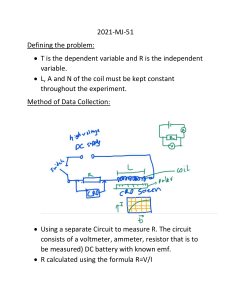

Cathode Ray Oscilloscope (CRO) CRO is very useful and versatile laboratory instrument used for display, measurement and analysis of waveforms and other phenomena in electrical and electronic circuits. In fact, CROs are X-Y plotters, displaying an input signal versus another signal or versus time. The "stylus" of this "plotter" is a luminous spot which moves over the display area in response to an input voltage. The luminous spot is produced by a beam of electrons striking on the fluorescent screen. The normal form of a CRO uses a horizontal input voltage which is an internally generated ramp voltage called "Time Base". This horizontal voltage moves the luminous spot periodically in a horizontal direction from left to right over the display area or screen. The vertical input to the CRO is the voltage under investigation. The vertical input voltage moves the luminous spot up and down in accordance with the instantaneous value of the voltage, and thus traces the waveform of the input voltage with respect to time. When the input voltage repeats itself at a fast rate, the trace (display) on the screen appears stationary on the screen. Thus, CRO provides a means of visualizing time varying voltages. CRO has become a universal tool in all kinds of electrical and electronic investigations. Cathode Ray Oscilloscope (CRO) A CRO consists of a Cathode Ray Tube (CRT), which is the heart of the tube, and additional circuitry to operate the CRT. The main parts of a CRT are: Electron gun assembly Deflection plate assembly Fluorescent screen Glass envelope Base, through which connections are made to various parts Cathode Ray Oscilloscope (CRO) The source of focused and accelerated electron beam is the electron gun. The electron gun, which emits electrons and forms them into a beam, consists of a heater a cathode, a grid, a pre-accelerating anode, a focusing anode and an accelerating anode. Electron gun assembly produces a sharply focused beam of electrons which are accelerated to high velocity. This focused beam of electrons strikes the fluorescent screen with sufficient energy to cause a luminous spot on the screen. After leaving the electron gun, the electron beam passes through two pairs of "Electrostatic deflection plates". Voltages applied to these plates deflect the beam. Voltages applied to one pair of plates move the beam vertically up and down and the voltages applied to the other pair of plates move the beam horizontally from one side to another. These two movements i.e. horizontal and vertical are independent of each other and thus the beam may be positioned anywhere on the screen. CRT is enclosed in an evacuated glass envelope so that the emitted electrons are able to move about freely from one end of the tube to the other. Cathode Ray Oscilloscope (CRO) In smaller CRTs, connections to the various electrodes are brought out through pins in the base of the tube. Large and medium sized high performance tubes operate at very high voltages, and these leads are usually brought out through the sides of the glass envelope. Electrons are emitted from the indirectly heated cathode. A layer of barium and strontium oxide is deposited on the end of the cathode-which is a cylinder-to obtain high emission of electrons at moderate temperatures. These electrons pass through a small hole in the "control grid". This control grid is usually a nickel cylinder, with a centrally located hole, co-axial with the CRT axis. The intensity of electron beam depends upon the number of electrons emitted from the cathode. The grid with negative bias controls the number of electrons emitted from the cathode and hence the intensity is controlled by the grid. The electrons, emitted from the cathode and passing through the hole in the control grid are accelerated by the high positive potential which is applied to the "pre-accelerating" and "accelerating anodes". The electron beam is focused by the "focusing anode". The accelerating and focusing anodes are cylindrical in form, with small openings located in the center of each electrode, co-axial with the tube axis. After leaving the focusing anodes, the electron beam passes through the vertical and horizontal deflection plates and then goes on to the fluorescent screen. Cathode Ray Oscilloscope (CRO) There are two methods of focusing an electron beam: • Electrostatic focusing • Electromagnetic focusing The CRO uses electrostatic method of focusing as compared to a TV picture tube which employs electromagnetic focusing. Deflection Plates: The electron beam, after leaving the electron gun, passes through two pairs of deflection plates. • One pair of plates is mounted horizontally and produces an electric field in the vertical plane. This pair produces a vertical deflection and is thus called Vertical Deflection Plates or Y Plates. • The other pair of plates is mounted vertically and produces a horizontal deflection. This pair of plates is called Horizontal Deflection Plates or X Plates. The plates are flared so as to allow the beam to pass through them without striking the plates. Cathode Ray Oscilloscope (CRO) Screens for CRTs: The screen material on the inner surface of a CRT is called Phosphor. This material absorbs the kinetic energy of the bombarding electrons and re-emit it in the form of a bright spot. Several materials of different characteristics are used for CRT screen. CRT phosphors are specific chemical compounds, which are luminescent and are arranged on the inside of the