KKS

Identification System for Power Stations

This booklet serves as an information tool about the

KKS identification system for all types of power plants

with the expection of nuclear power systems.

It is not intended and it is not suitable as an instruction manual

for KKS codification.

For this purpose, please refer to project-specific

"KKS Guidelines and Keys".

KKS - GUIDELINES AND KEYS

Table of Contents

Con~n~

1. KKS·INTRODUCTION (IDENTIFICATION SYSTEM FOR POWER STATIONS)

Page

3

2. PROJECT RELATED RULES, AGREEMENTS AND PROCEDURES

12

3. KKS FUNCTION KEY (F 1 F2 F3)

14

4.

EQUIPMENT UNIT KEY (A1 A2)

5. COMPONENT KEY (B 1 82)

130

133

1. KKS-INTRODUCTION

1. 1

Purpose and Area of

Application

1.2

(IDENTIFICATION SYSTEM FOR POWER STATIONS)

Requirements

tion, operation, maintenance

and waste management

In order to perform the set

tasks the identification system

must be capable of satisfying

the following requirements:

The power plant identification·

system is applied to clearly

identify plants, systems, parts

and components to their

purpose, type and location.

Interdisciplinary applicability

to mechanical engineering,

civil engineering, electrical

and instrument & control

engineering combined with

ability to identify according

to process functions, points

of installation and locations

Uniform identification for all

types of power stations and

any connected processes

The content is in accordance

with "KKS Identification

Systems for Power Stations "

issued by VGB PowerTech

Service GmbH Essen,

Germany.

Sufficient capacity and detail

for identification of all

systems, components and

structures

Consideration of national

and international standards

Sufficient capacity for

extension to accommodate

new technologies

Non-language-based coding

to ensure international

usability

Consistent identification for

planning, licensing, construe-

Application in computer data

processing.

Serial number of breakdown level

0

Name of breakdown level

Total plant

Example

Unit 1

2

3

Function

Equipment unit

Component

Feedwater system

Pump unit

Pump

Breakdown levels, referring to Process-Related Identification.

1.3

1.3. 1 Identification a~.:~d Type

of Data Characters

Table 1 summarizes the

identification and type of

data characters of the breakdown levels for all three

different types of identification

appearing in the KKS.

Structure and Application

The KKS consists of three

types of identification:

The process-related code

identifies installations and

eguipment according to their

assigned task in the power

plant process

The location code identifies

the rooms and floors, or

other installation sites for

installations and eguipment

in building structures.

Serial number of

breakdown level

Name of breal<·down level

0

Designation of data character

G

Type of data character

(A) or (N)

UNIT.

The identification letters now

used for the point of installation

identification in the breakdown

level FUNCTION may be

the same as those for the

3

2

Total Plant

Function

Fo F1

(N) A

F2 F3

A

Fn

A NN

Alphabetical symbols (letters, special symbols)

1l

Numerical symbols (digits)

These data characters may be omitted

-'

1.3.3 Point of Installation

Identification

As with the process-related

identification, the KKS is also

used to identify locations,

principally of electrical and

I&C equipment, but also of

mechanical equipment.

Locations - for example,

coordinates, racks and

positions in cubicles etc. are identified in the breakdown level EQUIPMENT

The process-related identification corresponds to the

identification block "Pla nt" in

DIN 40719, part 2. This

block has the prefix sign "=".

According to the standard,

the prefix sign can be

omitted provided that the

identification remai ns

unambiguous.

The process-related identification is for many applications

the most important identification,

since it permits, for example,

identification of electrical and

control eguipment, signals,

and the identification in circuit

A uniform identification

structure, with a maximum of

four breakdown levels, was

created for all three types;

the units referred to becoming

smaller from left to right.

A

N

()

In the electrical and instrumentation & control (I&C)

engi neering sectors, the

eg uipment for auxiliary

services, power supply, openloop-control, instrumentation,

protection, etc., is treated as

a process engineering function.

The same applies to structures

in civil engineering work_

1.3.2 Process-Related

Identification

In this type of identification

the entire system is subdivided

according to the function or

process, since, whether for

mechanical, electrical, control

or civil engineering, the

eguipment units and components must be identifiable in

relation to the process.

The point of installation

code identifies the points

of installation within an

installation unit (e.g. cubicles,

consoles, panels)

-

diagrams re lated to particular

functions.

process-related identification.

This improves recognition of

the identification in the overall

system. In order to prevent

possible confusion between

process-related identification

and point of installation

identification the prefix sign

"+"must be added to the

point of installation code

(according to DIN 40719,

part 2). Resp. the breakdown

symbol "full stop" between

breakdown Level 1 and 2

must be used_ This prefix

sign may be omitted only

when there is absolutely no

ambiguity- e.g. in layout

documents.

Equipment Unit

Component

A 1 A 2 AN A 3

A A NNN (A)

Bl

A

B2 BN

A NN

3

1.3.4 Location Identification

In order to clearly identify the

position of plants, sub-systems

and equipment in the power

station, the code of building

structure and floor is entered

at the breakdown level

FUNCTION and the rooms

on the various floors of the

building structure at the

breakdown level EQUIPMENT

UNIT. The brea kdown level

COMPONENT is not used

in location identification.

Fire protection sections are

identified according to the

room identification _

1.3.5 Title and Contents of the Breakdown Levels

Breakdown levels

0

2

3

Total plant

Function

Equipment unit

. •'

Component

Process-related code

Totcil plant

System code

Equipment unit code

Component code

Mechanical engineering

Unit

System

Pump unit

(Pump)

Civil engineering

Unit

Structure, floor

Rolling door

(Motor)

Unit

Structure, floor

Fan unit

(Fan)

Control and instrumentation

Unit

System

Measuring circuit

Transducer

(for mechanical and civil

Unit

Structure, floor

Measuring circuit

Temp. sensor

engineering)

Unit

System

Open-loop control

Push-button

Unit

Unit coordinate level

Closed-loop control

Controller

Electrical and control

Unit

Switchgear

Switchgear assembly

Fuse

and instrumentation

Unit

Transformer

Fan unit

Motor

engineering

Unit

Transformer

Measuring circuit

Indicator

Unit

Transformer

Terminal box

Terminal block

Unit

Elect. Equipment cab.

Measuring circuit

Smoke detector

Unit

Structure, floor

Junction box

Telephone jack

Total plant

Installation

Installation

unit code

space code

Point of installation

Electrical and control

Unit

Switchgear

Tier/Space

& instrumentation

Unit

Elect. Equipment cab.

Tier/Space

engineering

Unit

Control console

Coordinates

Location code

Total plant

Structure code

Room code

Civil engineering

Unit

Structure, floor

Room/ coordinates

Unit

Outdoor area

Coordinates

1.4

Structure and Contents of the Breakdown Level~

1.4. 1 General

The KKS is divided into different BREAKDOWN LEVELS and codes from left to right in dim ini sh ing order of

the units of a complete power plant:

0

Total Plant

Function

2

3

Equipment Unit

Component

G

Fo

F1 F2F3

Fn

A1 A2

An

A3

A or N

N

AAA

NN

AA

NNN

A

NN

Overall plant prefix No.

(Chapter 2.1)

Function level prefix No.

(Chapter 2. 1)

Function code

(Chapter 3)

Equipment unit code

(Chapter 4)

Component code

(Chapter 5)

Systems and sub-systems limit descriptions in the breakdown level Function are pa rt of the function code list. W here

they are not defined, the beginning of a new system is at branch-off or outlet of other system or at a point where

unequivocal allocation of a component to a system is possible.

from

incl.

from

I~

excl.

I~ ~I

to

exd.

I

to

~incl .

