sensors

Article

Dynamic Vehicle Detection via the Use of Magnetic

Field Sensors

Vytautas Markevicius *, Dangirutis Navikas, Mindaugas Zilys, Darius Andriukaitis,

Algimantas Valinevicius and Mindaugas Cepenas

Received: 12 November 2015; Accepted: 4 January 2016; Published: 19 January 2016

Academic Editor: Andreas Hütten

Department of Electronics Engineering, Kaunas University of Technology, Studentu St. 50–418,

LT-51368 Kaunas, Lithuania; dangirutis.navikas@ktu.lt (D.N.); mindaugas.zilys@ktu.lt (M.Z.);

darius.andriukaitis@ktu.lt (D.A.); algimantas.valinevicius@ktu.lt (A.V.); mindaugas.cepenas@ktu.edu (M.C.)

* Correspondence: vytautas.markevicius@ktu.lt; Tel.: +370-37-300-522

Abstract: The vehicle detection process plays the key role in determining the success of intelligent

transport management system solutions. The measurement of distortions of the Earth’s magnetic field

using magnetic field sensors served as the basis for designing a solution aimed at vehicle detection.

In accordance with the results obtained from research into process modeling and experimentally testing all

the relevant hypotheses an algorithm for vehicle detection using the state criteria was proposed. Aiming

to evaluate all of the possibilities, as well as pros and cons of the use of anisotropic magnetoresistance

(AMR) sensors in the transport flow control process, we have performed a series of experiments with

various vehicles (or different series) from several car manufacturers. A comparison of 12 selected

methods, based on either the process of determining the peak signal values and their concurrence in

time whilst calculating the delay, or by measuring the cross-correlation of these signals, was carried out.

It was established that the relative error can be minimized via the Z component cross-correlation and Kz

criterion cross-correlation methods. The average relative error of vehicle speed determination in the best

case did not exceed 1.5% when the distance between sensors was set to 2 m.

Keywords: magnetic field; AMR sensors; vehicle speed detection

1. Introduction

Intelligent transport [1], smart cities [2,3] and the Internet of Things [4] are terms that surround all

of us nowadays. One of the key factors allowing one to consider intelligent solutions [3–5] specifically

designed for urban areas is the constantly decreasing price of sensors capable of providing information

about traffic flows, environmental conditions and other parameters. The processes of integrating

sensors into the existing infrastructure and forming large sensor networks has thus become increasingly

less complicated. In turn, the physical medium is less disrupted and society gains access to a brand

new quality of life, facilitated by environmentally responsive public services, continual surveillance

and a direct connection with other information users [6].

The capability to detect vehicles is the main element in intelligent transport management systems,

allowing us to gather information about the traffic intensity and vehicle speed. Amongst the most

popular transport sensors are induction loops, commonly used due to their low price and relatively

high signal quality. However, the process of installing such devices normally results in significant

damage to an extensive area of the road surface and the loop itself may suffer from the thermal

expansion of the road pavement. Anisotropic magnetoresistance (AMR) sensors are an alternative to

induction loops capable of measuring even extremely weak magnetic fields. When a vehicle is above

the sensor, its metal construction distorts the Earth’s magnetic field and this allows one to determine

the location of the vehicle.

Sensors 2016, 16, 78; doi:10.3390/s16010078

www.mdpi.com/journal/sensors

Sensors 2016, 16, 78

2 of 9

Magnetoresistive sensors are small, so their installation and maintenance are much less complex

and pricey in comparison to induction loops. Nevertheless, since their introduction, they have been

subject to little scrutiny or testing in this particular application area.

As the Earth’s magnetic field distortion signal can be used not only for the detection, but also

for the classification and recognition of transport vehicles [7], it is highly important to ensure sensor

effectiveness and the repetition rate of the recognized signal. Various objects and processes taking place

in the surrounding environment have a major impact on the readings of magnetic sensors. The factors

determining the success of locating a vehicle are multiple, therefore, distinguishing the distortions

of the magnetic field caused by the vehicle from those caused by certain environmental changes is a

rather difficult task [8,9]. The accuracy of locating vehicles in the environment with no undesirable

objects affecting the magnetic field would be significantly higher, but, unfortunately, the possibilities

of creating such an environment are slim to none at all. Taking that into account, in comparison to road

induction loops the process of locating vehicles using magnetic fields is way more complicated. When

conducting the task of locating a vehicle using the magnetic field method, these external factors must

be eliminated. The literature analysis reveals that the majority of research in the field of AMR sensors

has been carried out in laboratories, which indicates the lack of practical research activity when it

comes to real transport vehicles and road environment conditions [10].

