. The soil bearing capacity for a foundation with a lateral load will be significantly smaller than that without a lateral load. However, this is often poorly communicated in geotechnical investigation reports. The soil ultimate bearing capacity was estimated based on the formula proposed by Vesic (1973, 1975), in which the influence of lateral load on the bearing capacity is considered. Table 1 summarizes the soil ultimate bearing for the four cases under higher GWL and lower GWL conditions. Taking the vertical bearing resistance factor of 0.5 as recommend in Canadian Foundation Engineering Manual (2006), the factored ULS bearing capacity was calculated and is shown in Table 1. It was found that the factored ULS bearing capacity was lower than 300 kPa Table 1. Soil bearing capacity Case Ultimate Lower Higher GWL GWL 1 351 256 2 534 395 3 338 248 4 512 381 Unit: kPa. Factored ULS Allowable Lower Higher Lower Higher GWL GWL GWL GWL 176 128 117 85 267 198 178 132 169 124 175 83 256 191 173 127 as recommended in the geotechnical investigation report for all cases. At the higher GWL, the estimated ULS bearing capacity with the consideration of the lateral earth pressure was only 43% to 66% of that recommended in the geotechnical investigation report, in which the influence of lateral load to the bearing capacity was probably not considered. At the serviceability limit states (SLS), the bearing capacity is typically defined by settlement criteria under the load and resistance factor design (LRFD). However in common practice, the bearing capacity at the SLS is often taken as the same as the allowable bearing capacity in the traditional working stress design (WSD). Taking a global factor of safety of 3, the allowable bearing capacity was calculated and is shown in Table 1. Again the estimated allowable bearing capacity with the consideration of the lateral earth pressure was only 43% to 66% of the recommended allowable bearing capacity in the geotechnical investigation report. It is noted the vertical stress at the retaining wall base level ranged from 176 to 194 kPa at the location of the road centre and ranged from 116 to 132 kPa at the location of the retaining wall. If the influence of the lateral earth pressure was not considered, the allowable bearing capacity of 200 kPa recommended in the geotechnical report met the vertical load requirement. However, under the action of the lateral earth pressure, the average working load on the effective base of the retaining wall ranged from 206 to 212 kPa, which was greater than the allowable bearing capacity recommended in the geotechnical report. It seems that the working load was underestimated and soil bearing capacity was overestimated without the consideration of the influence of lateral earth pressure on the work load and the soil bearing capacity during the retaining wall design for this project. 4.2 Stabilities A retaining wall should be designed for overturning, sliding and overall (global) stabilities. Although the LRFD has been widely used for structure design, the WSD is still used for retaining wall design in the checking of the overturning, sliding and overall (global) stabilities. Table 2 summarizes the factor of safety (FOS) against these stability failures under the working stress condition for the four cases. Figure 3 shows a typical result of overall stability analysis using commercial limit-equilibrium software. The analyses indicate that the overturning and overall stabilities of the gabion wall are marginally acceptable, but less than the generally accepted requirements of a FOS of 2 for overturning and FOS of 1.5 for overall stability. The stability of the gabion wall in 2010 was worse than the Figure 3. A typical result of overall stability analysis Table 2. Factor of safety against stability failures Case 1 2 3 4 Min. FOS Min. FOS against against overturning sliding 1.81 1.85 1.69 1.72 1.36 1.96 1.15 1.51 Min. FOS against overall Lower GWL 1.39 1.48 1.38 1.47 Higher GWL 1.35 1.44 1.34 1.38 designed wall as the FOSs for the wall in 2010 were less than the designed wall under the same condition. This is primarily due to the loss of batter, i.e. the wall became vertical in 2010. The factor of safety against basal sliding for the wall in 2010 was in the critical condition with a FOS of 1.15 when the groundwater level was modelled to lie at the base of the gabion wall if the soil parameters proposed in the geotechnical report were used. It is noted that the outlet of the drainage pipes for the wall in 2010 was located close to the existing ground surface. When the groundwater level at the wall toe reaches the ground surface, local sliding failure would occur. In the case of the groundwater table rising up at the back of wall due to clogging of filter fabric at the back of wall, local sliding failure would also occur. This could be one reason that a lateral movement of 413mm was recorded. Bulging of gabion baskets may also be a contributing factor. 