1H=J-1~ 1 H=J-1 ~ 1 H=J-1 ~ 1H=J1~

Legend for the limits:

"from incl."

means "including"

the mentioned component

"from excl."

means "excluding"

the mentioned component

"to excl."

means "excluding"

the mentioned component

"to incl."

means "including"

the mentioned component

1.4.2 Breakdown Level "Function"

Function identification:

Serial No. of breakdown level

Function

Name of the breakdown level

•

•

•

•

•

Identification of data character

Fo

Fl

F2 F3

Type of data character

N

A

A

Function level prefix No

Main group

Fl

System group

Fl F2

System

F1 F2 F3

Sub-system

Fn

Function Key, main groups F1:

Code

I

A

Fn

NN

'

I

(Only the main groups far steam plants and combined cycle power plants are considered in this d acumentJ

Identification

;

A

GRID AND DISTRIBUTION SYSTEMS

B

POWER TRANSMISSION AND AUXILIARY POWER SUPPLY

C

INSTRUMENTATION AND CONTROL EQUIPMENT

(Identification on a priority basis according to main, instrumentation and control function also

acceptable in composite structure hardware packaging systems.)

E

CONVENTIONAL FUEL SUPPLY AND RESIDUES DISPOSAL

G

WATER SUPPLY AND DISPOSAL

H

CONVENTIONAL HEAT GENERATION

L

·sTEAM, WATER, GAS CYCLES

M

MAIN MACHINE SETS

P

COOLING WATER SYSTEMS

Q

AUXILIARY SYSTEMS

S

ANCILLARY SYSTEMS

T

·blocked ·

U

STRUCTURES

Z

WORKSHOP AND OFFICE EQUIPMENT

For complete function code list including system limits of function groups F1F2 and function

subgroups F1Fl 3 see Function Key (chapter 3).

JS

1.4.3 Breakdown Level "Equipment Unit"

Equipment unit identification:

Serial No. of breakdown level

2

Name of the breakdown level

Equipment Unit

Identification of data character

Al A2

An

A3

Type of data character

A A

NNN

NN

I

• Main groups

of equipment units

A1

• Sub-groups

of equipment units

A2

• Numbering equipment units

• Additional code

I

Equipment Unit Key, groups A 1:

Code

Identification

A

MECHANICAL EQUIPMENT

B

MECHANICAL EQUIPMENT

c

DIRECT MEASURING CIRCUITS

D

CLOSED-LOOP-CONTROL CIRCUITS

E

ANALOG AND BINARY SIGNAL CONDITIONING

F

INDIRECT MEASURING CIRCUITS

G

ELECTRICAL EQUIPMENT

H

SUB-ASSEMBLIES OF MAIN AND HEAVY MACHINERY

-

For complete equipment units code of the sub-groups A 1 A2 see Equipment Unit Key (chapter 4)

1.4.4 Breakdown Level "Component"

Component identification:

Serial No. of breakdown level

3

Name of the breakdown level

Component

Identification of data character

Type of data character

• Main groups

of components

• Sub-groups

of components

• Numbering components

B1

B2

NN

Component code main groups B1:

Code

Identification

K

MECHANICAL COMPONENTS

M

MECHANICAL COMPONENTS

Q

INSTRUMENTATION AND CONTROL COMPONENTS (Non electrical)

ELECTRICAL COMPONENTS

X

SIGNAL ORIGIN

Y

SIGNAL APPLICATION

Z

GATED SIGNALS

For complete component code of the sub-groups B1 82 see Component Key (cha pter 5). In P&IDs breakdown level 3

is NOT used. In other documents it may be used according to separate agreements.

1.4.5 Overview

G

Identification of data character

Type of data character

Function

Total Plant

Name of breakdown level

=

J

•

Prefix sign of process

related identification

•

Identification of power station

units and non-unit specific plants

2

3

Equipment Unit

Component

0

Serial No. of breakdown level

A or N

Fo F, F2 F3

(N)

MA

Fn

A, A2

NN

AA

A3

Bn

NNN (A)

NN

An

J

•

Prefix No. of the function code

Numbering of similar systems and plants in the

parts of power station identified on breakdovn level 0

•

System-classifying

Classifying sub-division of systems

and plants of a unit as per Function key

•

System-numbering

Numbering sub-division of systems and

plants into sub-systems and sections of plants

•

Equipment-classifying

Classifying sub-division of mechanical, electrical

and I&C equipment as per Equipment unit key

•

Equipment-numbering

Numbering of similar mechanical, electrical and I&C equipment

•

Additional identification of breakdown level 2

Identification of pilot valves, multiple drives/el. loads,

measuring points with multiple output/operating points

•

Component-classifying

Classifying sub-division of components, signals or signal-applications

•

Component-numbering

Numbering of components, signals or signal-applications

The data character marked ( ) and the prefix sign can be omitted if the identification remains unequivocal.

1.5

KKS Relevant Symbols in P&ID's and Principle S.ketches

In P&IDs the following symbols to indicate KKS code and limit functions and pi ping sections are recommended :

The symbol 11 pin with empty head 11 is used to identify the limits of fu nctions

and sub·functions.

(G F0 F1 F2 F3 FN)

DN600

I

The symbol pin with full head 11 is used to identify the limits of piping sections.

{Al A2 AN)

~

Reducers are assigned to the piping with the larger diameter.

They need not be shown on flow diagrams.

(see KKS Application Commentaries Part B 1, page 52)

11

DN800

NNAAANN

The symbol 11 Fiag 11 is used for the identification of pipings.

The direction of the flag shows the direction of the medium flow.

AANNN

~

>

~

NNAAANN

The extended 11 Fiag 11 symbol is used for the identification of a pipe

where medium flow direction alters according to the operating condition.

AANNN.

)

~

-

The symbol pointer between connected systems represented on different P&IDs.

Breakdown level Function of the connected system as a minimum information.

NNAAANN

The symbol

11

1

& C- circuits 11 (DIN 19227, sheet 1)

is used to represent measuri ng circuits.

NNAAANN AANNNA

KKS-code for measuring circuits.

s

2. PROJECT RELATED RULES, AGREEMENTS AND PROCEDURES

2.1

2.2

·'

Agreement on Break·

down Level "G" - Overall

Plant and F0 - Function

Prefix Number

consecutive or grouping.

- Numbering need not be

continuous.

It may be necessary to identify

units, non-unit specific plants

or extension stages w ihin a

power station, such that a

clear and unambiguous distinction exists between them.

This is provided by breakdown

level 0 - Overall plant. This

identification must be agreed

upon by all parties concerned,

regarding the contents and

and typre of data character

{A or N). Especially the identification of existing units has

to be taken into account.

The breakdown level "Overall

plant" can be omitted when

the designation remains

unambiguous.

If in the overall plant two or

more identical plants or systerns are to be identified {e.g.

2 boiler plants, 2 gas turbines

with attached el. generators

and HRSGs, 2 structures with

equal purpose) the prefix

number F0 is used to distinguish between them. Each F0

number is valid only in the

area of the Function concerned.

O n no accounts it to be

considered for the counting

of system sections as parallel

lines, data characters FN

being used for this purpose.

- Numbering conventions,

once established, may not

be altered, not even in the

event of changes made in

the progress of planning.

- Redundant zeros must be

written.

- An application-speci fic

scheme of numbering may

be established . However, it

has to be valid throughout

all project disciplines in

order of an unequivocal

understand ing of the code.

- Management systems {e.g.

computer checking programs,

allocation sheets) have to

assure, that no double

KKS numbers occur in the

project and that no multiple

KKS numbers are assigned

to one item.

