Two-Phase Natural Circulation Cooling of Core Catcher System

advertisement

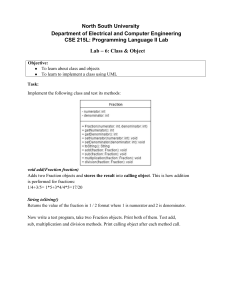

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/275255803 Study of Two-Phase Natural Circulation Cooling of Core Catcher System Using Scaled Model Article in Journal of Thermal Science and Engineering Applications · September 2015 DOI: 10.1115/1.4030249 CITATIONS READS 3 1,475 6 authors, including: Shripad T Revankar Bo Wook Rhee Purdue University Korea Atomic Energy Research Institute (KAERI) 355 PUBLICATIONS 2,820 CITATIONS 56 PUBLICATIONS 375 CITATIONS SEE PROFILE SEE PROFILE Some of the authors of this publication are also working on these related projects: Severe Accident Code Development, and Aerosol Transport Modeling in RCS and Containment of NPPs. View project Betavoltaic Evaluation View project All content following this page was uploaded by Shripad T Revankar on 21 October 2016. The user has requested enhancement of the downloaded file. Shripad T. Revankar1 Fellow ASME School of Nuclear Engineering, Purdue University and Pohang University of Science and Technology, 400 Central Drive, West Lafayette, IN 47906 e-mail: shripad@purdue.edu Kiwon Song DANE, Pohang University of Science and Technology, Pohang, Gyeongbuk 790-784, South Korea e-mail: k1song@postech.ac.kr B. W. Rhee Korean Atomic Energy Research Institute, Daejeon, Yuseong-gu 305-353, South Korea e-mail: bwrhee@kaeri.re.kr R. J. Park Korean Atomic Energy Research Institute, Daejeon, Yuseong-gu 305-353, South Korea e-mail: rjpark@kaeri.re.kr K. S. Ha Korean Atomic Energy Research Institute, Daejeon, Yuseong-gu 305-353, South Korea e-mail: tomo@kaeri.re.kr Study of Two-Phase Natural Circulation Cooling of Core Catcher System Using Scaled Model A two-phase natural circulation cooling has been proposed to remove melted core decay heat by external core catcher cooling system during sever accident scenario. In this paper, two types of the core catcher cooling loops, one with heated loop and the other adiabatic loop simulated with air water system are analytically studied. First, a scaling analysis was carried out for natural circulation flow in a closed loop. Based on the scaling analyses, simulation of two-phase natural circulation is carried out both for air–water and steam–water system in an inclined rectangular channel. The heat flux corresponding to the decay heat is simulated with steam generation rate or air flux into the test section to produce equivalent flow quality and void fraction. Design calculations were carried out for typical core catcher design to estimate the expected natural circulation rates. The natural circulation flow rate and two-phase pressure drop were obtained for different heat inputs or equivalent air injection rates expressed as void fraction for a select downcomer pipe size. These results can be used to scale a steam water system using scaling consideration presented. The results indicate that the air–water and steam water system show similar flow and pressure drop behavior. [DOI: 10.1115/1.4030249] J. H. Song Korean Atomic Energy Research Institute, Daejeon, Yuseong-gu 305-353, South Korea e-mail: dosa@kaeri.re.kr Introduction Single-phase and two-phase natural circulations have been employed in a number of industrial thermal transport systems including nuclear reactor cooling systems. These systems are based on thermally induced density gradients in single-phase fluid or buoyancy due to two-phase gas–liquid mixture, which induce circulation of the working fluids without need for any external power or mechanical moving parts such as pumps and pump controls. Such systems have increased reliability and safety and reduce installation, operation, and maintenance costs. Recently, natural circulation cooling has been proposed to remove nuclear reactor decay heat during severe accident scenario where the reactor core might experience high temperature leading to core melt. Designs for external vessel cooling for in-vessel core retention using natural circulation have been studied [1–4]. Similarly, if the corium is discharged from the reactor vessel, the ex-vessel corium cooling in the containment will be considered [5,6]. There are currently two reactor systems that have fully developed ex-vessel corium retention systems, a crucible-type catcher developed for Russian nuclear power plants with a VVER-1000 reactor [7] and a core catcher with melt spreading developed for the European pressurized reactor (EPR) [8]. In the design of EPR, the corium is captured and spread into a large lateral compartment, which is then followed by flooding, quenching, and cooling with water drained 1 Corresponding author. Contributed by the Heat Transfer Division of ASME for publication in the JOURNAL OF THERMAL SCIENCE AND ENGINEERING APPLICATIONS. Manuscript received