2. Related Works

Previous research papers mostly addressed the problems related to the detection of vehicles

parked on parking lots or in car parks [11]. The measurement system based on AMR sensors

was thus created for the purpose of locating vehicles using the Earth’s magnetic field distortion

method. It comprises magnetoresistive sensors produced by four different manufacturers and

researchers have focused on analyzing the temperature stability and parameter spread influence

on detection relevant to reliability [12]. Following a lengthy period of observation, the researchers

determined several shortcomings of the method, which were as follows: dependence of the sensor

signal on temperature, residual magnetic moment and diffusion of the sensor parameters during the

manufacturing process [13]. Upon analyzing the impact of the vehicle construction on the magnetic

field changes in the parameters of the mounted sensors, it was determined that said construction plays

a vital role in terms of magnetic field distortion and sensor output signals. Even vehicles of similar

construction impact the magnetic field components differently when entering and exiting a parking

space. The amplitude and form of an AMR sensor signal is also dependent on how the sensors and

vehicles are arranged in terms of their positions magnetic fieldwise [13]. When a vehicle is on top of

the sensor, in some cases one can determine the critical zones which display no change in the magnetic

field. Based on modeling and practical research results, researchers have proposed a location algorithm

reliant on the state criteria. It has been established that the most accurate way of determining the state

of the parking location sensors relies on the use of complex criteria [14]. Via the use of this method the

researchers observed a 93.3% detection effectiveness.

In the case of moving vehicles, the majority of the proposed stationary vehicle detection methods

have been proven unsuitable due to the need to not only record the fact of the vehicle’s presence, but

also measure its speed and the dependence of the magnetic field distortions on the vehicle construction.

It is noteworthy that the majority of publications contain algorithms and methods designed to locate

vehicles and determine their speed via the use of AMR sensors, yet most of these papers lack any

consideration of the fact that small sensors can be passed by vehicles following different trajectories,

which can significantly complicate the task of determining the vehicle type.

The bottom of the vehicle under the engine is commonly magnetically open whilst the engine

section holds a generator and the ignition starter, each of which generate their own operating magnetic

fields. In between the engine department and vehicle interior there is typically a steel (magnetic)

partition, similar to the ones found between multiple interior and baggage compartments. Much of

uncertainty is caused by the aforementioned partitions, knowing that regardless of their distance to

Sensors 2016, 16, 78

Sensors2016,

2016,16,

16,7878

Sensors

3 of 10

3 of

3 of

109

distance to the AMR sensor, they can act as a vehicle driving nearby, or the one being located above,

distance

to the

sensor, they

can act

a vehicle

driving nearby, or to

thea one

being located

above,of

i.e.,

sum

ofAMR

thethey

magnetic

field

itsas

separate

components,

partition

the vicinity

the the

AMR

sensor,

can act

as and

a vehicle

driving

nearby, or subject

the one being

locatedinabove,

i.e., the

i.e.,

the sum of the magnetic

field and

its separate

components,

subject tonotion

a partition in

vicinity of

the

sensors,

increase

or

decrease.

Therefore,

thethe

Z component

summagneto-resistive

of the magnetic field

andcan

its separate

components,

subject tothe

a partitionthat

in the

vicinity

of the

the

magneto-resistive

sensors,

can increase

or decrease.

Therefore,

the notion

that

the

Z component

of

the

Earth’s

magnetic

field

increases

under

the

vehicle

is

not

necessarily

true

in

all

cases,

and

this

magneto-resistive sensors, can increase or decrease. Therefore, the notion that the Z component

of

ofcan

thesignificantly

Earth’s magnetic

field

increases

under

the

vehicle

is

not

necessarily

true

in

all

cases,

and

this

complicate

the process

of identifying

located in

thein

same

line asand

thethis

sensor.

the Earth’s magnetic

field increases

under

the vehicle aisvehicle

not necessarily

true

all cases,

can

can significantly complicate the process of identifying a vehicle located in the same line as the sensor.

significantly complicate the process of identifying a vehicle located in the same line as the sensor.

3. Experiments

3.3.Experiments

Experiments

An experiment was conducted with 24 various models of cars produced by different

An

was

conducted

with

ofof cars

by

different

An experiment

experiment

was

conducted

with 24

24 various

various

models

cars produced

produced

by sensors

different

manufacturers

seeking

to evaluate

the possibilities

as wellmodels

as

pros and

cons

of

using AMR

in

manufacturers

seeking

to

evaluate

the

possibilities

as

well

as

pros

and

cons

of

using

AMR

sensors

in

manufacturers

seeking to

evaluate

the possibilities

well as pros

and

cons of1)using

AMR sensors

in

the

control of transport

flows.

A brand

new vehicleas

scanning

system

(Figure

was designed,

which

the

transport

flows.

AAbrand

scanning

system

(Figure

1)1)was

which

thecontrol

control

transport

flows.

brandnew

new

vehicle

scanning

system

(Figure

was

designed,Vehicle

which

allowed

usofofto

measure

the distortion

of vehicle

the

Earth’s

magnetic

field

caused

by designed,

vehicles.

allowed

to measure

measure

the

distortion

of the

Earth’s

field

caused

by measurement

vehicles.

Vehicle

allowed us

uswas

to

the

distortion

the

Earth’s

magnetic

field caused

by

vehicles.

Vehicle detection

detection

conducted

using

twoof

sensors

located

atmagnetic

a distance

of 30

cm.