- If necessary, subdivisio ns

of number ranges in FN

according to the division of

work could be made. They

have to be written down

directly in the project-related

Function key and must

be respected by the partners

involved.

General Rules on

Numbering Code

Elements (FN, AN, BN)

- Numbering starts anew

w hen one of the preceding

code elements changes.

- Numbering may be

2.3

for system code "Fo" and

structures {F 1 = U) only.

-The counting is not related

to any geographical

direction {e.g. not from

west to east, not from

north to south)

2.4

allocated KKS numbers for

a project, if these numbers

have been released for

the project.

-The original KKS number is

still kept, even w hen another

kind of equipment is used,

provided that the function

according to the KKS

equipment unit code is not

changed {e.g. substitution

of a gate valve by a

globe va lve).

2.5

j 12

Writing Modus of KKS

Code

Following structures of the

KKS code are allowed:

-in one line with space

between Function Level,

Equipment Unit Level {and

Component Level) .

e.g.

19PAB10 APOOl {-MOl )

- in two {three) li nes

e.g. 19PAB10

A POOl

{-MOl)

General Rules Regarding

Direction of Numbering

- Standard identi fications

have priority in all cases.

- Numbers are increasing in

media or process flow

direction .

- Project counting directives

referred to local layouts are

related to breakdown

level 11 G 11 , prefix number

Rules on Modifications

and Cancellations of

KKS Numbers

- It is not allowed to change

2.6

General Rules on Process·

related Identification

- Piping & Instrument Diagrams

(P&ID) are the basic

•"

-

documents (origins) for a

process-related KKS coding.

- Single line diagrams are

the basic documents (origins)

for a process-related KKS

coding in electrical engineering. However, KKS codes

for electrical consumers,

measuring loops and items

of I & C represented in

Function Diagr9ms are

originated in P&IDs.

- For other eng ineering

activities (e.g. component

engineering), KKS code

must always be taken from

the above mentioned basic

documents.

- In basic KKS documents

(P&IDs, single line diagrams

and site layouts) the brea k

down level 3 (component

code) is never used .

-The detailed KKS coding in

process-related identification

has to be made accord ing

to the KKS-Application

Commentaries, Part B1, B3

and B4 by VGB PowerTech

GmbH.

d

:l

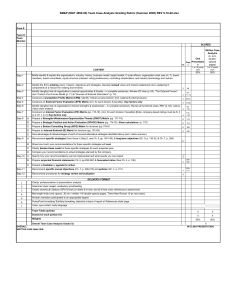

2.7 Rules on AN Numbering for Piping and In-Pipe-Components

Serial No.

Application for

NNN

e

s

001-199

Piping and in-pipe-components incl. instruments for main media/systems *)

201-299

Piping and in-pipe-components incl. instruments in discharge, drains and venting

301-399

1st isolation valves in instrument lines

401-499

Piping and isolation valves between technological and sampling & dosing systems

501-599

Piping and in-pipe-components incl. instruments for testing functions

601-699

Piping and in-pipe-components incl. instruments for heating and maintaining heat

701-799

Piping and in-pipe-components incl. instruments for special purposes:

701-719

- N 2 purging / conservation connections

720-749

-Water/ Steam purging (e.g. temporary blow-out)

750-779

-Compensators

780-789

- Hydro tests

790-799

- Fr~e for project-specific allocations; documented agreement necessary

801-899

Piping and in-pipe-components incl. instruments for special purposes:

801-819

- Hydraulic control piping and in-pipe-components

820-829

-Temporary flushing piping

830-899

- Free for project-specific allocations; documented agreement necessary

901-999

Indirect measuring circuits (according to Application Commentaries B4, Chpt. 2 . 1.2.2)

I)

*)Main media/ system= in F1, F2 , F3 (FNJ identified system with its media; e.g. LAB(95) = High pressure feedw ater

piping system

s-

Note: Special rules on point of installation identification and location identification have to be

established within the relevant engineering disciplines (electrical, I&C and civil engineering)

according to the KKS-Application Commentaries, Part 82, 83 and B4 by VG8 Powerlech GmbH.

ns

The KKS basic documents for these types of KKS code have to be identified as well.

3. KKS FUNCTION KEY (F1 F2 F3)

Table of Contents

Contents

Page

A

GRID AND DISTRIBUTION SYSTEMS

15

B

POWER TRANSMISSION AND AUXILIARY POWER SUPPLY

21

c

INSTRUMENTATION AND CONTROL EQUIPMENT

26

(Identification on a priority basis according to main i nstrumentation and control

function also acceptable in composite structure hardwa re p ackag i ng systems).

II

E

CONVENTIONAL FUEL SUPPLY AND RESIDUES DISPOSAL

31

G

WATER SUPPLY AND DISPOSAL

43

H

CONVENTIONAL HEAT GENERATION (HRSG)

53

L

STEAM-WATER CYCLE

62

M

MAIN MACHINE SETS

70

N

PROCESS

. ENERGY I MEDIA SUPPLY FOR EXTERNAL USERS

78

(e.g. District Heating)

p

COOLING WATER SYSTEMS

80

Q

AUXILIARY SYSTEMS

87

R

GAS GENERATION AND TREATMENT

93

s

ANCILLARY SYSTEMS

107

u

STRUCTURES AND BUILDINGS FOR COMBINED CYCLE POWER PLANTS

112

X

HEAVY MACHINERY (NOT MAIN MACHINE SETS)

122

z

WORKSHOP AND OFFICE EQUIPMENT

129

GRID AND DISTRIBUTION SYSTEMS

AB > 4 20 kV syst em s.

AS Decentralized panels and ca binets.

AC 380 (420} kV syste m s.

AT Transformer e q uipment.

AD 220 - 3 59 kV syste m s.

AU Open-loop control, checkback and

auxiliary e quipme nt.

AE 110 - 21 9 kV syste m s.

AV Marshalling racks.

AF 60 - 1 09 kV sy ste ms .

AW Instrument p a ne ls.

AG 45 - 59 kV syste ms.

AX Ce ntral e q uipment.

AH 30 - 44 kV systems.

AY Commu nica tion equipme nt.

AJ 20 - 29 kV syste m s.

AK 1 0 • 19 kV syste ms.

AL 6 • 9 kV syste m s.

AM 1 -· 5 kV syste m s.

AN < 1 kV syste ms.

AP Control consoles.

AQ Me a s uring and m ete ring e quipment.

AR Protection e quipment.

r

GRID AND DISTRIBUTION SYSTEMS

AB > 420 kV systems.

AEB

110- 219 kV systems.

(diameter

ABA

>420 kV systems.

ABB

>420 kV systems.

ABC

>420 kV systems.

(diameter

(diameter

(diameter

ABO

I

I

I

AEC

(diameter

feeder subdivision).

AED

feeder subdivision).

I

feeder subdivision).

110 - 219 kV systems.

I

feeder subdivision).

110 - 219 kV systems.

(free for use).

AEM

feeder subdivision).

110 - 219 kV systems.

(busbar section) .

AEN

>420 kV systems.

11 0 - 219 kV systems.

(busbar section).

(free for use).

ABM >420 kV systems.

AEZ

110 -219 kV systems.

(Line

(busbar section).

I

transformer feeder).

ABN >420 kV systems.

(busbar section}.

ABZ

AF 60 - 109 kV systems.

>420 kV systems.

(Line

I

AFA

transformer feeder).

60 - 109 kV systems.

(diameter

AC 380 (420) kV systems.

(diameter

I

60 - 109 kV systems.

AFC

60 - 109 kV systems.

AFD

60- 109 kV systems.

360 - 420 kV systems.·

ACC

360 - 420 kV systems.

ACD

360- 420 kV systems.

