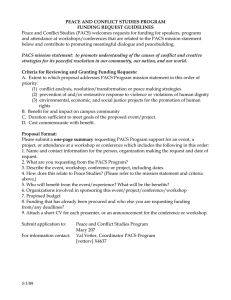

PACS Software for RVP-4 Software Manual Version 1.0.0. 11.05.2007 Before installing and operating the system, please read this software manual and the operating instructions carefully. BARTEC BENKE cannot accept liability for injuries or damages caused by failure to observe the software manual and the operating instructions and safety precautions. We have checked the information in this document carefully to ensure its completeness and correctness. However, as alterations may occur due to technical improvements, we cannot accept liability for complete consistency. This software manual does not constitute any obligation or guarantee of performance on the part of BARTEC BENKE. The software manual and the operating instructions were compiled according to the requirements defined in the EU Directive 94/9/EG, Appendix II. For translations into other languages, the German version is to be regarded as the original document. If you have any problems or questions, please contact: BARTEC BENKE GmbH Borsigstraße 10 21465 Reinbek/Hamburg Germany Tel.: Fax: E-Mail: +49 (0) 40 - 72703 - 0 +49 (0) 40 - 72703 - 363 service@bartec-benke.de © 2007 BARTEC BENKE GmbH, Reinbek. All rights reserved. This software manual is copyrighted. This document may not be reproduced or transmitted, neither whole nor in parts, by any electronic, mechanical or other means, without prior written permission from BARTEC BENKE GmbH. The manufacture of any component with the aid of this manual without prior written permission is also prohibited. Inhalt I Contents 1 2 3 4 Introduction to PACS..........................................................................1 1.1 Application Area and Properties ......................................................................... 2 1.2 Touch Panel........................................................................................................ 3 Design and Function of the RVP-4 ....................................................5 2.1 Measuring Principle of the RVP-4 Analyzer ....................................................... 6 2.2 Design of the RVP-4 Analyzer ............................................................................ 7 2.2.1 Temperature control system.................................................................... 8 2.2.2 Measuring cell ......................................................................................... 8 2.2.3 Drive mechanism..................................................................................... 8 2.2.4 Valves ...................................................................................................... 9 2.2.5 Control of the Pneumatic Cylinders....................................................... 11 2.2.6 Position Feedback ................................................................................. 12 2.3 Process Flow .................................................................................................... 13 2.3.1 Process Diagram ................................................................................... 13 2.3.2 Program Start ........................................................................................ 15 2.3.3 StartUp .................................................................................................. 15 2.3.4 Wait Coarse Temperature ..................................................................... 15 2.3.5 Standby ................................................................................................. 16 2.3.6 Wait Fine Temperature.......................................................................... 16 2.3.7 Flushing ................................................................................................. 16 2.3.8 Filling ..................................................................................................... 17 2.3.9 Expand .................................................................................................. 17 2.3.10 Measure................................................................................................. 17 2.3.11 Ready .................................................................................................... 17 2.3.12 Safe State .............................................................................................. 18 First Steps with PACS ......................................................................19 3.1 Starting PACS................................................................................................... 20 3.2 Watchdog Module ............................................................................................. 21 3.3 Defining User Rights ......................................................................................... 22 3.4 Exiting PACS .................................................................................................... 22 PACS Overview .................................................................................25 4.1 Definitions: Streams, Parameters and Conversion........................................... 26 4.2 The PACS Main Window .................................................................................. 27 4.2.1 Local System Control ............................................................................ 28 4.2.2 Sample Streams .................................................................................... 28 4.2.3 Validation ............................................................................................... 29 4.2.4 Process Status and System Control...................................................... 30 4.2.5 Graphical Display of the Measuring Results ......................................... 32 Version 1.0.0., 11.05.2007 PACS Software for RVP-4 II Inhalt 5 6 7 8 9 The PACS Menu................................................................................ 35 5.1 The IO Menu ..................................................................................................... 36 5.1.1 IO - Test ................................................................................................. 37 5.1.2 IO - Log .................................................................................................. 39 5.1.3 IO - Configuration .................................................................................. 40 5.1.4 IO Modbus (optional) ............................................................................. 46 5.2 The Configure Menu ......................................................................................... 47 5.2.1 Configure - Parameters ......................................................................... 49 5.2.2 Configure - Controller ............................................................................ 51 5.2.3 Configure - Alarms................................................................................. 52 5.2.4 Configure - Validation ............................................................................ 53 5.3 The Report Menu .............................................................................................. 54 5.3.1 Report - Report ...................................................................................... 54 5.3.2 Report - Pressure Plot ........................................................................... 57 5.3.3 Report - Controller Values Plot .............................................................. 59 5.3.4 Report - Add Message to LogBook ....................................................... 60 5.4 The Utilities Menu ............................................................................................. 61 5.4.1 Utilities - Manual Controller Operation................................................... 61 5.4.2 Utilities - Manual Process Operation ..................................................... 62 5.5 The Accesslevel Menu ...................................................................................... 64 5.5.1 Changing the Expert Password ............................................................. 65 5.6 The Help Menu.................................................................................................. 66 Process Control System Interface .................................................. 69 6.1 Analog inputs .................................................................................................... 70 6.2 Analog output .................................................................................................... 70 6.3 Digital inputs...................................................................................................... 71 6.4 Digital outputs ................................................................................................... 72 Options.............................................................................................. 73 7.1 Modbus Interface .............................................................................................. 74 7.2 Remote maintenance interface ......................................................................... 74 Troubleshooting ............................................................................... 75 8.1 Error Monitoring in PACS.................................................................................. 76 8.2 Software error ................................................................................................... 76 8.3 Error messages from the analysis process....................................................... 78 Program Parameters ........................................................................ 83 9.1 Notes ................................................................................................................. 84 9.2 General Parameters.......................................................................................... 85 PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Abbildungsverzeichnis III Figures Figure 1.1: Touch panel ......................................................................................3 Figure 2.1: Flow diagram ....................................................................................7 Figure 2.2: Process Diagram.............................................................................. 14 Figure 3.1: Watchdog Module............................................................................ 21 Figure 4.1: PACS Main Window.......................................................................... 27 Figure 5.1: PACS – IO Menu.............................................................................. 36 Figure 5.2: PACS - Testing Digital and Analog Inputs and Outputs ....................... 37 Figure 5.3: PACS – Record Analog Input Signals ................................................. 39 Figure 5.4: PACS - Configuring Digital and Analog Inputs and Outputs................. 41 Figure 5.5: PACS - Modbus Application............................................................... 46 Figure 5.6: PACS - Modbus Data........................................................................ 46 Figure 5.7: PACS - Configure Menu .................................................................... 47 Figure 5.8: PACS - Configuration of General Parameters ..................................... 49 Figure 5.9: PACS – Configuring the Controller..................................................... 51 Figure 5.10: PACS - Alarm Table ......................................................................... 52 Figure 5.11: PACS – Configure Validierung ........................................................... 53 Figure 5.12: PACS - Report Menu ........................................................................ 54 Figure 5.13: PACS - File Selection Window ........................................................... 54 Figure 5.14: Report LogBook............................................................................... 55 Figure 5.15: Report History ................................................................................. 56 Figure 5.16: Report Alarms ................................................................................. 56 Figure 5.17: Report Debug.................................................................................. 56 Figure 5.18: PACS – Pressure and Temperature Plot............................................. 57 Figure 5.19: PACS – Controller Values.................................................................. 59 Figure 5.20: PACS – AddMessage ........................................................................ 60 Figure 5.21: PACS – Controller Operation............................................................. 61 Figure 5.22: PACS – Process Operation ................................................................ 62 Figure 5.23: PACS - Help Menu ........................................................................... 