The

was

detection

was

conducted

using

two

sensors

located

at

a

distance

of

30

cm.

The

measurement

was

was conducted

using

twoalong

sensors

a distance

of 30capturing

cm. The measurement

was carried

carried

out every

1 cm

thelocated

X axis at

direction

whilst

the vehicle position

and out

the

carried

every

1the

cmX along

the X along

axis

direction

whilst

capturing

therepeated

vehicle

position

andalong

the

every 1out

cm

along

axis

direction

whilst

the

vehicle

and the

magnetic

field

magnetic

field

parameters.

Scanning

thecapturing

direction

of

the

X axis position

was

every

20 cm

magnetic

fieldScanning

parameters.

Scanning

alongof

the

of the

X axisevery

was

every

cm alongof

parameters.

along

the direction

thedirection

X axissensors

was

repeated

20 cm along

the20direction

the

direction

of

the Y axis

whilst

moving

both

AMR

(Figure

2). repeated

the

of themoving

Y axis whilst

moving

both(Figure

AMR sensors

(Figure 2).

thedirection

Y axis whilst

both AMR

sensors

2).

RS485

RS485

RS485

RS485

I2C

I2C

I2C

I2C

Distance

Distance

meter

meter

MicroMicrocontroller

controller

MSP430

MSP430

Figure 1. Experiment structure.

Figure1.1.Experiment

Experimentstructure.

structure.

Figure

20cm

20cm

Y

Y

Y

AMR

AMR

X

X

Y

X

X

AMR

AMR

40cm

40cm

Figure 2.

2. Vehicle

Vehicle scanning

scanning scheme.

scheme.

Figure

Figure 2. Vehicle scanning scheme.

For the purpose of gathering data a digital distance measuring instrument was used, which

For the purpose of gathering data a digital distance measuring instrument was used, which

transferred

all the data

via a RS 485

communication

port to a computer where

it was

then

For the all

purpose

of gathering

dataserial

a digital

distance measuring

was used,

which

transferred

the data

via a RS 485

serial

communication

port to ainstrument

computer where

it was

then

processed with

the specifically

designed

software.

The data acquired

from thewhere

sensor

the

RS

transferred

all the

via a RSdesigned

485 serial

communication

to a from

computer

it via

wasRS

then

processed with

thedata

specifically

software.

The data port

acquired

the sensor via

the

485

485 port. with

The process

of transferring

data

and reading

theacquired

data from

the the

AMR

sensors

via RS

the485

I2C

processed

the

specifically

designed

software.

The

data

from

sensor

via

the

port. The process of transferring data and reading the data from the AMR sensors via the I2C interface

interfaceprocess

was carried

out using data

a low-power

MSP430

microcontroller.

port.

of transferring

and reading

the data

from the AMR sensors via the I2C interface

was The

carried out using

a low-power MSP430

microcontroller.

The Earth’s

magnetic

field distortions

were detected on different vehicles. A sample set of the

was carried

out

using

a

low-power

MSP430

microcontroller.

The Earth’s magnetic field distortions were detected on different vehicles. A sample set of the

Earth’s

magnetic

field distortions

data caused

by detected

several of them

is provided

in Figure

3. The

research

The

Earth’s magnetic

field distortions

were

different

vehicles.

A sample

setresearch

of the

Earth’s magnetic

field distortions

data caused

by several ofon

them

is provided

in Figure

3. The

results

indicate

that

the

change

in

the

magnetic

field

modulus

and

separate

components

when

the

Earth’s

fieldthe

distortions

by several

of them isand

provided

in Figure

3. The when

research

resultsmagnetic

indicate that

change data

in thecaused

magnetic

field modulus

separate

components

the

vehicle is driven

on top change

of the magneto-resistive

sensor

is different

and

depends

on the vehicle

brand

results

that

in the magnetic field

modulus

andand

separate

components

when

the

vehicleindicate

is driven

on the

top of the magneto-resistive

sensor

is different

depends

on the vehicle

brand

vehicle is driven on top of the magneto-resistive sensor is different and depends on the vehicle brand

Sensors 2016, 16, 78

Sensors 2016, 16, 78

4 of 9

4 of 10

andthe

theposition

positionofofsensors

sensorswith

withrespect

respecttotoa aparticular

particular

vehicle

(Figure

This

reason

behind

and

vehicle

(Figure

3).3).

This

is is

thethe

reason

behind

the

the that

fact

that

when

a

vehicle

passes

the

sensor

in

different

places

(with

respect

to

the

Y

axis),

very

fact

when

a

vehicle

passes

the

sensor

in

different

places

(with

respect

to

the

Y

axis),

very

diverse

Sensors 2016, 16, 78

4 of 10

diverse magnetic

field are

profiles

are recorded.

As the

a result,

the based

methods

based on measuring

and

magnetic

field profiles

recorded.

As a result,

methods

on measuring

and comparing

and

the

position

of

sensors

with

respect

to

a

particular

vehicle

(Figure

3).