June 29, 2014; final manuscript received January 12, 2015; published online April 15, 2015. Assoc. Editor: Suman Chakraborty. passively from an internal reservoir, the in-containment refueling water storage tank (IRWST). Recently, Song et al. [9] have developed a core catcher concept for ex-vessel corium cooling, where a core catcher plate is placed directly under reactor vessel that arrests the corium and is cooled by natural circulation. The natural circulation flow is similar to external vessel cooling where water flows through an inclined narrow gap below hot surface and is heated to produce boiling. The two-phase natural circulation enables cooling of the corium pool collected on core catcher. This core catcher is a passively actuating device, which can arrest, stabilize, and cool the molten core material inside the reactor cavity and thus reduce its impact on containment pressurization. Primary goal of the proposed ex-vessel core catcher is to reliably accommodate and rapidly stabilize the corium, including the entire core inventory and reactor internals which are injected into the cavity following a postulate severe accident. The core catcher body made of carbon steel is to be placed inside the reactor cavity under a reactor vessel. Molten corium discharged from the reactor vessel is to be collected and spread inside the core catcher body, which is made of lower walls and side walls. Proposed core catcher provides a feature for a natural circulation driven cooling, which is schematically shown in Fig. 1. It consists of a core catcher body made of carbon steel and a sacrificial material located on top of the core catcher body. The thickness of the carbon steel is selected such that the maximum heat transfer allowed by conduction is 200 kW/m2. As shown in Fig. 1, after the molten corium is relocated to the core catcher body the water will be flooded from the bottom to the top of the molten corium. The water will be flooded from IRWST by the gravity. Journal of Thermal Science and Engineering Applications C 2015 by ASME Copyright V SEPTEMBER 2015, Vol. 7 / 031006-1 Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms must be removed by the bottom side of the plate where the water flow is driven by natural circulation. As a conservative estimation, half of the 20 MW is considered to be removed from the coolant channel water flow. Thus, the channel coolant is required to remove 10 MW heat from the bottom side of the core catcher plate. For a reasonable size of the model test facility to simulate coolant channel performances, a channel width of 0.3 m is considered instead of 16 m as in prototype. The corresponding heat removal requirement power from this model coolant channel is given as 0:3m=16 m 10 MW ¼ 187:5 kW Fig. 1 Core catcher concept with natural circulation cooling with two-phase flow under core plate and return circulation through downcomer The ability of natural circulation cooling of the core catcher plate dictates its effectiveness in retaining the corium. The core catcher system has a large water supply that circulates through an inclined channel where the upper core catcher plate is cooled by the water flow in the channel. The two-phase natural circulation is driven by steam–water boiling process at inclined region. The geometry of cooling channel is rectangular with an inclined channel section (inclination angle of 10 deg) followed by a vertical section. The flow starts from a single-phase liquid and with boiling processes bubbles are generated in the flow. Hence, various flow regimes are possible as void fraction increases along the cooling channel. Hence, the flow in the channel is continuously developing as the steam quality is increasing. The flow rate is function of the heat flux and flow loop losses. The present paper is a simulation of a prototype natural circulation flow in core cooling system which has heated boiling section. In the simulation, a prototype system and scaled model system were considered at prototype condition with steam–water at one atmosphere. Simulation was also carried out with air–water system on scaled model. Instead of heated boiling system, the air water system with distributed air injection along flow channel is used in the simulation study. The objective of the paper is to predict the natural circulation flow rates and expected pressure drop in loop and their dependent on the flow losses in the natural circulation loop with air water system as well as in heated loop. Model System Design Considerations Scaled System Design. The design of scaled facility is carried out using set of geometrical parameters of core catcher cooling system proposed by Song et al. [9]. As shown in Fig. 1, the prototype core catcher cooling channel is symmetric at the center of the core catcher plate. Each half of the symmetrical