66 Figure 5.24: PACS – Selecting a Manual ............................................................... 66 Figure 5.25: PACS – Help About .......................................................................... 67 Version 1.0.0., 11.05.2007 PACS Software for RVP-4 IV PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Introduction to PACS 1 1 Introduction to PACS Version 1.0.0., 11.05.2007 PACS Software for RVP-4 2 1.1 Introduction to PACS Application Area and Properties PACS (Process Analyzer Control Software) is a software application for BARTEC BENKE process analyzers. It is designed for automatic control of the process flow in which certain product properties (here: the vapour pressure of petrochemical products) are analyzed. With the aid of the sensors and actuators of the analyzer, PACS controls the process flow and displays and documents the process status and the results of the analysis. A Watchdog module supervises PACS and, in case of an error, resets the analyzer. Communication with the process control room and transmission of the results can be carried out via Modbus, using an optional module. Software Properties PACS is based on Microsoft Windows operating systems (Windows XP or Windows 2000) and is installed on a PC that complies with industry standard. By means of its adjustable parameters, PACS can be configured for every specific application. Before delivery, the system is installed and configured for the specific application by BARTEC BENKE. It is advisable to install a software application for remote maintenance of the system via network, modem/ISDN or serial interface. This optional interface allows the user and BARTEC BENKE to access the system convieniently, if required, to facilitate maintenance, configuration and system diagnosis. Hardware Properties PACS is installed on an industry standard PC. Depending on the specific application and customer requirements, various hardware interfaces (network, modem/ISDN, etc.) are implemented. Additional Software In addition to the operating system and PACS, further software is installed. • Acrobat Reader – this freeware program is started by PACS in order to display user manuals. Copyright © 2006 Adobe Systems Incorporated. • CSView – this freeware program is started by PACS in order to view tables and data in the CSV file format. Copyright © 2005 Diamond Computer Systems Pty. Ltd. • Optionally - as a commercial licence - remote control software (e.g. PC-Anywhere) PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Introduction to PACS 1.2 3 Touch Panel The system is equipped with a touch panel which allows you to control the software without having to use a mouse. For easier use and to avoid fingerprints on the panel, a touch pen is supplied. Figure 1.1: Touch panel The mouse functions click, double-click and drag and drop are similar to the use of a normal mouse. A right-click is carried out by first clicking on a mouse icon and then on the element to which the right-click is to be applied. (Alternatively, click on the mouse icon in the task tray.) Version 1.0.0., 11.05.2007 PACS Software for RVP-4 4 Introduction to PACS The mouse icon becomes visible by opening the touch icon in the Windows task tray and selecting the menu function “Event selector”. Danger of explosion caused by electrostatic discharge! Sparks caused by electrostatic discharge can ignite an explosive atmosphere. – To clean plastic parts, especially the display, always use a moist cloth, never a dry cloth. – Observe the cleaning instructions in the operating manual. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Design and Function of the RVP-4 5 2 Design and Function of the RVP-4 Version 1.0.0., 11.05.2007 PACS Software for RVP-4 6 2.1 Design and Function of the RVP-4 Measuring Principle of the RVP-4 Analyzer A sample of the product is preheated or cooled to the required temperature and is then fed into a measuring cylinder, which is usually heated to 37.8°C. By means of a measuring piston, a defined volume is aspirated. After dosing is complete, the measuring cylinder is closed by means of valves. The measuring piston now retracts further and so creates a vapour area (ratio 1:4). When the thermodynamic equilibrium has been reached, the pressure inside the measuring cell is measured. This corresponds to the sum of the sample vapour pressure and the partial pressure of the gases dissolved in the sample. The measured pressure is converted and the result is displayed (see parameters P_Conversion and P_Unit). After the measurement, the measuring cell is rinsed with product, and the next analysis cycle starts. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Design and Function of the RVP-4 2.2 7 Design of the RVP-4 Analyzer The main part of the analyzer consists of the following components: temperature control system, measuring cell, and drive mechanism. A simplified flow diagram shows the fittings, sensors and actuators which are required to control the process flow. Figure 2.1: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Flow diagram Measuring cell pilot valve Outlet valve Inlet valve Temperature control system Sample heat exchanger Peltier element Coolant heat exchanger Temperature sensor Temperature fuse Temperature limiter Cooling medium outlet Cooling medium inlet Sample inlet Temperature sensor sample inlet 15 Temperature sensor sample 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Proximity switch ExpandFW Proximity switch ExpandBW Proximity switch DoseBW Proximity switch DoseFW Instrument air inlet Dosing cylinder Expansion cylinder Dose BW valve Dose FW valve Expand FW valve Expand BW valve Measuring cylinder Measuring cell Measuring cell temperature sensor 30 Measuring piston 31 Pressure transmitter Version 1.0.0., 11.05.2007 PACS Software for RVP-4 8 Design and Function of the RVP-4 2.2.1 Temperature control system The temperature control system (4) controls the temperature of the sample flowing through the system. It consists of two heat exchangers which are connected by peltier elements (6). The sample flows continually through the sample heat exchanger (5), where it is heated or cooled to the target temperature. The temperature is controlled via the temperature sensor sample (15), which is situated immediately before the measuring cell. Excess heat is lead off to the cooling medium via the coolant heat exchanger (7). Both heat exchangers are equipped each with a temperature sensor (8), a temperature fuse (9) which is destroyed if the temperature is too high, and a temperature limiter (switching with hysteresis). Additionally, a temperature sensor for monitoring the sample inlet temperature (14) is located here. 2.2.2 Measuring cell The measuring cell (28) consists of a measuring cylinder (27) and a movable measuring piston. The pressure transmitter (31) and the inlet and outlet valves (3, 2) are mounted onto the measuring cylinder. The inlet and outlet valves are actuated pneumatically via the measuring cell pilot valve (1). The measuring cell temperature is measured by means of the measuring cell temperature sensor (29). 2.2.3 Drive mechanism The drive mechanism for the measuring piston consists of the interconnected pneumatic cylinders (21, 22) which are used for adjusting the position of the measuring pison inside the measuring cylinder. 4 magnetic valves (23 ... 26) are also part of the system. To check the final positions of the pneumatic cylinders, proximity switches (16 ... 19) are used. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Design and Function of the RVP-4 2.2.4 9 Valves For better understanding of the process cycle, the following table contains a short description of the valves, which are marked with "Y". Optionally, PACS offers a stream switching feature. The required valves are not shown in the flow diagram. Valve / Tag Name Function Y_MEASURING_CELL • actuated: The line through the measuring cell is open. The inlet valve has opened the line from the sample inlet to the measuring cell, and the outlet valve is also open. Name of this position: Flow Through • not actuated: The line through the measuring cell is closed. The inlet valve has opened the line from the sample inlet to the slop, and the outlet valve is closed. Name of this position: FlowLocked • actuated: Forward pressure is applied to the dosing cylinder. • not actuated: Forward pressure is released from the dosing cylinder – it is ready for backward motion. • actuated: Backward pressure is applied to the dosing cylinder. • not actuated: Backward pressure is released from the dosing cylinder – it is ready for forward motion. • actuated: Forward pressure is applied to the expansion cylinder. • not actuated: Forward pressure is released from the expansion cylinder – it is ready for backward motion. • actuated: Backward pressure is applied to the expansion cylinder. • not actuated: Backward pressure is released from the expansion cylinder – it is ready for forward motion. • actuated: The line between validation stream and analyzer inlet is open. • not actuated: The line between online stream and analyser inlet is open. • actuated: The line between analyzer outlet and validation backflow is open. • not actuated: The line between analyzer outlet and validation backflow is closed. (Measuring cell pilot valve (1)) Y_DOSE_FW Y_DOSE_BW Y_EXPAND_FW Y_EXPAND_BW Y_Validierung OPTION Y_VALIDIERUNG_OUT OPTION Version 1.0.0., 11.05.2007 PACS Software for RVP-4 10 Design and Function of the RVP-4 Valve / Tag Name Y_STREAM1 OPTION Y_STREAM2 OPTION Y_STREAM1_BB Y_STREAM2_BB Y_Validierung_BB OPTION PACS Software for RVP-4 Function • actuated: The line between stream 1 and analyser inlet is open. • not actuated: The line between stream 1 and analyser inlet is closed. • actuated: The line between stream 2 and analyser inlet is open. • not actuated: The line between stream 2 and analyser inlet is closed. Same function as Y_STREAM1, Y_STREAM2, Y_Validierung. Optional for block-and-bleed valve control. Version 1.0.0., 11.05.2007 Design and Function of the RVP-4 Control of the Pneumatic Cylinders The following table describes the actuation patterns for the pneumatic cylinder valves. Actuation of the pneumatic cylinder valves Y_EXPAND_FW Y_EXPAND_BW Effect of the actuation pattern Y_DOSE_BW Name of the actuation pattern Y_DOSE_FW 2.2.5 11 GoUndefined 0 0 0 0 Both ends of the cylinders are pressure-free. The resulting position of the measuring piston is undefined, it depends on the sample pressure. GoClear 1 0 1 0 Both cylinders work in the forward direction. The measuring piston moves to the forward position – the measuring cell is emptied. GoPrefill 1 1 1 0 Starting from the position GoClear, Y_DOSE_BW is also actuated. This causes the rear of the dosing cylinder to be pressurized, ready for the following actuation pattern GoFill. GoFill 0 1 1 0 The measuring piston moves to the dosing position – the measuring cell is filled with sample. If the rear of the dosing cylinder is already pressurized (see GoPrefill), the restrictor in line Y_DOSE_FW acts immediately. This ensures a soft start of the movement. GoExpand 0 1 0 1 The measuring piston moves to the expansion position – the sample is enclosed in the measuring cell, and the volume of the measuring cell is increased. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 12 2.2.6 Design and Function of the RVP-4 Position Feedback The final positions of the pneumatic cylinders are checked by means of several proximity switches. For easier understanding, the defined positions are described in the following table. Dose FW Dose BW Expand FW Expand BW Position Description 1 0 1 0 PosClear The measuring piston is in the forward position (emptied). 0 1 1 0 PosAllot The measuring piston is in a position of 1/5 of the way from the front (dosed). 0 1 0 1 PosExpand The measuring piston is in the backward position (expanded). 0 0 x x PosUndefined The measuring piston is not in a final position. x x 0 0 1 1 x x PosError Error in position feedback (positioning not possible). x x 1 1 x means : The status of this proximity switch is irrelevant for this position. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Design and Function of the RVP-4 2.3 13 Process Flow This chapter describes the process flow of the analyzer, i.e. the program steps which are carried out by the analyzer during an analysis cycle. The process flow is controlled by the PACS software and displayed in the main window. 2.3.1 Process Diagram The process diagram shows the simplified analysis process which is described in the following sections. The commands CMD_SafeState and CMD_Reset represent commands which stop or restart the process flow by triggering an alarm. CMD_Reset is also triggered by starting PACS or switching the analyzer on (Power On), or by activating the Reset input (by user / control system), or by pressing the Reset button in the main window. Note: The process flow is influenced strongly by the configuration of parameters and alarms. For further information, please refer to chapter 5.2. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 14 Design and Function of the RVP-4 State Name StreamRequest ==0 / Outputs failsafe Condition / output dT > 1.5°C / Y = FlowThrough, Piston released StreamRequest >= 0 Alarm No Sample Flow Alarm Over Temperature Alarm no pressure Power Up / Outputs initial state StartUp WaitCoarse StreamRequest < 0 Cmd = SafeState Cmd = Reset Cmd = Restart Cmd = Reset StreamRequest < 0 SafeState Cmd != Reset / Outputs failsafe dTsample && dTcell < 1.5°C Remote && DI-Reset / unchanged Alarm No Sample Flow Alarm Over Temperature Alarm no pressure Standby t > ReadyTime Stream Request >= 0 && ! DI-Reset / Y = FlowThrough, Piston = Clear Alarm No Pressure Detected / 1. Lock & Fill, 2. Through & Undef Alarm No Sample Flow Alarm Over Temperature Alarm no pressure Ready Alarm Wait-T Timeout Alarm No Sample Flow Alarm Over Temperature Alarm no pressure WaitFine Vapor Pressure Detected P and T in range t < ReadyTime / 1. Lock & Fill, 2. Through & Undef output results Alarm Initial Pressure Alarm No Sample Flow Alarm Over Temperature Alarm no pressure dTsample < FineTemperatureLimit dTsample >= FineTemperatureLimit / Y = FlowThrough, Piston = Clear Alarm Piston Timeout Alarm No Sample Flow Alarm Over Temperature Alarm no pressure Measure Flush Not detected / Y = Locked, Piston = Expand Position != CLEAR / Y = FlowThrough, Piston = Clear Position == EXPAND Wait 5 s Position == CLEAR Wait 10 s Position != EXPAND / Y = Locked, Piston = Expand Alarm Piston Timeout Alarm No Sample Flow Alarm Over Temperature Alarm no pressure Expand StreamRequest <0 none 0 stream 1 1 stream 2 2 validation Figure 2.2: PACS Software for RVP-4 Position != FILL / Y = FlowThrough, Piston = Fill Position == FILL Wait 5 s Piston Positions CLEAR Volume = 4ml FILL Volume = 17.6ml EXPAND Volume = 88ml Released Volume undefined Sample Valve Y FlowThrough into cell Locked into slop Process Diagram Version 1.0.0., 11.05.2007 Fill Alarm Piston Timeout Alarm No Sample Flow Alarm Over Temperature Alarm no pressure State Name Main States PID type controllers (P type controllers otherwise) Design and Function of the RVP-4 2.3.2 15 Symbol Meaning ! not (logical negation) & and (logical) < lower than > higher than == equal != not equal Program Start After starting the program, PACS loads the configuration parameters and the main window settings which were active at the last program shutdown (settings for Local/Remote, Stream selection, and Automatic on/off). The program then starts with the state StartUp. 2.3.3 StartUp The process cycle changes to the state StartUp if one of the following events occurs: the program is started, or the reset line is activated, or the button Reset in the main window is activated while the process is in the state Safe State, or no sample stream is selected. In the state StartUp, the valves, controls etc. are set to their default states (all valves not active, heater control off). The process remains in this state until a sample stream is selected. As soon as a sample stream is selected, the temperature controls for the measuring cell and the flowing sample are activated. The sample temperature is measured using the temperature sensor before the measuring cell. The program switches to the state Wait Coarse Temperature. 2.3.4 Wait Coarse Temperature The inlet and outlet valves are in position FlowThrough (sample flows through the cell), and the pneumatic cylinder valves remain unactuated (GoUndefined). The program remains in this state until the temperatures of the measuring cell and of the flowing sample do not deviate by more than 1.5 K from their respective target values. The status remains active for at least 5 seconds. Next state: Standby. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 16 2.3.5 Design and Function of the RVP-4 Standby This state is reached either from the state Wait Coarse Temperature, or after the end of a successful analysis cycle (from the Ready state), or after a reset. Exception: a reset is triggered if the process is in the state Safe State. At first, the valve positions are not changed. If a reset is held (in remote control mode, a reset can be held by holding the signal input in its active state), the program holds and waits for the reset state to end. If a different sample stream has been requested, it is activated. If no sample stream is selected (Stream = 0), the state switches to Startup immediately. The inlet and outlet valves of the measuring cell are switched to the position FlowThrough, and the pneumatic cylinders are switched to the position PosClear. The program remains in the state Standby until a sample stream is switched on and there is no reset signal. The status remains active for at least 5 seconds. Exception: Stream = 0. Next state: Startup (if Stream = 0) or Wait Fine Temperature (start of an analysis cycle). 2.3.6 Wait Fine Temperature The measuring cell valves are actuated with FlowThrough and the pneumatic cylinders with GoClear. The program waits for at least 10 seconds. If the sample stream was changed, the program waits for another period of time, as defined in the parameter StreamSettleTime. The program then checks if the measuring cell temperature and the sample temperature are within the target range. If the temperature values are within the target range, the program switches to the state Filling. If the target range is not reached within the time defined by MaxWaitFineTime (parameter), the alarm TA_TO_WAIT_FINE is triggered. To determine the tolerance, the temperature deviations of the flowing sample and of the measuring cell are monitored for the period of time defined in the parameter ObserveTime. If the measuring cell temperature deviates by less than T_Fine_Limit, it is within the target range. For the temperature of the flowing sample, the tolerance threshold is twice as high. 2.3.7 Flushing For flushing, the measuring cell valves remain in the position FlowThrough, and the pneumatic cylinders are actuated with GoClear. The measuring cell is constructed so that, in this position, a circular gap for the sample flow remains. After 10 seconds, the program switches to the state Filling. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Design and Function of the RVP-4 2.3.8 17 Filling For filling, the measuring cell valves are actuated with FlowThrough, and the pneumatic cylinders are actuated for 1 second with GoPreFill. In this way, pressure is exerted on the rear end of the dosing cylinder. Now the dosing cylinder is actuated with GoFill. Caused by the pressure on the dosing cylinder, the cushioning in Y_DOSE_FW is active immediately, and the measuring piston slowly moves to the filling position. The program now waits for the proximity switches on the pneumatic cylinders to signal the position PosAllot. After another 5 seconds, the program switches to the state Expand. 2.3.9 Expand First, the measuring cell valves are actuated with FlowLocked. After 2 seconds, the pneumatic cylinders are actuated with GoExpand. The measuring piston now moves back to its expansion position. The program now waits for the proximity switches on the pneumatic cylinders to signal the position PosExpand. After another 5 seconds, the program switches to the state Measure. 2.3.10 Measure To measure the vapour pressure, the measuring cell valves remain acutated with FlowLocked, and the pneumatic cylinders with GoExpand. The pressure in the measuring cell is monitored continually, the measured value is rounded to 0.1 kPa and recorded. Evaluation starts after 2 minutes. If the current pressure deviation, and the pressure deviation measured 1 and 2 minutes earlier, remains within 0.1 kPa, the average of these pressure values is recorded as ASVP. This ASVP is then converted according to the selected conversion algorithm and unit (parameters Conversion and Unit) and is signaled to the various output channels (analog output, Modbus, panel, history file, plot). The next state is Ready. If the vapour pressure is not detected within 15 minutes, the error No Vapor Pressure detect is signaled, and the next state is Standby. 2.3.11 Ready The digital output Ready is set; it signals a valid measuring signal. The measuring cell valves remain actuated with FlowLocked, and the pneumatic cylinders are actuated with GoFill . As soon as the pneumatic cylinders have reached the position PosAllot, the measuring cell valves are actuated with FlowThrough and the pneumatic cylinders with GoUndefined. As soon as the time defined in the parameter ReadyTime has expired, the digital output Ready is reset, and the program switches to the state Standby. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 18 Design and Function of the RVP-4 2.3.12 Safe State The state Safe State is reached by activating the button SafeState in the main window, or by triggering an alarm that is configured accordingly. The measuring cell valves are actuated with FlowThrough and the valves for the pneumatic cylinders with GoUndefined . The digital output TDO_ENABLE_POWER is deactivated so that heating and cooling are disabled. A selected stream is deactivated. The analysis process remains in the state Safe State until CMD_Reset is triggered. The next state is StartUp. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 First Steps with PACS 19 3 First Steps with PACS Version 1.0.0., 11.05.2007 PACS Software for RVP-4 20 3.1 First Steps with PACS Starting PACS To start PACS, proceed as follows: • Switch on the analyzer, as described in the operating manual. The computer for data analysis (ACU) boots up and starts the operating system, and the PACS process software starts automatically. Only as an exception, it may be necessary or convenient to start PACS manually, e.g. if PACS was closed manually, or if the shortcut to PACS in the Autostart directory has been removed. To do this, proceed as follows: • In the Windows Start menu under Programs – Bartec Benke, select the PACS program symbol. Note: PACS always starts on the Operator user level, using the same settings as were stored at the end of the last session. If the analysis process was active when the program was ended, it will now be started again. Otherwise, only the outputs will be initialized with their starting values. You can change the user level, for example to adjust program settings on the Expert level (see chapter 5.5). After starting PACS, the Watchdog module starts automatically (see chapter 3.2), and also, if applicable, the Modbus module. Additionally, if installed, the remote maintenance software starts. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 First Steps with PACS 3.2 21 Watchdog Module After starting PACS, the Watchdog module starts automatically. The Watchdog module shows whether particular applications which are necessary for correct system operation are active (e.g. PACS, Modbus, etc.). These applications are registered by the Watchdog module, and they are then polled in turn. If a registered application does not react to the polling request, all applications and the operating system are shut down. After a delay time, the Watchdog triggers a system reset of the PC which restarts the operating system and the PACS software. Figure 3.1: Watchdog Module The LED WD shows the status of the Watchdog hardware. If the LED is grey, the hardware is inactive. If it is green, the hardware is active. The LED CON shows the available connections. If at least one application is registered and polled by the Watchdog module, the LED is green. If no application is registered, the LED is grey. The registered applications are shown in the center of the Watchdog window under "Connections". The LED TRIG changes color from blue to orange. While the Watchdog module is checking if the connected applications are active, the progress bar shows the current status of the polling process. If all connected applications are active, the hardware is triggered, and the LED is orange. If not all applications are active, the hardware is not triggered, and the LED remains blue. The Watchdog module then resets the system within the next few seconds, i.e. it stops all active applications, shuts down the operating system, resets the hardware and restarts. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 22 First Steps with PACS Additionally, the Watchdog window contains information on the software version. • To close the Watchdog module, click Quit. Note: If the Watchdog module is closed while registered applications are still running, the correct function of the applications can no longer be checked. If you click Reset, a system reset of the PC will be carried out. This should only be done in exceptional cases and for test purposes, as any changes in the system configuration which were not previously stored will be lost. 3.3 Defining User Rights To avoid unauthorized changes to the system, you must restrict acces by defining user rights. Changes to the system can only be made on the user level Expert. You can restrict access by means of a password. For further information, please refer to chapter 5.5. 