This

is

the

reason

behind

comparing

absolute

values arefor

unsuitable

detecting

the

type of

and

speed of vehicles.

absolute

values

are unsuitable

detectingfor

the

type and

speed

vehicles.

the factcompleting

that when athe

vehicle

passes the sensor

different data,

places (with

the magnetic

Y axis), very

Upon

interpolation

of acquired

the inacquired

fullofrespect

view

ofto the

field

Upon

completing the

interpolation

of the

data, a full aview

the magnetic

field distortion

diverse

magnetic

field

profiles

are

recorded.

As

a

result,

the

methods

based

on

measuring

andare

distortion

caused

by

a

vehicle

was

acquired

(Figure

4).

From

the

data

it

can

be

noticed

that

there

caused by a vehicle was acquired (Figure 4). From the data it can be noticed that there are a number

comparing absolute values are unsuitable for detecting the type and speed of vehicles.

a areas

number

of areas

as “Dead

zone”)

under the

vehicle

where the magnetic

field

remains

of

(marked

as (marked

“Dead the

zone”)

under

the

where

the magnetic

remains

undistorted

Upon completing

interpolation

ofvehicle

the acquired

data,

a full viewfield

of the

magnetic

field

undistorted

(as

if

the

vehicle

was

not

present

at

all).

Such

situations

are

critical

when

using

AMR

(as if the

vehicle

was by

nota vehicle

presentwas

at all).

Such

situations

arethe

critical

sensors

distortion

caused

acquired

(Figure

4). From

data itwhen

can be using

noticedAMR

that there

are for

sensors

for

determining

the

presence

of

a

vehicle

in

a

static

state.

determining

theofpresence

of a vehicle

in azone”)

static state.

a number

areas (marked

as “Dead

under the vehicle where the magnetic field remains

1000

Y1

400

600

800

1000

-200

-600

0

-200

400

600

800

1000

200200

400

600

Z1

800

1000

1200

M ag m etic field , m G

200

400

200

0

200

400

0

200

400

600

800

600 cm

X position,

800

400

1000

800

1000

1200

Y2

400

600

800

1000

1200

X position, cm

400

600

Z2 800

1000

1200

X position, cm

Z2

800

600

600

400

400

200

200

0

200

0

1200

1000

Y2

600

X position, cm

800

600

1200

-200

M ag m etic field , m G

M ag m etic field , m G

400

1000

0

-400

200

Z1

800

600

800

X position, cm

-200

X position, cm

800

600

0

-400

200

1200

400

200

X position, cm

-600

200

-600

-800

1200

Y1

-400

-800

200

1200

X position, cm

-400

-600

200

M ag m etic field , m G

800

200

M ag m e tic fie ld , m G

-400

600

-4000

X position, cm

0

-200

400

-600

-800

200

200

M ag m e tic fie ld , m G

-400

X2

200

-200

M ag m e tic field , m G

-800

200

0

-200

M ag m e tic fie ld , m G

-600

0

M ag m e tic fie ld , m G

-400

X1

200

-200

M ag m e tic field , m G

0

M ag m e tic field , m G

M ag m e tic field , m G

undistorted (as if the vehicle was not present at all). Such situations are critical when using AMR

X1

X2

200sensors for determining the presence of a vehicle in a static

200 state.

1200

200

400

400

X position, cm

600

800

1000

600 X position,800

cm

1000

1200

X position, cm

Figure

3.3.The

of

magnetic

measured

by

twodistinct

distinctsensors

sensors

(plots

ofmagnetic

magnetic

Figure

The

distribution

of the

the

field

distinct

sensors

(plots

Figure

3.distribution

The distribution

of the

magnetic

fieldmeasured

measured by

by two

two

(plots

of of

magnetic

field

X1,

and

X2,

Y2,

Z2

ofZ2

sensors

1 and

2 respectively).

PlotPlot

curves

areare

color

coded

fieldcomponents

components

X1,Y1,

Y1,Z1

Z1

and

X2,

Y2,

Z2

ofofsensors

11 and

22 respectively).

respectively).

Plotcurves

curves

are

color

field

components

X1,

Y1,

Z1

and

X2,

Y2,

sensors

and

color

by

sensor

along

latitudinal

vehiclevehicle

line.

coded

by position

sensor

position

along

latitudinal

coded

by sensor

position

along

latitudinal

vehicleline.

line.

VehicleNo.

No.11

Vehicle

Z1

Z1

Z1

Z1

800

800

700

Dead zone

700

Dead zone

200

Magmetic field, mG

400

600

Magmetic field, mG

600

Magmetic field, mG

Magmetic field, mG

600

400

200

0

0

200

200

Yp

Yp

150

os

iti o

n

150

os

iti o

n

100

,c

m

100

,c

m

50

200

0

50

0

200

400

600

800

800

, cm

600

osition

400 X p

m

c

,

n

io

X posit

1000

1000

600

500

500

400

400

300

300

200

200

100

1000

0

-100

-100

Figure 4. Cont.

Figure 4. Cont.

Figure 4. Cont.