section of the cooling channel has a horizontal section where single-phase water enters, an inclined channel with 10 deg inclination, a vertical section that opens up to the water pool. The total length of this channel is about 4 m where heat is transferred from the core plate to the flowing water. The channel height is 10 cm and the width of the channel is 16 m. There are 13 downcomer pipes of diameter 15 cm located at equal distance along the width of channel. The total decay heat associated with the corium is considered at 40 MW assuming 1% of the 4000 MW reactor power 1 hr after reactor shutdown in an accident sequence. Since the core catcher is symmetrical only half of the channel is modeled. Hence, total power removal requirement for each side of the channel is 20 MW. The corium on the plate is submerged in water pool; substantial heat is removed from the top water pool. Remaining heat 031006-2 / Vol. 7, SEPTEMBER 2015 (1) The reason for choosing a 0.3 m width channel is based on the largest stable bubble size in water, which is about 0.1 m–0.15 cm [10,11] and can be estimated by using the maximum cap bubble size Db as rffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi r (2) Db ¼ 40 gðqf qg Þ The system scales for components in the scaled model are shown in Table 1. Instead of heated section and steam generated due to boiling, air is used to simulate the two-phase flow in the coolant channel. The heat flux corresponding to the decay heat is simulated with air flux to the test section to produce equivalent flow quality and void fraction. The upper tank is also simplified with single tank where two-phase separation occurs and downcomer line is connected. A schematic of the test geometry is shown in Fig. 2, where the steam generated is replaced by air injection rate. For this design, the following parameters were matched between the prototype and the scaled facility: heat flux, mass flux, exit void fraction, total pressure drop, and friction coefficient. Thus, scaled facility has same channel height and length along the flow direction as the prototype but with scaled down channel width. Scaling Parameters. The similarity laws and scaling criteria are required for design, operation, and analysis of simulation experiments using a scaled model. The scaling of the two-phase flow is carried out using the transient form of governing equations, mass, momentum, and energy balances based on onedimensional drift-flux model [12–14]. For a two-phase natural circulation system, similarity groups have been developed from a perturbation analysis to these governing equations. The four equation drift-flux model consisting of the mixture mass, momentum and energy equations, and vapor continuity equation is analytically integrated along the flow path. From this, the integral response functions between various variables such as the velocity, density, void fraction, enthalpy, and pressure drop are obtained. The nondimensionalization of these response functions yields the key integral scaling parameters. From these, the scaling criteria for dynamic simulation can be obtained. The important dimensionless groups that characterize the kinematic, dynamic, and energy similarities are given as follows [12]: ! 000 4qo dlo Dq (3) phase change no: Npch qg duo qf if g ! isub Dq subcooling no: Nsub (4) qg ifg 2 uo qf (5) Froude no: NFr glo ao Dq Vgj drift-flux no: Ndi ðvoid quality relationÞ (6) uo i time ratio no: Ti lo =uo d2 =as (7) i Transactions of the ASME Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms Table 1 Geometrical parameters for model and prototype core catcher cooling system Component Downcomer Horizontal part Inclined part Vertical part Heating power Prototype Air–water modeling 6.6 m A0.15 m, N ¼ 13 0.3 m 0.1 m 16 m 2.74 m 0.1 m 16 m, 10 deg 1 m 0.1 m 16 m 10 MW, 0.5–100% 6.6 m A0.1 m, N ¼ 1 0.3 m 0.1 m 0.3 m 2.74 m 0.1 m 0.3 m, 10 deg 1 m 0.1 m 0.3 m 187.5 kW, 0.5–100% qs cps d qf cpf d i # 2 " 1 þ x Dq=qg fl ao Nfi D i 1 þ xDl=lg 0:25 ai thermal inertia ratio Nthi friction no: orifice no: h i a o 2 Noi Ki 1 þ x3=2 Dq=qg ai where ao, the reference void fraction in Eq. (5), is given by ! qf 1 ao ¼ Dq 1 þ ðNd þ 1Þ= Npch Nsub (8) (9) (10) (11) The phase change number, Npch is the scale for the amount of heating and vapor flow generation by phase change whereas the subcooling number, Nsub is the scale for the cooling in the condensation section or the pressurization of liquid relative to the saturation condition. For steady state, Npch and Nsub are related by Dq xe ¼ Npch Nsub (12) qg where xe is the vapor quality at the exit of the heated section. The scaling of the natural circulation with air–water system requires fluid–fluid scaling consideration for flow dynamic similarity. The void fraction is related to quality through void-quality relation. ! Dq