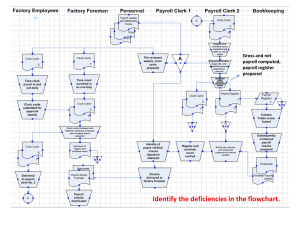

Chapter 4 A sales order processing diagram illustrates the steps involved in processing a customer's order within a business or organization. It outlines the sequence of actions, departments, and systems involved in fulfilling a customer's request for products or services. The process generally includes several stages from order placement to order fulfillment and delivery. Below is a basic breakdown of the key steps typically found in a sales order processing diagram: 1. Order Initiation: The process begins when a customer places an order. This can be done through various channels such as a company's website, phone call, email, or in-person. 2. Order Verification: The order details are reviewed to ensure accuracy, completeness, and validity. This step involves checking whether the requested products are available in the inventory and if the customer's information is correct. 3. Order Entry: The verified order information is entered into the company's order management system. This may include the customer's contact details, shipping address, product details, quantities, prices, and any special instructions. 4. Inventory Check: The inventory system is checked to determine whether the requested products are in stock and available for fulfillment. If items are out of stock, the process may involve backordering or notifying the customer of the delay. 5. Credit Check and Payment Processing: If applicable, a credit check may be conducted to assess the customer's creditworthiness. The payment information is processed, and the payment is authorized or charged. 6. Order Processing and Fulfillment: This stage involves picking the products from the inventory, packing them securely, and generating any necessary shipping labels or documents. The fulfillment process can vary depending on whether the company handles physical goods or digital products/services. 7. Shipping and Delivery: The packed products are handed over to the shipping department or a third-party logistics partner. Shipping options chosen by the customer are used to determine the shipping method and delivery timeframe. 8. Order Tracking and Communication: The customer may be provided with tracking information so they can monitor the progress of their order. Regular communication is maintained to keep the customer informed about any changes or delays. 9. Invoicing and Documentation: An invoice is generated detailing the ordered products, quantities, prices, taxes, and any additional charges. This document is usually sent to the customer along with the shipment. 10. Order Completion and Confirmation: Once the products are successfully delivered to the customer's specified address, a confirmation is sent to the customer. This confirms that the order has been fulfilled and provides an opportunity for the customer to report any issues. 11. Returns and Customer Support: If the customer wants to return or exchange products, there should be a clear process for handling such requests. Customer support plays a role in assisting customers with inquiries, issues, or returns. 12. Order Analytics and Reporting: Sales order data can be used for various purposes, including analyzing sales trends, forecasting inventory needs, and assessing the efficiency of the order processing system. Remember, the exact steps and processes can vary depending on the organization's size, industry, and specific procedures. Sales order processing diagrams help visualize these steps and the interactions between various departments and systems, aiding in process optimization and effective customer service. Short Question 1.Segregation of Functions: Sales Order Processing: Credit Authorization separate from SO Processing: This means that the individuals responsible for approving credit (allowing customers to make purchases on credit) should be different from those handling the sales order processing. This helps prevent conflicts of interest and reduces the risk of approving orders for customers with questionable credit. Inventory Control separate from Warehouse: Separating inventory control from the warehouse means that the individuals responsible for managing inventory levels and accuracy should be different from those responsible for physically handling and storing the inventory. This separation reduces the risk of theft or mishandling. Accounts Receivable Sub-ledger separate from General Ledger Control Account: The accounts receivable sub-ledger contains detailed information about individual customer accounts, while the general ledger control account summarizes the overall accounts receivable balance. Separating these functions helps prevent unauthorized changes to customer accounts and ensures accuracy. Cash Receipts Processing: Cash Receipts separate from Accounting Records: The individuals handling cash receipts (payments from customers) should be different from those responsible for maintaining the accounting records. This helps prevent embezzlement or manipulation of financial records. Accounts Receivable Sub-ledger separate from General Ledger: Similar to the previous point, this separation ensures that the detailed accounts receivable information is distinct from the summarized data in the general ledger. It prevents unauthorized adjustments or errors. 2.Access Controls Access to assets and information (accounting records) should be limited. Within the revenue cycle, the assets to protect are cash and inventories and access to records such as the accounts receivable subsidiary ledger and cash journal should be restricted. 