0

0

200

200

400

600

X position, cm

400

600

X position, cm

800

800

1000

1000

1200

Sensors 2016, 16, 78

5 of 9

Sensors 2016, 16, 78

5 of 10

Vehicle No 2

Z1

Z1

700

Magmetic field, mG

Magmetic field, mG

600

600

500

400

300

200

200

Yp

150

100

os

iti o

n,

cm

50

400

200

0

600

X positi

800

1000

500

Dead zone

400

300

200

on, cm

100

0

200

400

600

X position, cm

800

1000

800

1000

Vehicle No. 3

Z1

Z1

650

600

Magmetic field, mG

Magmetic field, mG

550

600

500

400

300

200

200

Y p 150

100

os

iti o

n,

cm

50

0

200

400

600

800

ion, cm

X posit

1000

500

Dead zone

450

400

350

300

250

200

150

0

200

400

600

X position, cm

FigureFigure

4. The4. distribution

of the

magnetic

field

component)caused

caused

three

different

The distribution

of the

magnetic

fielddistortion

distortion (Z component)

byby

three

different

vehicles

(different

color means

different

position

of sensor

with respect

Y axis—across

the

vehicles

(different

color means

different

position

of sensor

with respect

to thetoY the

axis—across

the vehicle).

vehicle).

4. Analysis of Vehicle Detection Methods

4. Analysis of Vehicle Detection Methods

The key

must must

be addressed

whenwhen

designing

the system

for detecting

speed

andand

vehicle

Thetask

keywhich

task which

be addressed

designing

the system

for detecting

speed

type isvehicle

relatedtype

to the

accuracy

of

determining

the

duration

between

signals

from

separate

sensors.

Once

is related to the accuracy of determining the duration between signals from separate

established

the

stable

signal discretization

andfrequency

completing

matching

both signals,

sensors.

Once

established

the stable signalfrequency

discretization

and the

completing

the of

matching

of

it becomes

possible

to calculate

the delay

between

signals

and the

vehicle

both signals,

it becomes

possible

to calculate

the delay

between

signals

andspeed.

the vehicle speed.

Seeking

to evaluate

the accuracy

of determining

the vehicle

speed

using

AMR

sensors,

Seeking

to evaluate

the accuracy

of determining

the vehicle

speed

using

AMR

sensors,

we we

turned

turned

to

the

data

acquired

from

conducting

the

experiment

and

carried

out

a

comparison

12

to the data acquired from conducting the experiment and carried out a comparison of 12 of

selected

selected

methods.

The

list

of

these

methods

is

provided

in

Table

1.

methods. The list of these methods is provided in Table 1.

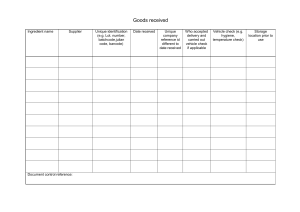

Table 1. List of methods.

Table 1. List of methods.

No.

1

No.

2

31

4

52

63

74

85

9

6

10

7

11

8

12

Method

Z component peak detection

Method

Z component

cross-correlation

Module

detection

Z componentpeak

peak

detection

Module cross-correlation

Z component

cross-correlation

Vectorial

deviation

peaks (Equation (1))

Modulecross-correlation

peak detection(Equation (1))

Vectorial deviation

Combined vectorial

Module deviation—peaks

cross-correlation(Equation (2))

Combined

vectorial

deviationpeaks

cross-correlation

(2))

Vectorial

deviation

(Equation (Equation

(1))

Kz criterion peaks

Vectorial deviation cross-correlation (Equation (1))

Kz criterion cross-correlation

Combined

vectorial

deviation—peaks

(Equation (2))

Z peaks

±50 readings

of cross-correlation

CombinedModule

vectorial

deviation

cross-correlation

(Equation (2))

peaks

±50 readings

of cross-correlation

9

10

11

12

Kz criterion peaks

Kz criterion cross-correlation

Z peaks ˘50 readings of cross-correlation

Module peaks ˘50 readings of cross-correlation

Sensors 2016, 16, 78

6 of 10

Sensors The

2016, selected

16, 78

methods are based on either the process of finding the peak signal values or6 their

of 9

superposition in time whilst calculating the delay, or via calculation of the cross-correlation of these

signals and determining the lag.

The

selected

methods

based

on either

the process

Vectorial

deviation

is a are

simple

criterion

defined

as [11]:of finding the peak signal values or their

superposition in time whilst calculating the delay, or via calculation of the cross-correlation of these

K | cos cos 0 cos cos 0 cos cos 0 |

(1)

signals and determining the lag.

Vectorial

deviation between

is a simple

criterionfield

defined

asand

[11]:x, y, z axis respectively.

where

α, β, γ—angle

magnetic

vector

Combined vectorial deviation

criterion

compiled

K “|cosα is

´ acosα

´ cosβfrom

cosγ“square”

´ cosγ0 |and vectorial deviations.

(1)

0 | ` | cosβ

0 | ` |the

According to the fact that the Z component increases when a vehicle is moving over and decreases

where α, β, γ—angle between magnetic field vector and x, y, z axis respectively.

nearby the vehicle, it can be used to increase the sensor’s sensitivity when a vehicle is moving:

Combined vectorial deviation is a criterion compiled from the “square” and vectorial deviations.