ðxe ÞR ¼1 (13) qg R This indicates that the vapor quality should be scaled by the density ratio. If this condition is satisfied, the friction similarity in terms of Nfi and Noi can be approximated by dropping the terms related to the two-phase friction multiplier. Furthermore, by definition it can be shown that Nd ¼ Dq xe qg ! qf 1 1 Dqao (14) Therefore, similarity of the drift-flux number requires void fraction similarity Dq ðae ÞR ¼ 1 or ðae ÞR 1 (15) qf R The drift-flux number takes into account the drift effects due to the relative motion of the fluid. Thus, it plays an important role in the two-phase flow which is similar to diffusion processes. Also, since Vgj depends on the flow regime, this group parameter also characterizes the flow pattern. The density ratio group, given by the (Dq/qg) term, scales the fluids. This also appears in the groups Nsub, Npch, Nf, and No. The representative constitutive equation for the relative motion based on the drift velocity correlation is given by 1 rffiffiffiffiffi qg rgDq 4 j þ 1:4 Vgj ¼ 0:2 1 qf q2f (16) where the volumetric flux, j, in the heated section is given by !! Dq j¼ 1þx (17) uo qg The classical void-quality correlation is qg lg a ¼ a x; ; ; etc: qf lf (18) The relative motion similarity based on the drift velocity correlation becomes !# 1 rffiffiffiffiffi" qg Dq 1:4 rgDq 4 Nd ¼ 0:2 1 1þx (19) þ qg uo qf q2f Natural Circulation Flow Rate and Pressure Drop The loop mass flow rate in the coolant channel is determined by a balance between the pressure drop and hydrostatic head difference. The basic governing equations involved matching total buoyancy pressure drop due to the presence of gas phase with the total pressure loss in the flow loop. Pressure drop of the system is made up of two parts, due to single-phase flow along the downcomer and two-phase flow in the test section. Pressure drop in single-phase flow is calculated by X L qv2 Kþf (20) Dps ¼ d 2 f ¼ 0:316 Re1=4 Fig. 2 Schematic of air–water simulation loop Journal of Thermal Science and Engineering Applications (21) Two-phase pressure drop is made up of three parts in the inclined, vertical test sections and at the bends with abrupt changes in area SEPTEMBER 2015, Vol. 7 / 031006-3 Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms DpTP ¼ Dpinclined þ Dpvertical þ Dplocal (22) For each part of the two-phase pressure drop, it can be obtained by dp dp ¼ /2 (23) dL tp dL l l where (dp/dl) is the equivalent single-phase pressure gradient and can be expressed by fw ql v2w dp ¼ dl l 2d (24) Two-phase multiplier is crucially important in determining the two-phase performance ! ql qg fm 2 1þx (25) /lo ¼ flo qg In Eq. (25), the Fanning friction factor is defined by equations [15,16] " fm ¼ 2 8 Rem 12 þ " am ¼ 2:457 ln flo ¼ 2 8 Relo (26) ðam þ bm Þ3=2 #16 (27) ð7=Rem Þ0:9 þ0:27e=d 37530 16 Rem 12 þ " alo ¼ 2:457 ln #1=12 1 bm ¼ " 1 1 (28) #1=12 (29) ðalo þ blo Þ3=2 #16 1 ð7=Relo Þ0:9 þ0:27e=d blo ¼ 37530 16 Relo (30) (35) (1) Horizontal part: L ¼ 300 mm, L/D 1, the slip ratio is assumed to be approximately unity, S ¼ 1. This is based on the data by Franc and Lahey [18] for horizontal air–water flow with various flow regimes, stratified, wavy, and slug, where the distribution coefficient C0 was observed to be close to 1. (2) Inclined part: L ¼ 2740 mm, D ¼ 200 mm, L/D ¼ 13.7, inclination angle ¼ 10 deg. We can obtain slip ratio by linear interpolation based on horizontal and vertical model (0 deg and 90 deg). (3) Vertical part: L/D ¼ 5, not fully developed. L/D ¼ 20 can be regarded as fully developed condition. The interpolations can be depicted in Fig. 3 for inclined and vertical parts, respectively. The total pressure drop is sum of two-phase flow pressure drop in inclined and vertical channel and single-phase flow pressure drops in downcomer channel and is given as 1 1 xe 2 fLtwo 1 þ ðR 1Þ m þ K Dptotal ¼ two lp 2 qf A 2 D 2 fLsp 1 1 þ (36) m2 þ Ksp 2 qf A2 lp D It consists of skin friction and geometric loss. As there will be a flow blockage in the coolant channel, we included the geometric loss K factor. Here, R is density ratio, which is defined as qf/qg. Ltwo is the length of two-phase region, Lsp is the length of singlephase region, Ktwo is the geometric K factor in the two-phase region, and Ksp is the geometric K factor in the single-phase region. A is the flow area. Here, xe is the flow quality at the exit. As the density ratio R is in the order of 1000, we can neglect the second term in Eq. (36), and let’s assume that the length of two-phase region is close to L. Then, the pressure drop can be approximated as Dptwo ¼ (32) C0 ð1 C0 aÞ C0 a C0 a 1 þ qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi pffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi gd h Dq=ql gdh Dq=qg As seen from Eqs. (34) and (35), the drift velocity is