TV tube in a certain order and are available in various colors, starting with basic red, green and blue for color CRTs, with precise grain size control, dispersion control and surface treatment to match exact tube. Upon excited by a scanning electron beam in the CRT, the phosphors will glow momentarily forming a picture composed of colors by utilizing the red, green and blue combinations. If we look at TV screen (while it is turned on) with a magnifying glass, you can see the colored elements. CRT phosphors are frequently referred to by P numbers (e.g. P-1, P-2, and so on) as specified by the Electronics Industries Association (EIA) of the US. A unified worldwide Phosphor Type Designation System (WTDS) using one or two letter codes was developed later on. Cathode Ray Oscilloscope (CRO) The bombarding electrons, striking the screen, release secondary emission electrons. These secondary electrons are collected by an aqueous solution of graphite, called aquadag which is connected to the second anode. Collection of secondary electrons is necessary to keep the screen in a state of electrical equilibrium. Cathode Ray Oscilloscope (CRO) CRT Graticule: The graticule is usually rectangular in, form and is placed inside the display area to alloy correct measurements. Most CROs have a graticule inscribed on a clearer tinted plastic plate, placed over the outside of the CRT face. Time Base Generators: Most of the CRO applications involve measurement or display of a quantity which varies with respect to time. This requires that the CRT spot move across the screen from left to right with a constant velocity. In order that the beam deflect linearly from left to right, ramp voltages are applied to horizontal deflection or X plates. The circuits which develop these ramp voltage are called time base generators or sweep generators. The output of a sweep generator is called a sweep voltage. Other Measuring Instruments Ammeters arc connected in Series in the circuit whose current is to be measured. Therefore, they should have a low electrical resistance. This is essential in order that they cause a small voltage drop and consequently absorb small power. Voltmeters are connected in parallel with the circuit whose voltage is to be measured. They should have a high electrical resistance. This is essential in order that the current drawn by them is small and consequently the power absorbed is small. Ohmmeters are used for measuring electrical resistance, which is expressed in ohms. Microohmmeters make measurements of low resistance and Megohmmeters (a trademarked device Megger) measure large values of resistance. The unit of measurement for resistance is the ohm (Ω). Ohmmeter: Series-Type d’Arsonval Movement: A DC moving coil movement where the moving coil is suspended between the poles of a permanent magnet restrained by helical springs, and the measured current flowing through the moving coil produces a torque on the attached pointer proportional to the current. The ohmmeter is a direct reading device for measurement of resistance. An ohmmeter is useful for getting the approximate resistance of circuit components such as heater elements or machine field coils, measuring and shorting resistors used in electronic circuits and for checking continuity of circuits. Series-Type Ohmmeter: It consists of basic d’Arsonval movement connected in parallel with a shunting resistor R2. This parallel circuit is in series with resistance R1 and a battery of emf E. The series circuit is connected to the terminals A and B of the unknown resistance Rx. R1 = Current limiting resistor R2 = Zero adjusting resistor E = emf of internal battery Rm = Internal resistance of d'Arsonval movement Ohmmeter: Series-Type When unknown resistance Rx = 0 (i.e. terminals A & B are shorted), maximum current flows through the meter. Under this condition, resistor R2 is adjusted until the meter indicates full scale current Ifs. This full-scale current position of the pointer is marked “0” Ω on the scale. Similarly, when Rx is removed from circuit (i.e. terminals A & B are open), the current in the meter drops to zero and the movement indicates zero current which is then marked "∞''. When the unknown resistance is inserted at terminals A & B, the current through the meter is reduced and hence pointer drops lower on the scale. Since the meter has "0" at extreme right and "∞" at the extreme left, intermediate scale markings may be placed on the scale by different known values of resistance. The accuracy of these scale markings depends on the repeating accuracy of the movement and the tolerances of the calibrating resistors. Although the series type ohmmeter is a popular design and is used extensively in portable instruments for general service work, its use presents certain difficulties. Ohmmeter: Series-Type Important among these is the internal battery whose voltage decreases gradually with time and age. So, the full scale current drops down and the meter does not read '0' when terminals A and B are shorted. The variable resistor R2 provides an adjustment to counteract the effect of battery voltage change. Without R2, it would be possible to bring the pointer back to full scale by adjusting resistance R1, but this would change the calibration all along the scale, and therefore change in resistance R2 is a superior solution. The ohmmeter circuit does not completely compensate for ageing of the battery, but it does a reasonably good job within the expected limits of accuracy of the instrument. Some