K Z| cos

cos0 increases

cos when

cos 0a| vehicle

( Bz / Bis

1)

According to the fact that the

component

over and decreases

(2)

z 0 moving

nearby the vehicle, it can be used to increase the sensor’s sensitivity when a vehicle is moving:

where cos α, cos β—cosines of magnetic field vector’s angles on the influence of vehicle, cos α0,

cosβ ´ cosβ

K “|cosα

´ cosα

(2)

z {B

0 | ` | without

0 | ` pBof

z0 ´ 1q B —magnetic induction

cos β0—cosines of magnetic

field vector

angles

influence

vehicle,

z

on thecos

influence

of vehicle, ofBzmagnetic

value without

influenceof

ofvehicle,

vehicle. cos α0 , cos

where

α, cos β—cosines

fieldinduction

vector’s angles

on the influence

0 —magnetic

β0 —cosines

of

magnetic

field

vector

angles

without

influence

of

vehicle,

B

—magnetic

induction on

z

Kz criterion:

the influence of vehicle, Bz0 —magnetic induction value without influence of vehicle.

B

K z z 1

Kz criterion:

(3)

BB

z z0

Kz “

´1

(3)

Bz0

where B —magnetic induction value without influence

of vehicle.

z0

whereThe

Bz0 —magnetic

inductiondata

value

without

influence

vehicle. which are interpreted in search for

view of the gathered

when

using

differentofmethods

The

view

of

the

gathered

data

when

using

different

methods

which are interpreted in search for

signal matching, is presented in Figure 5.

signal matching, is presented in Figure 5.

900

Magmetic field, mG

800

700

600

500

400

300

200

100

0

0

200

400

1

600

2

Data

3

800

4

1000

1200

5

Figure 5. The gathered data when using different methods (1—Z component, 2—Module, 3—Vectorial

deviation,

deviation,

Figure 5.4—Combined

The gatheredvectorial

data when

using 5—K

different

methods (1—Z component, 2—Module, 3—

z criterium).

Vectorial deviation, 4—Combined vectorial deviation, 5—Kz criterium).

In Figure 6 a view of the data samples from two matching sensors via the use of Z component

cross-correlation

mismatch

data

samplessensors

from the

two

be due

In Figure 6isa presented.

view of theThe

data

samplesbetween

from two

matching

via

thesensors

use of could

Z component

tocross-correlation

the different sensitivity

or

positioning

of

sensors.

Such

a

mismatch

could

be

eliminated

by

using

is presented. The mismatch between data samples from the two sensors could

be

data

techniques.

due normalization

to the different

sensitivity or positioning of sensors. Such a mismatch could be eliminated by

using data normalization techniques.

Sensors

Sensors 2016,

2016, 16,

16, 78

78

of10

9

77of

Sensors 2016, 16, 78

7 of 10

300

1 Sensor

2 Sensor

100

0

Magnetic field, mG

Magnetic field, mG

200

-100

-200

300

1 Sensor

2 Sensor

200

100

0

-100

-300

0-200

100

200

-300

0

100

300

200

400

300

500

X position

a)

400

500

X position

300

700

600

700

800

900

800

900

1000

1000

a)

1 Sensor

2 Sensor

300

1 Sensor

2 Sensor

100 200

Magnetic field, mG

Magnetic field, mG

200

600

0 100

-100

0

-200 -100

-300 -200

0

100

200

-300

0

100

300

200

400

300

400

500

X position

600

500

b)

X position

600

700

700

800

900

800

900

1000

1000

b)

Figure

sensors

(a)(a)

and

samples

matching

(b) (b)

via via

the the

use use

of the

Figure 6.

6. A

A view

view of

ofthe

thedata

datasamples

samplesfrom

fromtwo

two

sensors

and

samples

matching

of

Figure 6. A view of the data samples from two sensors (a) and samples matching (b) via the use of

Z

component.

the Z component.

the Z component.

Upon conducting the analysis and processing of the data collected during the experiment using

Upon conducting the analysis and processing of the data collected during the experiment using

Uponsignal

conducting

the analysis

and

of the data

the experiment

using

the selected

matching

methods,

weprocessing

have determined

thecollected

averageduring

and maximum

relative

errors

the selected signal matching methods, we have determined the average and maximum relative errors

the

selected

signal

matching

methods,

we

have

determined

the

average

and

maximum

relative

errors

when the distance between sensors was considered to be equal to 2 m. The results are displayed

when

thethe

distance between sensors was considered to be equal to 2 m. The results are displayed in

when

in Table

2. distance between sensors was considered to be equal to 2 m. The results are displayed in

Table

2.