not explicit, so iteration calculations are necessary to obtain the results. Since the channel of the test section is complicated, it can be treated separately in different parts when calculating the slip ratios: (31) Zuber–Findlay drift-flux model [14] defines void fraction and velocity in two-phase flows based on some measurable quantities Vg ¼ C0 j þ Vgj Vgj ¼ 1 1 Q 2 fL xe þ K 1 þ ðR 1Þ 2 qf A2 xe ifg D 2 (37) We will assume that the inlet flow is saturated for simplicity in the analysis. The energy balance in the heating section determines the exit flow quality Void fraction based on the drift-flux model can be given by a¼ jg C0 jg þ Vgj (33) where the two parameters, distribution coefficient C0 and drift velocity Vgj are crucial to the system. A drift-flux model by Sonnenburg [17] is applied to calculate slip ratio in the present study, where the distribution coefficient and the drift velocity can be described by C0 ¼ ð1 þ 0:32Þ 0:32 qffiffiffiffiffiffiffiffiffiffiffi qg =ql 031006-4 / Vol. 7, SEPTEMBER 2015 (34) Fig. 3 The interpolations in terms of the inclined angle and length Transactions of the ASME Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms Q ¼ mlp ifg xe (38) The driving head, which is difference between the water column and two-phase column in the coolant channel, is as below: Dpdr ¼ DqaHg ¼ xe R DqHg xe ðR 1Þ þ 2 Table 2 Scaling ratios for prototype and scaled model Component Loop (39) Coolant channel where the relation between the void fraction and flow quality is used by assuming that there is slip between liquid velocity and vapor velocity as given by a¼ 1 1 x ug 1þ x Ruf (40) For assumed downcomer pipe size and given air flow rate corresponding to the heat flux, the void fraction and the mass flow rates were calculated. Both homogenous two-phase flow and a driftflux model were assumed for the two-phase system. The calculation procedure is shown in Fig. 4. Results and Discussion Scaling Results. The scaled down model facility is scaled at power ratio of 0.01875. The following requirements were imposed on the facility design. The scaled model should have similar heat flux, mass flux, exit void fraction, frictional coefficient in each components, and total loop drop ðqÞP ¼ ðqÞM (41) ðae ÞP ¼ ðae ÞM (42) ðGÞP ¼ ðGÞM X X L L Kþf ¼ Kþf d P d M (43) ðDptotal ÞP ¼ ðDptotal ÞM (45) (44) However, it should be noted that the mass flux and total pressure drop are dependent on void fraction and loss coefficients. In Table 2, the ratios of key scaling parameters are shown. One of the key design parameter is the choice of the downcomer pipe size. Only distortion between the model and the prototype was in the hydraulic diameter of the coolant channel. As it turns out that Downcomer Description Ratio (model/prototype) Total L/D Power Minor loss coefficient 1 0.01875 1 Flow area Heat flux Power Hydraulic diameter Exit void Length 0.01875 1 0.01875 0.75 1 1 Flow area with 7.6 cm pipe Flow area with 7.87 cm pipe L/D 0.01861 0.01875 1 the single-phase pressure drop is a major contributor to the total loop pressure drop. Hence, the distortion of the hydraulic diameter did not impact the natural circulation flow rate. From Table 2, the flow area ration between the prototype and model downcomer should be same as the power ratio of 0.01875. When this criterion is used, the downcomer pipe size for model is 7.87 cm (3.1 in.). Since commercial pipes available are in sizes 7.6 cm (3 in.) and 8.9 cm (3.5 in.). If 7.6 cm pipe is used for the model facility, then the downcomer flow area ratio is 0.0186 which is about 8% from the ideal scaling ratio of 0.01875. In the calculations of the natural circulation flow rate for the model loop, both 7.6 cm and 8.9 cm downcomer pipes sizes are used for comparison. Homogeneous Flow Results. Design calculations were carried out for prototype core catcher cooling system, the scaled model with steam–water and model with air–water system to estimate the expected natural circulation rates, void fraction, and pressure drop characteristics. For homogenous flow, no slip between gas and liquid phase is assumed. The maximum power (qmax) assumed is 10 MW for the prototype and that for the model is 187.5 kW and this power was considered to be uniformly distributed. Thus, the calculations presented represent a uniform heat flux condition. However, in real situation the distribution of heat flux may vary along the coolant channel length. The integrated void generation will still be the calculated exit void fraction for given heat flux. Though the flow regimes may be different along the length of the channel, the buoyancy force that drives natural circulation flow does not change. Since the majority of the pressure drop is in the single-phase flow in downcomer pipe, the flow regime has little impact on the total pressure drop. Thus, the