3.4 Exiting PACS Before you exit PACS, close all dialog windows. There are several ways of exiting the program: • Select Exit form the File menu. • Press Alt-F4. • Double-click on the program icon in the top left corner of the main window. • Click on the "Close" symbol in the top right corner of the main window. The current settings for the software configuration are stored and will be loaded automatically at the next system start. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 First Steps with PACS 23 The following dialog window appears. To exit PACS, click on Yes. To continue working with PACS, click on No. If you want to exit PACS and shut down the operating system as well, click on Shutdown. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 24 PACS Software for RVP-4 First Steps with PACS Version 1.0.0., 11.05.2007 PACS Overview 25 4 PACS Overview Version 1.0.0., 11.05.2007 PACS Software for RVP-4 26 4.1 PACS Overview Definitions: Streams, Parameters and Conversion Parameters are adjustable values which influence the measuring process (e.g. TW_Ready). Parameters are stored in a file and can be edited and changed by means of specific program functions. A sample stream (Stream) is a physical pipeline through which a sample flows into the analyzer. PACS allows you to take a sample either from one of two available online streams or from a validation stream. The vapour pressure is originally measured as ASVP (DIN absolute pressure, ASTM total pressure). The measured value can be converted and output in accordance with other measurement methods (Conversion). In this case, the output value is calculated by means of a linear equation. Value = Offset + Gain * Pressure Conversion Parameter Conversion Offset Gain ASVP 0 0.0 ASTM_DVPE 1 -3.78 0.965 EPA_DVPE 2 -2.39 0.956 CARB_RVPE 3 -4.93 0.972 ASTM_RVPE 4 6.07 0.752 CustomVP 5 CustomVPOffset CustomVPGain 1.0 The values of offset and gain are derived from the applicable standards and publications. CustomVP represents a non-standardized conversion. In this case, the values of offset and gain are taken from the parameters. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 PACS Overview 4.2 27 The PACS Main Window The PACS main window displays currently and previously measured values. You can activate and deactivate measurements. The status of the system and any occurring errors are displayed. 1 2 3 4 Figure 4.1: PACS Main Window 1 Sample streams 2 Validation 3 Process state and system control 4 Graphical Display of the Measuring Results Version 1.0.0., 11.05.2007 PACS Software for RVP-4 28 PACS Overview The menus in the menu bar are explained in detail in chapter 5. For a better overview, the main window is divided into the sections shown in Figure 4.1: PACS Main Window. The following description refers to these sections. 4.2.1 Local System Control The system can be controlled either locally or from a central DCS (Distributed Control System). To control the system locally: • Make sure that Local is activated in section 3. Otherwise, click on Remote. The button Remote changes to Local. You can now set parameters and control the system directly with PACS. Remote control by the DCS is deactivated. 4.2.2 Sample Streams Selecting Sample Streams Manually In section 1, both sample streams are displayed side by side. At the top of the section there is a text field where you can enter the name or tag of the stream. The defaults are "Stream1" and "Stream2". The LED on the right lights up green when the stream is active, i.e. the measuring cycle with this stream is in progress. You can analyze both sample streams separately. To select a sample stream: Note: The entries in the cycles fields are irrelevant for manual measurment of the sample streams. These fields are only required for automatic measurements. • Click on one of the two buttons Stream 1 or Stream 2 in section 1 with the status Off. The status changes to On and the button becomes green. This triggers a request for a measuring cycle with this stream. If a measuring cycle with another stream is in progress, this will not be aborted. As soon as the current measuring cycles is finished, the selected stream is activated and the green LED next to this sample stream lights up. The most recent measuring results for both sample streams are displayed. Below, the times for the respective sample names are displayed. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 PACS Overview 29 Alternate Automatically between Sample Streams The two sample streams can be measured automatically in an alternating sequence. A sample stream can be measured several times before switching to the other sample stream. In section 1, both sample streams are displayed side by side. • Enter the names of the sample streams in the two text fields at the top. • In the field Cycles, enter the required number of measurements for each sample stream. • Click the button in the field Automatic Stream Switching. The status changes from Off to On. Automatic stream switching is now activated. If a measurement is in progress, this will first be completed. Automatic stream switching will then start with the first sample stream. The two sample streams are now measured automatically in an alternating sequence. Each stream is measured as many times as specified in Cycles, afterwards the system switches to the next stream. If a sample stream is active, the green LED next to the name of the sample stream lights up. The Cycle display in the field Automatic Stream Switching shows the remaining number of measurements for the active sample stream. The most recent measuring results for both sample streams are displayed. Below, the times for the respective sample names are displayed. 4.2.3 Validation Information for system validation is displayed in section 2. At the top of the section there is a text field where you can enter the name or tag of the validation stream. The default is "Validation". The LED on the right lights up green when the validation stream is active. In the field Cycles, enter the required number of measurements for validation. To start validation manually: • Click the buttonValidierung while it is in the state Off. • The button changes to On. The LED Ins indicates that a number of validation cycles has been requested. Note: If the button On is switched back to Off, the LED Ins will remain active. If a sample stream measurement is in progress, validation will start after the current measurement is complete. As soon as the validation stream starts, the LED at the top lights up green. The number of measuring cycles specified in Cycles is carried out. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 30 PACS Overview The most recent result is displayed. The field below shows the time of the corresponding sample measurement. Note: 4.2.4 Validation can also be started remote from the central DCS (Distribution Control System), or it can be activated by an automatic timer (see chapter 5.2.4). The validation stream is not included in automatic stream switching. Process Status and System Control In section 3, you can control general system functions, and the process status and errors are displayed. In the field Tag, you can enter the name of the analyzer. This helps you to identify the analyzer. Error messages If there are any error messages, they aber displayed in the field Error. • Read the error messages carefully. • If required, remove the cause of the error. To confirm an error message: • Click Quit. Information on the Process Status The following status information is displayed: • State shows the current process state. • Cycle Time displays the time since the measuring cycle started. • The progress bar below Cycle Time shows the progress of the current action, depending on the corresponding process step (time t, pressure (difference) P, temperature (difference) T etc.). • T-Cell displays the current measuring cell temperature. • P-Cell displays the current pressure in the measuring cell. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 PACS Overview 31 Configuring the Measuring Units To the right of the displays T-Cell and P-Cell, you can select the measuring unit for the current temperature and the current pressure. • The setting for T-Cell (current measuring cell temperature) affects not only the display in the PACS main window, but also all other cases where the measuring cell temperature is signaled, e.g. in the history, and all other temperature displays. • The setting for P-Cell (current pressure in the measuring cell) only affects this display. The measuring unit for the measured vapour pressure is set by a parameter. Note: You can change parameters in the menu Configure. For more information, please refer to chapter 5.2. Local or Central Control You can control the system directly via PACS or via a central DCS (Distribution Control System). To control the system with PACS: • Make sure that Local is active. Otherwise, click on Remote. The button Remote changes to Local. You can now control the system directly with PACS. To control the system centrally via the remote interface (digital inputs or Modbus signals): • Make sure that Remote is active. Otherwise, click on Local. The button Local changes to Remote. Put System into Safe State For maintenance, tests or troubleshooting, you can put the system into the Safe State. You can then control actuators via the IO-Test panel and the Utility panels without interfering with the process cycle. The state Safe State is only conditionally safe because it is acquired through software functions. Please observe the operation instructions. • Click SafeState. For more information on the state Safe State, please refer to chapter 2.3. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 32 PACS Overview Restart after Serious Error After a serious error, the system will be put into the Safe State. Remove the cause of the error. To restart the system after a serious error: • Click Reset. The system is reset, depending on the most recent state. The system is ready for operation. Transmit Analog Value as Output Signal to the DCS In addition to the measuring result (vapour pressure), another analog value can be transmitted to the DCS (Distribution Control System). To select an analog value: • Select a value from the field Selectable Signal. The current value of the signal is displayed in the field Value. The signal will be transmitted to the DCS via the analog output SelectedSignal. 4.2.5 Graphical Display of the Measuring Results In section 4, the sequence of measuring results is displayed in a chart. You can select the streams you want to display. Additionally, you can select the value range for the X-axis and the Y-axis. To select the streams for the display: • In the main window above the graphical display, click on Plot Data of.. and select a stream. You can also display all streams at the same time. To select the value range for the X-axis: • In the field Horizon, select a time range between 3 h and 192 h. All measured values are displayed, from the current value back to the earliest value as specified in Horizon. Note: With << or >> you can display the intervals before or after the current interval. Both functions are only available if there are sufficient measured values available before or after the current interval. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 PACS Overview 33 To select the value range for the Y-axis: • In the field Upper to the left of the graphical display, enter the top value for the Yaxis, or use the arrow keys. • In the field Lower to the left of the graphical display, enter the bottom value for the Y-axis, or use the arrow keys. To display the values of individual measuring points: • Click on a measuring point in the graphical display. The measuring point is highlighted with crosshairs in blue. Above the graphical display, the measuring result, the average temperature, the time of the measurement and the corresponding stream are shown. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 34 PACS Software for RVP-4 PACS Overview Version 1.0.0., 11.05.2007 The PACS Menu 35 5 The PACS Menu Version 1.0.0., 11.05.2007 PACS Software for RVP-4 36 The PACS Menu The menu bar shows all PACS menus from which you can access the sub-menus. File IO Exit Test Log 2 1 Configure Report Utilities Accesslevel Help Parameters 2 Manual Controller Operation Operator Manual(s) Expert About Controller Configuration 2 Modbus Alarms 3 Report 3 Pressure Plot Manual Process Operation 3 Controller Values Plot Validierung Add Message to Logbook 2 5.1 1 write access only on Manufacturer and Expert level 2 unlimited write access only on Manufacturer level limited write access on Expert level 3 write access only on Manufacturer level 3 Manufacturer Change Password ¹ The IO Menu The options in the IO menu allow you to carry out a hardware test. All outputs can be switched manually, and the input values are displayed. Each input and output can be configured and calibrated. Figure 5.1: PACS – IO Menu An explosive atmosphere can be a danger to your life! If you need to open the cabinet for checks or calibration, observe all safety instructions in the operating manual for the analyzer. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.1.1 37 IO - Test To check the input and output channels, select IO – Test. The window Input/Output Test opens: Figure 5.2: Note: PACS - Testing Digital and Analog Inputs and Outputs Depending on the user level, this dialog window offers different functions. For further information on the user levels, please refer to chapter 5.5. Do not click on the buttons unless you are well acquainted with the functions! Operating errors can cause damage! An explosive atmosphere can be a danger to your life! If you need to open the cabinet for checks or calibration, observe all safety instructions in the operating manual for the analyzer. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 38 The PACS Menu In this dialog window, all analog and digital inputs and outputs are displayed with their current value or switch status. When the digital inputs and outputs are switched, the adjacent LED or switch button becomes green, otherwise it remains grey. The digital outputs, e.g. those which switch a single valve, can be switched manually for testing by clicking on the switch button. Similarly, you can change the values for the analog outputs manually for testing purposes. Note: If you change the digital outputs during an analysis cycle, you may affect the process and the results. In the field Modulator, you can adjust the settings for a modulator that is implemented in the system. Note: The modulator is not used fully by the Vapor Pressure Analyzer, only limit monitoring functions are used. Unexplained parts can be ignored. The LEDs Upper Limit and Lower Limit light up red if the limit value for the sensor temperature T-HeatExchanger is violated. They switch off again as soon as the temperature returns to a value within the tolerance range. The LED NotLockout is switched off if the temperature falls outside the limits, and it remains off, even if the temperature reaches the normal range again. It can only be reactivated by pressing the push-button LockOut Reset (-SH2) in the control unit housing. The LED LockOutReset lights up while the push-button is being pressed. Limit monitoring is implemented by means of hardware on the IO board, it functions without the aid of PACS. NotLockout is also a digital output which is part of the safety system (see connection diagram). If NotLockout is not active, the measuring cell heater and the temperature control unit are disconnected. The status of the IO board is indicated in the field IO 98 alive: During normal operation, the LED lights up green. The LED is red if the IO board is faulty. Additionally, the type of IO board is displayed as either ISA or ETH. The Temperature Conversion Tool is an additional utility which allows you to convert temperature values between the units Kelvin (K), Celsius (°C), Fahrenheit (°F) and Ohm. To close the window Input/Output Test, click Cancel. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.1.2 39 IO - Log You can record analog input signals, e.g. from the temperature sensors. • Select IO – Log from the main menu. The following window opens: Figure 5.3: PACS – Record Analog Input Signals The input signals are saved in separate CSV files. • Enter the file name in the field Log-Files Name. By default this is io_log. In one file, a maximum of 32000 entries can be recorded. For further entries, new files are generated. For this, the end of the specified file name is extended by consecutive numbers. • Enter the time interval between two recordings in the field Sampling Time. • Select the input channels you want to record in the field Selectable Input Channels to be locked. The selected channels are marked with a check symbol, they will now be recorded. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 40 The PACS Menu To start recording the input channels: • In the field Execution, click Start. The LED in the field Log Status Information shows the status of the IO board. During normal operation, the LED lights up green, otherwise it is red. The field Next Value in displays the time before the next recording. The field TINI Ticks displays the internal time of the IO board. Value Number shows the current number of entries in the file. The number of entries is limited to 32000. To stop recording the input channels: • In the field Execution, click Stop. The recording is stopped. To view the recorded data: • In the field Current File, double-click on the displayed file path. The CSV file is opened as a chart in the Diamond CS Viewer. 5.1.3 IO - Configuration To configure the digital and analog inputs and outputs and to calibrate and set other parameters, select IO – Configuration. The following dialog window appears. Note: These signals are configured by BARTEC BENKE before delivery of the analyzer. The settings should only be changed in exceptional cases, and only after consulting BARTEC BENKE. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu Figure 5.4: 41 PACS - Configuring Digital and Analog Inputs and Outputs Configuring the Digital Output By clicking the button labeled Tag, you can select a digital output in the section Digital Output. A drop-down menu opens with the names of all configured digital outputs. Click on one of these outputs. The name will then be displayed on the button under Name. To change the name, click on Rename and enter a new name for the selected tag in the dialog. The name can be up to 15 characters long. Click on OK. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 42 The PACS Menu In the Channel field you can assign a channel on the I/O board to the currently selected digital output. This is only accessible at Manufacturer level, as changes in this configuration can result in hardware errors. The checkbox Invert allows you to invert the state of the channel (negative / positive logic). The checkbox Init determines which value will be used to initialize the digital output after starting the program, before the first analysis cycle. If the check box is selected, the output is switched to active status, if the checkbox is deactivated, the output is inactive. Configuring the Digital Input To configure the digital inputs in the section Digital Input, proceed as described above for the section Digital Output. There is no initialization value for inputs. Configuring the Analog Output In the section Analog Output, select a channel of your I/O board. The name will then be displayed on the button under Name. To change the name, click on Rename and enter a symbolic name for the corresponding property name. The name can be up to 15 characters long. Click on OK. The field Init shows the start value for initializing the outputs, as described for the section Digital Output. The names of the analog and digital inputs and outputs are shown in the window Input / Output Test. Configuring the Analog Input The channels for the analog input values are set in the section Analog Input. To configure the analog input, select a channel on your I/O board and assign a symbolic name to it which stands for the corresponding input value. The name can be up to 15 characters long (as described above for the digital outputs). Calibrate Analog Inputs and Outputs Note: These settings are factory-set and must not be changed! If a calibration should become necessary due to an error, the measuring process must be aborted first. The analog inputs and outputs are calibrated based on a 2-point linear equation, i.e. the relationship between the physical property and the value in the converter is assumed to be linear. If two values are known, their relationship can be described in a linear equation. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 43 The measuring results are output as an analog signal (4-20 mA). To do this, the physical measuring range of each channel must be adjusted by calibration to match the digital measuring range. The analog input channels must also be calibrated. An exception is the temperature measurement with Pt100 sensors which are connected directly to the IO board. To determine the temperature, first the resistance is measured, then the temperature is calculated using a known standard formula (according to DIN 43760 / IEC 571). Two examples of analog input and output calibration: PT100 input: • Select an Analog Input, e.g. "T_SampleHE", and set the Conversion to "Pt-100". An explosive atmosphere can be a danger to your life! If you need to open the cabinet for checks or calibration, observe all safety instructions in the operating manual for the analyzer. • Disconnect the sensor from the input and connect a variable resistance box. • Determine the calibration points (e.g. -30 °C and + 50 °C), and enter these values in the fields Convert Value Low and Convert Value High. The required resistance values can now be read from the fields Physical Value Low and Physical Value High. • Set the resistance to the value in Physical Value Low. The value in field Digital Value Current changes accordingly. • Select this value with the arrow button to the left of field Digital Value Low. • Set the resistance to the value in Physical Value High. The value in field Digital Value Current changes accordingly. • Select this value with the arrow button to the right of field Digital Value High. The calibration is now complete. To save the changes, click Save, to exit without saving the changes, click Cancel. • Reconnect the sensor to the input. Note: If you have the relevant resistance values available, during calibration you can specify the "Physical Values" and read off the resulting "Converted Values", i.e. the temperature, from the display fields. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 44 The PACS Menu 4 – 20 mA output: • Select an Analog Output, e.g. „TAO_VAPOR_PRESSURE“. An explosive atmosphere can be a danger to your life! If you need to open the cabinet for checks or calibration, observe all safety instructions in the operating manual for the analyzer. • Connect an amperemeter to the output. • Determine the measuring range with 4.0 und 20.0 (mA), and enter the values in the fields Physical Value Low and Physical Value High respectively. • Copy the value in Physical Value Low into field Physical Value Current, using the arrow button on the left. The output current should now be about 4 mA. • Set the output current to 4 mA by changing the value in Digital Value Current, and transfer this value into the field Digital Value Low with the arrow button on the left. • Copy the value in Physical Value High into field Physical Value Current, using the arrow button on the right. The output current should now be about 20 mA. • Set the output current to 20 mA by changing the value in field Digital Value Current and transfer this value into the field Digital Value High using the arrow button on the right. The calibration is now complete. To save the changes, click Save, to exit without saving the changes, click Cancel. Note: The physical measuring range of an analog output can be changed at any time. The calibration to the measuring range of 4-20 mA is retained. Scan Parameters The field Scan Parameters shows the scanrate (Scan-Interval), the field IO98-Al-Filter displays the smoothing factor for the analog inputs. The field dAI/dtGain shows a factor for derivation. Note: These settings are factory-set and must not be changed! PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 45 Loading and Saving the Configuration The menu File in the menu bar allows you • to load an IO configuration (Load), • to save an IO configuration under a different name (SaveAs), • to load initial values for the IO configuration (LoadInitial). Select File – Load to load a configuration. A dialog appears from which you can select the required file. The standard path is C:\Program Files\BBS\RVP4\config. Click Load to load the selected configuration file. To save a configuration you have changed under a different name, so that it can be reactivated later, select File – Save As. A dialog appears from which you can select the file name and path for saving the configuration file. The standard path is C:\Program Files\BBS\RVP4\config. With File – LoadInitial, you can load the configuration file "InitialIO.ini". This is only necessary if the IO board is changed. In this case, further calibration steps are required. Note: It is recommended to save a backup copy of the config directory. The directory contains all PACS program settings, such as parameters, products, alarms, and IO settings. For further information, please refer to chapter 5.2. As soon as you have made a change, the Save button becomes active. To save the changed settings, click Save, and then click Cancel to close the window. To close the window without saving the changes, click Cancel. Note: When the program starts, settings are always retrieved from the file conf.io. The menu described above serves to save various configuration settings. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 46 5.1.4 The PACS Menu IO Modbus (optional) As an addition or a substitute for the physical interface (analog inputs, analog outputs, digital outputs, digital inputs) to a DCS (Distribution Control System), a Modbus interface module can be installed. This module is described in a separate manual (Modbus Interface Description). Figure 5.5: PACS - Modbus Application To put this module into operation, the necessary hardware and software must be installed and configured, and the parameter "ModbusActive" must be set to 1 (0 = inactive). The Modbus interface is then started automatically by PACS. Then select IO – Modbus from the menu to open the following window: Figure 5.6: PACS Software for RVP-4 PACS - Modbus Data Version 1.0.0., 11.05.2007 The PACS Menu 47 The LED Active indicates the status of the connection to the DCS. Via the analog input Reserved (optional), an analog signal can be read from the DCS. The remaining LEDs indicate the states of the digital inputs (Modbus) as monitored by the system. The inputs Reset, StreamRQ1, StreamRQ2 and ValidationRQ correspond to the digital inputs with the same name (physical, discrete connections). See also chapter 6. Via the Modbus interface, more signals are transmitted than is shown in the dialog window. For further details, please refer to the separate manual (Modbus Interface Description). 5.2 The Configure Menu The options in the Configure menu allow you to set parameters and to edit the settings for controls, alarms, and validation. Figure 5.7: PACS - Configure Menu For the process run, PACS requires a number of parameters and settings. These parameters and settings can be defined in the Configure menu. Configuration files: Parameters and validation: • File: .\config\conf.par Alarms: • File: .\config\conf.al Controller: • File: .\config\CoConf.csv IO (access via IO – Configure): • File: .\config\conf.io Version 1.0.0., 11.05.2007 PACS Software for RVP-4 48 The PACS Menu In the file ".\config\ProgTermination.ini", the start and exit times of PACS are saved. This can be used to determine whether PACS was exited correctly. In the file ".\config\ProgPara.ini", some elements of the main window are saved, so that on restart, PACS can be initialized with the saved settings and results (stream selection, selected analog output, tag, the scale of the graphical display, the display of the most recent measuring results, settings for Cycles). Note: It is recommended to save a backup copy of the config directory. The directory contains all PACS program settings, such as parameters, alarms, and IO settings. The standard path is C:\Program Files\BBS\RVP4\config. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.2.1 49 Configure - Parameters To edit the parameters, select Configure – Parameters. The following dialog window appears: Figure 5.8: PACS - Configuration of General Parameters The window header shows the path and name of the file which contains the PACS parameters. In this window, you can edit general parameters, such as the maximum and minimum temperature values for all temperature measuring points (TemperaturMax, TemperaturMin). For an overview of the parameters and their meanings, please refer to chapter 9. To edit the value of a general parameter, click on Parameter Name in the section General. A drop-down menu opens with the parameters you can select by clicking. A Value is assigned to each parameter. You can change the parameter value by using the arrow buttons next to it, or by typing the new value directly into the field. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 50 The PACS Menu In the lower section of the window, the meaning of the corresponding parameter is explained. Note: All parameters are preset by the manufacturer before delivery. The parameters should only be changed after consulting BARTEC BENKE, and only if it is necessary for adjustment to the product. In the File menu, you can load a configuration (Load) or save a configuration under a different name (Save As). Select File – Load to load a previously stored set of parameters. A dialog appears from which you can select the required file. The standard path is C:\Program Files\BBS\RVP4\config. Click Load to load the selected configuration file. To save a configuration you have changed under a different name, so that it can be reactivated later, select File – Save As. As soon as you have made a change, the Save button becomes active. To save the changed settings, click Save, and then click Cancel to close the window. To close the window without saving the changes, click Cancel. Note: Changes in most of these parameters will not become active immediately, but only at the start of the next analysis cycle. For further information, please refer to chapter 9. Note: It is recommended to save a backup copy of the config directory. The directory contains all PACS program settings, such as parameters, products, alarms, and IO settings. For further information, please refer to chapter 5.2. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.2.2 51 Configure - Controller Figure 5.9: PACS – Configuring the Controller. In this window, you can edit the configuration of the two controllers for the temperature of the flowing sample and for the measuring cell. The settings are pre-set by BARTEC BENKE and should only be changed after consulting BARTEC BENKE. Changes can only be made on the Manufacturer level. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 52 5.2.3 The PACS Menu Configure - Alarms Select Configure – Alarms.. to configure alarms and warnings. Figure 5.10: PACS - Alarm Table If an error occurs, the corresponding error message is displayed under Message in the PACS main window. The reaction to these errors is configured by BARTEC BENKE and should only be changed if absolutely necessary. A warning indicates non-critical irregularities in the process flow, but the cause of a warning should still be investigated. An alarm indicates a serious error and should trigger a "Break" (process abort) or a "Shutdown". "Break" means that the running process is aborted and the program switches to the state Standby; the process then starts again from the beginning. If an alarm is configured as "ShutDown", the program switches to the state Safe State. The process then remains in this state until the button Reset is activated, or the digital input "Reset" is activated, or the button Reset in the main window is pressed. "mA 0" means that the signal outputs are set to their initial values. "1" activates the respective reaction, "0" deactivates it. Note: For further information on error messages and alarms, please refer to chapter 8. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.2.4 53 Configure - Validation Select Configure – Validation to open the window, and to view and edit the settings. To insert one or several validation cycles into the flow of the measuring process, select one or several days of the week under Day(s), and the time under Hour. With ValidierungoutDelay, the delay (in seconds) is specified after which the valve Y_ValidierungOut is actuated, relative to the valve Y_Validierung. Figure 5.11: PACS – Configure Validierung For further information on validation, please refer to chapter 4.2.3. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 54 5.3 The PACS Menu The Report Menu The menu Report allows you to view various recorded data either in a table or a chart, and to add new entries to the logbook. Additionally, you can add a message to the logbook. Figure 5.12: 5.3.1 PACS - Report Menu Report - Report Select the menu option Report to open a file selection window. The directory C:\Program Files\BBS\RVP4\DATA is preselected, which contains the report files. You can select only files with the extension .csv. Figure 5.13: PACS - File Selection Window The selected report file is displayed in the program CSView. Available report files: • LogBook.csv - chronological logbook which records various events • History.csv – measuring results • Alarms.csv – triggered alarms PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu • 55 Debug.csv – records a large number of signals at short intervals, for troubleshooting The report file is only saved if requested (see menu Utilities). Instead of "Debug", a different name may be chosen. Examples for report files: Figure 5.14: Report LogBook Entries are marked with an ID as follows. A (Action): Action during the process flow, e.g. program start ("StartProgram") E (Error): Error messages N (Note): Operator's comments W (Warning): Warning messages R (Result): Result of the measurement Version 1.0.0., 11.05.2007 PACS Software for RVP-4 56 The PACS Menu Figure 5.15: Report History Figure 5.16: Report Alarms Figure 5.17: Report Debug PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.3.2 57 Report - Pressure Plot To display the pressure and the temperature deviation from the target temperature of the measuring cell in a chart, proceed as follows: • In the menu Report, select Pressure Plot. The window Pressure and Temperature Plot opens. This window displays the pressure and temperature values in the state Measure, up to the time when the vapour pressure is detected. Figure 5.18: PACS – Pressure and Temperature Plot In the upper section of the window, the deviation from the target temperature of the measuring cell is displayed as a chart. In the lower section of the window, the pressure in the measuring cell is displayed. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 58 The PACS Menu The fields Lowest Value and Highest Value and the corresponding bar diagrams show the minimum and maximum pressure values at the times t (current time), t - 1 minute and t - 2 minutes. The display starts 2 minutes after the program has switched to the state Measure. To scale the Y-axis of the pressure chart manually: • In the field Scaling, click Manual. The upper and lower limits of the value range on the Y-axis are displayed in separate number fields. • Click in the number field you want to edit. Enter the required values. Confirm with Return. The new value range for the Y-axis is displayed in the chart. To scale the Y-axis of the pressure chart automatically: • Click Auto. The new value range for the Y-axis is displayed in the chart. Note: If the pressure or temperature values fall outside the permitted limits, the graphical display is archived automatically. The following limit values are monitored: TA_PRESS_TIMEOUT, TA_RANGE, TA_PRESS_TREND, TA_INACCURATE_TEMP. To view archived measuring results with measured values outside the permitted limits, proceed as follows: • Doubleclick in the pressure chart. The window Pressure Plot opens. • Select a file and load it. The pressure and temperature values are displayed in the window Pressure and Temperature Plot. The field File No shows the number at the end of the file name. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.3.3 59 Report - Controller Values Plot Figure 5.19: PACS – Controller Values To display the temperature values for the measuring cell and the flowing sample in a chart, together with the corresponding set values of the temperature controllers, proceed as follows: • In the menu Report, select Controller Values Plot. A window opens which shows the following charts: - Temperature deviation of the measuring cell from the target temperature (Cell) and temperature deviation of the flowing sample from the target temperature (Sample). - MV Cell (MV - manipulated value) for the measuring cell heater. - MV Sample (MV – manipulated value) for the heater module. The sample stream can be cooled or heated. Consequently, negative or positive values are equally possible. The time axes are scaled in minutes, the Y-axes of the set values are scaled in %. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 60 The PACS Menu You can scale the Y-axes manually or automatically. To scale the Y-axes manually: • In the field Scaling Mode, click Manual. The upper and lower limits of the value range on the Y-axes are displayed in separate number fields. • Click in the number field you want to edit. Enter the required values. Confirm with Return. The new value range is applied to the chart. To scale the Y-axes automatically: • Click Auto. The new value range for the Y-axis is displayed in the chart. 