ohmmeters are constructed with a soft iron shunt across the pole pieces of the meter (permanent magnet moving coil instrument). The magnetic shunt serves to mollify the air gap flux density of the magnet, and hence controls the sensitivity of the meter movement. This is a great advantage as it does not alter the electrical circuit at all. Some ohmmeters use rectified alternating current as the power source. In this case, the voltage may be regulated to give a constant voltage supply. The range of the instrument can be extended by providing proper shunts and thus the ohmmeter may be designed to read resistance values over a wide range. Ohmmeter: Shunt-Type Shunt-Type Ohmmeter: It consists of a battery in series with an adjustable resistor R1 and a basic D'Arsonal movement (meter). The unknown resistance is connected across terminals A & B, parallel with the meter. In this circuit it is necessary to have an "off-on" switch to disconnect the battery from the circuit when the instrument is not in use. When the unknown resistor Rx = 0Ω (A & B are shorted), the meter current is zero. If the unknown resistance Rx= ∞ (A & B are open), the current finds path only through the meter and selecting a proper value for resistance R1, the pointer may be made to read full scale. The ohmmeter therefore has “0" mark on the left hand side of the scale (i.e. no current) and infinite mark on the right hand side of the scale (i.e. full scale deflection current). Ammeter: Shunt-Type Shunt-Type Ammeter: The basic movement of a DC ammeter is a PMMC d'Arsonval galvanometer. The coil winding of a basic movement is small & light and therefore, can carry very small currents of less than 100 mA. Since the construction of an accurate instrument with a moving coil to carry currents greater than 100 mA is impracticable owing to the bulk and weight of the coil; therefore, to measure heavy currents, the major part of the current is bypassed through a low resistance called “shunt”, and this shunt resistance can be calculated using conventional circuit analysis. Rm= Internal resistance of movement (i.e. the coil), Im= Ifs = Full scale deflection current of movement, Rsh = Shunt resistance, Ish = Shunt current, and I = Current to be measured. Since the shunt resistance is in parallel with the meter movement, the voltage drops across shunt and movement (meter) must be the same, i.e. sh sh m m. Thus, sh m m sh Since sh m, Therefore sh m m m or m m m sh or m m sh The ratio of total current to the current in the movement is called “multiplying power” of shunt, i.e. m. Accordingly, m sh Therefore, Shunt Resistance sh m Ammeter: Multi-Range Multi-Range Ammeters: The current range of a d.c. ammeter may be further extended a by a number of shunts, selected by a range switch. Such meter is called a multi-range ammeter. The circuit has four shunts Rsh1 Rsh2, Rsh3 and Rsh4, which can be put in parallel with the meter movement to give four different current ranges I1, I2, I3 and I4. Low range ammeters use a multi-position ‘make-before break’ switch provided on the case of the instrument. When larger currents are used, the connections are brought out to binding posts and the loads are connected directly to the binding post which is identified with the described current range. When using a multi-range ammeter, first use the highest current range, then decrease the current range until good upscale reading is obtained. Ammeter: Universal Shunt Universal Shunt: The universal shunt or Ayrton shunt is also used for multi-range ammeters. The advantage of an Ayrton shunt is that it eliminates the possibility of the meter being in the circuit without a shunt. But this advantage is gained at the cost. For switch at position 1, Since 1 1 m m m 1, m 1 m 1 Therefore, 1 m 1 For switch at position 2, m 1 2 m 2 m 2 or 2 1 m 2 For switch at position 3, m 1 3 m 3 m 3 or 3 1 m 3 Thus the values of different selections of resistances i.e. (R1-R2), (R1- R3), and R3 may be found. Voltmeter Multipliers The d'Arsonval basic meter movement is converted into a voltmeter by connecting a series resistance with it. This series resistance is known as a multiplier. This combination (meter movement and the multiplier) is put across the circuit whose voltage is to be measured. The multiplier limits the current through the meter so that it does not exceed the value for full scale deflection and thus prevents the movement from being damaged. The value of a multiplier, required to extend the voltage range, is calculated as under : If Im= Ifs = Full scale deflection current of meter, Rm = Internal resistance of meter movement, Rs= Multiplier resistance, v = Voltage across the meter movement for current Im, V = Full range voltage of instrument; then, the voltages of the circuit are m m& m m s Multiplying factor for multiplier m = = Thus, Resistance of multiplier 𝑠 ( ) =1+ 𝑚 Hence for the measurement of voltage m times the voltage range of the instrument, the series multiplying resistance should be (m-1) times the meter resistance. Thus, to extend the voltage range to 10 times, the instrument range, s m m. Voltmeter Multipliers Multi-range Voltmeters: In a multi-range voltmeter, different full scale voltage ranges may be obtained by the use of individual multiplier resistors or by a potential divider arrangement. Individual Multipliers: We can obtain different voltage ranges by connecting different values of multiplier resistors in series with the meter. The number of these resistors is equal to the number of ranges