natural circulation rates calculated assuming the constant heat flux can be applied to distributed heat flux condition. The present models address both air water and vapor–water flow systems. In the steam–water system simulation, the heat fluxes typical of the corium decay heat generate vapor along the channel length from top plate. The void fraction changes along the channel length. As used in the present calculations for uniform heat flux, the void changes linearly with channel length. For calculation of the pressure drops in each section, the average void fraction was accounted by the following way. The two-phase flow channel is divided in to five sections using location of air injection as shown in Fig. 2. For each section area, weighted void fraction was calculated, ði aðxÞwdx i ¼ 1; 5 (46) ai ¼ i1 ði wdx i1 Fig. 4 Natural circulation flow rate calculation Journal of Thermal Science and Engineering Applications where w is the width of the channel. For uniform heat flux, the void fraction also uniformly linearly changes with distance. Then, the averaged void fraction at section i is given as SEPTEMBER 2015, Vol. 7 / 031006-5 Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms ai ¼ ðai þ ai1 Þ=2 (47) Equation (37) was used to calculate the two-phase pressure drop for each of these five sections using an average void fraction for each section given by Eq. (47). Then, these each pressure drops were added to obtain the total two-phase pressure drop. In the buoyancy force calculations, channel average void fraction was calculated using the five section values. In Figs. 5–10, the results are presented for steam–water systems. In Figs. 5(a) and 5(b), the mass flow rate and the mass flux are shown as function of nondimensional heat load, q/qmax, for prototype core catcher coolant loop, the model loop with 7.6 cm (3 in.) downcomer pipe, and the model loop with 8.9 cm (3.5 in.) downcomer pipe. The mass flow rate for prototype is 589 kg/s that corresponds to maximum heat load of qmax ¼ 10 MW. Similarly at maximum power for the model loop at qmax ¼ 187.5 kW, the mass flow rate in the model loop with 7.6 cm downcomer pipe is 11.8 kg/s and that with 8.9 cm downcomer pipe is 14.6 kg/s. As shown in Fig. 5(b), mass flux for the prototype is slightly higher than mass flux for the model loop with 7.6 cm downcomer pipe. The model loop with 8.9 cm diameter downcomer pipe has quite higher mass flux compared to prototype mass flux. So for the design, 8.9 cm pipe seems as an appropriate sized pipe since one can easily introduce additional losses with valve or orifice to match the prototype mass flux with the scaled model. The exit void fraction is shown in Fig. 6 for different heat loads. The profiles of exit void fraction for all three cases look similar. Fig. 5 (a) Natural circulation mass flow rate and (b) mass flux as function of heat load in the prototype and steam–water model loop 031006-6 / Vol. 7, SEPTEMBER 2015 Fig. 6 The exit void fraction as function of heat load in the prototype and air–water model loop The difference of the exit void fraction between prototype and the model with 7.6 cm downcomer pipe is less than 3%. It should be noted that this agreement between the model and the prototype is due to heat flux similarity. The exit void fraction reaches almost 90% for maximum heat flux considered. This indicates a highly turbulent two-phase flow in the channel. The total pressure drop in the entire loop and the two-phase pressure drop at the cooling channel are shown in Figs. 7(a) and 7(b) as a function of nondimensional heat load. Total loop pressure of 12.7 kPa was predicted for heat load qmax. The dependence Fig. 7 (a) Total loop pressure drop and (b) two-phase pressure drop at different heat loads Transactions of the ASME Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms Fig. 10 Comparison of natural circulation mass flux predicted using homogeneous model and drift-flux model in the model facility with 7.6 cm downcomer pipe Fig. 8 (a) Single-phase, two-phase, and total pressure drop and (b) the liquid velocity in downcomer pipe as a function of exit void fraction for model loop with 7.6 cm diameter downcomer Fig. 11 Single-phase, two-phase, and total pressure drop (kPa) against nondimensional heat load Fig. 9 Comparison of exit void fraction predicted using homogeneous model and drift-flux model in the model facility with 7.6 cm downcomer pipe of the total loop pressure drop on the heat load is similar to the exit void fraction. The two-phase pressure drop for model loop with 7.6 cm downcomer pipe is 2.4 kPa and that for prototype is 1.78 kPa. These values are very small compared to the total pressure drop. In Fig. 8(a), the single-phase, two-phase, and total Journal of Thermal Science and Engineering Applications Fig. 12 Slip ratios between