5.3.4 Report - Add Message to LogBook To add an entry to the report file LogBook.csv, select Report – Add Message to Logbook. A window appears where you can enter the required information. Then click Enter. The entry will be added to the report file LogBook.csv, together with the current date and time, and marked with the ID N (Note). Figure 5.20: PACS Software for RVP-4 PACS – AddMessage Version 1.0.0., 11.05.2007 The PACS Menu 5.4 5.4.1 61 The Utilities Menu Utilities - Manual Controller Operation This window can be used for manipulating the controllers for testing purposes. Note: Use this utility only if you are well acquainted with the functions. Operating errors can cause damage! The manipulations can interfere with normal operation. Figure 5.21: PACS – Controller Operation With On/Off, the controllers can be switched on or off. With Man/Auto you can change the mode between Automatic and Manual. The actual value is displayed in PV (process value), standardized in %. The set value MV (manipulated value) remains the same. With Manual Set, the value MV can then be changed (relatively). Next to Manual Set on the right, various statistical values of the controller deviation are displayed over an observation period (as set in Config Controller Observe Time). MAX: The maximum value of deviation within the observation period. MIN: The minimum value of deviation within the observation period. DC and AC: The direct and the alternating parts of the deviation within the observation period. Slope: The slope is calculated by means of a regression algorithm of the deviation within the observation period. MeanSQ: The mean standard deviation of the regression of the slope. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 62 5.4.2 The PACS Menu Utilities - Manual Process Operation This window allows you to manipulate the process for testing purposes, and for recording data. Note: Use this utility only if you are well acquainted with the functions. Operating errors can cause damage! The manipulations can interfere with normal operation. Figure 5.22: PACS – Process Operation With Debug, you can record the most important signals and process data at short intervals and save them in a report file (e.g. Debug.csv). After clicking Debug, a file selection window appears where you must select or enter the file name. While the data is recorded, you can add a comment in the field Comment. Note: The record should not continue for too long, because it requires a lot of hard disk space. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 63 To switch from the current process state directly to the next state: • Click NextState. State Time shows the duration of the current process state. You can stop normal operation, in order to avoid interference with manual operation: • Set the button Hold in standby to on. When the process reaches the state Standby, it will remain in that state. You can now control the system manually with Piston Command and Valves. To change back to normal operation: • Set the button Hold in standby to off. • The process proceeds from the state Standby. For testing purposes it can be necessary to skip the measuring piston position "clear" in normal operation. To do this, activate Skip Pos. Clear. To control the measuring piston in manual operation (see also chapter 2.2.5): • Select a position in the field Piston Command. • The measuring piston attempts to move to the selected position. The position of the measuring piston is displayed under Piston Position: - Error: if two positioning sensors of the same cylinder are active simultaneously. - Undefined: The measuring piston is not in one of its end positions, it is probably in motion. - Clear, Fill and Expand: The respective target position has been reached. To control the two measuring cell valves (see also chapter 2.2.3): • Move the slide under Valves to one of the following positions: - Through: The inlet and outlet valves of the measuring cell are opened. - Locked: The inlet and outlet valves of the measuring cell are closed. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 64 5.5 The PACS Menu The Accesslevel Menu In PACS, there are three user levels: Operator, Expert, and Manufacturer. Operator The Operator level is the level for operators on-site. This level provides monitoring functions and allows you to switch sample streams. This is the usual level for routine operation. Expert At Expert level, you have access to all software functions, except: - Manufacturer controller settings in the menu Configuration – Parameters settings in the fields Scan Parameters and Channel in the menu IO – Configure manual operation of the digital and analog outputs during the measuring process in the menu IO – Test settings in the dialog window Configuration – Alarms At Manufacturer level, you have unlimited access to all functions of the software. The Manufacturer level allows you to configure the hardware. These settings are generally configured by BARTEC BENKE. They are system-specific and should not be changed without consulting BARTEC BENKE. To change to a highter user level, e.g. from Operator to Expert level, proceed as follows: • In the main window, select the menu AccessLevel. A drop-down menu opens from which you can select the desired user level. • For example, select the user level Expert. A dialog window appears in which you are required to enter the password for the user level. On delivery, the password benke is pre-set for the Expert level. In order to prevent unauthorized access to the system, you should change this password as soon as possible. The following section describes how you can change the Expert password. • To change to Expert level, enter the password in the dialog window, and click on OK. Note: No password is needed to change to a lower user level, e.g. from Manufacturer or Expert level to Operator level. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 The PACS Menu 5.5.1 65 Changing the Expert Password On delivery, the password benke is pre-set for the Expert level. You should change this password as soon as possible. To change the Expert password, proceed as follows: • Log in to Expert level. • In the menu, select AccessLevel : Change Password A dialog window opens. • Enter a new password with at least 5 characters, and enter it again in the second line to confirm it. Note: For the passwort, only characters from the internation ASCII code can be used, no blanks or special characters are allowed. A password must have at least 5 characters. Please note that the program distinguishes between upper case and lower case letters. • To save the new password, click on OK. To keep the old password, click on Cancel. The new password is active immediately. The next time you log in as Expert, you will have to enter the new password. For safety reasons, treat passwords as confidential and change them regularly in order to prevent unauthorized access to the system! Note: The password for the Manufacturer level cannot be changed. If you need it for maintenance purposes, please contact BARTEC BENKE. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 66 5.6 The PACS Menu The Help Menu The Help menu offers help for working with PACS and the analyzer. Figure 5.23: PACS - Help Menu Select Help – Manual(s) to access the system documentation as a PDF file. A dialog window opens in which you can select the required document. Figure 5.24: PACS Software for RVP-4 PACS – Selecting a Manual Version 1.0.0., 11.05.2007 The PACS Menu 67 Under Help – About, you will find the serial number of the analyzer, the software version, and information on BARTEC BENKE. Please keep the software version number ready if you contact us. Figure 5.25: PACS – Help About Version 1.0.0., 11.05.2007 PACS Software for RVP-4 68 PACS Software for RVP-4 The PACS Menu Version 1.0.0., 11.05.2007 Process Control System Interface 69 6 Process Control System Interface Version 1.0.0., 11.05.2007 PACS Software for RVP-4 70 Process Control System Interface As a standard, the interface to the process control system is equipped with a number of discrete signals: digital outputs and inputs, and analog outputs and inputs. Alternatively, these signals and further information can be transmitted via a Modbus Interface (optional). For further details, please refer to the manual "Modbus Interface Description RVP-4". 6.1 6.2 Analog inputs Analog input Meaning Option Reserved reads from the DCS yes Analog output Analog output Meaning Option VaporPressure Output of the measured value no SelectedSignal One of the following signals: no PACS Software for RVP-4 Off No signal selected T_Cell Measuring cell temperature T_Inlet Sample temperature at analyzer inlet T_CoolantHE Temperature of the cooling medium heat exchanger T_SampleHE Temperature of the sample heat exchanger MV-Sample Set value of the controller for the flowing sample (T-Sample) MV-Cell Set signal of the controller for the measuring cell (T-Cell) P-Sample Pressure in the measuring cell Version 1.0.0., 11.05.2007 Process Control System Interface 6.3 71 Digital inputs Digital input Meaning Option Reset/Standby Abortion of analysis cycle (flank 0/1), acknowledging alarm and holding in Standby (static 0), if required no ValidationRQ request for validation cycle no StreamRQ1 request for stream 1 yes StreamRQ2 request for stream 2 yes Stream- StreamRQ1 RQ2 Validation- Reset / RQ Standby Function 0 0 0 0 After finishing the current measuring cycle, the analyzer switches to the state "Start up" and waits for a new stream selection. 1 0 0 0 Request stream 1 0 1 0 0 Request stream 2 1 1 0 0 Request automatic stream switching x x 1 0 A flank (0/1) causes insertion of validation cycles (number: Cycles). If the signal is kept active, further validation cycles are carried out (exceeding the number Cycles). x x x 1 Reset Legend: 0 - low 1 - high X - the state is irrelevant Version 1.0.0., 11.05.2007 PACS Software for RVP-4 72 6.4 Process Control System Interface Digital outputs Digital output Meaning Option Alarm (NC) A (serious) error has occurred. no Warning A (minor) error has occurred. yes Ready A measuring cycle has been finished, and the measured values at the analog outputs are valid. no ValidationID identification of a validation cycle no StreamID1 identification of stream 1 yes StreamID2 identification of stream 2 yes PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Options 73 7 Options Version 1.0.0., 11.05.2007 PACS Software for RVP-4 74 Options The following options are currently available: 7.1 Modbus Interface The Modbus interface is used for remote control and for requesting measuring results by a central DCS (Distribution Control System). It consists of a software module and hardware (e.g. RS485 interface board) required to provide a transmission channel. 7.2 Remote maintenance interface It consists of remote control software (e.g. PC-Anywhere) and hardware required to provide a transmission channel (e.g. modem). It is used for remote control and remote maintenance of the analyzer from a service office. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Troubleshooting 75 8 Troubleshooting Version 1.0.0., 11.05.2007 PACS Software for RVP-4 76 8.1 Troubleshooting Error Monitoring in PACS PACS constantly monitors key system functions and issues error messages when a fault occurs. There are two basic error types: • • Program errors, e.g. file not available, not enough memory, etc. These errors can be further classified as follows: • Errors during program start-up • Error during operation Errors in the analysis cycle. These can be further classified as follows: • Errors which are independent from the analysis cycle, e.g. measured value of a sensor too high, temperature of a Pt-100 too high, or conductor damage. These errors are monitored constantly at short intervals. • Errors which occur during the analysis cycle, e.g. "TimeOut Measure". Program errors are displayed in pop-up dialog windows. Errors of the analysis process are displayed in the field Error in the main window and recorded in the LogBook (Report – Alarms). They can be configured at Manufacturer user level in the menu Configuration – Alarms. 8.2 Software error Note: If PACS stops due to an error, the Watchdog (see chapter 3.2) will be activated, i.e. a system reset will be carried out and the computer will be restarted. In this case, the Log Book contains the comment "Start_after_abnormal_Termination". The following list of error messages gives you information on the cause of the problem and the necessary steps to be taken. PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Troubleshooting 77 Error Message Cause / Result Troubleshooting Error during program start Program is already running ! The program can only run No duplicate allowed. once. Another program window may be already running in the background or in the task bar (minimized). Can´t load Panel XXX PANEL! There is a memory problem or a program error. Unable to load XXX MENU BAR! Message for all dialog windows and menus (XXX stands for the respective dialog window or menu). Unable to display XXX Panel! There is a memory problem or a program error. Unable to display Panel for XXX! Message for all dialog windows (XXX stands for the respective dialog window). Confirm the message. Restart the program or the entire system. Check for possible memory errors. Restart the program or the entire system. Check for possible memory errors. Unable to access IO-board ! The IO board is not Continue without available, i.e. the IO board, connection? the Ethernet adaptor board or the connection cable are missing or defective. Check the supply voltage for the IO board, the connectors, the cable and the correct location of the Ethernet adaptor board. Unable to load "conf.xx"! Check that the corresponding file exists in the "Config" subdirectory and is not being used by another program (e.g. Notepad). If necessary, replace missing files with backup files. Unable to copy "conf.xx" from .