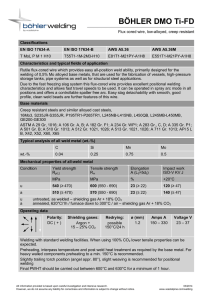

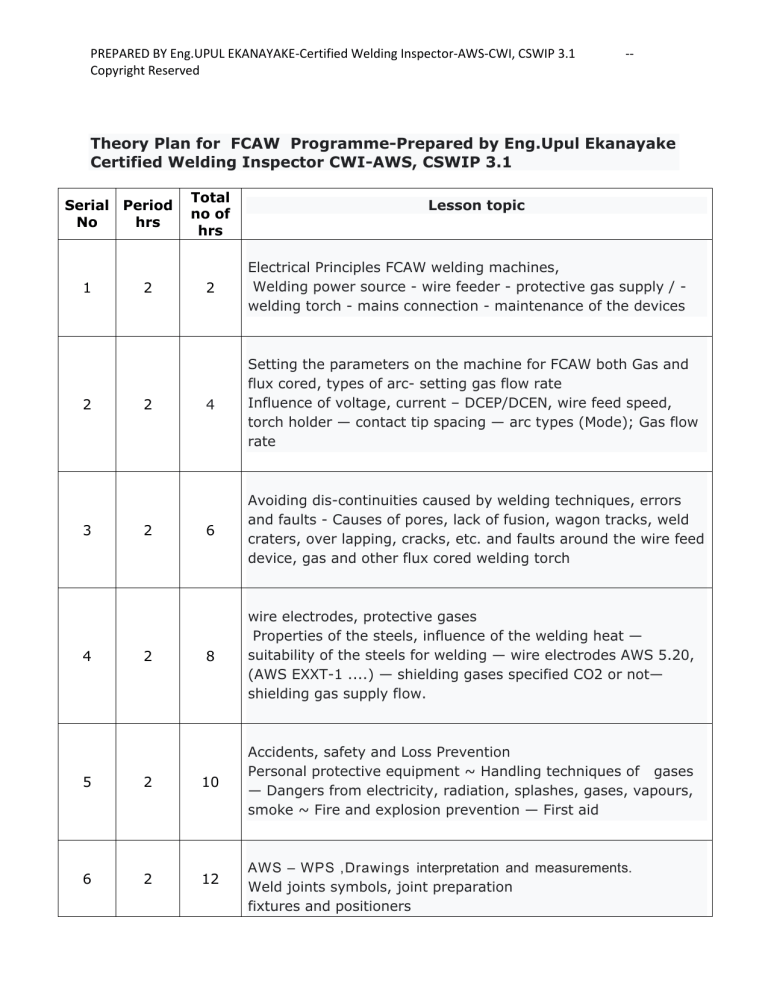

PREPARED BY Eng.UPUL EKANAYAKE-Certified Welding Inspector-AWS-CWI, CSWIP 3.1 Copyright Reserved -- Theory Plan for FCAW Programme-Prepared by Eng.Upul Ekanayake Certified Welding Inspector CWI-AWS, CSWIP 3.1 Serial Period No hrs 1 2 3 4 2 2 2 2 Total no of hrs Lesson topic 2 Electrical Principles FCAW welding machines, Welding power source - wire feeder - protective gas supply / welding torch - mains connection - maintenance of the devices 4 Setting the parameters on the machine for FCAW both Gas and flux cored, types of arc- setting gas flow rate Influence of voltage, current – DCEP/DCEN, wire feed speed, torch holder — contact tip spacing — arc types (Mode); Gas flow rate 6 Avoiding dis-continuities caused by welding techniques, errors and faults - Causes of pores, lack of fusion, wagon tracks, weld craters, over lapping, cracks, etc. and faults around the wire feed device, gas and other flux cored welding torch 8 wire electrodes, protective gases Properties of the steels, influence of the welding heat — suitability of the steels for welding — wire electrodes AWS 5.20, (AWS EXXT-1 ....) — shielding gases specified CO2 or not— shielding gas supply flow. Accidents, safety and Loss Prevention Personal protective equipment ~ Handling techniques of gases — Dangers from electricity, radiation, splashes, gases, vapours, smoke ~ Fire and explosion prevention — First aid 5 2 10 6 2 12 AWS – WPS ,Drawings interpretation and measurements. Weld joints symbols, joint preparation fixtures and positioners PREPARED BY Eng.UPUL EKANAYAKE-Certified Welding Inspector-AWS-CWI, CSWIP 3.1 Copyright Reserved pre heating and post heating. -- FCAW Practical plan *** Note:- this practical plan is scheduled to non-experienced in MIG/MAG personnel Se no 1 Period Total hrs hrs 2 2 Exercise task 2 12 16 Setting exercises for build-up welding with different types of arc systems constant – voltage/current 3 4 20 Flame cutting Work piece preparation. (Removal of all Dirt, oil, grease, corrosion around Joint area) 40 60 Wire Electrode diameter In mm Introduction to the handling of the devices for Gas Shielded Flux cored electrode, and SelfShielded Flux Cored Electrode. Work piece preparation. (Removal of all Dirt, oil, grease, corrosion around Joint area) 4 Welding Position Workpiec e thickness In mm Flat, up, 8 to12 Vertical up 10…12 Metal production tasks I-profile and base plate FCAW spot welding) Selected tasks Select specialist knowledge Selected tasks Tack weld back plate 0.8 to 2.4 0.8 to 1.2 Welding of V-Groove on Sheet metal with back 5 6 12 8 72 80 Weld checked for continuity, evenness, quality and completeness. Select Select Select PREPARED BY Eng.UPUL EKANAYAKE-Certified Welding Inspector-AWS-CWI, CSWIP 3.1 Copyright Reserved Visual and NDT test, no lack of fusion, undercuts, pores and cracks, slag inclusions, end crater etc. (Root pass, hot pass, capping Defects and causes) --