gas and liquid phase at inclined and vertical section of the cooling channel as function of heat drops are shown for the model loop with 7.6 cm downcomer pipe as function of exit void fraction. Thus, the single-phase pressure drop in downcomer section is the largest contributor to the total loop pressure drop. In Fig. 8(b), the downcomer velocity is shown SEPTEMBER 2015, Vol. 7 / 031006-7 Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms scenarios. A scaling analysis was performed to simulate a prototype core catcher cooling system with two-phase natural circulation loop. Key similarity parameters were identified for simulation of the two-phase natural circulation. A scaled down test facility design was conceived based on the scaling analysis. The natural circulation mass flux and system pressure drop were calculated for both prototype and the scaled model facility. Based on the calculation results, a proper sized downcomer pipe for the model facility was obtained. Various pare metric results are presented that characterize the natural circulation phenomena in the core catcher cooling systems. Using the scaling parameters, one can easily relate these results obtained from the scaled facility to the prototype condition. Acknowledgment Fig. 13 Natural circulation flow rates in a model test loop with air–water and steam–water system as function of the exit void fraction for the model loop with 7.6 cm downcomer pipe. The downcomer water velocity increases nonlinearly with increase in the exit void fraction. Drift-Flux Model Results. Figures 9–13 show the calculation results assuming drift-flux model for model loop with downcomer pipe size of 7.6 cm (3 in. size). The mass flux is shown in Fig. 9 as function of nondimensional heat load. When compared the mass flux results from drift-flux model show lower values than homogeneous flow based model at higher heat flux. In Fig. 10, the exit void fraction is presented as a function of nondimensional heat load. It can be seen that it has a similar trend as that with a homogeneous model, except that the void fractions predicted using drift-flux model are about 10% lower than those predicted from the homogeneous model. In Fig. 11, the single-phase pressure drop in the downcomer line, two-phase pressure drop in cooling channel, and the total pressure drop based on drift-flux model are compared with total pressure based on homogenous model. The single-phase pressure drop dominates the total flow resistance for void fractions below exit void fraction of 80% after which the two-phase pressure drop is higher than single-phase pressure drop. The total pressure drop calculated from the drift-flux model shown is higher than the one calculated with homogenous flow model. In Fig. 12, the slip ratios between gas and liquid phase at the inclined section and in vertical section are shown. Either in the inclined or in the vertical part, the flow seems more complex than that with a homogeneous model. Furthermore, the slip ratios are relatively small less than 2.5. This work was supported by the Korean Atomic Energy Research Institute and Pohang University of Science and Technology under BK21 Plus program. Nomenclature a¼ A¼ cp ¼ C0 ¼ d¼ D¼ f¼ g¼ G¼ H¼ i¼ ifg ¼ j¼ K¼ l¼ L¼ m¼ N¼ Nd ¼ Nf ¼ NFr ¼ No ¼ Npch ¼ Nsub ¼ Nth ¼ p, P ¼ q¼ Q¼ R¼ Re ¼ T* ¼ u¼ Vgj ¼ x¼ cross-sectional area (m2) flow area (m2) specific heat (J/kg C) distribution coefficient conduction depth diameter (m) friction factor gravitational acceleration (m/s2) mass flux (kg/m2 s) height (m) enthalpy (J/kg) latent heat of vaporization (J/kg) superficial velocity (m/s) minor loss coefficient length (m) length, two-phase axial length (m) mass flow rate (kg/s) nondimensional number drift-flux number friction number Froude number orifice number phase change number subcooling number thermal inertia ratio number Pressure (Pa) heat flux (W/m2) heat or power (W) ratio of fluid density to gas density Reynolds number time ratio number velocity (m/s) drift velocity (m/s) quality Simulation With Air–Water System. To simulate the twophase natural circulation using air–water adiabatic system instead of heated steam–water, the distributed vapor generation on the core plate is done by injecting air at several distributed locations along natural circulation channel that gives equal amount of void fraction along the channel length. Similar to void fraction (steam fraction) increase along the channel in the heated system (the prototype system), the simulated loop will have similar increase of air fraction as it accumulates along the length of the channel. In Fig. 13, the natural circulation flow rates and mass flow rate calculations as functions of exit void fraction are shown for model loop with 7.6 cm downcomer pipe for air–water system and for steam water system. The air–water system