\conf.bak\! Unable to load copy of"conf.xx" from .\conf.bak\! The required configuration file or its copy is not accessible, cannot be copied or loaded, or there is a memory problem or a program error. conf.xx stands for • • • conf.io conf.par conf.al Version 1.0.0., 11.05.2007 PACS Software for RVP-4 78 8.3 Troubleshooting Error messages from the analysis process The following list of error messages gives you information on the cause of the problem and the necessary steps to be taken. The abbreviations in the remarks column "R." have the following meanings: u – independent of the analysis process a – depending on the analysis process Tag / Message R. Explanation TA_DELTA_TEMPERATUR a E Difference between sample temperature at heat exchanger and at cell is higher than parameter "T_Delta_Max". TA_INACCURATE_TEMP Cannot reach piston position. Observe the technical data. Peltier elements controller is faulty. Control disturbance Observe the technical data. caused by large temperature change of the sample or the cooling medium. u There is an error in the IO board or Tini board is connection to the IO faulty. board. Check the electrical circuits for the IO board. u There is a leakage in the analyzer housing. Put the system out of operation. Remove the cause of the leakage. Observe the safety instructions in the operating manual. a The measuring piston position was not reached within the time "TW_Piston". Instrument air pressure is too low. Observe the technical data. Check the signals from the Measuring piston is proximity switches and the blocked, proximity switch moving velocity of the is faulty or wrongly pneumatic cylinders. adjusted. Choke restrictor valve is out of adjustment. PACS Software for RVP-4 Check that the peltier elements are operating correctly. The temperature deviation of the measuring cell has exceeded the value "T_Cell_Limit" in the process step Measure. The measuring result has been discarded. Leakage in analyzer housing! TA_PISTON_POSITION There is not enough sample flowing. a Lost Connection to IO98Card TA_LEAKAGE Solution Control disturbance. Inaccurate Cell Temperature. Analysis discarded. TA_IO_CONNECTION The temperature difference between T_Sample and T_SampleHE is greater than "T_Delta_Max". Possible cause Version 1.0.0., 11.05.2007 Troubleshooting 79 Tag / Message R. Explanation Possible cause Solution TA_PL_VAPOR u The pressure transmitter power is lower than 4 mA. Line to pressure transmitter interrupted. Check the electrical circuits for the pressure transmitter. The pressure in the measuring cell is higher than "P_Initial_Max" at the start of process step Measure. Leak in measuring cell. Sample pressure is lower than "P_Sample_Min" during the process steps with open measuring cell valves. No sample flow. a Pressure inside the measuring cell has not become stable within 15 minute interval in process step Measure. Leak in measuring cell. Check the measuring piston seals. a Pressure in the measuring cell has decreased by more than "P_Decrease_Max" in process step Measure. Leak in measuring cell. Check the measuring piston seals. a Pressure in the measuring cell rises above "P_Range_Max" in process step Measure. Pressure in the measuring cell exceeds the measuring range. Observe the technical data. u The safety chain of the No sample flow, temperature control temperature control system has been system is faulty. triggered. Check the temperature fuses on the sample heat exchanger and on the coolant heat exchanger. u A software error has occurred. Contact BARTEC BENKE. Try acknowledging the error or restart the program. Lower limit at pressure detector ! TA_PRESSURE_INITIAL a The intial pressure in cell at begin of measurement is too high ! TA_PRESSURE_LOW a Sample pressure lower than parameter "P_Sample_Min". TA_PRESSURE_TIMEOUT Pressure in cell did not stabilize within 900 seconds ! TA_PRESSURE_TREND Pressure in cell is regressing during measurement ! Check seals and pressure det ector ! TA_RANGE Pressure during Measure exceeded “P_Range_Max". Analysis discarded. TA_SAFTY_CHAIN Safety-Chain triggered (temperature fuses, lockout) ! TA_SOFTWARE Internal software error! Pressure transmitter is faulty. Measuring piston expands too slowly. Set the parameter "P_Initial_Max" to a suitable value. Check the measuring piston seals. "P_Initial_Max" depends on the sample. Process pressure too low. Check the position of the pressure relief valve. Observe the technical data. Check valve is faulty. Pressure relief valve actuated. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 80 Troubleshooting Tag / Message R. Explanation TA_TH_BOARD High temperature at IOboard! u The temperature on the IO board is too high. TA_TH_INLET u Temperature at sensor inlet is higher than parameter TemperaturMax. Conductor broken. Check the electrical circuits for the sensor. u Temperature at sensor Conductor broken. MeasuringCell is higher than parameter TemperaturMax. Check the electrical circuits for the sensor. u Temperature at sensor CoolantHE is higher than parameter TemperaturMax. Conductor broken. Check the electrical circuits for the sensor. u Temperature at sensor SampleFlow is higher than parameter TemperaturMax. Conductor broken, temperature control system faulty. Check the electrical circuits for the sensor. u Temperature at sensor SampleHe is higher than parameter TemperaturMax. Conductor broken. Check the electrical circuits for the sensor. u Temperature at sensor Inlet is lower than parameter TemperaturMin. Short circuit in sensor. Check the electrical circuits for the sensor. u Temperature at sensor MeasuringCell is lower than parameter TemperaturMin. Short circuit in sensor. Check the electrical circuits for the sensor. u Temperature at sensor CoolantHE is lower than parameter TemperaturMin. Short circuit in sensor. Check the electrical circuits for the sensor. u Temperature at sensor SampleFlow is lower than parameter TemperaturMin. Short circuit in sensor, temperature control system faulty. Check the electrical circuits for the sensor. Upper limit at temperature probe at sample inlet ! TA_TH_MEASURING_CELL Upper limit at temperature probe at cell! TA_TH_COOLANT_HE Upper limit at temperature probe at coolant heat exchanger ! TA_TH_SAMPLE_FLOW Upper limit at sample temperature probe in front of cell! TA_TH_SAMPLE_HE Upper limit at temperature probe at sample heat exchanger ! TA_TL_INLET Lower limit at temperature probe at sample inlet ! TA_TL_MEASURING_CELL Lower limit at temperature probe at cell ! TA_TL_COOLANT_HE Lower limit at temperature probe at coolant heat exchanger! TA_TL_SAMPLE_FLOW Lower limit at sample temperature probe in front of cell ! PACS Software for RVP-4 Possible cause Solution Make sure the environmental conditions are as specified (activate air-conditioning system if required). Version 1.0.0., 11.05.2007 Troubleshooting 81 Tag / Message R. Explanation TA_TL_SAMPLE_HE u Temperature at sensor Short circuit in sensor. SampleHe is lower than parameter TemperaturMin. u The lock circuit to the sensor T_CoolantHE has been triggered because temperature was too high or too low. Short circuit in sensor, conductor broken, flow rate too low (sample or cooling medium). Press the button LockoutReset. Button SH-2 in PAGS housing. a Timeout in process step Wait Coarse Temperature. Measuring cell heater or temperature control system is faulty. Sample flow rate too high. Check the peltier elements and the measuring cell heater and their controllers. Observe the technical data. a The temperature values (T_Sample and T_Cell) have not become stable in the time defined in the parameter MaxWaitFineTime. Temperature changes at cooling medium inlet or sample inlet are too high. Observe the technical data. Lower limit at temperature probe at sample heat exchanger ! TA_TLO_COOLANT_HE Temperature probe at sample heat exchanger triggered "LockOut", press push button "LockOutReset" ! TA_TO_WAIT_COARSE Timeout in process state "WaitCoarseTemperature" ! TA_TO_WAIT_FINE Timeout in process state Wait Fine Temperature ! Possible cause Version 1.0.0., 11.05.2007 Solution Check the electrical circuits for the sensor. PACS Software for RVP-4 82 PACS Software for RVP-4 Troubleshooting Version 1.0.0., 11.05.2007 Program Parameters 83 9 Program Parameters Version 1.0.0., 11.05.2007 PACS Software for RVP-4 84 9.1 Program Parameters Notes The following tables provide an overview of the parameters. Note: Generally, changes in these parameters will not become active immediately, but only at the start of the next analysis cycle. A small number of parameters will only become active after a program restart. These parameters are marked with "#N" (New start) in the table. For every parameter, the recommended value or range is indicated. The recommended value is an approximate recommendation, all values must be adjusted to the circumstances (measuring range, stream switching, etc.). The following abbreviations are used in the table: B binary value 1 or 0 (Yes/No, active/not active, true/false) N integer without unit T temperature in the unit °C or °F, as configured in the main window K Temperature difference in K F Floating point value % percent U factor in reference to 1 (1 corresponds to 100%) P Pressure in mbar V volume in ml F volume flow in ml/min s seconds h hours K/s Temperature change per second in Kelvin/s - no recommendation PACS Software for RVP-4 Version 1.0.0., 11.05.2007 Program Parameters 9.2 85 General Parameters Parameter Value/Range Meaning CustomVPGain 1.0 F Setting for Conversion = CustomVP: slope for conversion of ASVP to CustomVP. CustomVPOffset 0.0 F Setting for Conversion = CustomVP: offset for conversion of ASVP to CustomVP. HistoryLength 7N Data from the previous days are archived. The parameter specifies the length of the recording period in days. ModbusActive 0B "0" - Modbus function is switched off. "1" - Modbus function is switched on Caution, only switch on if the Modbus software is installed! P_Conversion 0…5 N Conversion of the measured pressure to Vapor Pressure 0 1 2 3 4 5 ASVP - no conversion ASTM_DVPE EPA_DVPE CARB_RVPE ASTM_RVPE CustomVP P_Decrease_Max 4P Maximum decrease in pressure during measurement. If the value falls below this limit, the alarm TA_PRESSURE_TREND is triggered. P_Initial_Max 900 P Maximum permitted pressure at start of measurement. If this value is exceeded, the alarm TA_PRESSURE_INITIAL is triggered. P_Range_Max 1600 P Maximum pressure during measurement. If this value is exceeded, the measurement is aborted and the alarm TA_RANGE is triggered. P_Sample_Min 1600 P Minimum pressure when the sample flows through the measuring cell. If the value falls below this limit, the alarm TA_PRESSURE_LOW is triggered. Version 1.0.0., 11.05.2007 PACS Software for RVP-4 86 Program Parameters Parameter Value/Range Meaning P_Unit 0…4 N Conversion of the measuring results to other pressure units 0 1 2 3 4 mbar kPa psi bar mmHg T_Cell_Limit 0.15 K Maximum permitted deviation from the target measuring cell temperature during measurement. If this value is exceeded, the measurement is aborted and the alarm TA_INACCURATE_TEMP is triggered. T_Delta_Max 10 K Maximum permitted temperature difference between sample heat exchanger and measuring cell while a sample stream is active. If this value is exceeded, the alarm TA_DELTA_TEMPERATURE is triggered. T_Fine_Limit 0.1 T Temperature tolerance in the state Wait Fine Temperature. T_Max 60.0 T Maximum temperature for all temperature measuring points. T_Min 0.0 T Minimum temperature for all temperature measuring points. TO_Wait_Fine 600 s Time limit for the state Wait Fine Temperature. If this limit is exceeded, the alarm TA_TO_WAIT_FINE is triggered. TO_Waitcoarse (600-1800) s Time limit for the state Wait Coarse Temperature. If this value is exceeded, the alarm TA_TO_WAIT_COARSE is triggered. TW_Piston 120 s Time limit for reaching the measuring piston position. If this limit is exceeded, the alarm TA_PISTON_POSITION is triggered. TW_Ready 5s Hold time for the output Ready. TW_StartUp 5s Delay for reading the IO values after starting PACS TW_Stream_Switch 240 s Minimum waiting time in the state Wait fine Temperature after stream switching (controller adjustment after disruption). PACS Software for RVP-4 Version 1.0.0., 11.05.2007