4.3 Settlement and Lateral Movement The monitoring results for vertical settlement and lateral movement for monitoring points 37 to 45 are shown in Figures 4 and 5, respectively. Monitoring points 37 to 42 were installed at the wall top with the wall height of less than 5m. Monitoring Point 43 was installed at the wall top with the wall height of 5.0m, Point 44 was positioned at the Figure 4. Vertical movement measured at wall top wall top with the wall height of 5.8m, and Point 45 at the corner of the wall near the bridge abutment wall. The measurements began in November 2007, a few months after retaining wall construction. The development of vertical settlement of up to 138mm and horizontal deflection of up to 413mm was recorded in July 2010, relative to the November 2007 baseline. The monitoring results show that the settlement of the wall due to soil consolidation could be considered as being essentially complete by August 2008, one year after wall construction (See Figure 4). The maximum consolidation settlement was 96mm, which was close to the settlement of the north approach embankment of about 100 mm. From August 2008 to July 2010, the increment of vertical movement at points 37 through 42 (wall height of less than 4.5m) was less than 10mm and remained comparatively stable; whereas the increment of vertical settlements at points 43 through 45 (wall height of 5.0 to 5.8m) ranged from 22 to 50mm and did not slow down. The significant vertical settlement of the highest wall sections may be partially due to overstressing of the founding soils which was induced by the loss of wall batter. From November 2007 to July 2010, a maximum lateral movement of 413 mm was recorded at monitoring point 44 installed in the highest retaining wall section (see Figure 5). Similar to the vertical movements, the lateral movements at points 37 to 42 have slowed down since January 2009, whereas the lateral movements at points 43 and 44 in the highest wall section did not decline. A relatively small lateral movement of 50mm at point 45 installed at the corner of the wall is reasonable as the gabion wall was butted against 3m high RSS (retained soil systems) wall at the corner. The significant lateral movement could not be purely due to the vertical settlement and the wall rotation. Sliding of the gabions may contribute part of the lateral movement. Some component of the apparent lateral movement may also be a result of expansion (bulging) of the gabion baskets. Workmanship in construction of the gabion baskets might not have been of the highest quality. The measurements in 2010 showed that individual basket heights varied from 800mm to the design filled height of 1000mm, but most baskets were 850 mm to 900 mm in Figure 5. Horizontal movement measured at wall top Figure 6. Comparison between predicted and measured settlements height. Many baskets appeared to be deformed under the self-weight load, suggesting that they were not tightly packed with stones. Since no consolidation testing was carried out for this project, an accurate estimation of the consolidation settlement is impossible. An approximate estimation of the vertical settlement can be conducted using empirical data for the glacial tills in Ontario as recommended by Cao, et al. (2015). Assuming that the compression index (Cc) is 0.037 for the very stiff to hard silty clay till and 0.1 for the firm to very stiff silty clay till, the recompression index (Cr) is 0.081 for the very stiff to hard silty clay till and 0.016 for the firm to very stiff silty clay till, the initial void ratio (eo) is 0.36 for the very stiff to hard silty clay till and 0.46 for the firm to very stiff silty clay till, and the coefficient of consolidation (cv) is 20 m2/year, the total ground settlement was 220mm including 90mm in the first three months after the construction of 2.8 to 7.8m height of the embankment. Even through the selected soil parameters were based on the empirical data, the predicted settlements are in good agreement with the measured settlements as shown in Figure 6. The back-analysis indicates that 95% of the consolidation settlement would be reached by July 2010. 5 DISCUSSIONS ON REMEDIAL WORKS The monitoring data show that the vertical settlement and lateral movement of the highest wall sections have not attenuated. Review of the wall stability indicates that the local bearing shear failure and sliding failure may occur when the groundwater level reaches the ground surface at the toe of the wall. These suggest that remedial work of the highest wall section may be required. Overstressing of the foundation soils beneath the highest sections of the gabion wall appears to be the main cause of settlement and tilting. The monitoring did not show an abating trend in settlement or deflection in the highest sections of the wall. If the horizontal component of the load on the retaining wall (i.e. the lateral earth pressure) can be significantly reduced, then the inclination of the resultant force acting on the base of