(diameter

(diameter

I

I

(diameter

feeder subdivision).

ACB

feeder subdivision}.

AFB

(diameter

ACA 360 - 420 kV systems.

I

feeder subdivision).

I

I

feeder subdivision).

feeder subdivision}.

(free for use).

AFM 60 - 109 kV systems.

feeder subdivision).

(busbar section).

AFN

60- 109 kV systems.

AFZ

60 - 109 kV systems.

(busba r section).

(free for use).

ACM 360 - 420 kV systems.

(busbar section).

(Line

I

transformer feede r) .

ACN 360 - 420 kV systems.

(busbar section).

ACZ

AG 45 - 59 kV systems.

360 - 420 kV systems.

(Line

I

AGA 45 - 59 kV systems.

transformer feeder).

(diameter

AD 220 - 359 kV systems.

(diameter

ADA 220 - 359 kV systems.

(diameter

ADB

I

feeder subdivision).

I

I

feede r subdivision) .

(diameter

I

feede r subdivision).

AGD 45 - 59 kV systems.

feeder subdivision).

(free for use).

AGM 45 - 59 kV systems.

220 - 359 kV systems.

(diameter

feeder subdivision}.

AGC 45 - 59 kV systems.

220 - 359 kV systems.

(diameter

ADC

I

I

AGB 45 - 59 kV systems.

feeder subdivision).

(busbar section).

ADD 220 - 359 kV systems.

AGN 45 - 59 kV systems.

(free for use).

(busbar section).

ADM 220 - 359 kV systems.

AGZ 45 - 59 kV systems.

(bus bar section).

(Line

I

transformer feeder}.

ADN 220 - 359 kV systems.

(bus bar section).

ADZ

AH 30 - 44 kV systems.

220 - 359 kV systems.

(Line

I

AHA 30 - 44 kV systems.

transformer feeder).

(diameter

AE 1 10- 219 kV systems.

AHB

AHC

110 - 219 kV systems.

(diameter

I

116

I

feeder subdivision}.

30 - 44 kV systems.

(diameter

feeder subdivision).

feeder subdivision} .

30 - 44 kV systems.

(diameter

AEA

I

I

feeder subdivision}.

s

~ND

GRID

AHD 30 - 44 kV systems.

DISTRIBUTION SYSTEMS

ALN

6 - 9 kV systems.

ALZ

6 - 9 kV systems.

(free for use).

(busbar section).

AHM 30 - 44 kV systems.

(busbar section).

(Line

I

transformer feeder).

AHN 30 - 44 kV systems.

(busbar section).

AHZ

AM 1 - 5 kV systems.

30 - 44 kV systems.

AMA 1 -· 5 kV systems.

(Line / transformer feeder).

(diameter

AJ 20 - 29 kV systems.

20 - 29 kV systems.

(diameter

AJB

I

AMC

feeder subdivision).

I

20- 29 kV systems.

AJD

20 - 29 kV systems.

(diameter

I

AJN

20 - 29 kV systems.

AJZ

20 - 29 kV systems.

(busbar section).

AMN 1 - 5 kV systems.

(busbar section).

AMZ 1 - 5 kV systems.

(busbar section).

(busbar section).

(Line

I

(Line

transformer feeder).

feeder subdivision).

I

feeder subdivision).

I

ANC

feeder subdivision).

10 - 19 kV systems.

(free for use).

AKM 10 -19 kV systems.

AND

(busbar section).

AKN

10 • 19 kV systems.

ANE

(bus bar section).

AKZ

1 0 - 19 kV systems.

(Line

I

transformer feeder).

6 - 9 kV systems.

(diameter

I

6 - 9 kV systems.

ALC

6 - 9 kV systems.

ALD

6 - 9 kV systems.

ALM

6- 9 kV systems.

(diameter

(free for use) .

< 1 kV systems.

(free for use).

Low voltage switchgear < 500 V,

Three-phase/ single phase alternating current.

I

I

Low voltage switchgear < 500 V,

Three-phase/ single phase alternating current.

(free for use) .

feeder subdivision).

ALB

(diameter

Low voltage switchgear 500-1 000 V,

Three-phase/ single phase alternating current.

(free for use).

ANF

AL 6 - 9 kV systems.

ALA

Low voltage switchgear 500-1 000 V,

Three-phase/ single phase a lternating current.

(free for use).

10 • 19 kV systems.

(diameter

AKD

(free for use).

ANB

10 - 19 kV systems.

(diameter

AKC

I

transformer feeder) .

ANA Low voltage switchgear 500-1 000 V,

Three· phase/single phase alternating current.

1 0 - 19 kV systems.

(diameter

AKB

I

AN < 1 kV systems.

AK 10 - 19 kV systems.

AKA

feeder subdivision).

(free For use).

(free for use).

20 - 29 kV systems.

I

AMM 1 - 5 kV systems.

feeder subdivision).

AJM

feeder subd ivision).

AMD 1 - 5 kV systems.

feeder subdivision).

AJC

I

1 - 5 kV systems.

(diameter

20- 29 kV systems.

(diameter

feeder subdi vision) .

AMB 1 - 5 kV systems.

(diameter

AJA

I

ANG Low voltage switchgear < 500 V,

Three· phase/single phase alternating current.

Feeder subdivision).

(free for use).

feeder subdivision).

ANH Low voltage switchgear < 500 V,

Three-phase/single phase alternating current.

(free For use).

(busbar section).

(free For use).

117

GRID AND DISTRIBUTION SYSTEMS

ANK Direct voltage switchgear 220/ 110 V.

ARC

Protection equipment.

ARD

Protection equipment.

ARZ

Protection equipment

(free for use).

ANL

(free for use).

Direct current switchgear 220/ 125 V.

(free for use).

(free for use).

ANM Direct current switchgear 220/ 125 V.

(free for use).

(line).

ANN Direct current switchgear 220/125 V.

(free for use).

AS Decentralized panels and cabinets.

ANQ Direct current switchgear 60/48 V.

ASA

ASB

(free for use).

ANR Direct current switchgear 60/48 V.

(free for use).

ANS

Direct current switchgear 60/48 V.

ASC

ASD

ASJ

(free for use).

ANU Direct current switchgear 24/ 12 V.

(free for use).

ANV Direct current switchgear 24/ 12 V.

ASL

(free for use).

ANW Direct current switchgear 24/ 12 V.

ANZ

ASM

ASN

ASP

ASQ

ASR

ASS

AST

ASU

(free for use).

< 1 kV systems.

(line).

AP Control consoles.

APA

Control consoles.

APB

Control consoles.

(free for use).

ASV

(free for use).

APC

Control consoles.

ASW

(free for use).

APD

Control consoles.

ASX

(free for use).

AQ Measuring. and metering equipment.

AT Transformer equipment.

AQA Measuring and metering equipment.

ATA

Transformer equipment.

ATB

Transformer equipment.

ATC

Transformer equipment.

ATD

Transformer equipment.

ATZ

Transformer equipment.

(free for use).

(free for use).

AQB Measuring and metering equipment.

(free for use).

(free for use) .

AQC Measuring and metering equipment.

(free for use).

(free for use).

AQD Measuring and metering equipment.

(free for use).

(free for use).

AQZ Measuring and metering equipment.

(free for use).

(line).

AR Protection equipment.

ARA

Protection equipment.

ARB

Protection equipment.

Circuit breaker appurtenances.

Multiplication, conversion,

decoupling.

Transducer appurtenances.

Compressed air, hydraulics.

Automated controls, closed-loop

control.

Grid simulation, voltage group

selection.

Measuring equipment.

Auxiliary power supply.

Recording.

Metering.

Protection.