flow rates are about 8% lower than the steam–water system flow rate. This is due to lower density of the steam compared to air density. Greek Symbols Conclusions Subscripts Passive cooling based on natural circulation is utilized in core catcher system of advanced reactors to handle severe accident 031006-8 / Vol. 7, SEPTEMBER 2015 a¼ as ¼ D¼ d¼ l¼ q¼ r¼ void fraction thermal diffusivity (m2/s) difference between quantities conduction depth (m) dynamic viscosity (kg/m s) density (kg/m3) surface tension (N/m) e ¼ exit f ¼ liquid Transactions of the ASME Downloaded From: http://thermalscienceapplication.asmedigitalcollection.asme.org/ on 04/15/2015 Terms of Use: http://asme.org/terms g¼ i¼ lo ¼ lp ¼ m¼ M¼ o¼ P¼ s¼ sp ¼ sub ¼ two ¼ th ¼ gas ith component liquid only liquid phase two-phase mixture model reference point/component prototype surface single phase subcooling two phase thermal Superscript * ¼ dimensionless quantity References [1] Song, J. H., Kim, S. B., and Kim, H. D., 2000, “An Analysis of Natural Circulation Cooling of a Reactor Vessel During Severe Accidents by RELAP5/MOD3 Computer Code,” Proceedings of the Korean Nuclear Society Spring Meeting, Kori, Korea, pp. 1–10. [2] Song, J. H., Kim, S. B., and Kim, H. D., 2002, “Analysis of External Cooling of the Reactor Vessel During Severe Accidents,” Nucl. Technol., 138(1), pp. 79–89. [3] Rempe, J. L., Suh, K. Y., Cheung, F. B., and Kim, S. B., 2003, “In-Vessel Retention Strategy for High Power Reactors,” Final Report, Idaho National Engineering and Environmental Laboratory, Report No. INEEL/EXT-04-02561. [4] Ha, K. S., Park, R. J., Song, J. H., Kim, J. T., and Cheung, F. B., 2004, “A NonHeating Experimental Study on the Two-Phase Natural Circulation Through the Annular Gap Between Reactor Vessel and Insulation Under External Vessel Cooling,” ICAPP’04, Pittsburgh, PA, June 13–17, pp. 1721–1728. [5] Farmer, M. T., Kilsdonk, D. J., and Aeschlimann, R. W., 2009, “Corium Coolability Under Ex-Vessel Accident Conditions for LWRs,” Nucl. Eng. Technol., 41(5), pp. 575–602. Journal of Thermal Science and Engineering Applications [6] Zhong, H., 2011, “A Study on the Coolability of Ex-Vessel Corium by Late Top Water Flooding,” M.S. thesis, Royal Institute of Technology, Stockholm, Sweden. [7] Kukhtevich, I. V., Bezlepkin, V. V., Granovskii, V. S., Bechta, S. V., and Gusarov, V. V., 2001, “The Concept of Localization of the Corium Melt in the Ex-Vessel Stage of a Severe Accident at a Nuclear Power Station With a VVER-1000 Reactor,” Therm. Eng., 48(9), pp. 699–706. [8] Fisher, M., 2004, “The Severe Accident Mitigation Concept and the Design Measures for Core Melt Retention of the European Pressurized Re-Actor,” Nucl. Eng. Des., 230(1–3), pp. 169–180. [9] Song, J. H., Ha, K. S., Park, R. J., Kim, J. T., and Cheung, F. B., 2011, “A Core Catcher Design for the Advanced Light Water Reactor,” Proceedings of the International Conference on Advanced Nuclear Power Plants (ICAPP), Nice, France. [10] Batchelor, G. K., 1987, “The Stability of a Large Gas Bubble Rising Through Liquid,” J. Fluid Mech., 184(1), pp. 399–422. [11] Kataoka, I., and Ishii, M., 1987, “Drift Flux Model for Large Diameter Pipe and New Correlation for Pool Void Fraction,” Int. J. Heat Mass Transfer, 30(9), pp. 1927–1939. [12] Ishii, M., Revankar, S. T., Leonardi, T., Dowlati, R., Bertodano, M. L., Babelli, I., Wang, W., Pokharna, H., Ransom, V. H., R. Viskanta, R., and Han, J. T., 1998, “The Three-Level Scaling Approach With Application to the Purdue University Multi-Dimensional Integral Test Assembly (PUMA),” Nucl. Eng. Des., 186(1–2), pp. 177–211. [13] Ishii, M., and Katoka, I., 1984, “Scaling of Laws for Thermal-Hydraulic System Under Single Phase and Two-Phase Natural Circulation,” Nuc. Eng. Des., 81, pp. 411–425. [14] Zuber, N., and Findlay, J., 1965, “Average Volumetric Concentration in TwoPhase Systems,” ASME J. Heat Transfer, 87(4), pp. 453–468. [15] Awad, M. M., and Muzychka, Y. S., 2004, “A Simple Two-Phase Frictional Multiplier Calculation Method,” Proceedings of the IPC 2004 International Pipeline Conference (IPC04-0721), Calgary, AB, Canada, Oct. 4–8, pp. 1–9. [16] Churchill, S. W., 1977, “Friction Factor Equation Spans All Fluid Flow Regimes,” Chem. Eng., 84(24), pp. 91–92. [17] Sonnenburg, H. G., 1989, “Full-Range Drift-Flux Model Base on the Combination of Drift-Flux Theory With Envelope Theory,” Proceedings of the Nuclear Reactor Thermal Hydraulics NURETH-4, Vol. 2, pp. 1003–1009. [18] Franca, F., and Lahey, R. T., Jr., 1992, “The Use of Drift-Flux Techniques for the Analysis of Horizontal Two-Phase Flows,” Int. J. Multiphase Flow, 18(6), pp. 787–801. SEPTEMBER 2015, Vol. 7 / 031006-9 publicationhttp://thermalscienceapplication.asmedigitalcollection.asme.org/ stats DownloadedViewFrom: on 04/15/2015 Terms of Use: http://asme.org/terms