the wall can be rendered essentially vertical, without significant eccentricity. Three methods of picking up or reducing the lateral earth pressure include: (i) Soil nailing; or (ii) Installation of closely spaced layers of horizontal geogrid; or (iii) Replacement of the backfill in the active wedge with light weight fill (expanded slag, expanded polystyrene or equivalent). The gabion wire baskets and gabion stones within the baskets present some practical difficulties as far as the advancement of horizontal soil nails through the wall is concerned. Although it might be technically feasible to vibro-drive steel bar through the gabions, without the benefit of field-trials to assess the feasibility of advancing soil nails through the cages and tension tests to assess their capacity, this method is not considered contractually viable. For this reason, the second alternative – installation of geogrid in the backfill soils behind the gabion wall in the north approach fill is more reliable. Option (ii) will require reconstruction of most, if not all, of the north approach fill and roadway infrastructure. The benefit of the geogrid fill reinforcement option is that the existing gabion wall is essentially converted from a gravity retaining structure to a facing wall only. A secondary benefit is that the upper sloped portion of the approach fill (which lies above the top of the gabions and below the asphalt road surface), can be reinforced. This area exhibited creep and surface erosion, resulting in tension cracking of the pavement and tilting of the guide rail. Reinforcement of the north approach fill would require road (bridge) closure during the full course of the work. The existing approach fill material can be salvaged and reused to create the reinforced fill. The face of the fill abutting the existing gabions wall will require a filter fabric lining, followed by a wrap of the geogrid. In this way, the reinforced fill will remain independent of the gabion wall. The potential conflict with existing reinforcing strips to the bridge abutment might also apply to Option (iii). This option involves the sub-excavation of existing fill behind the retaining wall within the active wedge zone and replacing this fill with compacted light weight fill, such as expanded slag. Alternatively, the use of ultra-light weight fill (expanded polystyrene) could also be considered. View publication stats The last option is to do nothing as the majority of the consolidation settlement of the underlain silty clay till has been reached, the soil strength has been improved under the embankment fill, and the retaining wall is marginally stable. Continuous monitoring of the wall movement is required if this option is chosen. More frequent maintenance of the road pavement will be required as the tensile cracks in pavement structures could continuously develop due to the lateral movement of the retaining wall. 6 CONCLUSIONS AND RECOMMENDATIONS From the review of an embankment retaining wall, the following conclusions can be provided: • The working pressure on a retaining wall base was higher than the vertical load, due to the contribution of the lateral earth pressure. For a preliminary analysis of a gravity retaining wall, the working pressure can be assumed as 150% to 200% of the vertical load. • The bearing capacity for the retaining wall design was significantly underestimated, probably without the consideration of the lateral earth pressure. For a preliminary analysis of a gravity retaining wall, the bearing capacity can be taken as 50% of that without consideration of a lateral load. • The significant vertical settlement is attributed to not only the soil consolidation, but also the overstressing of the founding soils which was induced by the loss of wall batter. • The significant lateral movement is contributed to not only the wall rotation and sliding, but also the compaction and expansion of the stone baskets under the self-weight load. For the preparation of a geotechnical investigation report for a retaining wall, a recommendation for a global stability analysis is required, and a settlement analysis must be carried out if the founding soils are underlain by relatively weak soils. Since details regarding retaining wall design are often not know at the time of preparation of a geotechnical investigation report, it is critical that the geotechnical engineer be engaged at the design stage to reassess the recommended soil parameters and to assess the wall stability. REFERENCES Canadian Geotechnical Society, 2006. Canadian Foundation Engineering Manual, 4th ed., BiTech Publisher Ltd, Richmond, BC, Canada. Cao, L.F., Peaker, S. and Ahmad, S., 2015. Engineering characteristic of glacial tills in GTA, 68th Annual Canadian Geotechnical Conference, Quebec, Canada. Vesic, A.S. 1973. Analysis of ultimate loads of shallow foundations, JSMFD, ASCE, 99: 45-73. Vesic, A.S. 1975. Foundation Engineering Handbook, 1st ed., Winterkorn and Fang, Van Nostrand Reinhold.