required. In the figure, multiplier resistors Rs1, Rs2, Rs3 and Rs4 are connected in series with the meter by a range selector switch for the desired voltage V1, V2, V3 and V4 respectively. Therefore, the corresponding multiplier resistances are: s1 1 m s2 2 m s3 3 m s4 4 m Where 1 1 2 2 3 3 4 4 Voltmeter Multipliers Potential Divider Arrangement: Another multi-range voltmeter in which the connections are made at the junctions of resistances R1, R2, R3 and R4 in series to obtain the voltage ranges V1, V2, V3 and V4. These connections are brought out to binding posts on the instrument, and the instrument is connected to the proper binding post for the desired voltage range. The series resistances for the voltage ranges V1, V2, V3 and V4 can be computed as: 1 2 2 m 3 4 𝑚 1 m / 1 m 1 1 2 2 2 1 1 / m 1 m 1 3 3 m m m 2 4 m 3 m While using a multi-range voltmeter, it is usual procedure first to connect the voltmeter to the highest voltage range terminal or set the switch to the highest voltage, and then connect the instrument to the circuit to measure the voltage. Then decrease the ranges of the instrument until a good upscale reading is obtained on the voltmeter. Types of Instruments The main types of instruments used as ammeters and voltmeters are: • Permanent Magnet Moving Coil (PMMC) • Moving Iron Instruments • Electrodynamometer • Thermocouple • Electrostatic • Induction The PMMC type can be used for DC measurements only, and the Induction type for AC measurement only. The other types can be used with either DC and/or AC measurements. The Moving Iron is the most generally used form of indicating instrument and the cheapest. The Electrodynamometer type of instruments are used both on AC and DC. Their calibration for both DC and AC is the same. Thermal instruments have the advantage that their calibration is the same for both DC and AC. They are particularly suited for AC measurements. The Electrostatic instruments have the advantage that their power consumption is exceedingly small. They can be made to cover a large range of voltages. The Induction principle is more generally used for Watt-Hour meters than for ammeters and voltmeters owing to the comparatively high cost, and inaccuracy of induction instruments for ammeters and voltmeters. Permanent Magnet Moving Coil (PMMC) The instruments which use the Permanent Magnet for creating the stationary magnetic field between which the coil moves is known as the PMMC instrument. The PMMC instrument allows you to measure the direct current through a coil by observing the angular deflection of the coil in a uniform magnetic field. The PMMC instrument gives the accurate result for DC measurement. It operates on the principle of Faraday’s Laws of electromagnetic induction, which states that a current carrying conductor when placed in a magnetic field, will experience a force. The magnitude of this force will be proportional to the amount of current through the wire. A pointer is attached to the end of the wire and it is put along a scale. PMMC Construction Coercive Force: The value of the external magnetic field that brings to zero the magnetization or magnetic flux density of a magnetic body when that external magnetic field is caused to operate in the opposite direction from the orientation of the magnetization of the magnetic body. A PMMC meter is constructed of 5 main components: Magnet System: In the present time, we use magnets of high field intensities, high coercive force instead of using U shaped permanent magnet. The Alcomax and Alnico materials are used for creating the permanent magnet because this magnet has the high coercive force and provides high field intensities. Moving Coil: The coil is the current carrying part of the instrument which is freely moved between the stationary field of the permanent magnet. The current passes through the coil deflects it. The coil is wound with many turns of copper wire and is placed on rectangular aluminum core which is pivoted on jeweled bearings. PMMC Construction Control System: The spring generally acts as control system for PMMC instruments. The springs are made up of phosphorous bronze and placed between the two jeweled bearings. The spring also provides the path to the lead current to flow in and out of the moving coil. Damping System: The damping torque is induced by the movement of aluminum core in the magnetic field created by the permanent magnets. Pointer & Scale: The pointer is linked with the moving coil. The pointer notices the deflection of the coil, and the magnitude of their deviation is shown on the scale. The pointer is made of the lightweight material, so that it can easily deflected with the movement of the coil. Moving Iron Instruments The instrument in which the moving iron is used for measuring the flow of current or voltage is known as the Moving Iron instrument. It works on the principle that the iron placed near the magnet attracts towards it. The force of attraction depends on the strength of the magnet field. The magnetic field induces by the electromagnet whose strength depends on the magnitude of the current passes through it. Attraction Type Moving Iron instrument The plate or vane of soft iron is used as the moving element of the instrument. The vane is so placed that it can freely move in the magnetic field of the stationary coil. This stationary coil is used as an electromagnet whose magnetic field strength increases or decreases with the magnitude of the current passes through it (or the voltage or current whose