Table

The 2.

analysis of the acquired results has revealed that the smallest average relative errors are

TheThe

analysis

of of

thetheacquired

that the

the smallest

smallestaverage

averagerelative

relative

errors

analysis

acquiredresults

resultshas

has revealed

revealed that

errors

areare

obtained with the second and the tenth methods (the maximum errors do not exceed 6.5%, Figure 7).

obtained

with

the

second

and

the

tenth

methods

(the

maximum

errors

do

not

exceed

6.5%,

Figure

obtained with the second and the tenth methods (the maximum errors do not exceed 6.5%, Figure 7). 7).

The dispersion of errors in the case of using these methods is shown in Figures 8 and 9.

TheThe

dispersion

of of

errors

ininthe

is shown

shownininFigures

Figures8 8and

and

dispersion

errors

thecase

caseofofusing

usingthese

these methods

methods is

9. 9.

Table 2. Method errors.

Table2.

2.Method

Method errors.

Table

errors.

Method No.

Method

No.

Relative

Error

Relative

Error

(%)(%)

Relative

Error

(%) 1 11 2 22

3

4

5

6

7

88

999

10

33

44

55

66

77

10 11

10

1111

Average

3.6

1.5

2.8

3.3

3.7

6.7

3.3

2.6

3.9

1.5

Average

3.63.6 1.51.5 2.82.8 3.3

3.3

2.6

3.9

1.5 3.1

3.1

Average

3.3 3.7

3.7 6.7

6.7

3.3

2.6

3.9

1.5

3.1

Maximum

28.5

6.0

14.5

15.0

15.0

23.5

Maximum

28.5 6.0

6.0 14.5

14.5 15.0

15.0 15.0

15.0 23.5

23.5 12.5

12.5 12.5

31.0

6.5

15.5

Maximum

28.5

12.5

12.5 31.0

31.0 6.5

6.5 15.5

15.5

16

16

14

14

12

Relative error %

Relative error %

12

10

10

8

8

6

6

4

4

2

2

0

1

0

1

2

2

3

3

4

4

5

5

6

7

8

Method No.

6

7

8

9

9

10

10

11

12

11

12

Method No.

Figure 7. Box plot of the methods’

(Table 1) relative errors.

Figure 7. Box plot of the methods’ (Table 1) relative errors.

Figure 7. Box plot of the methods’ (Table 1) relative errors.

12

1212

2.52.5

2.5

11.0

11.0

11.0

Sensors 2016, 16, 78

8 of 10

Sensors

2016,2016,

16, 78

Sensors

16, 78

8 of 10 8 of 9

6

64

Relative

error %

Relative

error %

42

20

0

50

100

150

200

0-2

0

50

100

150

200

-2-4

Distance (cm)

-4-6

Distance (cm)

-6

Figure

8. The

dependence of

of error

position

of sensors

with respect

vehicles

the second

Figure

8. The

dependence

errorononthethe

position

of sensors

with to

respect

tousing

vehicles

using the

method.

second method.

Figure 8. The dependence of error on the position of sensors with respect to vehicles using the second

method.

8

Relative

error %

Relative

error %

6

8

4

6

2

4

0

2

0

50

100

150

200

-2

0

-4

-2

-6

-4

0

50

100

150

200

Distance (cm)

Figure 9. The dependence of error on the position of sensors with respect Distance

to vehicles (cm)

using the tenth method.

-6

Figure

9. The dependence

of error on the centerline

position of sensors

respect

to vehicles

using8the

tenth

Sensor

placement

near the longitudinal

of the with

passing

vehicle

(Figures

and

9) increases

method.

the precision

of the speed detection. The analysis of the obtained results indicates that if the right

Figure 9. The

dependence

of error

the position

of sensors with

to vehicles

using

the tenth error) to

signal matching

method

of AMR

dataonsamples

is selected,

it is respect

possible

(with an

acceptable

Sensor placement near the longitudinal centerline of the passing vehicle (Figures 8 and 9)

method.

determine the speed and type of the vehicle (considering the length of vehicle). The benefits of such a

increases the precision of the speed detection. The analysis of the obtained results indicates that if the

system

aresignal

as follows:

right

matching method of AMR data samples is selected, it is possible (with an acceptable

1.

2.

3.

Sensor placement near the longitudinal centerline of the passing vehicle (Figures 8 and 9)

error)

to the

determine

and type

of

the The

vehicle

(considering

theclassification

length

of vehicle).

The

benefits

increases

precision

ofspeed

the speed

detection.

analysis

of the obtained

results

indicates

that

ifaccording

the

The

detection

of thethe

vehicle

location,

measurement

of speed

and

of vehicles

of

such

a

system

are

as

follows:

right

signal

matching method of AMR data samples is selected, it is possible (with an acceptable

to their

type.

error)

toinfrastructure

determine

and type

of the vehicle

(considering

the length

of vehicle). The

1. The

detectionthe

of speed

the vehicle

location,

measurement

of speed

and classification

of benefits

vehicles

Lower

costs.

of such

a

system

are

as

follows:

according to their type.

Relatively modest amount of data to be transferred due to the fact that signal processing can be

2. The

Lower

infrastructure

1.

detection

of the costs.

vehicle location, measurement of speed and classification of vehicles

performed

in

the sensor

itself.