Synchronization.

Transformation.

Panels and cabinets for auxiliary

equipment.

Group, intermediate and general

terminal blocks.

Indication, manual operation,

monitoring.

Alarm annunciation.

AU Open-loop control, checkback and

auxiliary equipment.

AUA Ope n-loop control, checkback and

auxiliary equipment.

(free for use).

(free for use).

(free for use).

J 18

5

GRID AND DISTRIBUTION SYSTEMS

AUB

Open-loop control, checkback and

auxiliary equipment.

AUC

Open-loop control, checkback and

auxiliary equipment.

AXC

(UPS).

(free for use) .

AXD Low voltage distribution.

AXE Compressed air generation system.

AXF Central equipment.

(free for use).

AUD Open-loop control, checkback and

auxiliary equipment.

(fre!3 fo r use).

AXG Central equipment.

(free for use).

AUE

AUF

(free fo r use).

Open-loop control, checkback and

auxiliary equipment.

AXH Central equipment.

(free for use).

AXJ

Open-loop control, checkback and

auxiliary equipment.

AXK Central equipment.

(free for use).

(free for use) .

(free for use) .

AXL

AXM Central equipment.

AUH Open-loop control, checkback and

auxiliary equipment.

(free for use) .

AXN Central equipment.

(free for use).

(free fo r use).

AXP

AV Marshalling racks.

Marshalling racks.

Marshalling racks.

AVF

Marshalling racks.

(free for use) .

(free for use} .

AXW Central equipment.

(free for use).

(free for use).

AXX Central equipment.

(free for use).

AVG

Marshalling racks.

(free fo r use) .

(free for use).

AVH

Central equipment.

AXV Central equipment.

(free for use).

Marshalling racks.

AXS

AXT Auxiliary power transformer.

AXU Central equipment.

(free for use) .

AVE

Central equipment.

(free for use).

(free for use) .

AVO

AXR

(free for use).

(free for use).

Marshalling racks.

AXY Central equipment.

Marshalling racks.

(free for use).

(free for use).

AXZ

Central equipment.

(free for use) .

AW Instrument panels.

AWA Instrument panels.

Central equipment.

(free fo r use).

Marshalling racks.

AVC

Central equipment.

(free for use}.

(free for use) .

AVB

Central equipment.

(free for use).

AUG Open-loop control, checkback and

auxiliary equipment.

AVA

Uninterruptible power supply

system.

AY Communication equipment.

(free for use) .

AWB Instrument panels.

AYA

Telephone system

AYB

AYC

Control console telephone system.

Alarm system

AYD

Alarm system

(PABX).

(free for use) .

AWC Instrument panels.

(free for use).

(acoustic) .

AWD Instrument panels.

(free for use).

(optical).

AYE

AYF

AYG

AYH

AX Central equipment.

AXA

AXB

Battery chargers.

Battery plant.

119

Fire alarm system.

Clock system.

Remote control system.

Telemetry system.

"

GRJD AND DISTRIBUTION SYSTEMS

AYJ

AYK

AYL

AYM

AYN

AYP

AYQ

Remote metering system.

HF carrier telephone system.

StaH paging system, wireless.

StaH paging system, inductive.

StaH paging system, hardwired.

Opt ical monitoring system.

General gas alarm system.

(if not assigned to specific system).

AYS

Radiotelephone system.

s

POWER TRANSMISSION AND

AUXILIARY POWER SUPPLY

BA Power transmission.

BB Medium-voltage distribution boards and

transformers, normal system.

BC Medium voltage distribution boards and

transformers, general-purpose.

BD Medium voltage emergency distribution

boards and transformers, (diesel)

emergency power system.

BF Low voltage main distribution boards and

transformers, normal system.

BP Power installations for large variable·

speed drives (e.g. for feedwater pump,

excitation equipment, GT starting

equipment, not power adiusters in

·switchgear).

BR Low voltage distribution boards, converter,

uninterruptible power system (UPS) and

stand-by diesel power system.

BT BaHery and charger systems.

BU Direct current distribution boards.

BV Direct current distribution boards.

BH Low voltage main distribution boards and

transformers, general-purpose.

BJ

Low voltage subdistribution boards and

transformers, normal system.

BL Low voltage subdistribution boards and

transformers, general-purpose.

BM Low voltage distribution boards and

transformers, (diesel) emergency power

system 1.

BY Control and protection equipment.

POWER TRANSMISSION AND AUXILIARY POWER SUPPLY

BA Power transmission.

BC Medium voltage distribution boards and

transformers, general-purpose.

BAA Generator leads.

from excl . generator bushings, incl . current

and voltage tran sformers, cooling and

ventilation systems to excl . generator transformer low side bushings or to excl . auxiliary power transformer high side bushings .

BCA

Medium voltage distribution

boards, general-purpose.

BCB

Medium voltage distribution

boards, general-purpose.

BCC

Medium voltage distribution

boards, general-purpose.

BCD

Medium voltage distribution

boards, general-purpose.

(free for use) .

BAB

BAC

(free for use) .

Foundation cabinets.

Generator circuit breaker, also

commutating pole circuit breaker,

incl. cooling system.

BAT Generator transformers, including

cooling system.

BAU Earthing and lightning protection

systems.

BAX Fluid supply system for control and

protection equipment.

BAY Control and protection equipment.

(free for use) .

(free for use) .

BCE

Medium voltage distribution

boards, general-purpose.

BCF

Medium voltage distribution

boards, general-purpose.

BCG

Medium voltage distribution

boards, general-purpose.

BCH

Medium voltage distribution

boards, general-purpose.

(free for use) .

(free for use) .

BB Medium-voltage distribution boards and

transformers, normal system.

(free for use).

BBA

Medium voltage distribution

boards, normal system.

(free for use) .

(free for use).

BBB

BCT

Medium voltage distribution

boards, normal system.

BCX

(free for use).

BBC

Medium voltage distribution

boards, normal system.

(free for use).

BBD

Medium voltage distribution

boards, normal system.

BBE

Medium voltage distribution

boards, normal system.

BCY

Start-up, offsite, general-purpose

transformers.

Fluid supply system for control and

protection equipment.

Control and protection equipment.

BD Medium voltage emergency distribution

boards and transformers, (diesel)

emergency power system.

(free for use) .

BDA

Medium voltage distribution

boards, blackstart-purpose.

BDB

Medium voltage distribution

boards, blackstart-purpose.

BDC

Medium voltage distribution

boards, blackstart-purpose.

(free for use) .

(free for use) .

BBF

Medium voltage distribution

boards, normal system.

(free for use) .

(free for use).

BBG

Medium voltage distribution

boards, normal system.

(free for use) .

(free for use).

BBH

BDD

Medium voltage distribution

boards, normal system.

(free for use) .

(free for use).

BBT

BBX

BBY

Medium voltage distribution

boards, blackstart-purpose.

BDT

Medium voltage auxiliary power

transformers.

Fluid supply system for control and

protection equipment.

Control and protection equipment.

BDX

BDY

BDZ

122

Start-up, off site, blackstart-purpose

transformer.

Fluid supply system for control and

protection equipment.

Control and protection equipment

-blocked-.

y

POWER TRANSMISSION AND AUXILIARY POWER SUPPLY

BF Low voltage main distribution boards and

transformers, normal system.

BHH

Low voltage main distribution

boards, general purpose.

BHR

Low voltage auxiliary distribution

boards, general-purpose.

BHT

Lo~

voltage auxiliary power

transformers.

BHU

Low voltage auxiliary power

transformers.

BHV

Low voltage auxiliary power

transformers.

(free for use).

BFA

Low voltage main distribution

boards, normal system.

(free for use).