magnitude is to be measured). Classification of Moving Iron Instruments Attraction Type: The instrument in which the iron plate attracts from the weaker field towards the stronger field, such type of instrument is known as the Attraction Type instrument. In such type of instruments, the stationary coil is flat and has a narrow opening. The moving element is the flat disc of the iron core. The current flow through the stationary coil produced the magnetic field which attracts the iron coil. The iron vane deflects from the low magnetic field to the high magnetic field, and the strength of the deflection is directly proportional to the magnitude of the current flow through it. Repulsion Type: The repulsion type instrument has two vanes or iron plates. One is fixed, and the other one is movable. The vanes become magnetised when the current passes through the stationary coil and the force of repulsion occur between them. Because of a repulsive force, the moving coil starts moving away from the fixed vane. Repulsion Type Moving Iron instrument MI Instruments: Advantages & Disadvantages Advantages: Universal Use: The MI instrument is independent of the direction of current and hence used for both AC and DC. Less Friction Error: The friction error is very less in MI instruments because their torque weight ratio is high (because their current carrying part is stationary and the moving parts are lighter in weight). Cheap: The MI instruments require less number of turns as compared to PMMC instrument. Thus, it is cheaper. Robustness: The instrument is robust because of their simple construction. Disadvantage: Accuracy: The scale of MI instruments is not uniform, and hence the accurate result is not possible. Errors: Some serious error occurs in the instruments because of the hysteresis, frequency and stray magnetic field. Differences Between PMMC and PMMI Instruments 1. The moving iron instrument uses the soft iron piece as a rotating element. Whereas the moving coil instrument uses the coil as a rotating element. 2. The working principle of the moving iron instrument depends on magnetism. Whereas, the working principle of moving coil instrument is similar to the working principle of DC motor. 3. The moving iron instrument has the non-uniform scale. Whereas the moving coil instrument has the uniform scale. 4. The moving iron instrument is the most general used form of indicating instrument, as well as the cheapest. 5. The moving iron instrument is less accurate as compared to the moving coil instrument. 6. The moving iron instrument is used for measuring both DA and AC, whereas the moving coil is used for the DC measurement. 7. In moving iron instruments, the spring provides the controlling torque to the instrument. Whereas in moving coil instrument, the spring provides the controlling torque to the moving coil instrument. Electrodynamometer Wattmeter An electrodynamometer or simply dynamometer wattmeter is an instrument that is universally used for the measurement of DC as well as AC electric power. It works on the principle of dynamometer i.e. a mechanical force acts between two current carrying conductors. Construction: The electrodynamometer wattmeter has a fixed coil divided into two parts and is connected in series with the load and carries the load current (I1). The moving coil is connected across the load through a series multiplier resistance (R) and carries a current (I2) proportional to the load voltage. The fixed coil is called as Current Coil and the moving coil is called as Potential Coil or Voltage Coil. The controlling torque is provided by two spiral springs. Air friction damping is provided in electrodynamometer wattmeter. A pointer is attached with the moving coil. Electrodynamometer Wattmeter: Construction Fixed Coil: The fixed coils connects in series with the load. It is considered as a current coil because the load current flows through it. The fixed coil produces the uniform electric field which is essentials for the working of the instruments. Moving Coil: The moving coil is connected in parallel with the supply voltage. The current flows through them is directly proportional to the supply voltage. The pointer mounts on the moving coil. The movement of the pointer controls with the help of the spring. The flows of currents control with the help of resistor which connects in series with the moving coil. Control: The control system provides the controlling torque to the instruments. The Electrodynamometer Wattmeter uses spring control system, which is used for the movement of the pointer. Damping: The damping is the effect which reduces the movement of the pointer. The damping torque produces because of the air friction. Scales and Pointers: The instruments use a linear scale because their moving coil moves linearly. Electrodynamometer Wattmeter Working Principle: When electrodynamometer wattmeter is connected in the circuit to measure the electric power. The current coil carries the load current and the potential coil carries a current proportional to the load voltage. Because of the current in the two coils, a mechanical force acts between them due to which the moving coil (potential coil) moves and hence the pointer attached to it. When the current is reversed in the circuit, the reversal of current takes place in both the current coil and potential coil so that the direction of the deflecting torque remains unchanged. Hence, the electrodynamometer wattmeter can be used for the measurement of DC as well as AC power.