3. according

Relativelytomodest

amount of data to be transferred due to the fact that signal processing can be

their type.

performed

inResearch

the sensor

itself.

2. Lower

infrastructure

costs.

5. Ideas

for

Further

3. Relatively modest amount of data to be transferred due to the fact that signal processing can be

There

is great in

potential

for

further research into the use of AMR sensors in the presence of a

performed

the sensor

itself.

different Z component angles (i.e. at different locations across the Earth) and for analyzing different

types of signal processing methods for vehicle speed detection. Moreover, there is still a knowledge

gap in terms of researching vehicle detection using the magnetic vehicle signature features.

6. Conclusions

By experimental research it has been established that AMR sensors can be used for the purposes of

vehicle speed control and vehicle classification. Upon conducting research with regard to the different

Sensors 2016, 16, 78

9 of 9

impact of distinct vehicle types on the Earth’s magnetic field it has been established that different

vehicles have distinct magnetic signatures which can be used for identifying the vehicle type.

According to the research results it can be concluded that is sufficient to use only one AMR Z

component for vehicle speed detection. Upon analyzing the 12 methods found suitable for the purpose

of speed control, it has been established that the minimum errors are obtained using the Z component

for methods 2 and 10 (the Z component cross-correlation and Kz cross-correlation criterion methods).

When using the proposed methods the average relative error of speed determinations in the case of

applying the most suitable method does not exceed 1.5% when the distance between sensors is 2 m.

It should be noted however that the vehicles can affect measurements by adding additional errors.

These can be eliminated through other magnetic field components.

Author Contributions: V.M. supervised the project direction. V.M., M.C. and A.V. designed the hardware. D.N.,

D.A. and M.Z. implemented the hardware. M.Z., D.N. and D.A. evaluated the system by developing software.

D.N. developed the final software. V.M and M.C. analyzed the data. V.M., D.N. and M.C. wrote the initial

manuscript; M.Z., D.A. and A.V. participated actively in the development, revision and proofreading of the

final manuscript.

Conflicts of Interest: The authors declare no conflict of interest.

References

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Schulz, W.; Geis, I. Future role of cost-benefit analysis in intelligent transport system-research. IET Intell.

Transp. Syst. 2015, 9, 626–632. [CrossRef]

Mone, G. The New Smart Cities. Commun. ACM 2015, 58, 20–21. [CrossRef]

Glasmeier, A.; Christopherson, S. Thinking about smart cities. Camb. J. Reg. Econ. Soc. 2015, 8, 3–12.

[CrossRef]

Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises.

Bus. Horiz. 2015, 58, 431–440. [CrossRef]

Surgailis, T.; Valinevicius, A.; Markevicius, M.; Navikas, D.; Andriukaitis, D. Avoiding Forward Car Collision

using Stereo Vision System. Elektron. Elektrotech. 2012, 18, 37–40. [CrossRef]

Zhu, H.; Yu, F. A Vehicle Parking Detection Method Based on Correlation of Magnetic Signals. Int. J. Distrib.

Sens. Netw. 2015, 1–13. [CrossRef]

Cirilo Gimeno, R.V.; Pla Castells, M.; Celda, A.G.; Plume, J.M. A simulation model using AMR sensors

applied to vehicle classification and identification. In Proceedings of the ISC’2013, Ghent, Belgium, 13–15

November 2013.

Zhou, X. Vehicle location estimation based on a magnetic sensor array. In Proceedings of the 2013 IEEE

Sensors Applications Symposium (SAS), Galveston, TX, USA, 19–21 February 2013; pp. 80–83.

Marshall, S.V. Vehicle detection using a magnetic field sensor. IEEE Trans. Veh. Technol. 1978, 27, 65–68.

[CrossRef]

Pitton, A.C.; Vassilev, A.; Charbonnier, S. Vehicle Re-Identification with Several Magnetic Sensors.

In Proceedings of the AMAA’2012, Berlin, Germany, 30–31 May 2012; Springer: Berlin, Germany; Heidelberg,

Germany; pp. 281–290.

Daubaras, A.; Zilys, M. Vehicle Detection based on Magneto-Resistive Magnetic Field Sensor.

Elektron. Elektrotech. 2012, 2, 27–32. [CrossRef]

Markevicius, V.; Navikas, D. Adaptive Thermo–Compensation of Magneto–Resistive Sensor. Elektron. Elektrotech.

2011, 8, 43–46. [CrossRef]

Daubaras, A.; Markevicius, V.; Navikas, D.; Cepenas, M.; Zilys, M.; Andriukaitis, D. Vehicle Influence on the

Earth's Magnetic Field Changes. Elektron. Elektrotech. 2014, 4, 27–32.

Daubaras, A.; Markevicius, V.; Navikas, D.; Zilys, M. Analysis of magnetic field disturbance curve for vehicle

presence detection. Elektron. Elektrotech. 2014, 5, 80–83. [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access

article distributed under the terms and conditions of the Creative Commons by Attribution

(CC-BY) license (http://creativecommons.org/licenses/by/4.0/).