BFB

Low voltage main distribution

boards, normal system.

BFC

Low voltage main distribution

boards, normal system (ACC).

Low voltage main distribution

boards, normal system.

Lighting, ventilation, air cond itioning .

(free for use according to voltage level) .

(free for use).

BFD

(free for use accord ing to voltage level).

(free for use).

BFE

Low voltage main distribution

boards, normal system.

(free for use accord ing to voltage level).

BHW Low voltage auxiliary power

transforme rs.

(free for use).

BFF

BFG

Low voltage main distribution

boards, normal system (option e.g.

for heating & freezing protection).

Low voltage main distributio_n

boards, normal system.

(free for use).

BFH

Low voltage main distribution

boards, normal system.

BFT

Low voltage auxiliary power transformer.

{free for use acco rding to voltage level).

BHX

BHY

BJ

Low voltage subdistribution boards and

transformers, normal system.

BJA

(free for use).

BH Low voltage main distribution boards and

transformers, general-purpose.

Low voltage main distribution

boards, general purpose.

BJD

(free for use).

Low voltage main distribution

boards, general purpose.

BJH

(free for use) .

BHC

Low voltage main distribution

boards, general purpose.

BHD

Low voltage main distribution

boards, general purpose.

BHE

Low voltage main distribution

boards, general purpose.

Low voltage subdistribution boards

and transformers, normal system.

(free for use).

BJC

BHB

Low voltage subdistribution boards

and transformers, normal system.

(free for use).

BJB

d

BHA

Fluid supply system for control and

protection equipment.

Control and protection equipment.

Low voltage subdistribution boards,

normal system. Water treatment.

Low voltage subdistribution boards,

normal system.

Low voltage subdistribution boards,

normal system.

(free for use) .

BJT

Low voltage auxiliary power transformers.

(free for use).

BL Low voltage subdistribution boards and

transformers, general-purpose.

(free for use) .

BLA

(free for use).

»se

td

BHF

Low voltage subdistribution boards,

general-purpose.

(free for use) .

Low voltage main distribution

boards, general purpose.

BLB

(free for use).

Low voltage subdistribution boards,

general-purpose.

(free for use).

BHG Low voltage main distribution

boards, general purpose.

BLD

(free for use) .

Low voltage subdistribution boards,

general-purpose.

(free for use).

123

POWER TRANSMISSION AND AUXILIARY POWER SUPPLY

BLE

Low voltage subdistribution boards,

general-purpose.

BLF

Low voltage subdistribution boards,

general-purpose.

BMW Low voltage auxiliary power

transformers.

(free for use).

(free for use accord ing to voltage level).

BMX Fluid supply system for control and

protection equipment.

BMY Control and protection equipment.

(free for use).

BLG

Low voltage subdistribution boards,

general-purpose.

(free for use).

BLH

Low voltage subdistribution boards,

general-purpose.

BLT

Low voltage auxiliary power

transformer.

Fluid supply system for control and

protection equipment.

Control and protection equipment.

BP Power installations for large variable·

speed drives (e.g.for feedwater pump,

excitation equipment, gt starting equipment, not power adiusters in switchgear).

(free for use).

BLX

BLY

(e.g. for feedwater pump, excitation equipment,

not power adjusters in switchgear).

BPA

(free for use) .

BPC

BM Low voltage distribution boards and

transformers, (diesel) emergency power

system 1.

BPD

Power installations for large

variable-speed drives.

BPT

Transformer for large variablespeed drives.

BPX

Fluid supply system for control and

protection equipment.

Control and protection equipment.

(free for use) .

(free for use).

BMB Low voltage emergency distribution

boards.

(free for use).

(free for use).

BMC Low voltage emergency distribution

boards.

(free for use) .

Power installations for large

variable-speed drives.

(free for use).

BMA Low voltage emergency distribution

boards.

BMD Low voltage emergency distribution

boards.

Power installations for large

variable-speed drives.

BPY

BR Low voltage distribution boards, converter,

uninterruptible power system (UPS) and

stand-by diesel power system.

(free for use).

BME

Low voltage emergency distribution

boards.

BRA

Low voltage (UPS) distribution

boards.

BRB

Low voltage {UPS) distribution

boards.

(free for use).

BMF

(free for use).

Low voltage emergency distribution

boards.

(free for use).

(free for use).

BMG Low voltage emergency distribution

boards.

BRC

(free for use).

(free for use) .

BMH Low voltage emergency distribution

boards.

BRD

Low voltage emergency distribution

boards.

BRF

Low voltage emergency distribution

boards.

BRG

Low voltage emergency distribution

boards.

BRH

Low voltage emergency distribution

boards.

(free for use).

BMT

Low voltage emergency distribution

boards.

(free For use).

Low voltage auxiliary power transformers.

(free for use according to voltage level).

(free for use) .

BMU Low voltage auxiliary power

transformers.

(free for use according to voltage level).

(free for use).

BMV Low voltage auxiliary power

transformers.

(free for use according to voltage level) .

(free for use) .

124

y

POWER TRANSMISSION

BRT

BRU

BRV

d

BRX

BRY

AN~

Converter {rotary).

Converter {static), inverter.

Stand-by power generation

equipment.

Fluid supply system for control and

protection equipment.

Control and protection equipment.

id

r,

BaHeries 125 V or 220 V DC.

BaHeries 125 V or 220 V DC.

BaHeries.

BaHeries.

BaHeries 24 V DC.

BaHeries 24 V DC.

BaHery chargers 125 V or 220 V

DC.

BTM BaHery chargers 125 V or 220 V

DC.

BTN BaHery chargers.

BTP BaHery chargers.

BTQ BaHery chargers 24V DC.

BTR BaHery chargers 24 V DC.

BTS DC/DC converter 125 or 220/48 V

DC.

Bn

DC/DC converter 125 or 220/48 V

DC.

BTW Common equipment.

BTX Common equipment.

BTY Common equipment.

BTZ Common equipment.

BTA

BTB

BTC

BTD

BTE

BTF

BTL

Direct curre nt distribution boards.

BUL

Direct current distribution boards

48 v.

(free for use).

BUM Dire ct current distribution boards

48 v.

(fre.e for use).

BUX

BVA

Direct current distribution boards

125 V or 220 V.

BVB

Direct current distribution boards

125 V or 220 V.

(free for use).

{free for use).

BVC

on

BVE

on

BVF

BVG

on

Direct current distribution boards

48 v.

(free for use) .

BVM Direct current distribution boards

48 v.

Direct current distribution boards

125 V or 220 V.

{free for use).

Direct current distribution boards

125 V or 220 V.

(free for use).

BVY

BUD

Direct current distribution boards

BUG

Direct current distribution boards.

(free for use).

BVL

Fluid supply system for control and

protection equipment.

Control and protection equipment.

BY Control and protection equipment.

Direct current distribution boards

24 v.

BYA

Control and protection equipment.

Direct current distribution boards

24 v.

BYB

Control and protection equipment.

(free for use).

BYC

Control and protection equipment.

(free for use).

(free for use).

on

Direct current distribution boards

24 v.

(free for use).

BVH

BVX

BUF

Direct current distribution boards

24 v.

(free for use).

BUC

BUE

Direct current distribution boards

24 v.

{free for use).

Direct cur.rent distribution boards

125 V or 220 V.

{free for use).

Direct current distribution boards.

{free for use).

(free for use).

on

Direct current distribution boards

125 V or 220 V.

{free for use).

BVD

(free for use).

BUB

Fluid s~pply system for control and

protection equipment.

BV Direct current distribution boards.

BU Direct current distribution boards.

BUA

BUH

(free for use).

BT BaHery and charger systems.