3.Point-of-Sale Systems Point of sale systems are used extensively in retail establishments. Customers pick the inventory from the shelves and take them to a cashier. The clerk scans the universal product code (UPC). The POS system is connected to an inventory file, where the price and description are retrieved. the inventory levels are updated and reorder needs can immediately be detected. The system computes the amount due. Payment is either cash, check, ATM or credit card in most cases. No accounts receivables required. If checks, ATM or credit cards are used, an on-line link to receive approval is necessary. At the end of the day or a cashier’s shift, the money and receipts in the drawer are reconciled to the internal cash register tape or a printout from the computer’s database. Cash over and under must be recorded 4.Reengineering using EDI Electronic Data Interchange (EDI) can be utilized to automate and expedite the process of placing orders between a customer and a supplier. In this context, EDI streamlines the transaction by eliminating the need for human intervention and manual processes. Here's a breakdown of the process you've described: 1. Inventory Need Determination: The customer's computer system, likely integrated with their inventory management or enterprise resource planning (ERP) system, detects a need for specific products or inventory items. This could be triggered by factors such as reaching reorder points or anticipated customer demand. 2. Supplier Selection: The customer's system selects a supplier based on predefined criteria and a formal business agreement. This could include factors like price, delivery time, quality, and historical relationships. 3. Automated Order Placement: Once the supplier is determined, the customer's computer system initiates an automated order placement process. Instead of a human employee manually creating an order, the system automatically generates the necessary order details, including the products, quantities, and any other relevant information. CHAPTER 6 5.Payroll system A payroll system is a set of processes, software, and procedures used by organizations to manage and execute the payment of wages and salaries to their employees. It encompasses various tasks related to employee compensation, including calculating wages, deducting taxes and other withholdings, generating paychecks or direct deposits, and maintaining accurate records of earnings and deductions. The primary purpose of a payroll system is to ensure that employees are paid accurately and on time while complying with relevant tax and labor regulations. Here's a breakdown of each department's responsibilities and their interactions within the payroll process: Personnel Department: The personnel department handles personnel action forms to manage employee-related changes, including new hires, pay rate adjustments, changes in marital status, and terminations. These forms provide essential information to update employee records and initiate necessary processes. Production Employees: Production employees fill out two forms—job tickets to record time spent on specific production jobs and time cards to capture total time worked. These forms are signed by a supervisor to authenticate the accuracy of the reported data. Cost Accounting Department: The cost accounting department uses the job tickets to allocate labor costs to Work-in-Progress (WIP) accounts. They summarize these charges in a labor distribution summary, which is then sent to the General Ledger (G/L) department. Payroll Department: The payroll department receives personnel action forms and time cards. Their responsibilities include preparing the payroll register, entering relevant information into employee payroll records, generating paychecks, and sending both paychecks and a copy of the payroll register to the Cash Disbursements department and a copy of the payroll register to the Accounts Payable department. Accounts Payable Department: The Accounts Payable department prepares a cash disbursements voucher for the total amount of the payroll. Copies of this voucher are sent to the Cash Disbursements and General Ledger departments. Cash Disbursements Department: The Cash Disbursements department reviews and signs the paychecks before forwarding them to a paymaster for distribution to employees. Additionally, they write a check for the total payroll amount and deposit it into the payroll imprest account. General Ledger Department: The General Ledger department receives information from the cost accounting department and Accounts Payable department. They use this data to update relevant accounts and maintain accurate financial records. 6.Job tickets to record time spent on specific production jobs. The purpose of a job ticket is to accumulate the hours that an employee will be paid in the next payroll. job ticket ensures that the workers receive accurate payment. Time cards are used to capture total time worked. Moreover it is used to record the start and end time of tasks or simply the duration of the task. Timecards may contain a detailed breakdown of tasks accomplished by the individual(s) who worked on the task. The information can be used for project costing, job estimation, tracking, management, client billing and payroll. Tracking time can reduce an organization’s costs by making payroll processing more efficient, by making costs visible so you can lower them, and by automating billing and invoicing. These forms are signed by a supervisor to authenticate the accuracy of the reported data 7. computer based payroll system and manual payroll system. which one is better Whether a computer-based payroll system or a manual payroll system is better depends on various factors, including the size of the organization, the complexity of payroll processes, the budget, and the specific needs of the business. Here's a comparison of both systems to help you understand their advantages and disadvantages: Computer-Based Payroll System: Advantages: 1. Efficiency: Computerized systems can automate calculations, tax deductions, and other complex payroll tasks, saving time and reducing the chances of errors. 