Risk and Management in Supply Chains

advertisement

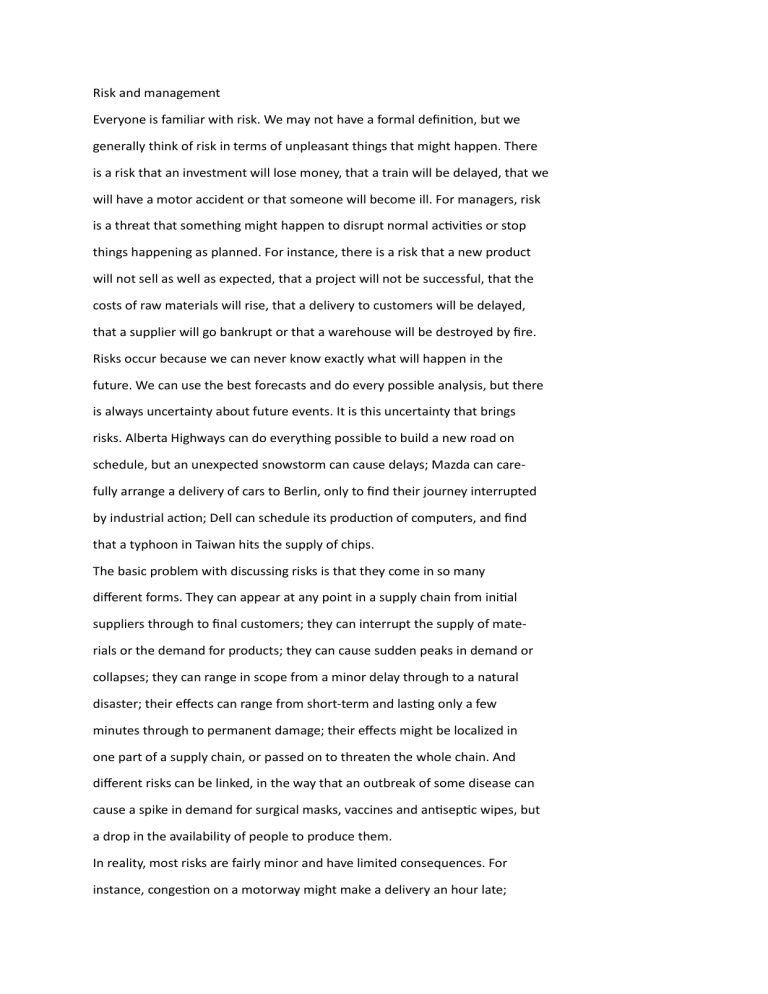

Risk and management Everyone is familiar with risk. We may not have a formal definition, but we generally think of risk in terms of unpleasant things that might happen. There is a risk that an investment will lose money, that a train will be delayed, that we will have a motor accident or that someone will become ill. For managers, risk is a threat that something might happen to disrupt normal activities or stop things happening as planned. For instance, there is a risk that a new product will not sell as well as expected, that a project will not be successful, that the costs of raw materials will rise, that a delivery to customers will be delayed, that a supplier will go bankrupt or that a warehouse will be destroyed by fire. Risks occur because we can never know exactly what will happen in the future. We can use the best forecasts and do every possible analysis, but there is always uncertainty about future events. It is this uncertainty that brings risks. Alberta Highways can do everything possible to build a new road on schedule, but an unexpected snowstorm can cause delays; Mazda can carefully arrange a delivery of cars to Berlin, only to find their journey interrupted by industrial action; Dell can schedule its production of computers, and find that a typhoon in Taiwan hits the supply of chips. The basic problem with discussing risks is that they come in so many different forms. They can appear at any point in a supply chain from initial suppliers through to final customers; they can interrupt the supply of materials or the demand for products; they can cause sudden peaks in demand or collapses; they can range in scope from a minor delay through to a natural disaster; their effects can range from short-term and lasting only a few minutes through to permanent damage; their effects might be localized in one part of a supply chain, or passed on to threaten the whole chain. And different risks can be linked, in the way that an outbreak of some disease can cause a spike in demand for surgical masks, vaccines and antiseptic wipes, but a drop in the availability of people to produce them. In reality, most risks are fairly minor and have limited consequences. For instance, congestion on a motorway might make a delivery an hour late; although this is unfortunate, in the big scheme of things it is rarely a catastrophe. On the other hand, risks occasionally have enormous consequences. For instance, unexpected market conditions in 1997 left the clothing retailer Next with the wrong things in stock – and when it could not meet customer demand there was a dramatic drop in sales, followed by a fall in share price (Braithwaite and Hall, 1999a, 1999b). In 2001 over-optimistic forecasts encouraged the electronics manufacturer Cisco to build up stocks to meet customer demand that never materialized. It eventually wrote off $2.2 billion of excess stock. In 2006, the weaver Camillario lost 60 per cent of sales when its main customer moved operations to China, and it almost immediately went into liquidation. Toyota shut down 20 of its 40 assembly lines for six weeks following a fire at a valve supplier, with an estimated cost of $40 million a day (Nelson, Mayo and Moody, 1998).