·).

AUXILIARY POWER SUPPLY

(free for use) .

Direct current distribution boards

24 v.

(free for use).

BYD

{free for use).

Control and protection equipment.

(free for use).

125

INSTRUM ENTATION AND

CONTROL EQUIPMENT

(Identificatio n on a pri ority basi s accord ing

to main instrumentation and control function

also acceptable in composite structure

hardware packa ging sy stems}.

CA Protective interlocks.

CS Instrumentation and control equipment.

CB Functional group control, subloop control.

CU Closed-loop control (power section).

CC Binary signal conditioning.

CV Marshalling racks.

CD Drive control interface.

CW Control rooms.

CE Annunciation.

CG Closed-loop control (excl. power section).

CX Local control stations (e.g. for coal

handling plants, ash handling plants,

cooling water systems, diesel units, supervision of generator cooling,

remote shutdown station).

CH Protection (excl. reactor protection).

CY Communication equipment.

CF Measurement, recording.

CJ

Unit coordination level.

CK Process computer system.

CM Instrumentation and control equipment.

CN Instrumentation and control equipment.

CP Instrumentation and control equipment.

CQ Instrumentation and control equipment.

CR Instrumentation and control equipment.

-

~- 1--:-;-:--;-:-;-~

.

f.\=~= t==--~= ~'-' -~---"() . ._;

b --

ID

IT

19

INSTRUMENTATION. AND CONTROL EQUIPMENT

CA Protective interlocks.

CFD

Cabinets for measurement.

(free for use) .

)n

CAA

CFQ

Cabinets for protective interlocks.

(free for use).

re

CAB

CAC

CAD

5}.

Cabinets for protective interlocks.

Cabinets for protective interlocks.

Cabinets for protective interlocks.

Cabinets for recording (meters,

pen recorders).

CG Closed-loop control (excl. power section).

CGA Cabinets for closed-loop control.

CB Functional group control, subloop control.

CBA

(free for use).

(free for use).

er·

CGD

CH ·Protection (excl. reactor protection).

Cabinets for binary signal

conditioning.

Cabinets for binary signal

conditioning.

ceo

Cabinets for generator and

transformer protection.

CHB

Cabinets for generator and

transformer protection.

CHC

Cabinets for generator and

transformer protection.

CHD

Cabinets for generator and

transformer protection.

CHE

Protection (excl. reactor protection).

CHF

Protection (excl. reactor protection).

(free for use).

(free for use).

CCC

CHA

(free for use).

(free for use).

CCB

Cabinets for closed-loop control.

(free for use).

Binary signal conditioning.

CCA

Cabinets for closed-loop control.

Cabinets for auxiliary power

changeover.

(free for use)

cc

CGC

Cabinets for synchronization.

(free for use)

CBQ

Cabinets for closed-loop control.

(free for use).

(free for use).

CBP

CGB

Cabinets for DCS cubicles.

Cabinets for binary signal

conditioning.

(free for use).

(free for use) .

Cabinets for binary signal

conditioning.

(free for use).

(free for use).

(free for use).

CD Drive control interface.

(free for use).

CDA

Cabinets for drive control interface.

(free for use).

COB

CJ

(free for use).

CDC

CJA

Cabinets for drive control interface.

(free for use) .

COD

CJD

Cabinets for drive control interface.

(free for use).

CJF

CE Annunciation.

CEK

CJJ

Fault recording.

(free for use).

Instrumentation and control

cabinets for steam turbine set.

CJP

Cabinets for measurement.

Instrumentation and control

cabinets for gas turbine set.

Instrumentation and control

cabinets for gas turbine set.

(free for use).

(free for use) .

(free for use).

Cabinets for measurement.

(free for use).

CFB

Cabinets for measurement.

CJQ

(free for use) .

CFC

Unit control system (including

cabinets).

Start-up control, setpoint control

(unit) (incl. cabinets).

Boiler control system (incl.

cabinets).

Instrumentation and control

cabinets for steam turbine set.

CJK

CF Measurement, recording.

CFA

Unit coordination level.

Cabinets for drive control interface.

127

INSTRUMENTATION

AND CONTROL EQUIPMENT

.

CJU

Instrumentation and control

cabinets for other main and heavy

machinery.

CNC

(free for use).

CND

(free for use for system combination).

CK Process computer system.

CNT

Online supervisory and diagnostic

computer.

CKB

Online supervisory and diagnostic

computer.

(free for use).

CPA

Online supervisory and diagnostic

computer.

Instrumentation and control

equipment.

(free for use for system combination) .

CPB

(free for use).

Online supervisory and diagnostic

computer.

Instrumentation and control

equipment.

(free for use for system combination).

(free for use).

CKE

Instrumentation snd control

' equipment (network cubicles).

CP Instrumentation and control equipment.

(free for use).

CKD

Instrumentation and control

equipment.

(free for use for system combination) .

CKA

CKC

Instrumentation and control

equipment.

CPC

Instrumentation and control

equipment.

CPD

Online supervisory and diagnostic

computer.

(free for use for system combination).

CKJ

Access control computer.

Instrumentation and control

equipment.

(free for use).

(free for use for system combination).

CKK

Access control computer.

CKL

Access control computer.

(free for use).

(free for use).

CQ Instrumentation and control equipment.

(free for use).

CQA Instrumentation and control

equipment.

CKM Access control computer.

(free for use).

CKN

(free for use for system combination).

Process computer system.

(free for use).

lnstrumentatio~. and

Instrumentation and control

equipment.

CQC

Instrumentation and control

equipment.

CQD

Instrumentation and control

equipment.

(free for use for system combination).

CM Instrumentation and control equipment.

CMA

CQB

control

(free for use for system combination).

equipment.

(free for use for system combination).

CMB

Instrumentation and control

equipment.

(free for use for system combination).

(free for use for system combination) .

CMC

Instrumentation and control

equipment.

CR Instrumentation and control equipment.

(free for use for system combination) .

CRA

CMD Instrumentation and control

equipment.

(free for use for system combination).

(free for use for system combination).

CRB

Instrumentation and control

equipment.

CRC

Instrumentation and control

equipment.

CRD

Instrumentation and control

equipment.

CN Instrumentation and control equipment.

~

(free for use for system combination).

CNA Instrumentation and control

equipment.

(free for use for system combination) .

(free for use for system combination).

CNB

Instrumentation and control

equipment.

Instrumentation and control

equipment.

(free for use for system combination).

(free for use for system combination).

128

~T

INSTRUMENTATION. AND CONTROL EQUIPMENT

cs

Instrumentation and control equipment.

CWF Main control panels.

(free for use).

CSA

CSB

esc

CSD

Instrumentation and control

equipment.

CWG Main control panels.

(free for use for system combination).

CWH Main control panels.

(free for use) .

Instrumentation and control

equipment.

(free for use) .

CWJ

(free for use for system combination).

(fre'e for' use) .

Instrumentation and control

equipment.

CWP Main control panels.

(free for use for system combination).

CWQ Control rooms.

Instrumentation and control

equipment.

CWR Control rooms.

(free for use).

(free fo r use).

(free for use for system combination).

cu

Main control panels.

cws

Closed-loop control (power section).

(free for use).

Control rooms.

(free fo r use).

·CWT Control rooms.

CUA

Static excitation system or generator

voltage regulator.

cwu

(free for use).

CUB

cue

CUG

cv

Closed-loop control (power section).

Closed-loop control (power section).

Closed-loop control (power section).

(free fo r use).

ex

Marshalling racks.

CVA

eve

CXA Local control stations.

Marshalling racks.

(free for use).

(free for use).

Marshalling racks.

(free for use).

CVD

Local control stations.