2. Accuracy: Automated calculations reduce the risk of manual errors, which can be common in manual systems. 3. Scalability: Computer systems are better suited for larger organizations with a significant number of employees. 4. Reporting: Computer systems can generate detailed reports and analytics that provide insights into labor costs, trends, and other important data. 5. Compliance: Automated systems often include built-in tax and regulatory compliance features to help ensure accurate and up-to-date payroll processing. Disadvantages: 1. Cost: Setting up and maintaining a computer-based payroll system can be expensive due to software, hardware, and training costs. 2. Complexity: Implementing and maintaining the system may require specialized IT knowledge and ongoing technical support. 3. Security Concerns: Data security is crucial, and computer systems can be vulnerable to cyberattacks if not properly secured. 4. Learning Curve: Employees may require training to use the system effectively. Manual Payroll System: Advantages: 1. Simplicity: Manual systems are generally simpler and more cost-effective for small businesses with few employees. 2. Control: Some organizations prefer the hands-on approach of manually calculating and managing payroll. 3. No Technical Dependencies: Manual systems don't rely on technology, so there's no risk of technical failures or system crashes disrupting payroll processing. 4. Privacy: Some businesses prefer not to store sensitive payroll information digitally due to security concerns. Disadvantages: 1. Time-Consuming: Manual calculations and paperwork can be time-consuming, especially as the organization grows. 2. Error-Prone: Manual calculations are more susceptible to errors, which can lead to incorrect pay and compliance issues. 3. Limited Reporting: Generating comprehensive reports and analytics may be challenging with a manual system. 4. Scalability Challenges: As the organization grows, manual systems can become overwhelming and inefficient. In most cases, computer-based payroll systems offer greater accuracy, efficiency, and scalability, especially for larger organizations. However, the decision ultimately depends on your organization's size, budget, technical capabilities, and the importance you place on accuracy and efficiency. Smaller businesses with limited resources might find manual systems sufficient, while larger businesses or those with complex payroll needs might benefit more from a computer-based system. Many businesses today opt for a hybrid approach, leveraging technology for payroll processing while maintaining manual oversight. 8.Batch Production System Production Planning and Control Materials and operations requirements Production scheduling Materials and Operations Requirements Materials requirement – the difference between what is needed and what is available in inventory Operations requirements – the assembly and/or manufacturing activities to be applied to the product Production Scheduling Coordinates the production of multiple batches Influenced by time constraints, batch size, and other specifications Work Centers and Storekeeping Production operations begin when work centers obtain raw materials from storekeeping. It ends with the completed product being sent tothe finished goods (FG) warehouse . Inventory Control Objective: minimize total inventory cost while ensuring that adequate inventories exist of production demand Provides production planning and control with tatus of finished goods and raw materials inventory Continually updates the raw material inventory during production process Upon completion of production, updates finished goods inventory EXTRA QUESTION ) A Bill of Materials is a structured list that provides detailed information about the components, materials, and subassemblies required to manufacture a final product or assembly. It's a critical document in manufacturing, production planning, and supply chain management. Here's a bit more detail: Bill of Materials (BOM): A BOM is used to outline the entire structure of a product, breaking it down into its constituent parts. Each part is listed along with its description, quantity, and sometimes additional attributes such as part numbers, suppliers, and cost. The BOM defines the hierarchy of components, showing how they are assembled to create the final product. 9. Route Sheet: The Route Sheet details the sequence of operations and steps that a product or batch will go through during the manufacturing process. Its primary purpose is to define the production path and provide a roadmap for how a product is assembled or processed Work Order: The Work Order specifies the exact materials, components, and production processes required to complete a specific batch or order. Its primary purpose is to provide detailed instructions for the production team to follow. Move Ticket - records work done in each work center and authorizes the movement of the batch Materials Requisition - authorizes the inventory warehouse to release raw materials for use in the production process