CXD

Local control stations.

CXE

Local control stations.

CXF

Local control stations.

(free for use) .

(free for use) .

Marshalling racks.

(free for use) .

Marshalling racks.

(free for use) .

(free for use).

CVH

cxc

Marshalling racks.

(free for use).

CVG

Local control stations.

(free for use).

(free for use).

CVF

CXB

Marshalling racks.

(free for use).

CVE

Local control stations (e.g. for coal

handling plants, ash handling plants,

cooling water systems, diesel units, supervision of generator cooling,

remote shutdown station).

Marshalling racks.

(free for use).

CVB

(free fo r use) .

Control rooms.

CXG

Local control stations.

CXH

Local control stations.

Marshalling racks.

(free for use).

(free for use).

(free fo r use) .

CW Control rooms.

CXQ Local control stations.

(free for use) .

CWA Main control consoles.

(free for use).

CY Communication equipment.

CWB Main control consoles.

ewe

CYA

CYB

CYC

CYD

CYE

CYF

CYG

(free for use).

Main control consoles.

(free for use) .

CWD Main control consoles.

(free for use) .

CWE

Main control consoles.

(free for use).

129

Telephone system (PABX).

Control console telephone system.

Alarm system (acoustic).

Alarm system (optical).

Fire alarm system.

Clock system.

Remote control system.

INSTRUMENTATION AND CONTROL EQUIPMENT

CYH

Telemetry system.

CYH80

CYH90

CYH8

CYH9

CYJ

CYK

CYL

CYM

CYN

CYP

CYQ

CYR

CYS

Plant emission monitoring system,

Weather station.

Plant emission monitoring system

Weather station.

Remote metering system.

HF carrier telephone system.

Staff paging system, wireless.

Staff paging system, inductive.

Staff paging system, hardwired.

Optical monitoring system.

General gas alarm system (if not

assignet to a specific system).

Pneumatic tube conveyor.

Radiotelephone system.

J30

CONVENTIONAL FUEL SUPPLY

AND RESIDUES DISPOSAL

EA Unloading and storage of solid fuels.

EP Treatment of other fuels (use only for

combinations of different fuel types).

EB Mechanical treatment of solid fuels

(a lso for gas gene ration and tre atme nt)

(Crushing, mixing, drying, etc.).

EQ Conve rsion of othe r fue ls (use only for

combinations of different fuel types).

EC Distribution of solid fuels.

ER Ignition fue l supply.

ED Chemical treatment of solid fuels incl.

residues removal (e .g. d esulfurization

p lant).

ET

EE Conversion of solid fuels (Gas generation

and treatment see function key *R*).

Ash and slag re moval system (from excl.

removal e quipment).

EU Treatment and transport system for

combustion, fuel treatment, fuel conversion,

flue gas cleaning, gas generation

residues.

EG Supply of liquid fuels .

EV Lubricant supply system.

EH Chemical treatment of liquid fuels incl.

residues re moval.

EK Supply of gaseous fuels.

EL

Chemical treatment of gaseous fuels incl.

residues removal.

EM Supply and treatment of additive fuel s.

EN Supply of other fuel s (use only for

combinations of different fuel types).

EW Sealing/loose ning m edium supply.

EX Fluid supply system for control and

protection equipment.

EY Control and prote ction e quipment.

CONVENTIONAL FUEL S.UPPLY AND RESIDUES DISPOSAL

EA Unloading and storage of solid fuels.

EAA

EBE

Ship unloading system.

from incl. unloading equipment

to excl. tra nsport or storage plant.

EAB

from incl. receiving point

to excl. discharge into other system.

Rail wagon and truck unloading

bay.

EB~

from incl. unloading equipment

Transport system.

EBG

from incl. receiving point

to excl. storage incl. internal transport

from incl. receiving point

EBH

to excl. stacker.

EBJ

Bunker system, storage area

(stockyard).

EBK

EAY

recla imer or stacking system.

from incl. rece iving point

to excl. discharge into other system.

EBL

Weighing equipment.

Sampling equipment.

Lubricant supply system.

Fluid supply system for control and

protection equipment.

Control and protection equipment.

Transport system.

EBM

from incl. receiving poi nt

EBR

EBT

EBU

EBV

EBX

EBY

EC

II

to excl. discharge into other systems.

ECB

Crushing system, pulverizing

system.

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECC

Screening system.

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

from incl. receiving point

to excl . discharge into other system.

.L_

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

Mixing system.

from incl. receiving point

to excl. discharge into other system.

EBD

Residues removal system.

Weighing equipment.

Sampling equipment.

Lubricant supply system.

Fluid supply system for control

and protection equipment.

Control and protection equipment.

Distribution of solid fuels.

ECA

from incl. receiving point

to excl. discharge into other system.

EBC

Exhaust system.

to excl. d ischarge into other system.

from incl. receiving point

to excl. discharge into treatment or mixing

system.

EBB

Vapor compressor system.

from incl. receiving point

to excl. discharge into other system.

EB Mechanical treatment of solid fuels

(also for gas generation and treatment)

(Crushing, mixing, drying, etc.).

EBA

Dried coal temporary storage

system.

Bucket wheel system, reclaimer

system.

from excl. bunker system or stockyard

to excl . transport system .

EAT

EAU

EAV

EAX

Dried coal transport system incl.

aftercooling.

from incl. receiving point

to excl . d ischarge into other system.

from excl. unloading equipment or

transport system

to excl. transport or bucket wheel or

EAF

Main drying system.

from incl. receiving point

to excl. discharge into other system.

Stacking system.

from excl. transport system

to excl. storage plant.

EAE

Predrying system.

to excl. discharge into other system.

system within unloading and storage plant

EAD

Temporary storage system for

milled raw coal.

from incl. receiving point

to excl. discharge into other system.

to excl. transport or storage plant.

EAC

Separator system and discharge

equipment thereof - unless not

structural part of one of the former

systems (*EBA* to *EBD*).

to excl. discharge into other systems .

132

AIL

CONVENTIONAL FUEL SUPP.LY AND RESIDUES DISPOSAL

ECD

Distribution of solid fuels.

ECT

ECU

ECX

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

11er

ECE

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECF

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECG

ECY

ED Chemical treatment of solid fuels incl.

residues ~emoval (e.g. desulfurization

plant).

EDA

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECH

EDB

Distribution of solid fuels.

ECP

ECQ

EDE

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

Distribution of solid fuels.

(free for use).

EDF

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

EDG

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

EDH

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

EDJ

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

Distribution of solid fuels.

(free for use).

Distribution of solid fuels.

(free for use).

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ems)

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

(free for use).

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

lt.

EDD

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECN

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

(free for use).

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECM

EDC

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems .

ECL

(free for use) .

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ems)

ECR

ems)

(free for use).

Distribution of solid fuels.

EDK

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

EDL

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECS

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

(free for use) .

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECK

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

(free for use).

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

ECJ

Weighing equipment.

Sampling equipment.

Fluid supply system for control

and protection equipment.

Control and protection equipment.

(free for use).

Distribution of solid fuels.

(free for use according to transport systems)

from incl. receiving point

to excl. discharge into other systems.

(free for use).

133

CONVENTIONAL FUEL .SUPPLY AND RESIDUES DISPOSAl

EDM Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

EEJ

Conversion of solid fuels.

EEK

Conversion of solid fuels.

EEL

Conversion of solid fuels.

EEM

Conversion of solid fuels.

(free for use) .

(free for use).

EDN

(free for use).

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

(free for use).

(free for use).

EDP

' (free for use).

Chemical treatment of solid fuels

incl. residues removal (e.g.

desulfurization plant).

EER